Patents

Literature

57results about How to "Improve heat conduction and heat exchange speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

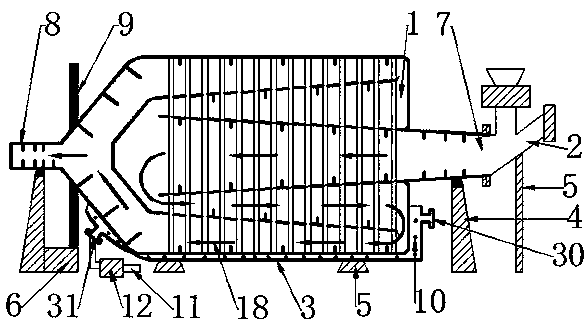

Vacuum dryer for cereals

InactiveCN108692555AEasy inflowIncreased durabilityDrying solid materials without heatGrains dryingHeat conductingEngineering

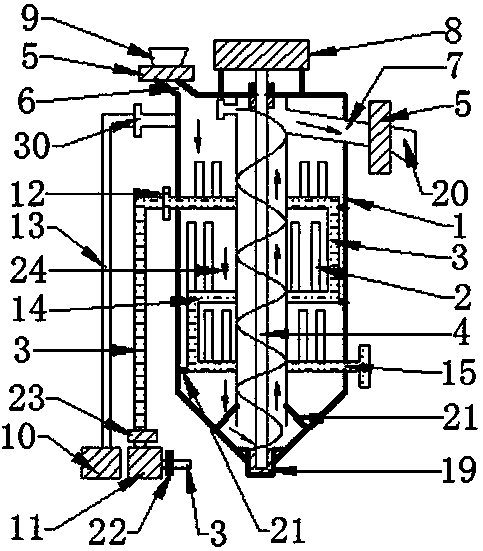

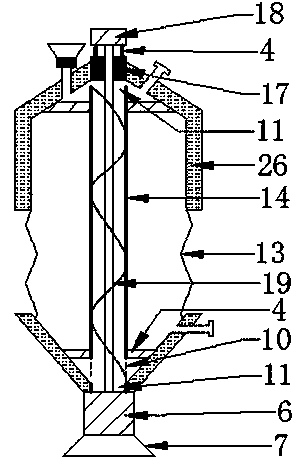

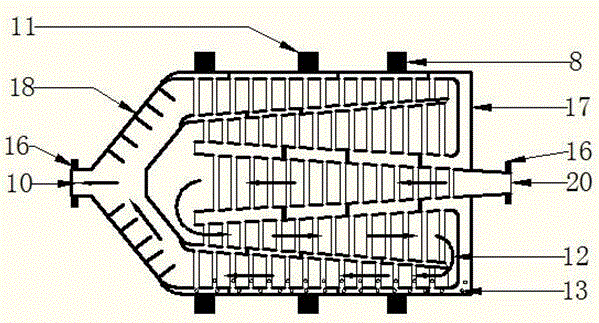

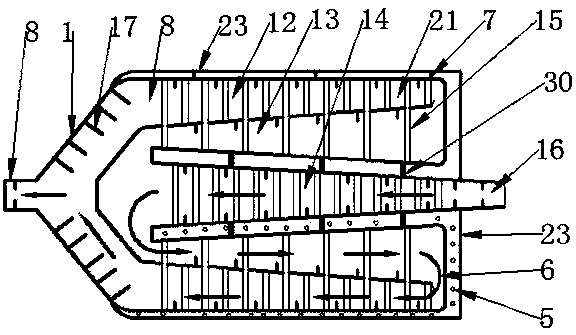

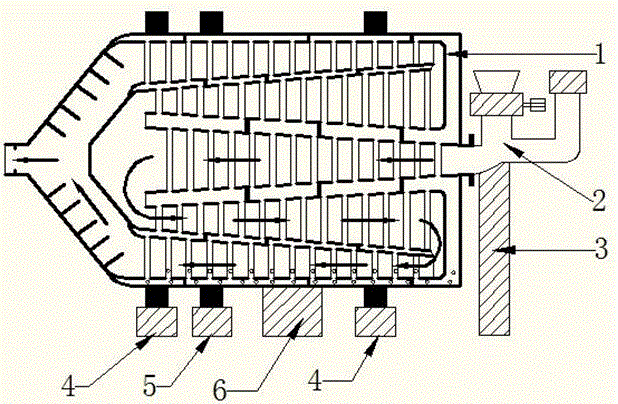

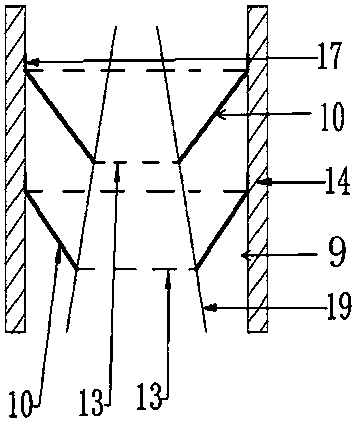

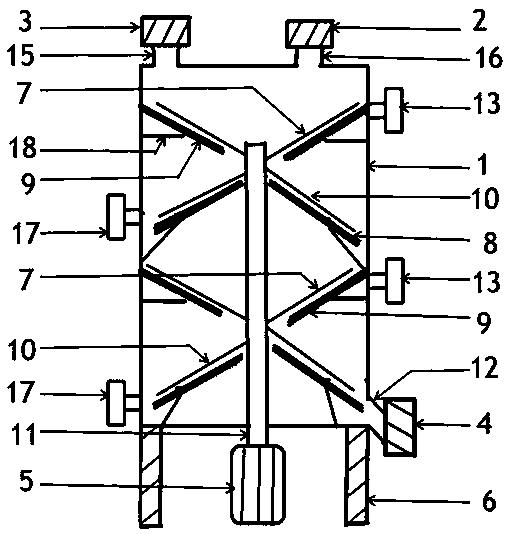

The invention provides a vacuum dryer for cereals. The vacuum dryer comprises a drying bin, a heat exchange device, a support, a lifting device, a vacuum unit, a heating device, an air guide pipe, a heat conducting pipe, a hot recycle pump, a wet material bin, a dry material bin and a discharge valve, wherein the discharge valve is mounted at a feeding port in the upper end of the drying bin and connected with the wet material bin; an exhaust port in the upper end of the drying bin is connected onto the vacuum unit through the air guide pipe; the heat exchange device is mounted in a body of the drying bin; the lifting device is mounted in the central position in the drying bin; the heat conducting pipe is used for connecting the heating device and the heat exchange device and conveying a heat-conducting medium; when the dryer is in drying work, the inside of the drying bin is in a sealed closed state. The vacuum dryer for the cereals is simple in structure, small in equipment size, lowin manufacturing cost and good in heat preservation effect; the heat exchange device in the drying bin adopts three-dimensional heat exchange and heat conduction, the heat conversion efficiency is high, the loss is low, the heat conduction and exchange speed is increased, and the drying speed of the cereals is increased.

