Automatic plate feeding and discharging system for double-faced AOI (Automated Optical Inspection) of circuit board and technological process of automatic plate feeding and discharging system

A circuit board and surface inspection technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of insufficient overall layout, occupying a large production area, reducing production efficiency, etc., to save equipment costs and costs. The effect of small land area and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

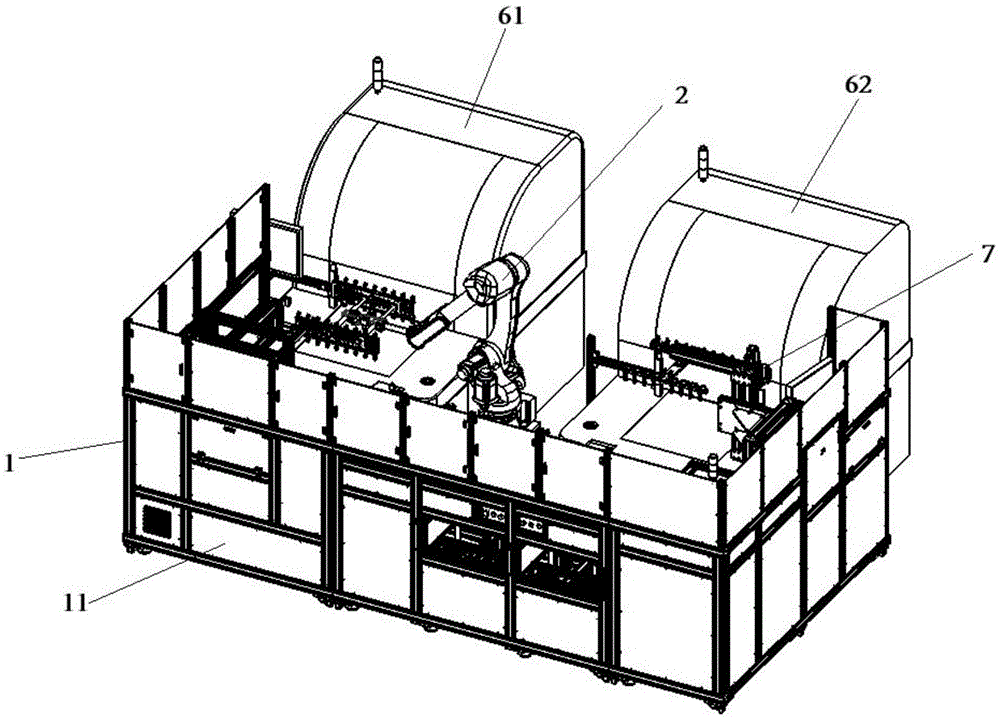

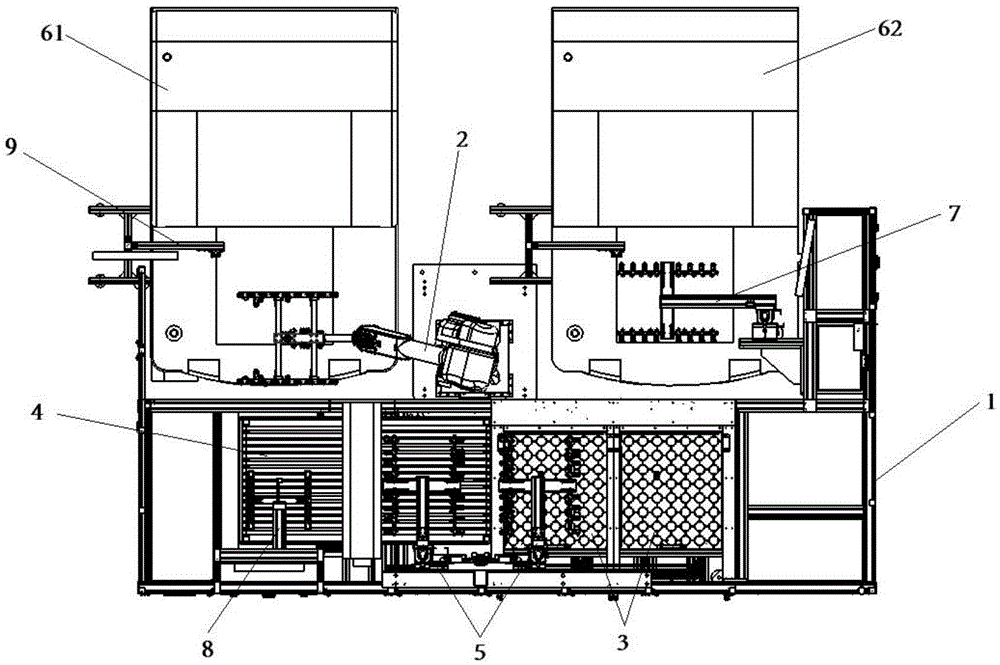

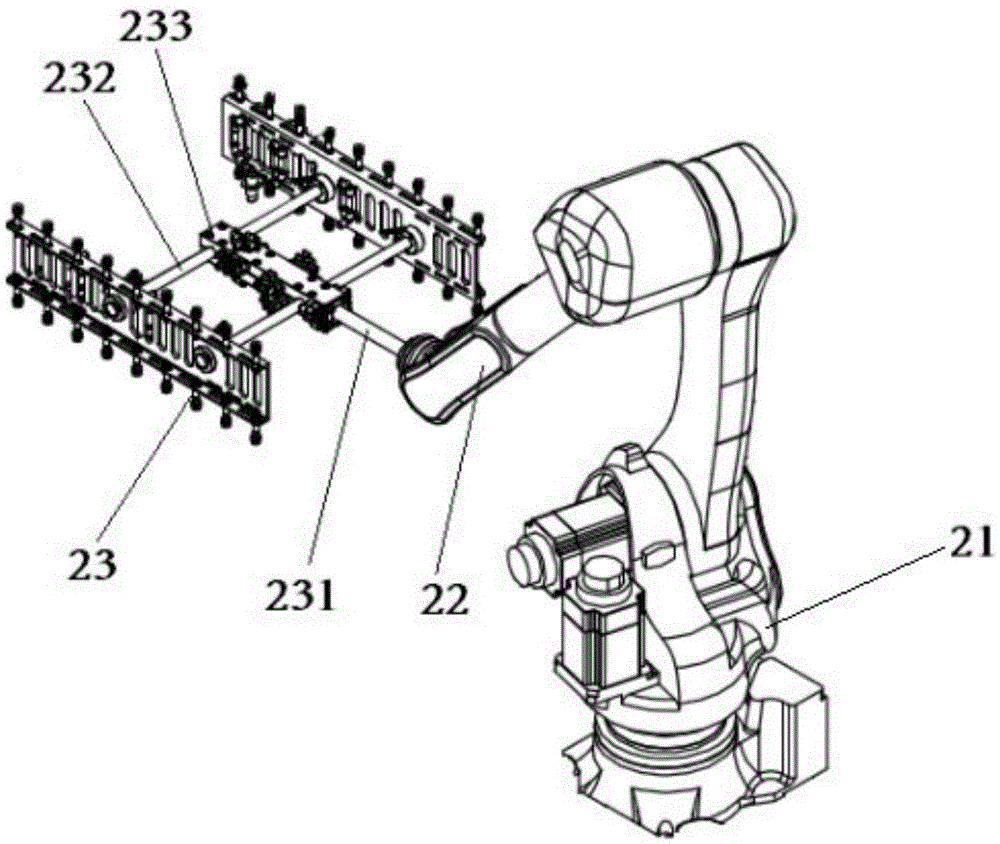

[0030] combine Figure 1 to Figure 8 As shown, an automatic board loading and unloading system for double-sided AOI detection of circuit boards, including a protective frame 1, a robot device 2, a feeding and discharging device 3, a double-sided dust sticking machine 4, a transfer device 5, an AOI automatic optical inspection machine, The docking device 7 and the master control system that controls the work of the above equipment, the protective frame 1 is an aluminum profile frame, the feeding and discharging device 3, the double-sided dust sticking machine 4, the transfer device 5 and the docking device 7 are all fixed on the frame, The protective frame 1 is equipped with a cabinet, and the main control system is placed in the cabinet; the AOI automatic optical inspection machine includes an A-side inspection machine 61 and a B-side inspection machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com