Solar air heat collection pasture drying equipment

A technology for air heat collection and drying equipment, which is applied in the direction of solar thermal collectors, solar thermal energy, solar thermal collectors in specific environments, etc. It can solve the problems of inability to directly dry, loss of pasture bales, and long cycle times, and improve intelligent automation. degree of drying, improved drying efficiency, and uniform drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

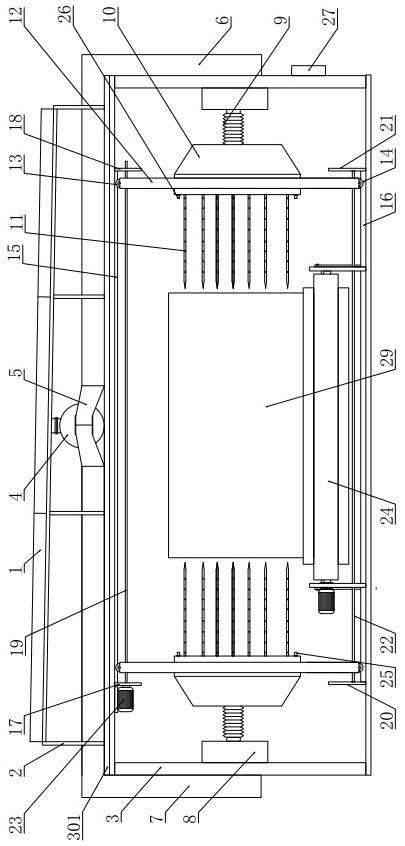

[0035] Please see attached Figure 1-7 As shown, the present embodiment provides a solar-air heat-collecting pasture drying equipment, including:

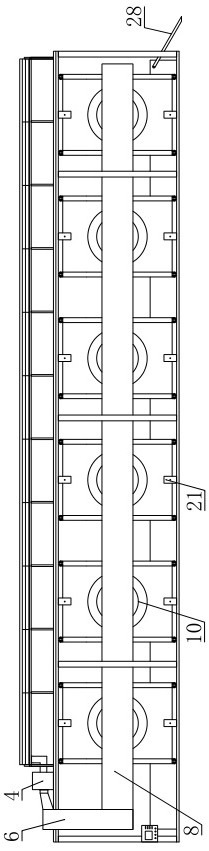

[0036] Drying frame 3, the top of the drying frame 3 is provided with a top plate, the top plate is provided with a support frame 2 and a fan 4, a chain plate conveyor 24 and a needle-punched drying mechanism are provided in the drying frame 3, and the outer sides of the left and right sides of the drying frame 3 are provided. A left air duct 7 and a right air duct 6 are respectively provided, and a distribution air duct 8 is provided on the inner sides of the left and right sides of the drying frame 3 horizontally and longitudinally;

[0037] Solar air collector array 1, the solar air collector array 1 is installed on the support frame 2, the air outlet of the solar air collector array 1 is connected with the air inlet of the fan 4, and the air outlet of the fan 4 is connected with an air supply pipe 5. The air supply duct 5 prov...

Embodiment 2

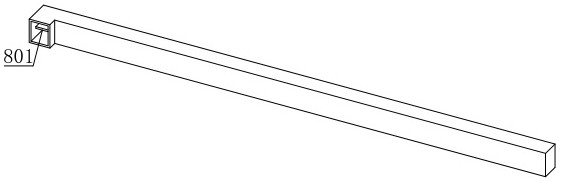

[0047] On the basis of Embodiment 1, a partition 801 is provided inside the distribution air duct 8, the partition 801 divides the inside of the distribution air duct 8 into two air ducts, and the partition 801 separates the upper air duct formed The first three ventilation holes 802 in sequence are communicated, and the lower air duct formed by the partition plate 801 is communicated with the last three ventilation holes 802 in sequence. The hot air in the distribution air duct 8 is divided into secondary distribution by the partition plate 801, so as to improve the utilization efficiency of the hot air and the drying efficiency of the pasture.

[0048] As an improvement, the outside of the air supply pipe 5 , the left air duct 7 , the right air duct 6 and the distribution air duct 8 are covered with thermal insulation material to further reduce heat loss.

Embodiment 3

[0050] On the basis of Embodiment 2, a guide frame 28 is installed on the side plate of one end of the chain conveyor 24 that outputs the forage bales 29 . The dried forage bales 29 are transferred from the chain conveyor 24 to the ground through the guide frame 28, which reduces the impact of direct landing and avoids the loss of forage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com