Owner:程长春

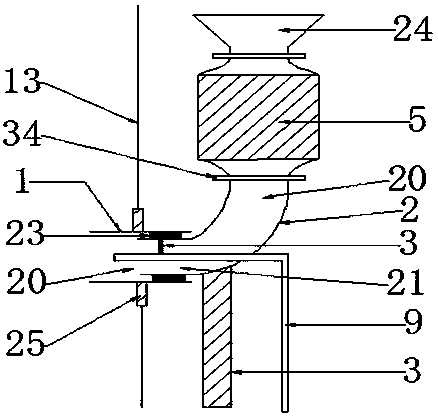

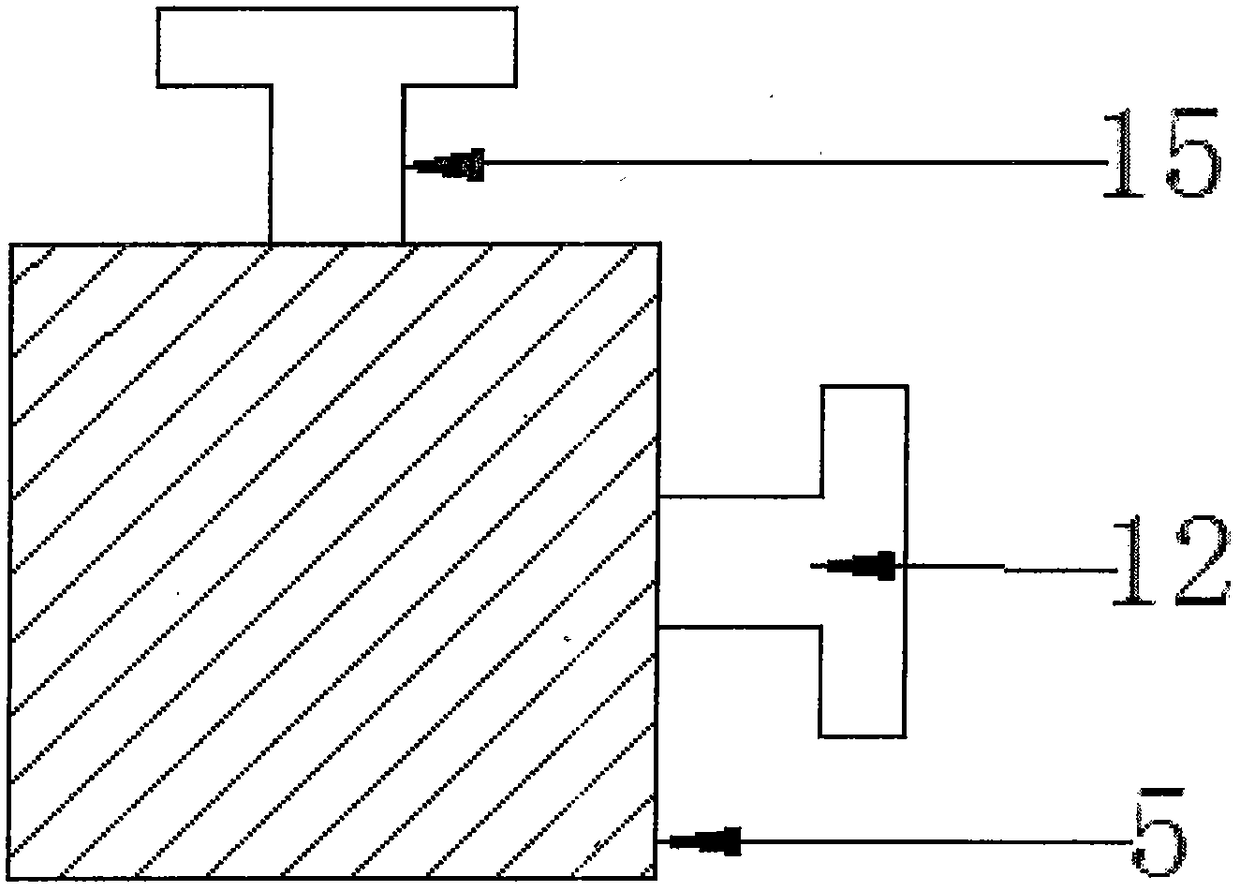

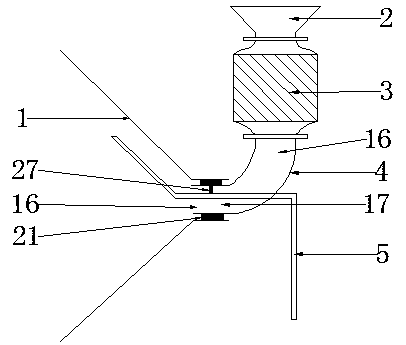

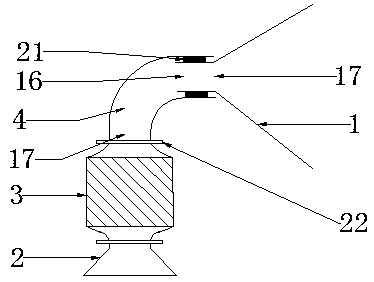

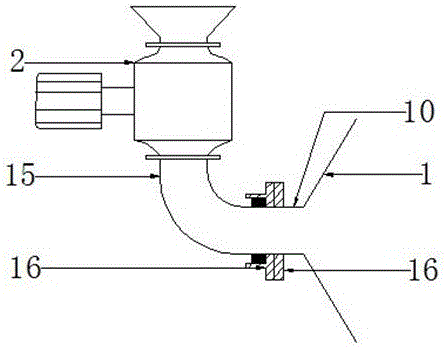

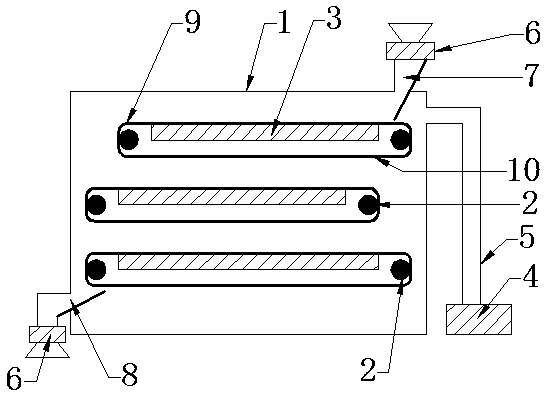

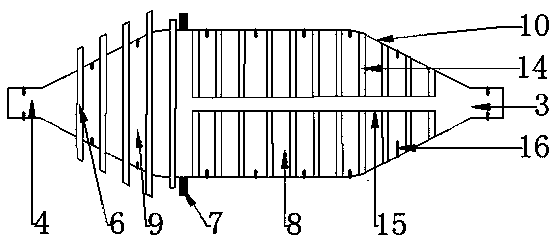

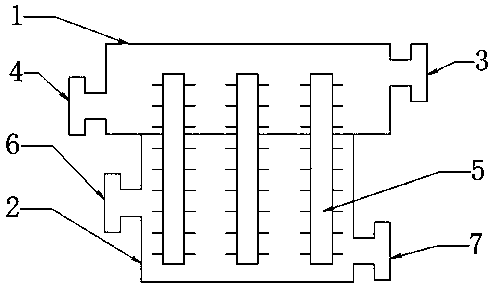

Three-cylinder type vacuum dryer

InactiveCN109210885AWon't leakNot breathableDrying using combination processesDrying chambers/containersFailure rateBoiling point

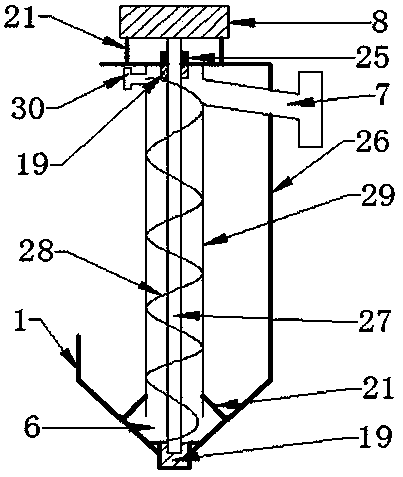

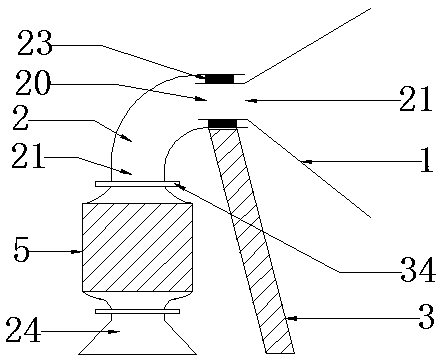

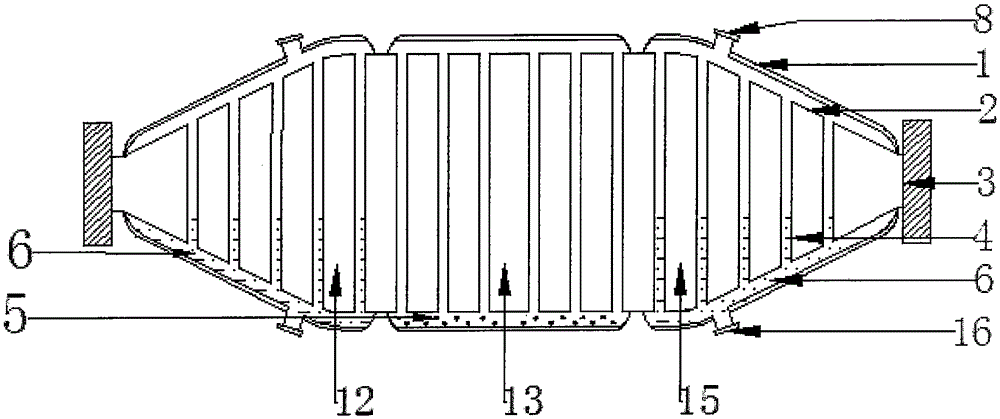

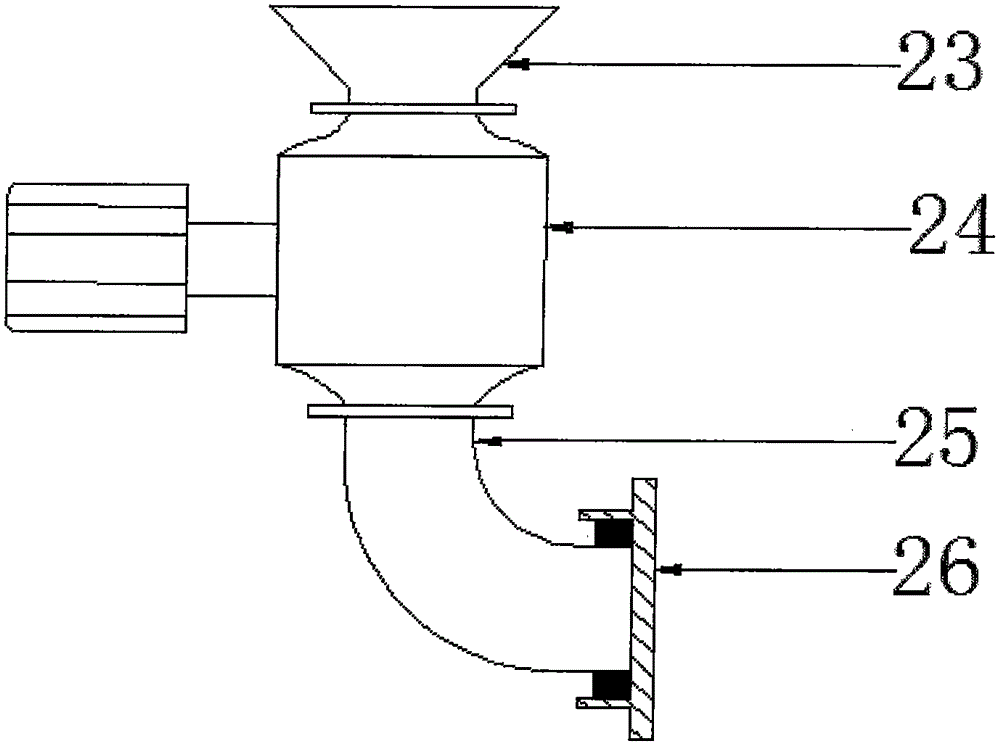

The invention discloses a three-cylinder type vacuum dryer. The three-cylinder type vacuum dryer comprises a three-cylinder drying cabin, a two-way bend pipe, a bracket, a heat conducting pipe, a discharging valve, a vacuum set, a driving device, a gear ring, an air guide pipe, a heat conducting medium, a heating cabin, a hopper, a connecting sealing device and a riding wheel. Under driving of thedriving device and supporting of the riding wheel, the three-cylinder drying cabin can rotate and work. The discharging valve is used for continuous wet materials in the hopper to enter the three-cylinder drying cabin through the discharging valve. The vacuum set extracts gas in the three-cylinder drying cabin and moisture generated by the drying of the material. The heat conducting medium carrying heat energy in the heating cabin is used for conducting heat conduction and heat dissipation to the material. The heat conversion efficiency is high and the loss is little. When one of heat pipes is damaged, the leakage does not affect the use of the whole three-cylinder type vacuum dryer. The failure rate of the three-cylinder type vacuum dryer is reduced.

Owner:张国利

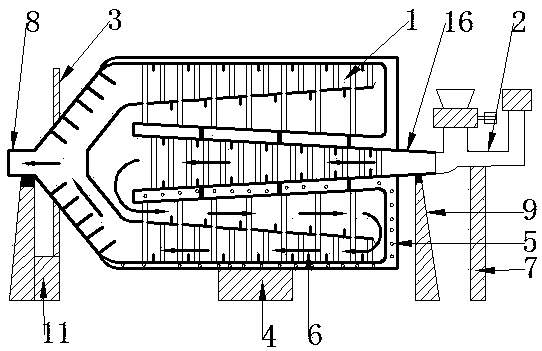

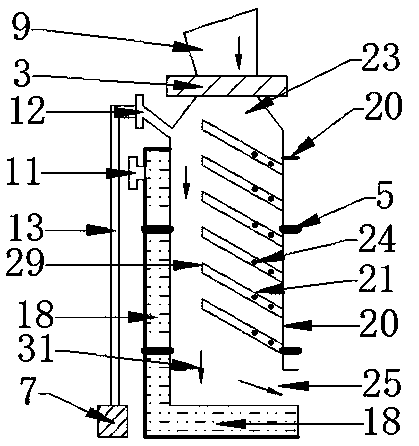

Vacuum drying machine with cooling section

ActiveCN105371621ANot easy to agglomerateShorten drying timeDrying solid materialsDrying machines with non-progressive movementsEngineeringDrying time

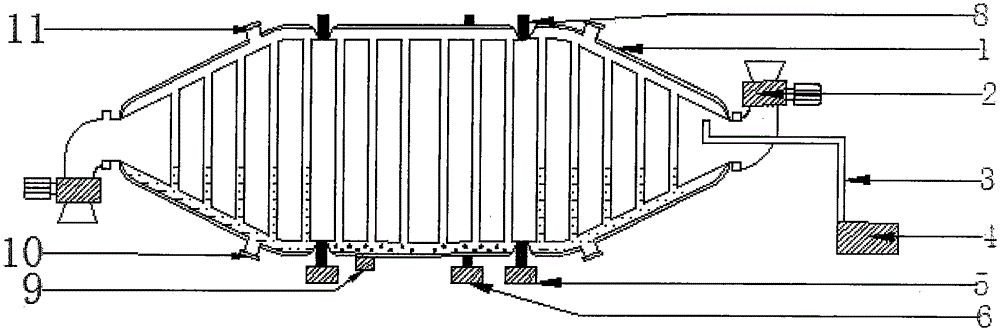

The invention discloses a vacuum drying machine with a cooling section. The vacuum drying machine is composed of a drying bin with the cooling section, a hopper, a discharge device, an elbow, a gas guide pipe, a support, a vacuum unit, a heating device, a driving device and rails. The drying bin with the cooling section is composed of a shell, an inner bin, a heat conduction medium and a safety valve. The support supports a feed port and a discharge port of the two ends of the inner bin. The vacuum unit sucks gas in a bin body of the inner bin through a gas guide pipe. In the material drying process, the drying bin with the cooling section can be rotated on the support through the driving device, cooling vertical pipes arrayed spirally have functions of stirring and propelling materials, no dead corners exist during material drying, materials are not prone to caking when dried in the drying section of the inner bin, material drying time is shortened, material drying quality is uniform, dried materials are cooled in the cooling section, material drying efficiency is improved, the material drying effect is optimized, and green, energy-saving and environment-friendly drying is achieved.

