Compound impurity removing and sorting machine for crop seeds

A sorting machine and seed technology, which is applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. Bad processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

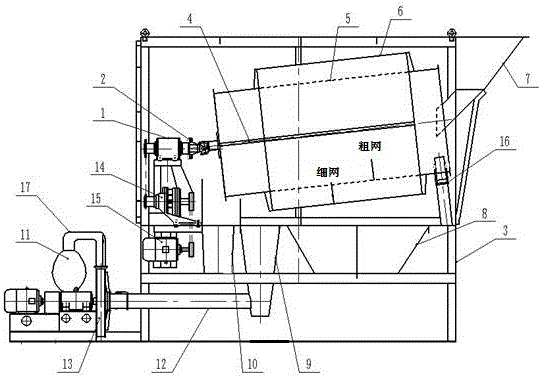

[0015] refer to figure 1 , a kind of compound impurity-removing sorting machine for crop seeds, comprising frame 3, feed hopper 7, discharge opening, filtering device and dust removal device, feeding hopper 7 is positioned at frame 3 top right, and filtering device comprises motor 15, rotating Shaft 4 and trommel, motor 15 are installed on frame 3, and trommel comprises the coarse mesh trommel 5 that is installed on the frame 3 and the fine mesh trommel 6 that is set on the rough mesh trommel 5, coarse mesh trommel 5 and the fine mesh drum screen 6 are inclined to the horizontal direction, and one end close to the feed hopper 7 is higher than the other end, the coarse screen drum screen 5 is connected to the outlet below the feed hopper 7, and the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com