Herbage crusher

A forage pulverizer and blower technology, which is applied in the direction of feed, dryer, grass drying, etc., can solve the problems of endangering the safety of animals, such as iron nails and soil, and achieve the effects of labor saving, convenient storage and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

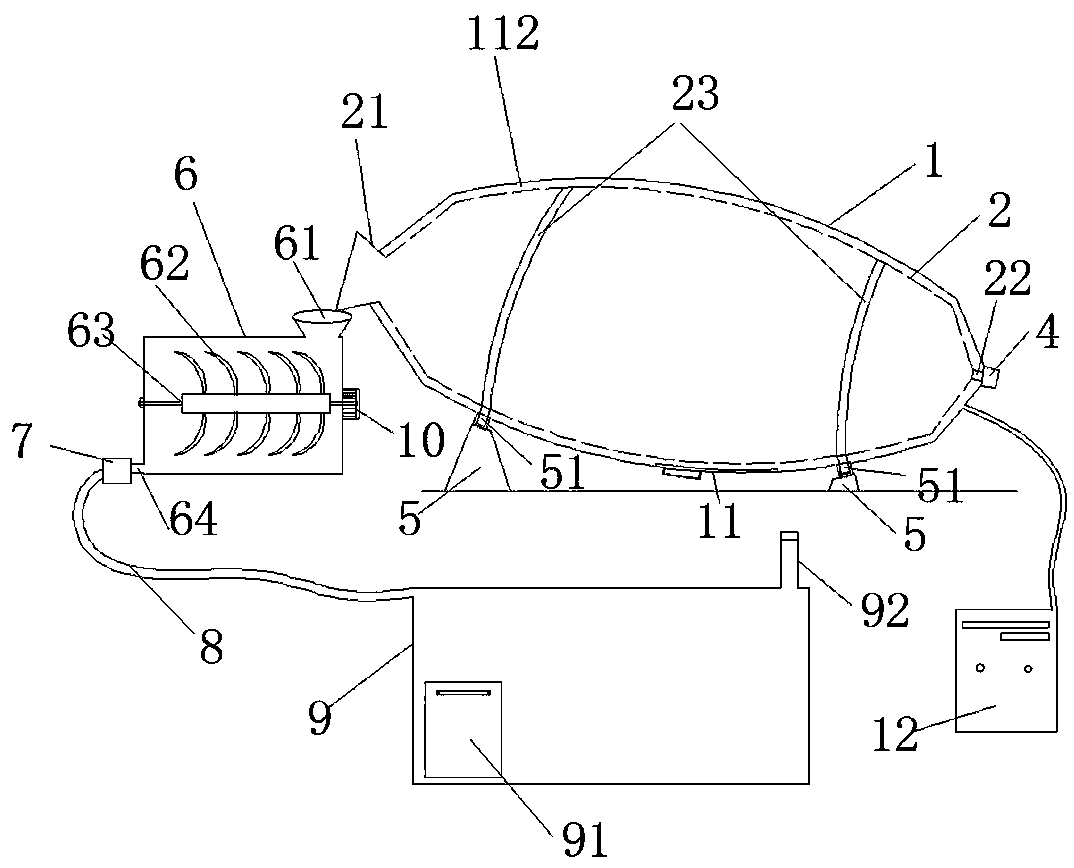

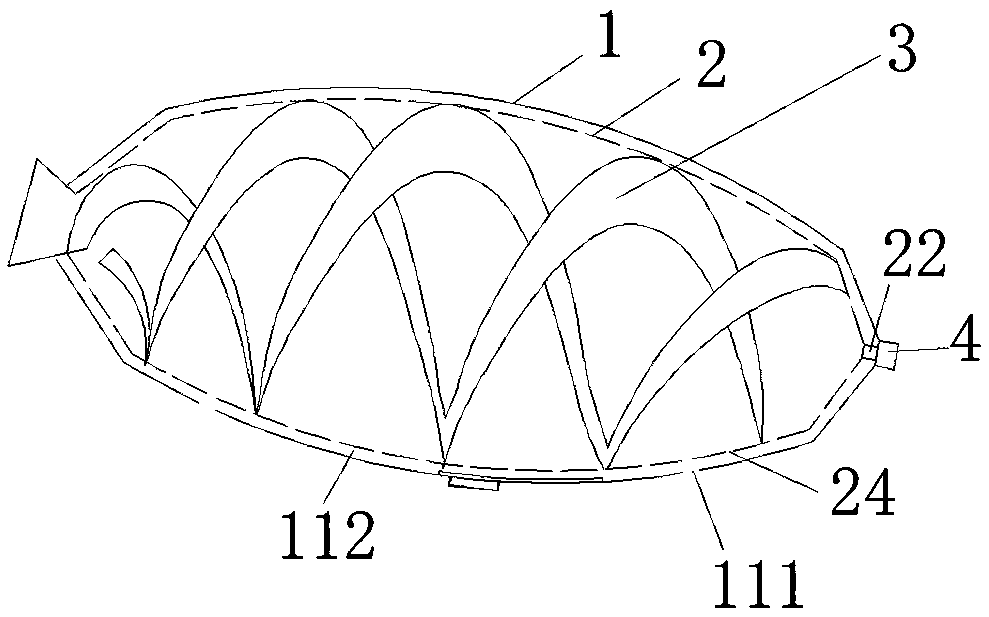

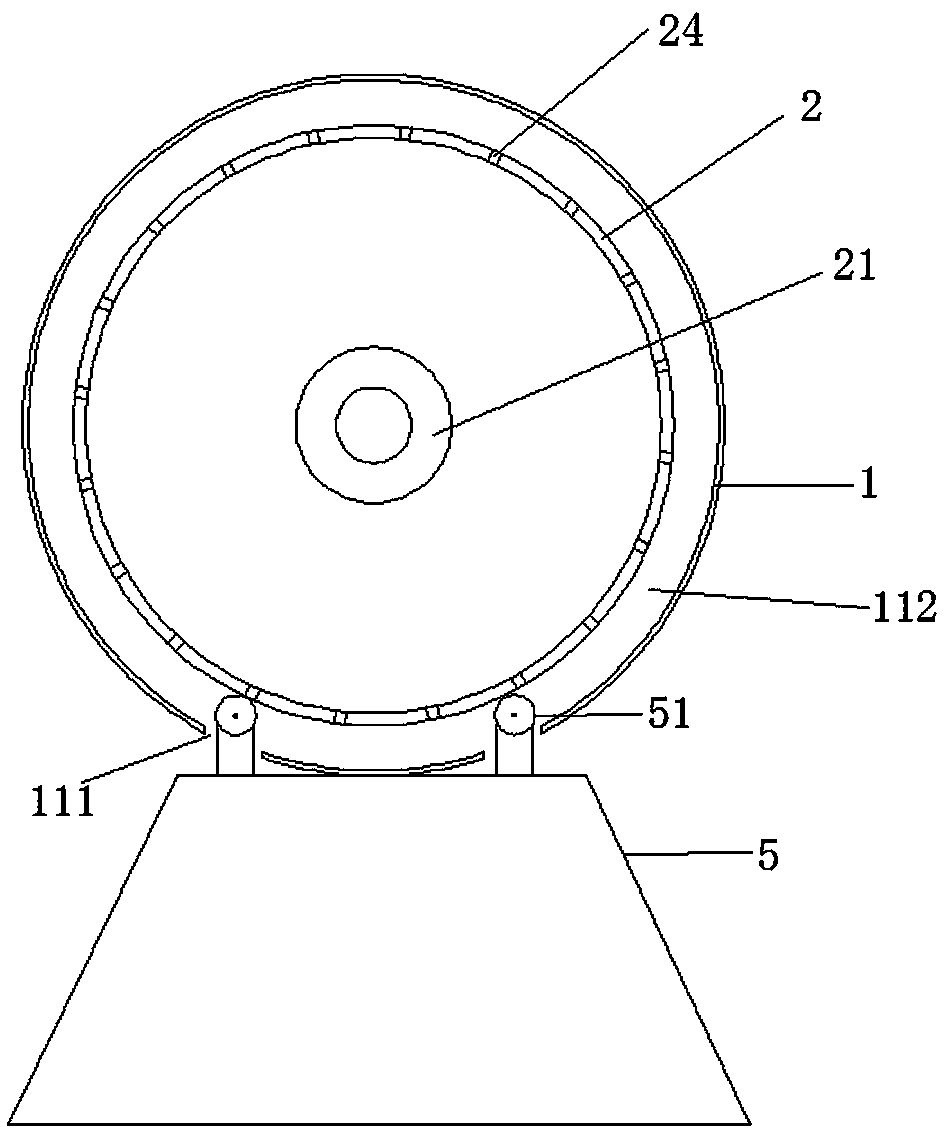

[0019] Such as Figure 1 to Figure 3 As shown, the hay pulverizer of the present embodiment includes a fixed outer cylinder 1, a rotatable inner cylinder 2, a rotating motor 4 that drives the inner cylinder 2 to roll forward and reverse, a plurality of support rollers 51, fixed support rollers 51 and The fixed frame 5 of the rotating motor 4, the hot air blower 12, the crushing chamber 6, the blower 7, the cutting motor 10, the feeding pipe 8 and the storage room 9; the outer cylinder 1 wraps the inner drum 2 and is arranged at intervals with the inner drum 2, enclosing the synthetic oven Dry chamber 112; the outer wall of the inner cylinder 2 is provided with a plurality of ring-shaped raceways 23 rolling with the support rollers 51; the outer cylinder 1 is provided with an opening 111 for the support rollers 51 to pass through; one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com