Owner:温州市金榜轻工机械有限公司

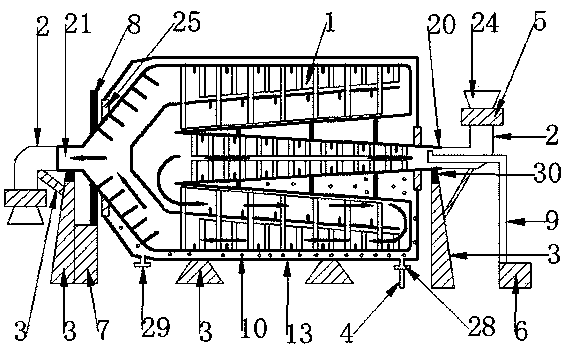

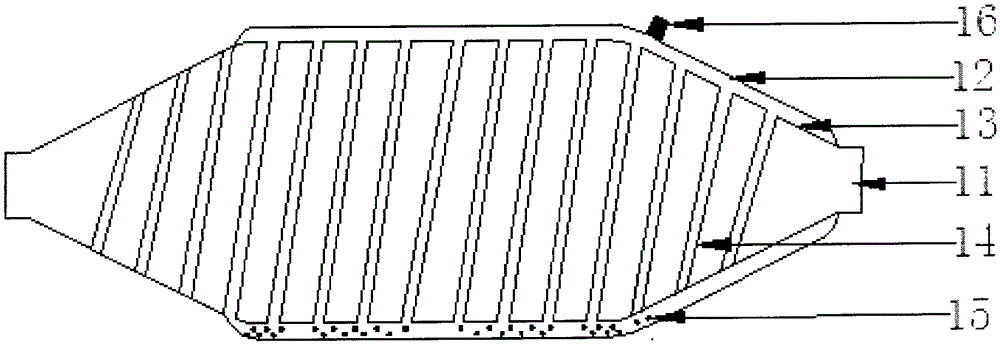

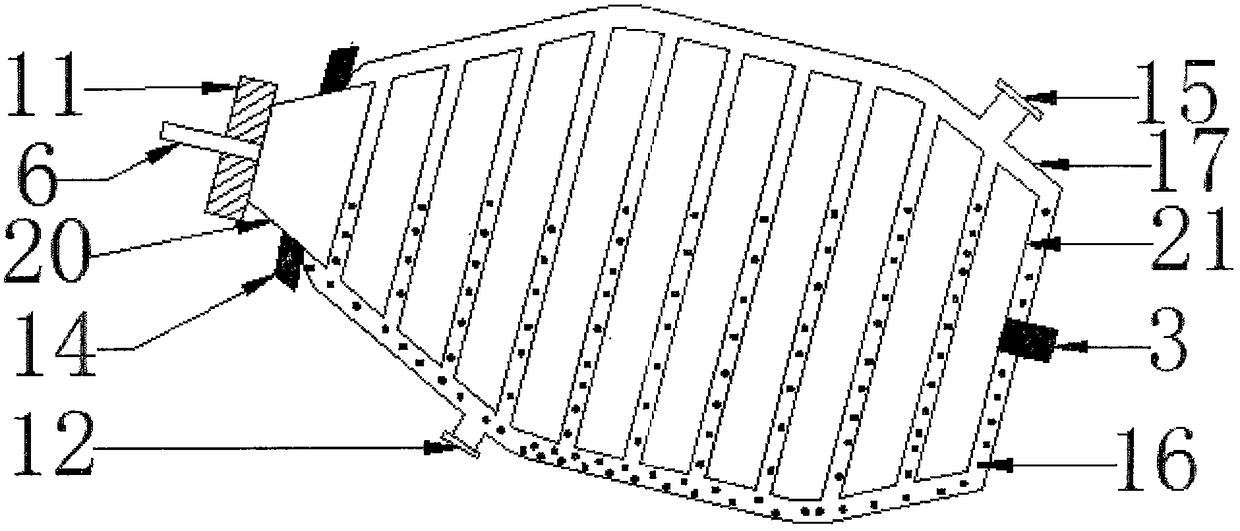

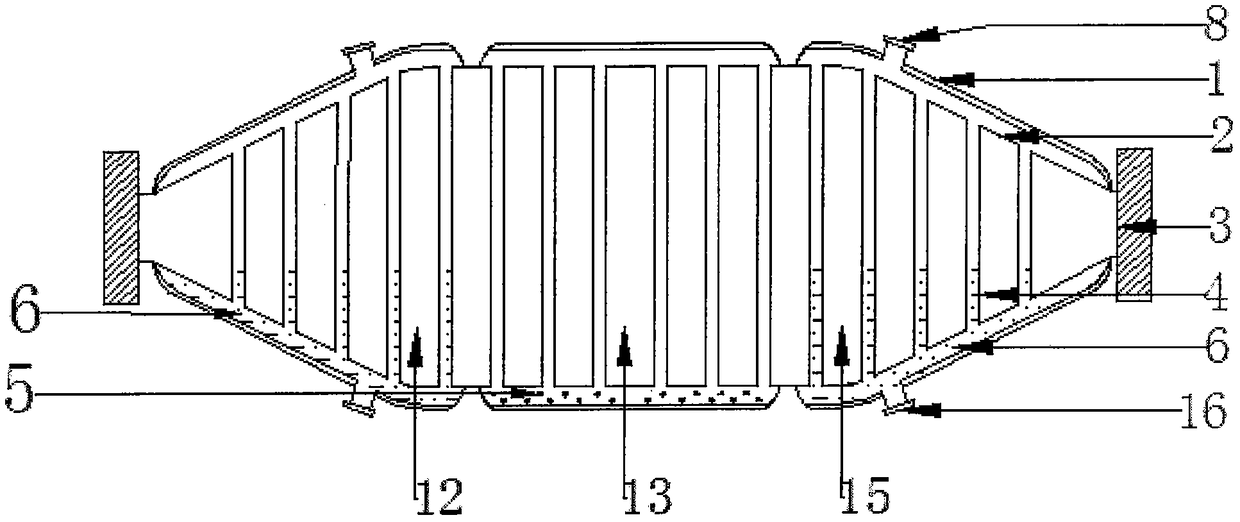

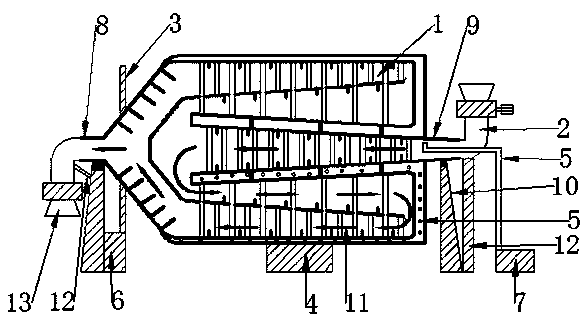

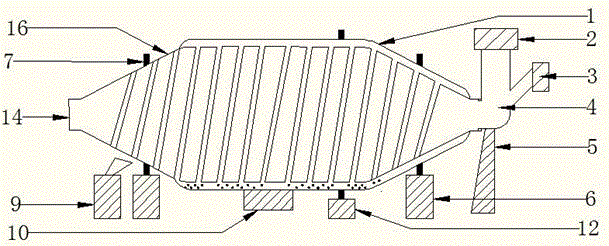

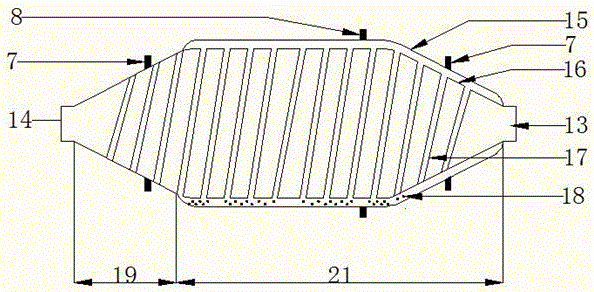

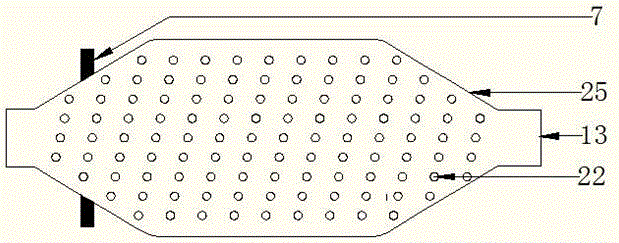

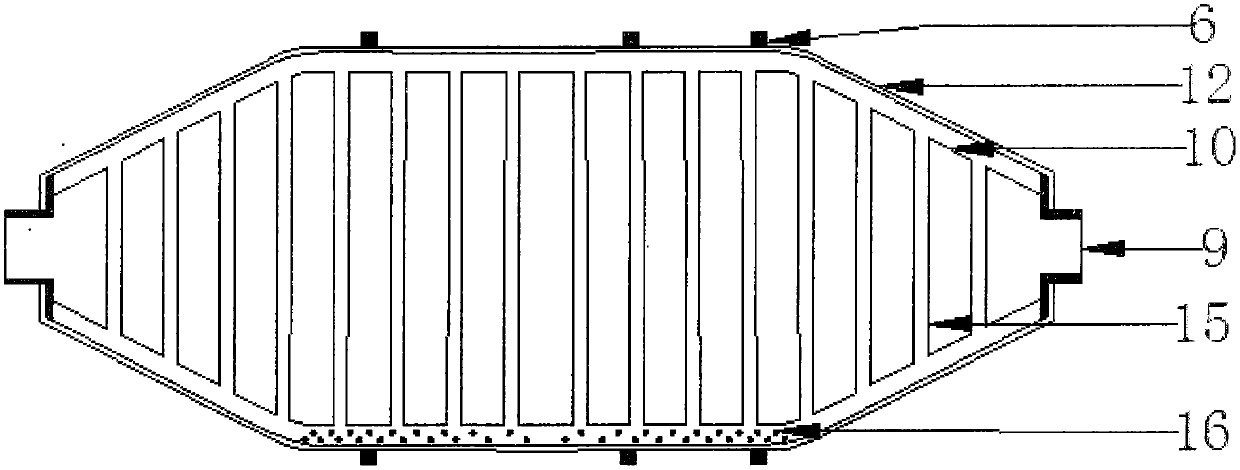

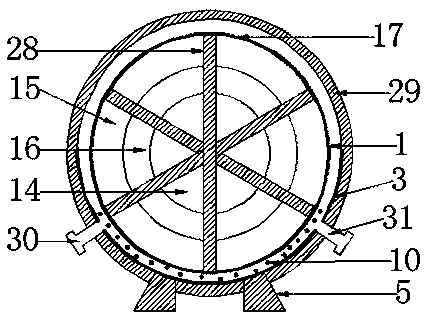

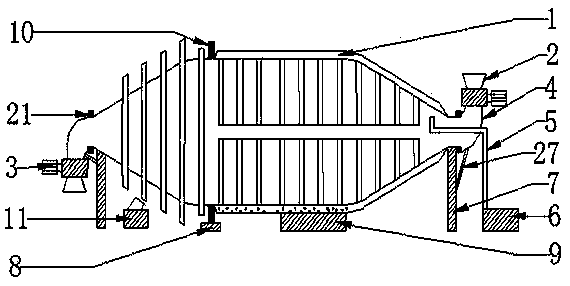

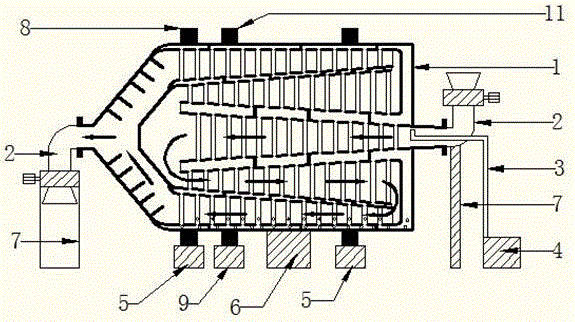

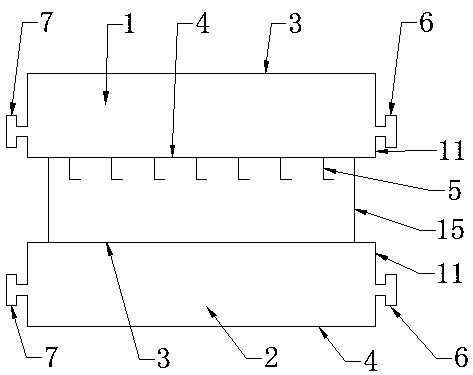

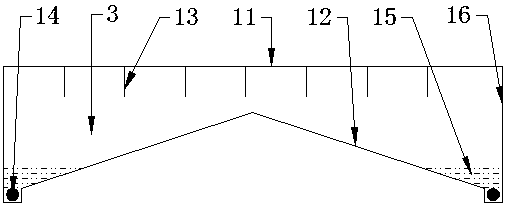

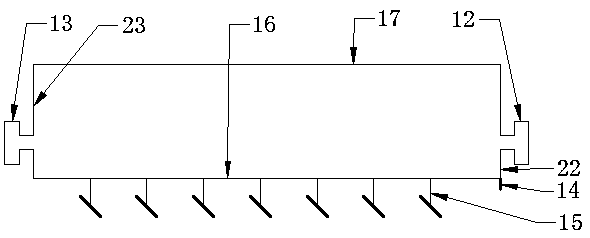

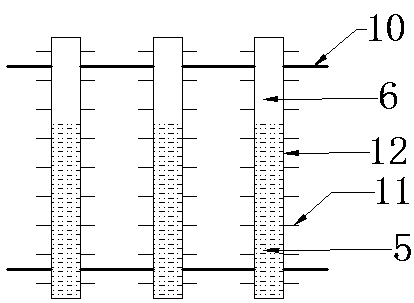

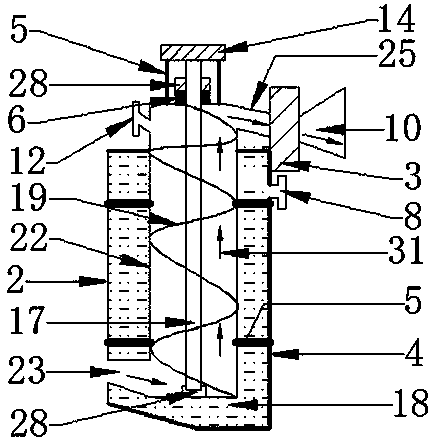

Rotary drying chamber with cooling section

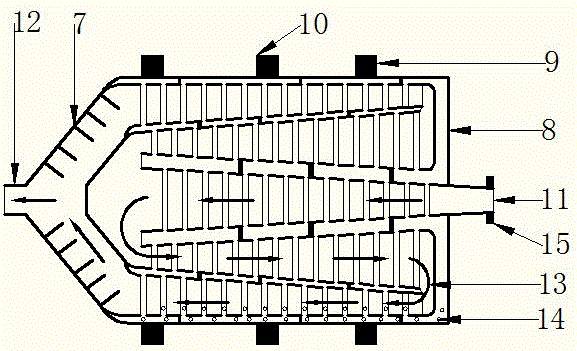

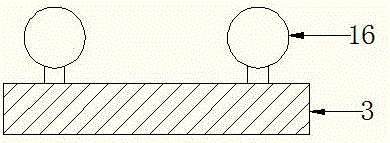

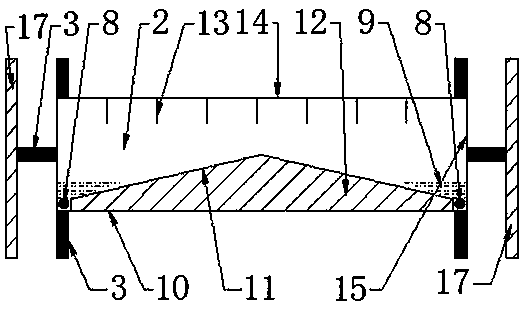

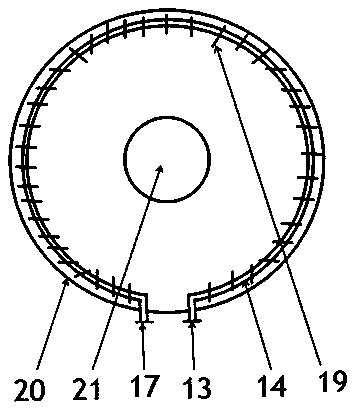

ActiveCN105444551BImprove heat conduction and heat exchange speedDry fastDrying solid materialsHeating arrangementVertical tubeHeat conducting

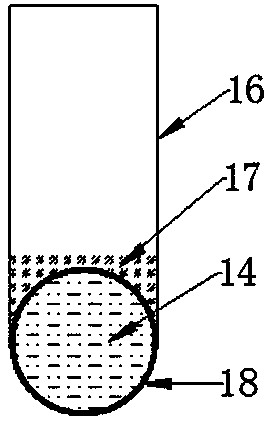

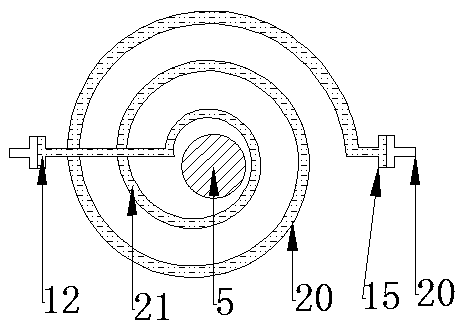

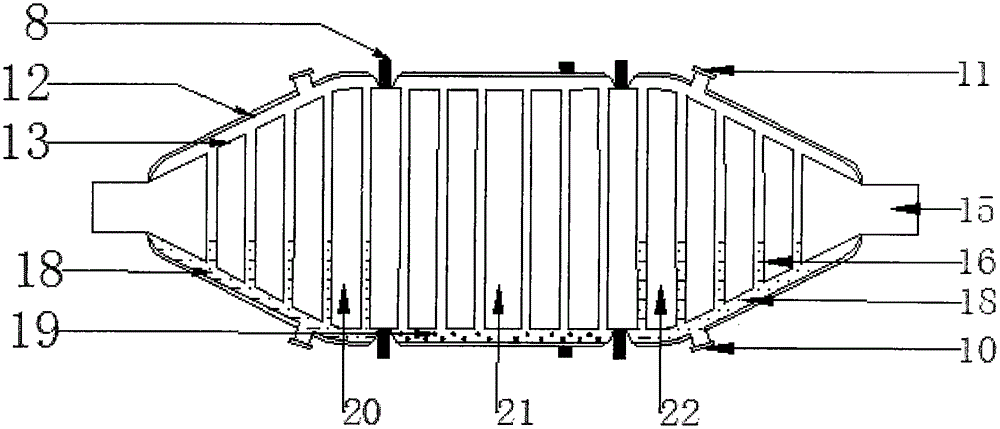

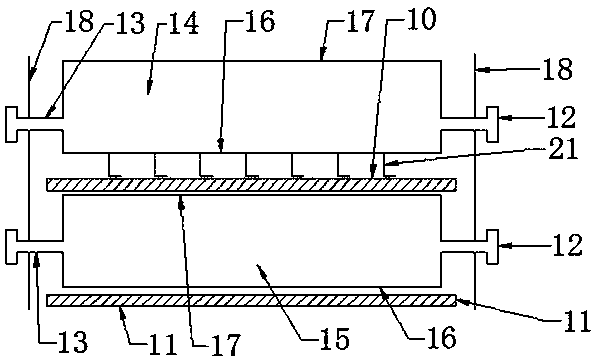

The invention discloses a rotary drying storehouse with a cooling section. The rotary drying storehouse consists of a housing, an inner storehouse and a heat-conducting medium, wherein the apparent shape of the rotary drying storehouse is cylindrical; the housing is arranged on the outer surface of the inner storehouse; the positions, which are in contact with the storehouse body of the inner storehouse, at the two ends of the housing are sealed into an integer by virtue of a sealing device; an inner cavity between the housing and the inner storehouse is sealed and air-proof; a heat energy inlet and a heat energy outlet are formed in the upper surface of the housing; the inner storehouse consists of a storehouse body and radiating vertical tubes, wherein charge and discharge holes are formed in the two ends of the inner storehouse; one end of the inner storehouse is a drying section, and the other end of the inner storehouse is a cooling section; heat energy carried by the high-temperature heat-conducting medium carries out heat conduction and heat exchange on materials by virtue of the storehouse body of the inner storehouse and radiating tubes, so that heat conduction and heat exchange speed of heat energy is increased due to an increased heat exchange area, and therefore, the purpose of quickly drying the materials is achieved. When the materials are dried, radiating vertical tubes which are spirally arranged have functions of stirring and pushing during rotation under action of external force, so that the material drying quality is improved, and the dried materials are cooled at the cooling section.

