Technique for producing regenerative rubber by using kneading machinery chemical method and interrelated device thereof

A technology of mechanochemical method and regenerated rubber, which is applied in the field of producing regenerated rubber by kneading mechanochemical method and related equipment, which can solve the problems of waste liquid, secondary pollution of waste gas, high cost of safety management, large amount of additives, etc. , to achieve the effects of no secondary pollution, no safety hazards, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

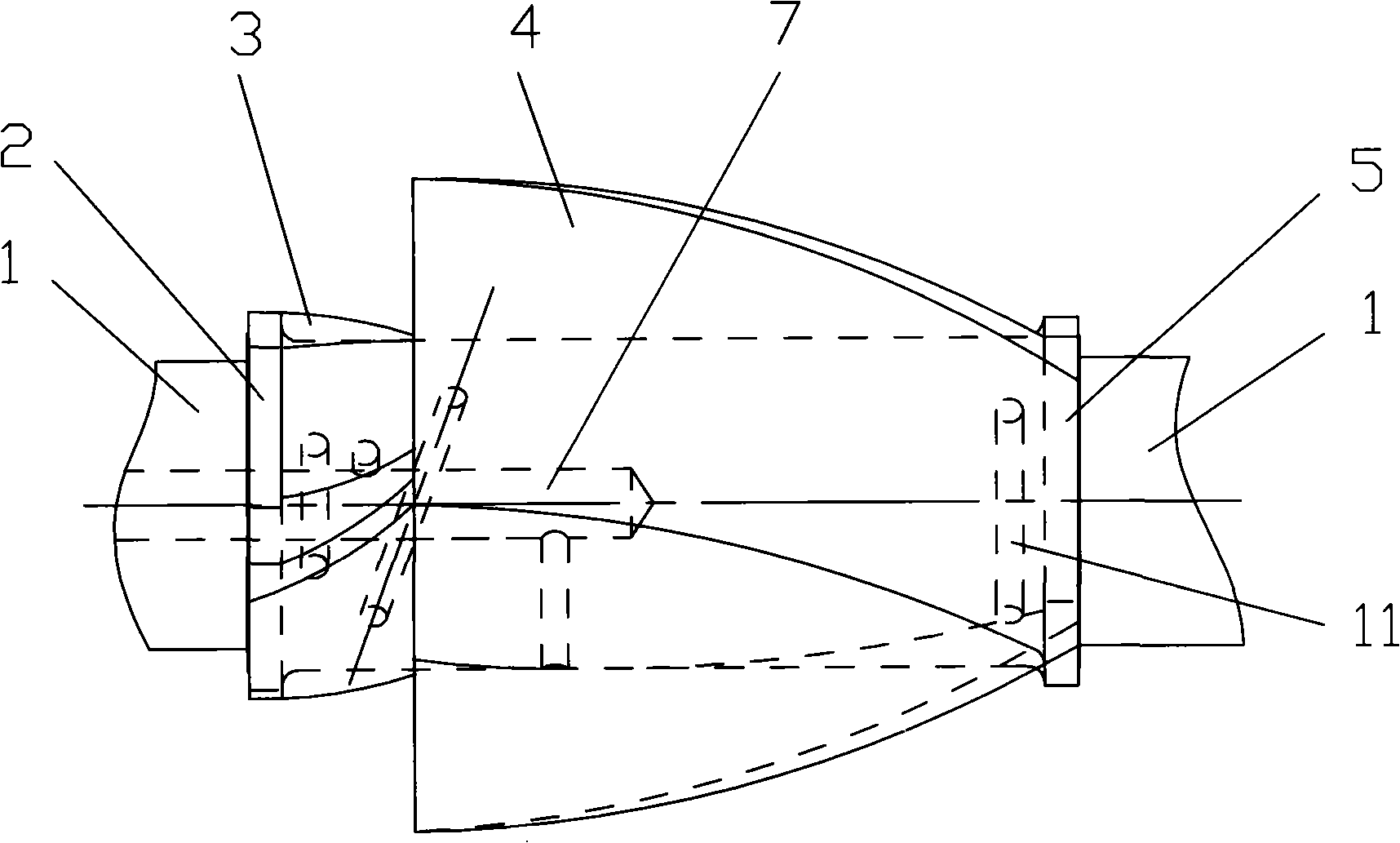

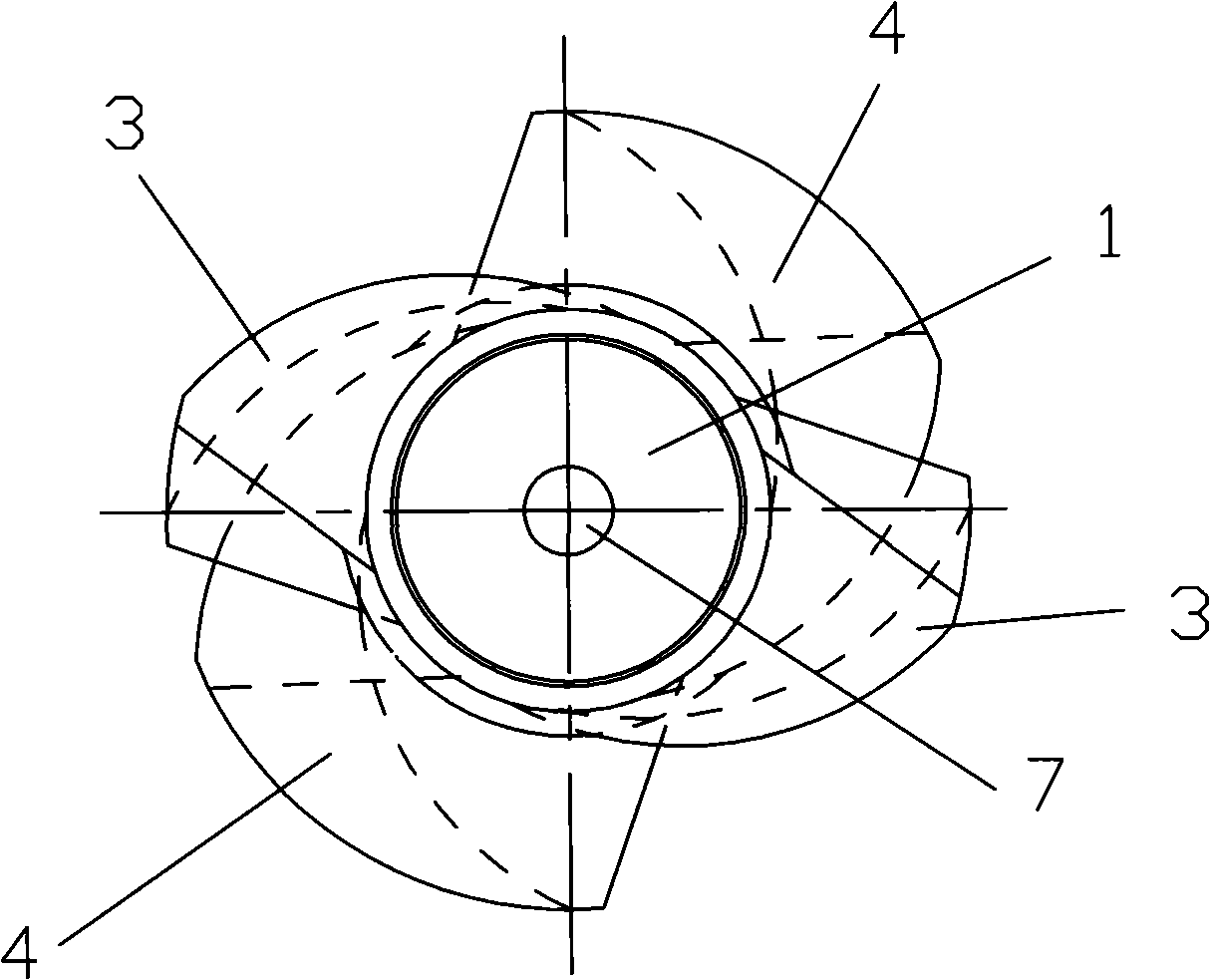

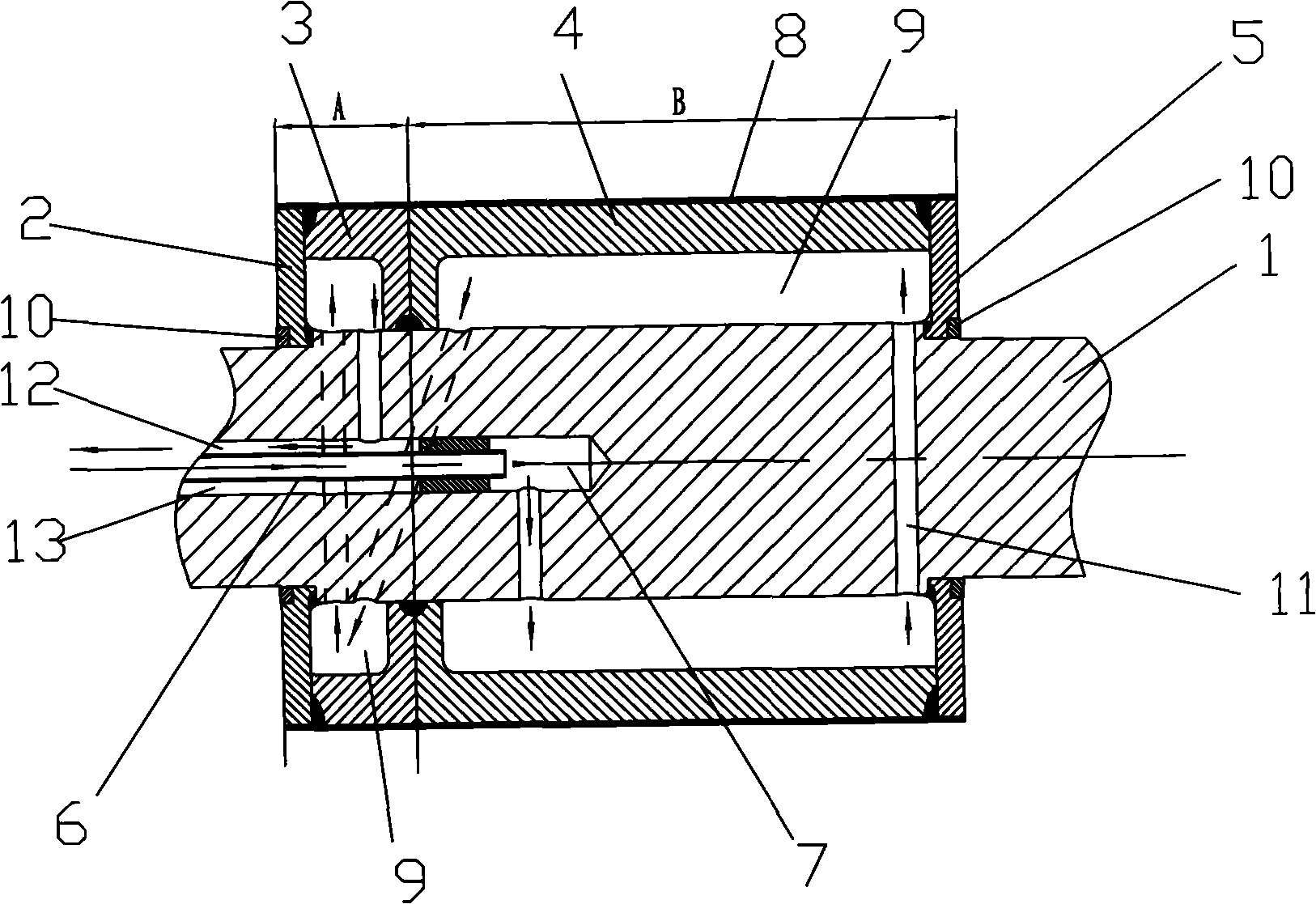

[0033] Utilize the technique of kneading mechanochemical method of the present invention to produce regenerated rubber, carry out as follows:

[0034] Take the 75-liter special kneader with four-edged synchronous rotor for the desulfurization and regeneration of radial tire vulcanizate as an example.

[0035] a. According to the processing method of the prior art, the waste radial tires are first sorted and crushed to make rubber powder to form a rubber compound for desulfurization.

[0036] b. Mix the above rubber with chemical additives. The chemical additives include activators, softeners, plasticizers or tackifiers. The weight ratio is as follows:

[0037] Activator: rubber compound = 0.2~0.3:100;

[0038] Softener: rubber compound = 8 ~ 10: 100;

[0039] Plasticizer or tackifier: rubber compound = 3 ~ 4: 100.

[0040] The activator is 420; the softener is pine tar; the plasticizer is rosin.

[0041] Weighing preparation:

[0042] Use 68kg of 30-mesh radial tire vulcani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com