Owner:SUZHOU EDWARD PETROCHEM CO LTD

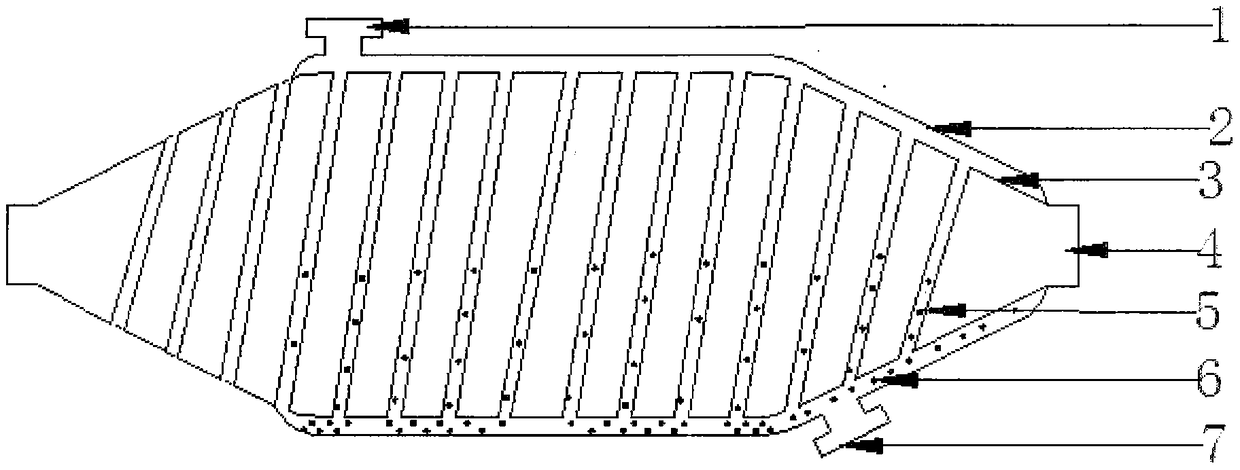

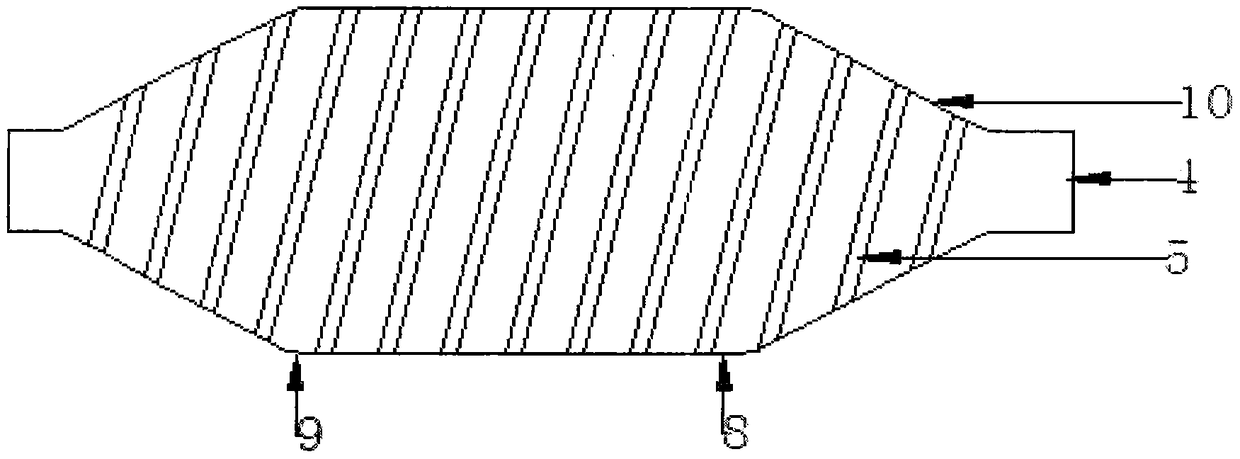

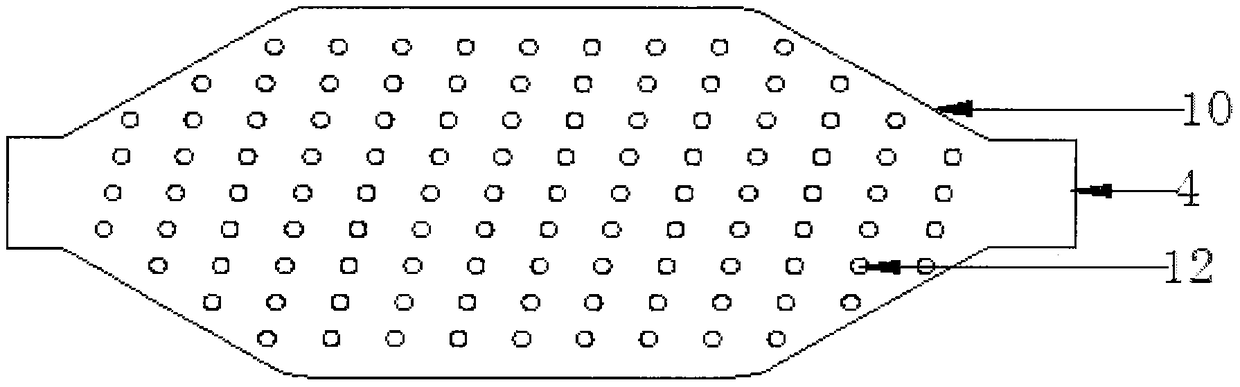

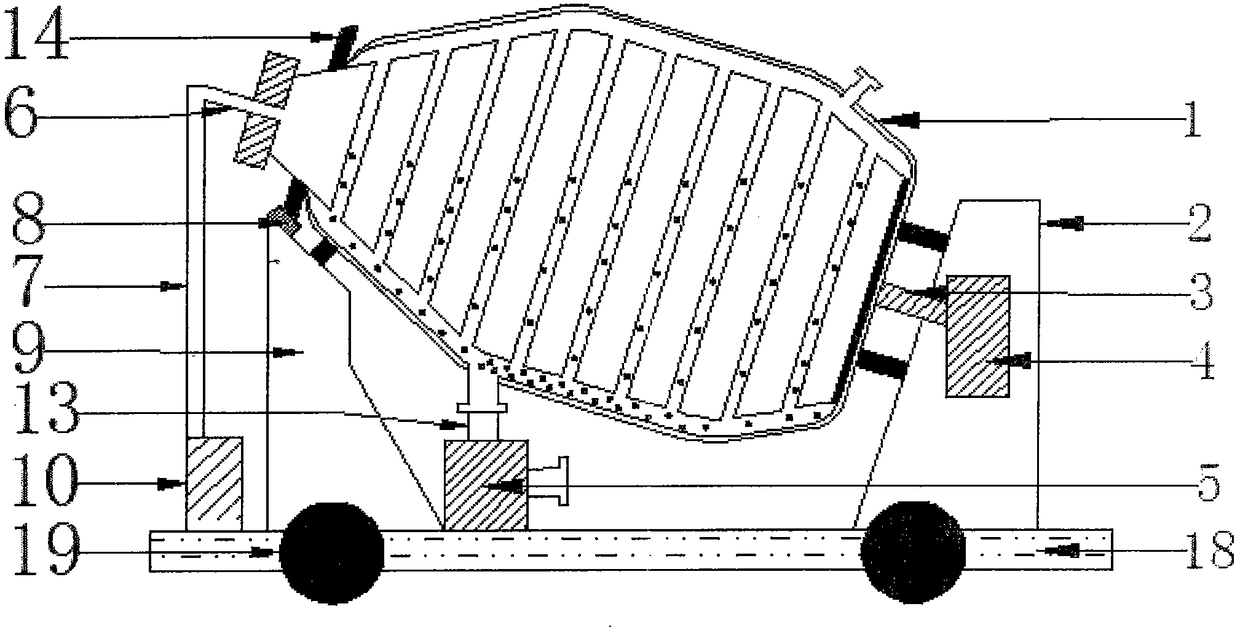

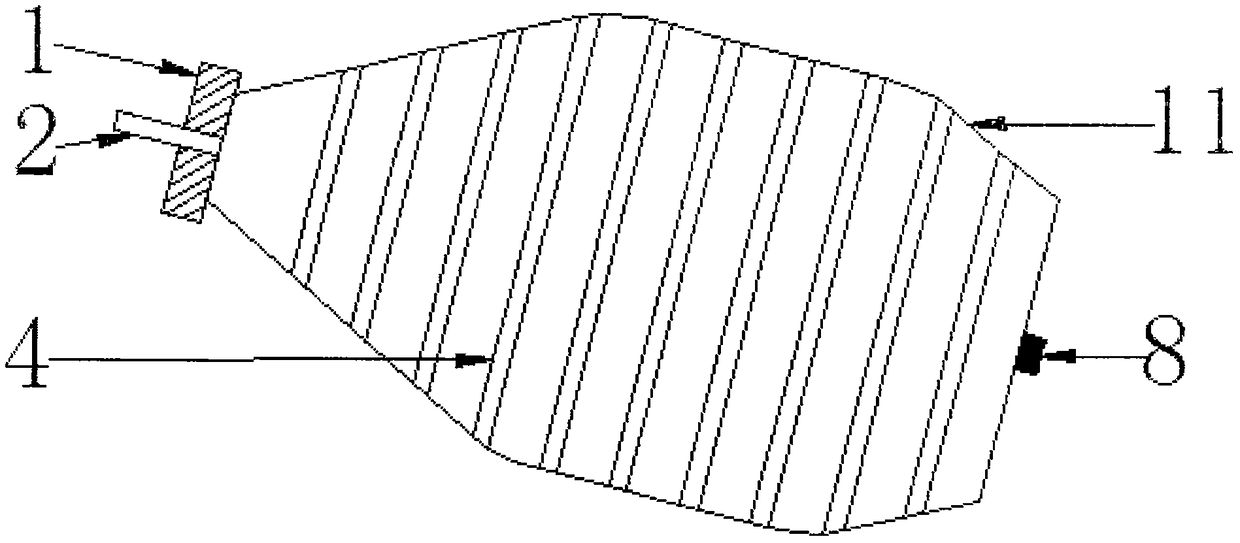

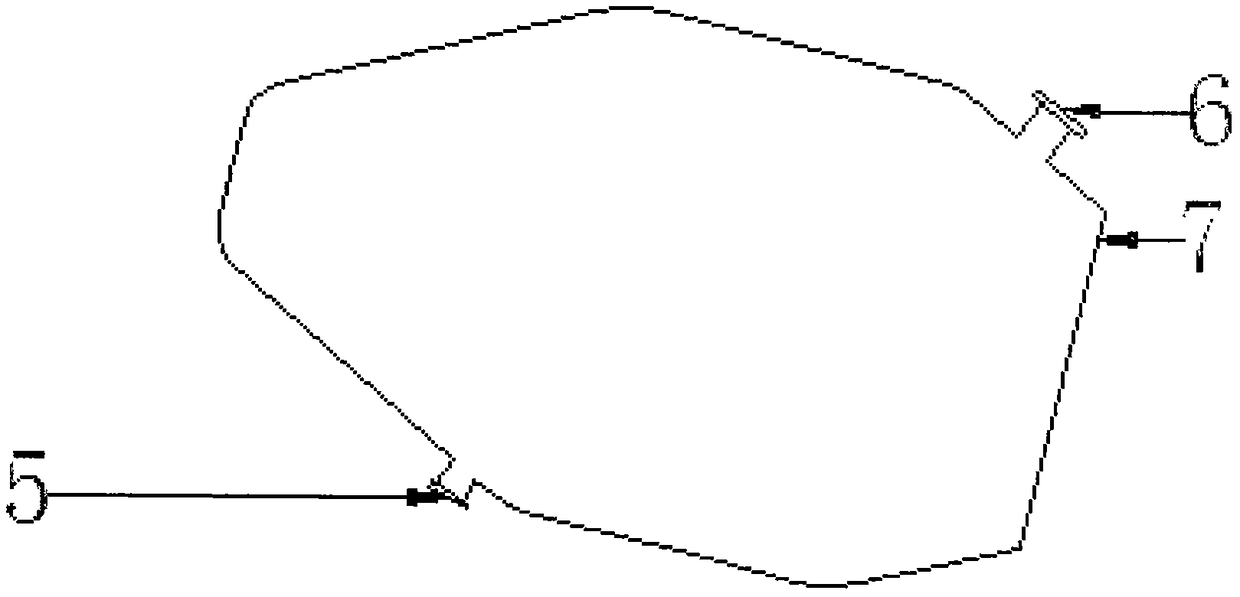

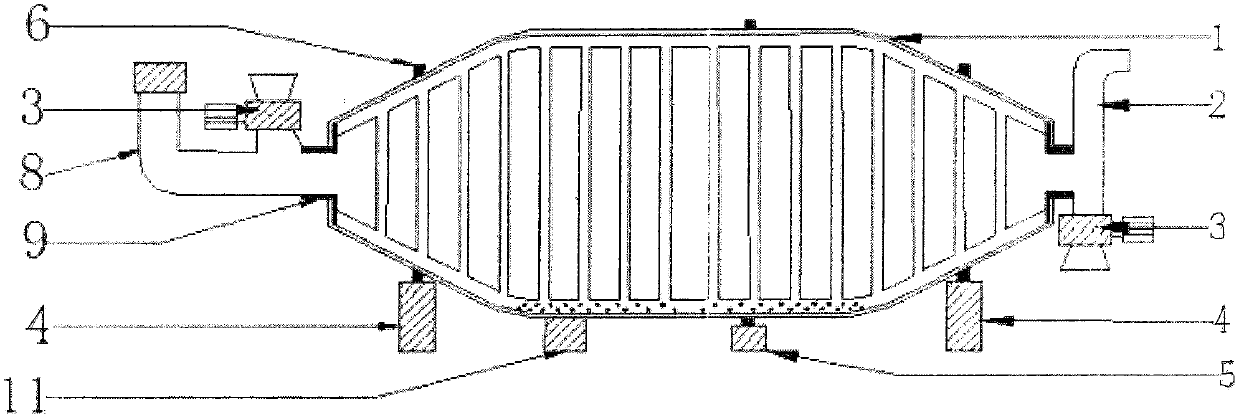

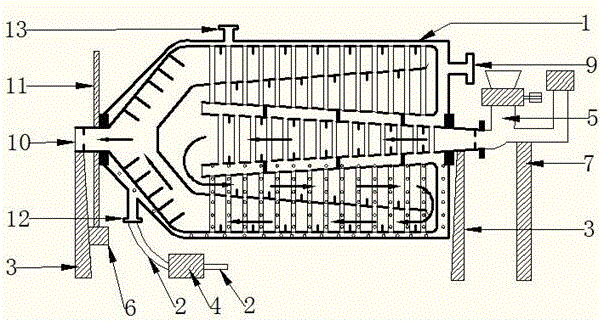

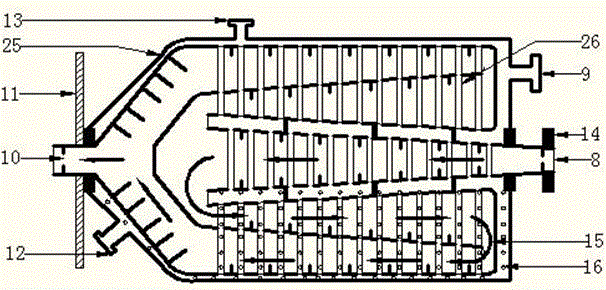

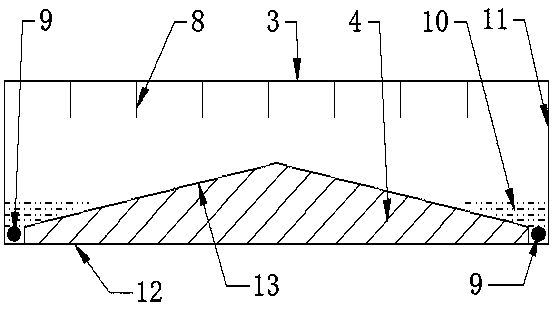

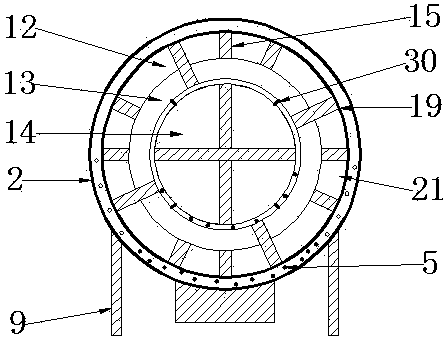

Drum Vacuum Dryer

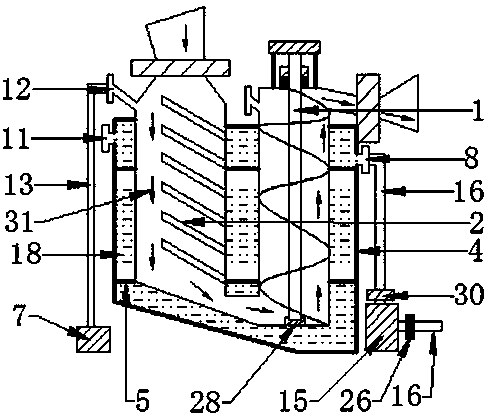

ActiveCN105222543BImprove heat conduction and heat exchange speedImprove drying efficiencyDrying chambers/containersDrying solid materialsThermal energyHeat conducting

Owner:临沂市罗庄区人才发展集团有限公司

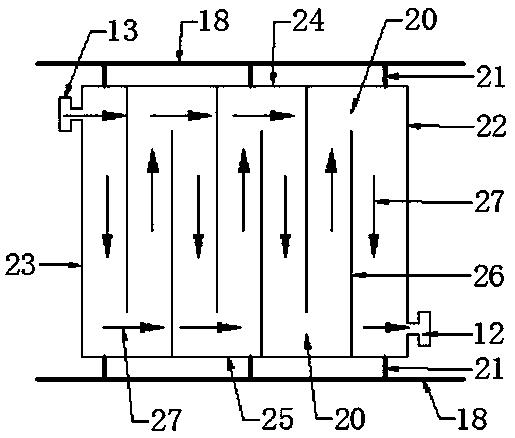

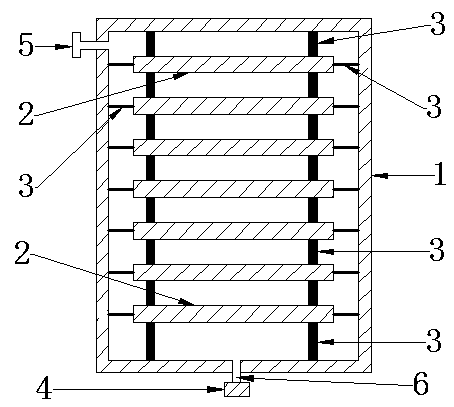

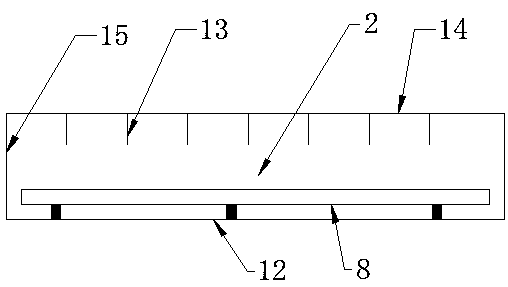

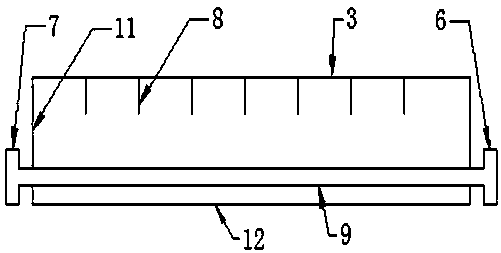

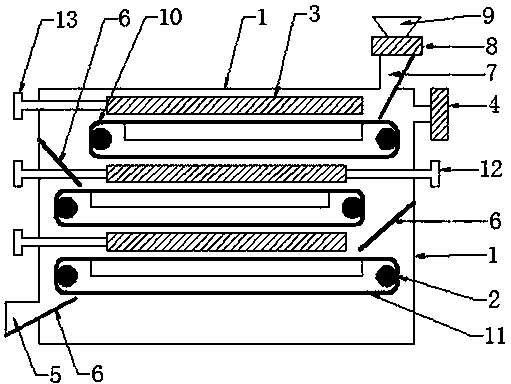

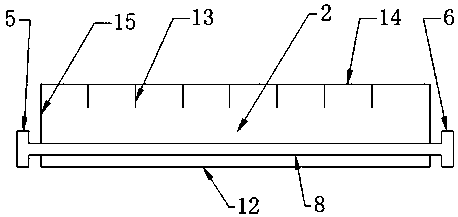

Vacuum net belt drying machine with double-layer heating plates

InactiveCN109751856AImprove effective utilizationImprove drying uniformityDrying solid materialsHeating arrangementHeat conductingProcess engineering

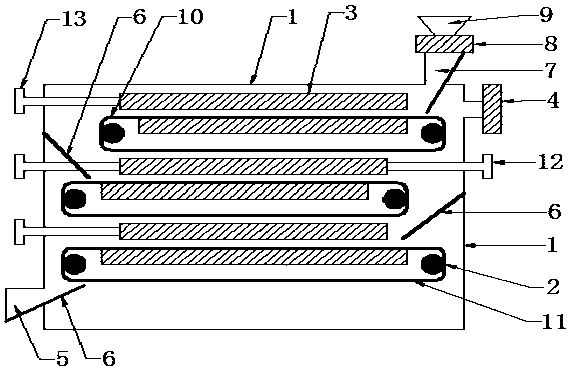

The invention discloses a vacuum net belt drying machine with double-layer heating plates. The vacuum net belt drying machine comprises a drying bin, net belt conveyors, heating devices, a vacuum unit, discharge valves, a feeding hopper, an air guide pipe, material stirring plates and material guide plates. One end of the air guide pipe is fixedly connected with an air outlet of the drying bin; and the other end of the air guide pipe is fixedly connected with the vacuum unit. The discharge valves are mounted at a feeding port and a discharge port of the drying bin. Upper-layer conveying beltsof the net belt conveyors pass through spaces between upper heating plates and lower heating plates of the heating devices. Heat energy inlets and heat energy outlets are formed in the heating plates,and guide plates are arranged in the heating plates. Heat-conducting media carrying heat energy carry out heat conduction and dissipation on materials on the upper-layer conveying belts through the upper heating plates and the lower heating plates, the heat conversion efficiency is high, and the losses are low, so that the heat conduction speed and the heat exchange speed are high, and the effective usage rate of heat energy conduction and exchange is high. The materials on the conveying belts are stirred by the material stirring plates under a conveying inertia effect of the conveying belts,so that the drying efficiency of the materials is improved, and the drying effect of the materials is optimized.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Heat pipe drying chamber that can utilize waste heat

ActiveCN105423739BImprove heat conduction and heat exchange speedAchieve dryingGranular material dryingGrass dryingThermal energyVertical tube

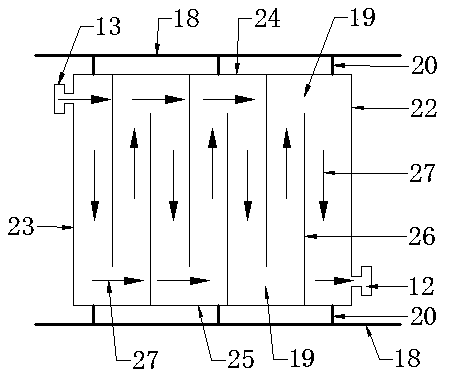

The invention discloses a thermo-tube drying storehouse capable of utilizing afterheat. The thermo-tube drying storehouse consists of shells, an inner storehouse, a discharging device, a heat conducting medium and a heat conducting working medium, wherein the three shells are respectively mounted over a preheating section, a drying section and a cooling section of the inner storehouse; the inner storehouse consists of a storehouse body, a cooling vertical tube and a helical blade; an inner chamber between the shells and the inner storehouse is filled with the heat conducting medium and the heat conducting working medium; the heat conducting working medium and the heat conducting medium are used for conducting heat and radiating heat by the storehouse body and the cooling vertical tube of the inner storehouse; the heat conduction speed and heat exchange speed of heat energy are increased; materials can be dried rapidly; the cooling vertical tube and the helical blade of the inner storehouse have the function of stirring the materials; wet materials are hard to cake during a drying process; the drying quality of the materials is improved; the materials can be cooled during the drying process; the heat energy released during cooling of the materials can be effectively used for preheating the materials, so energy-saving drying of the materials is realized.

Owner:宁波华泰盛富聚合材料有限公司

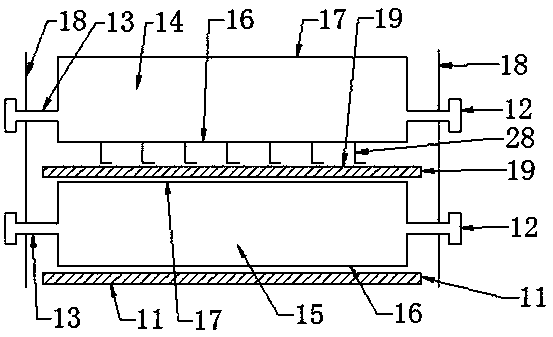

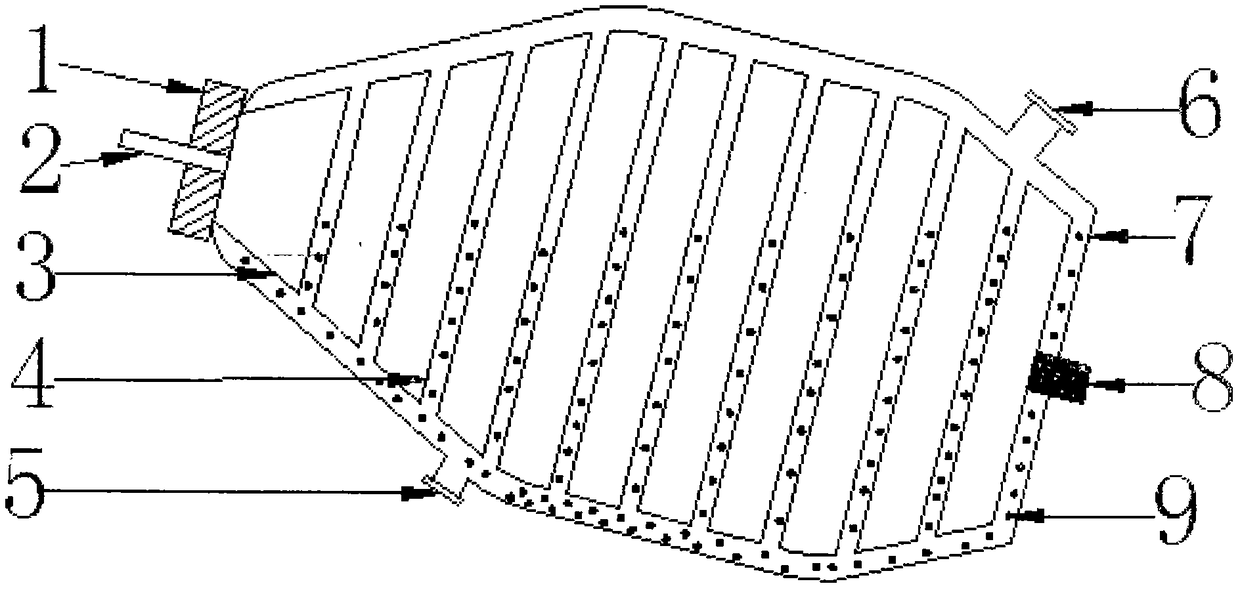

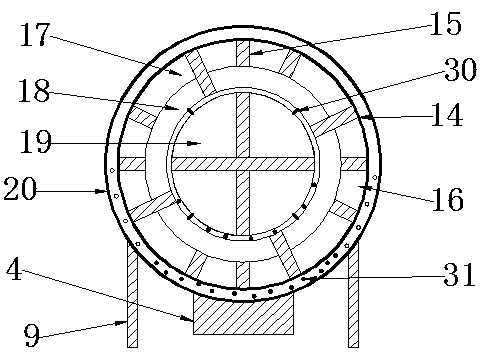

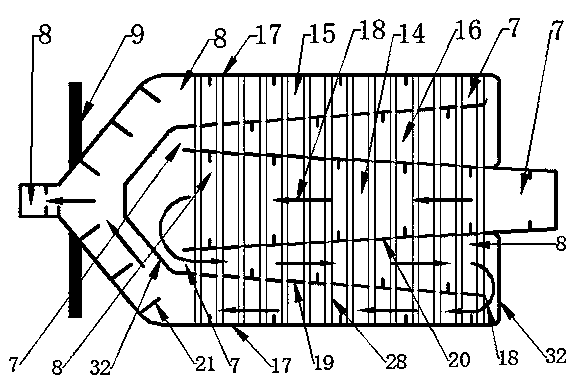

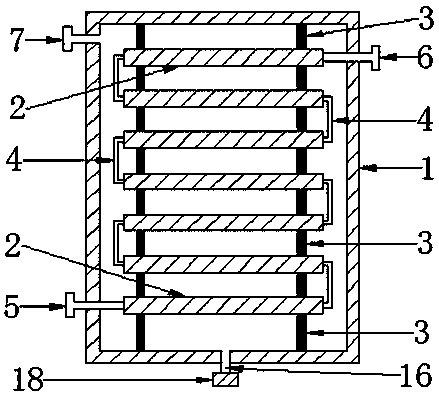

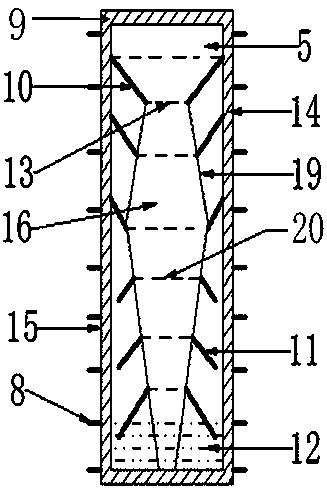

Heating heat exchange device

ActiveCN105276971BImprove heat conduction and heat exchange speedImprove drying efficiencyDrying solid materialsHeating arrangementSpiral bladeEngineering

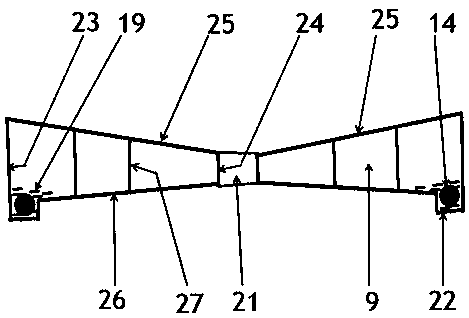

The invention discloses a heating heat exchange device which is composed of a shell, an inner bin and a heat conduction working medium. The inner bin is wrapped by the shell, and the distance between the shell and the inner bin is 5-150 mm. The inner bin is composed of a bin body, a heat dissipation vertical pipe, a sealing cover, a conduction shaft and a spiral blade. The conduction shaft in the position, on the larger end of the inner bin, of the bin body can drive the inner bin to rotate. An exhaust port is formed in the upper surface of the sealing cover. The spiral blade and the heat dissipation vertical pipe are arranged on the bin body of the inner bin. Heat exchange of the heating heat exchange device is three-dimensional heat exchange of an inner wall. Under the condition of the same space volume, the heat exchange area of the heating heat exchange device is increased by 8-50 times, the high-temperature heat conduction working medium conducts heat conduction and dissipation through the bin body and the heat dissipation vertical pipe of the inner bin, the heat conduction and heat exchange speed of heat energy is increased, the material drying efficiency is improved, and the purpose of fast drying materials is achieved; and the heat dissipation vertical pipe and the spiral blade have the function of material stirring, so that the wet materials are not prone to being agglomerated in the drying process, and the drying quality of the materials is optimized.

Owner:云霄县食品快检中心

Electric heating type drying box

PendingCN110243149AImprove stress resistanceCause deformationDrying machines with local agitationDrying machines with materials at restElectricityHeat conducting

The invention discloses an electric heating type drying box. The electric heating type drying box comprises a drying box, heating devices, a bracket and a drainage valve. The drainage valve is mounted in a drainage port on the outer surface of the drying box. The heating devices comprise top plates, base plates, side plates, electric heating pipes, fixed strips and heat conducting working mediums. The heating devices are fixedly mounted on a box body of the drying box through brackets. The electric heating pipes provide a heat source to the liquid-state heat conducting working mediums; the heat conducting working mediums transfer heat onto the top plates and the base plates of the heating devices through gas-liquid phase change; the heating devices on the upper and lower layers synchronously heat materials in trays up and down; through balanced temperature at four angles and the peripheries of the top plates and the base plates of the heating devices, the water drying uniformity of the materials is guaranteed, and the transfer drying of the materials is performed; and through up-down synchronous heating by the heating devices, the heat conduction and exchange speed of heat energy is accelerated. The electric heating type drying box flexibly selects vacuum low-temperature drying or air convection drying to improve the material drying efficiency and to optimize the material drying effect.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Four cylinder vacuum drying machine

InactiveCN107588623AConvenient nestingDoes not affect normal useDrying chambers/containersDrying solid materialsHeat conductingPulp and paper industry

The invention relates to a four cylinder vacuum drying machine. The four cylinder vacuum drying machine comprises a four cylinder drying bin, a feeding device, a discharging device, a gear ring, a heating device, a bracket, a supporting wheel bracket, a driving device, a gas-guide tube and a vacuum unit. Under the drive of the driving device, the four cylinder drying bin can rotate to work under the support of supporting wheels on the supporting wheel bracket. Heat energy generated by the heating device heats a heat-conducting medium through a bin body of the heating bin of the four cylinder drying bin; the feeding device is installed on a feed inlet of the four cylinder drying bin, and the discharging device is installed at a discharge hole of the four cylinder drying bin. One end of thegas-guide tube penetrates through an elbow of the feeding device, and the other end of the gas-guide tube is connected to the vacuum unit. The relative air pressure of gas in the four cylinder dryingbin is 0.025 Mpa-0.098 Mpa; The heat conversion efficiency of the four cylinder vacuum drying machine is high, the loss is small, and the heat conduction and heat exchange speed is increased. By meansof continuous vacuum drying, the material drying efficiency is improved, the material drying effect is optimized, and the purpose of drying the materials rapidly is achieved.

Owner:张海娟

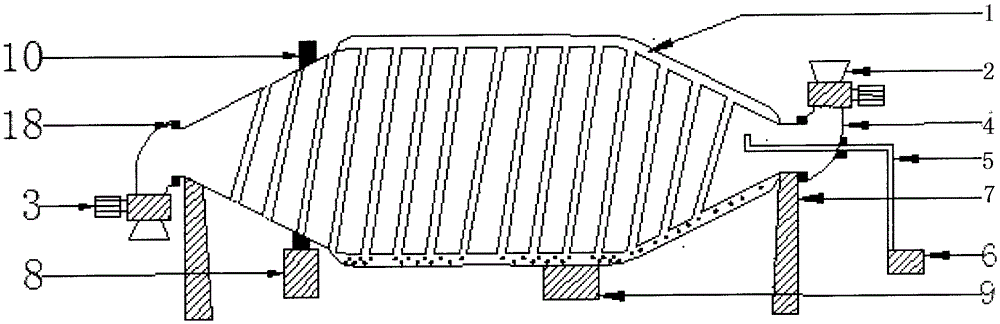

Continuous heat pipe drying machine

InactiveCN105806058AImprove cooling effectImprove heat conduction and heat exchange speedDrying machines with non-progressive movementsDrying solid materialsHeat conductingSpiral blade

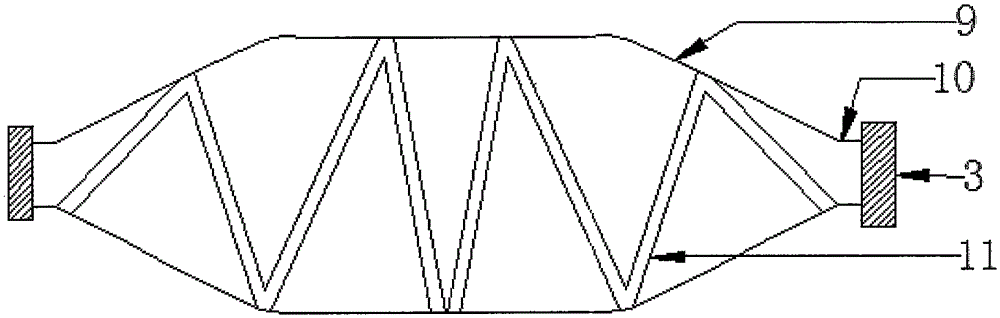

The invention discloses a continuous heat pipe drying machine. The continuous heat pipe drying machine comprises a drying bin, an exhaust device, a feed device, a three-way pipe, a bracket, a support roller bracket, a fan, a heating device, a sealing device and a drying device. The drying bin includes an inner bin, a shell and a heat conducting medium. The heat conducting medium is in an inner cavity between the shell and the inner bin. The heating device heats the shell of the drying bin; and one end of the inner bin is a drying area, and the other end is a cooling area. The fan is fixedly mounted out of the inner bin of the cooling area of the drying bin. The driving device drives a gear ring of the drying bin; and the drying bin is supported by the support roller bracket, and rotates on the support roller bracket. When materials are dried, the heat exchange area is increased, the heat conduction and exchange speed of heat energy is accelerated, the material drying efficiency is enhanced, and the quick material drying purpose is achieved; the drying bin rotates under the effect of external force; the materials stirred by a heat dissipating pipe and a spiral blade are not easy to cake during drying in the inner bin, so that the material drying quality is improved; and the heat conduction, the heat exchange and the cooling are performed for the dried materials in the cooling area.

Owner:张海娟

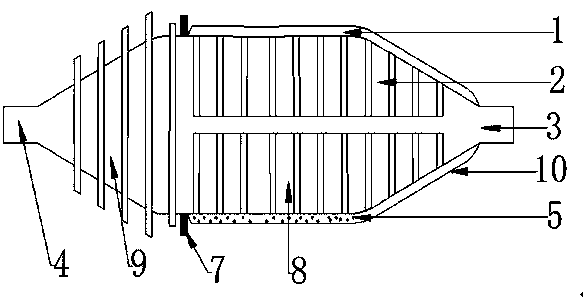

Continuous heat pipe type hot air drying machine

InactiveCN105509453AImprove heat conduction and heat exchange speedShorten drying timeDrying gas arrangementsHeating arrangementSpiral bladePulp and paper industry

The invention provides a continuous heat pipe type hot air drying machine, which consists of a heat pipe vacuum drying cabin, an air inlet device, a support frame, a discharging device, a heating device, a driving device, rails and an exhaust device, wherein the discharging device, the air inlet device and the exhaust device are arranged on material inlet and outlet openings of an inner cabin; the rails arranged on a case of the heat pipe vacuum drying cabin is arranged on the support frame; the driving device is used for driving the rails arranged on the case; the heating device is used for directly heating the case of the heat pipe vacuum drying cabin. The heat exchange is directly performed in the drying cabin; the heat exchange area is increased by 12 to 60 times; the heat conduction and heat exchange speed of material drying is accelerated. The materials are fed into or discharged from the vacuum drying cabin through the discharging device, and the materials can be subjected to continuous hot air drying. A heat radiation pipe and a spiral blade have the stirring function; no dead corner exists during the material drying; the material drying time is shortened, so that the material drying quality is uniform; the material drying efficiency is improved; the material drying effect is optimized; the dried materials are cooled; the effects of green drying, energy saving and environment protection are achieved.

Owner:张海娟

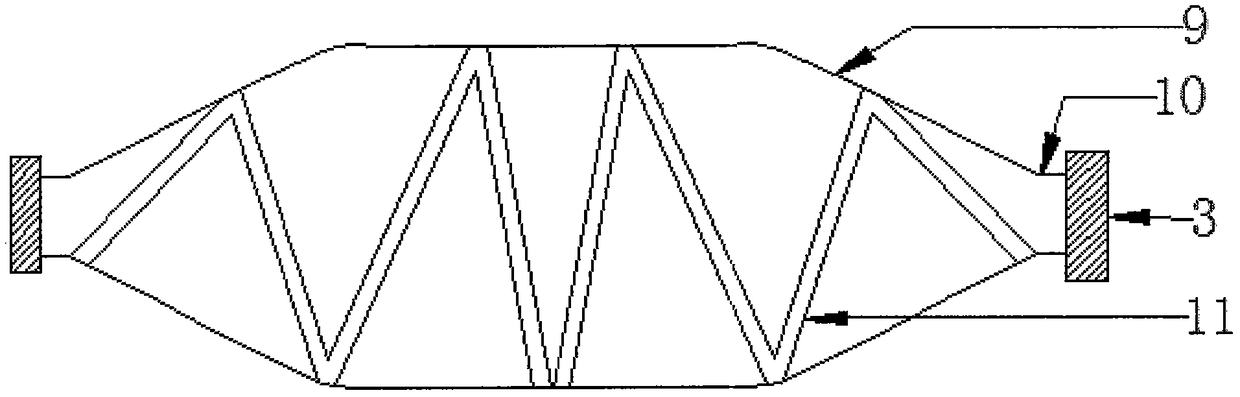

Continuous three-cylinder drying machine

ActiveCN106052338AEnsure safetyImprove delivery capacityDrying machines with non-progressive movementsDrying solid materialsHeat conductingHeat pipe

The invention provides a continuous three-cylinder drying machine. The continuous three-cylinder drying machine comprises a rotary type three-cylinder drying storehouse, a carrier roller supporting frame, a flow guiding pipe, a supporting frame, a heating device, a driving device, a material feeding and air exhausting device and a moving device. The rotary type three-cylinder drying storehouse comprises a shell, a combined type drying storehouse, transmission wheels, a heat conducting working medium and a sealing device. The combined type drying storehouse comprises an inner cylinder, an outer cylinder, a middle cylinder, the supporting frame, a blocking plate, a radiating pipe and a flow guiding plate. A heat energy inlet, a heat energy outlet and an air exhausting port are arranged in the shell. A material discharging port and a material feeding port of the combined type drying storehouse are supported by the carrier roller supporting frame. The transmission wheels are driven to rotate by the driving device. A flange connector on the material feeding port of the heat pipe type three-cylinder drying storehouse is integrated with the flange connector of the material feeding and air exhausting device in a connecting and fixing manner. According to the drying machine, the heat energy of the heating device conducts heating, heat conducting and radiating on materials through the heat conducting working medium, so that the thermal conversion efficiency is high and the lost is low; the materials can be dried continuously, so that the drying efficiency of the materials can be improved and the drying effect of the materials can be optimized.

Owner:常州鸿石干燥科技有限公司

Transmission dried three-roller dryer

InactiveCN107588620ADoes not affect normal useAchieve the purpose of dryingDrying gas arrangementsDrying chambers/containersInsulation layerEngineering

The invention relates to a transmission dried three-roller dryer. The dryer comprises a feeding and exhaust device, a heating groove, supporting wheel supports, supports, a driving device, a gear ring, a heat conduction medium, heat conduction tubes, a heating device and a heat insulation layer. Supporting wheels of the supporting wheel supports support a discharge hole and a feeding hole of a three-roller drying warehouse; the cylinder body of an external cylinder of the lower half part of the three-roller drying warehouse is soaked with the heat conduction medium in the heating groove; the feeding and exhaust device is arranged in the feeding hole of the three-roller drying warehouse. Heat energy of the heating device can conduct heat conduction and heat dissipation on materials in the three-roller drying warehouse through the heat conduction medium, the heat conversion efficiency is high, the loss is little, and the heat transfer speed of heat conduction is increased. When the materials are dried, surplus hot air does not need to be used, the heat loss which is taken away by the exhaust device can be ignored, the effective use rate of whole heat energy is within 75-90%, a flow guide plate stirs and pushes the drying materials, the evenness of material drying is improved, the efficiency of material drying is improved, and the effect of material drying is optimized.

Owner:张海娟

Vacuum dryer

InactiveCN108571875AImprove qualityImprove efficiencyGranular material dryingDrying solid materials without heatThermal energyCondensation process

The invention discloses a vacuum dryer. The vacuum dryer comprises a drying storehouse, a heat transfer device, grain discharge devices, a bracket, a lifting device, a valve, a feed hopper, an outlethopper, a sealing device, an online moisture test device, a vacuum set, a heating device, a gas guide tube, a heat conduction tube, a heat conduction medium and a thermal insulation layer, wherein thevacuum set is connected with an air exhaust port in the drying storehouse through the heat conduction tube; the valve is used for controlling the entry and exit of materials in the drying storehouse;the heat transfer device is connected with the heating device through the heat conduction tube; the drying storehouse is internally provided with 1-5 sets of grain discharge devices, the online moisture test device is arranged in the drying storehouse; the heat conduction medium carrying thermal energy directly performs heating and heat conducting on the materials through a heat pipe of the heattransfer device, the thermal conversion efficiency is high, loss is small, and the heat conduction and heat transfer speed is improved; waste-heat utilization can be carried out on the heat energy released by the condensable gas in the moisture in the condensation process of a condenser; the lifting device dries the materials circularly and drily; each grain discharge device has a stirring function, so that the drying quality of the materials is even, thereby improving the drying efficiency of the materials and optimizing the drying effect of the materials.

Owner:程相杰

Thermo-tube drying storehouse capable of utilizing afterheat

ActiveCN105423739AImprove heat conduction and heat exchange speedAchieve dryingGranular material dryingGrass dryingVertical tubeThermal energy

The invention discloses a thermo-tube drying storehouse capable of utilizing afterheat. The thermo-tube drying storehouse consists of shells, an inner storehouse, a discharging device, a heat conducting medium and a heat conducting working medium, wherein the three shells are respectively mounted over a preheating section, a drying section and a cooling section of the inner storehouse; the inner storehouse consists of a storehouse body, a cooling vertical tube and a helical blade; an inner chamber between the shells and the inner storehouse is filled with the heat conducting medium and the heat conducting working medium; the heat conducting working medium and the heat conducting medium are used for conducting heat and radiating heat by the storehouse body and the cooling vertical tube of the inner storehouse; the heat conduction speed and heat exchange speed of heat energy are increased; materials can be dried rapidly; the cooling vertical tube and the helical blade of the inner storehouse have the function of stirring the materials; wet materials are hard to cake during a drying process; the drying quality of the materials is improved; the materials can be cooled during the drying process; the heat energy released during cooling of the materials can be effectively used for preheating the materials, so energy-saving drying of the materials is realized.

Owner:宁波华泰盛富聚合材料有限公司

Drum vacuum dryer

InactiveCN109387039AReduce entryReduce air intakeDrying solid materials without heatDrying gas arrangementsHeat conductingEngineering

The invention relates to a drum vacuum dryer. The drum vacuum dryer comprises a vacuum drying chamber, a hopper, a discharging device, an elbow, an air duct, a vacuum unit, a riding wheel bracket, a driving device, a heating device, a gear ring, a fan, a sealing device and a bracket. The vacuum drying chamber comprises a heating chamber, a drying chamber and a heat conducting working medium; the riding wheel bracket fixedly supports the vacuum drying chamber and is provided with a feed opening and a discharge opening. A flange-free end of the elbow and the feed opening and the discharge opening of the vacuum drying chamber are hermetically connected into a whole by the sealing device, and an end with a flange of the elbow is fixedly connected into a whole with the discharging device. Whenthe vacuum drying chamber is driven to rotate by the driving device, the air duct and the elbow are stationary, and the joint of the air duct and the elbow is sealed and airtight. The heat energy of the heating device heats a material, conducts heat to the material and radiates heat from the material through the heat conducting working medium, so that the heat conversion efficiency is high and theloss is small; the dried material is cooled in a cooling section, so that the material drying efficiency is improved, and the material drying effect is optimized. When one heat pipe is damaged and leaks, the use of the whole drum vacuum dryer is not affected.

Owner:程长春

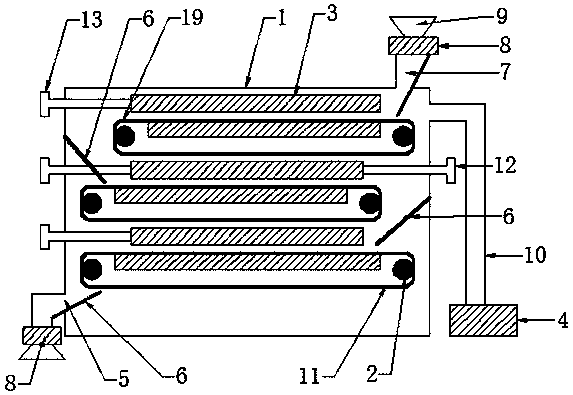

Hot pipe type three-barrel vacuum drier

ActiveCN106091653ACompact structureSimple structureDrying chambers/containersDrying solid materialsHeat conductingEngineering

The invention discloses a hot pipe type three-barrel vacuum drier. The hot pipe type three-barrel vacuum drier comprises a hot pipe type three-barrel drying chamber, an air guide tube, brackets, a vacuum unit, a heating device, a driving device, a vacuum feeding-discharging device and a moving device, wherein the vacuum feeding-discharging device is supported and fixed through the brackets; two to five groups of roller paths and 1 to 2 groups of gear rings are arranged on the outer shell of the hot pipe type three-barrel drying chamber; carrier roller brackets comprise the brackets and carrier rollers; a transmission gear on a transmission of the driving device occludes with racks of the gear rings on the outer shell; the heating device directly heats the outer shell of the hot pipe type three-barrel drying chamber; and the air guide tube penetrates through the vacuum feeding-discharging device of the hot pipe type three-barrel drying chamber to be connected with the vacuum unit. According to the hot pipe type three-barrel vacuum drier, the structure is compact, the construction is simple, the layout is reasonable, the heat exchange rate of materials and heat energy is increased, heat energy of the heating device heats the materials, conducts heat to the materials, and dissipates heat of the materials through a heat-conducting medium, the thermal conversion efficiency is high, the loss is low, the materials can be continuously dried under a vacuum and low temperature environment, the material drying efficiency is improved, the material drying effect is optimized, and the hot pipe type three-barrel vacuum drier performs eco-friendly drying, and is energy-saving and environment-friendly.

Owner:新沂市星辰新材料科技有限公司

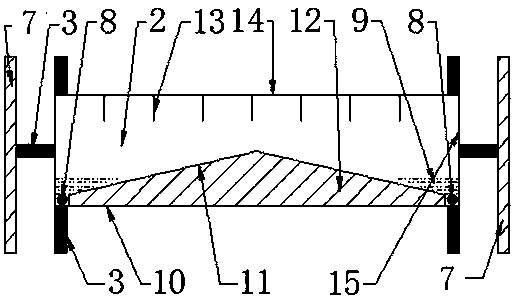

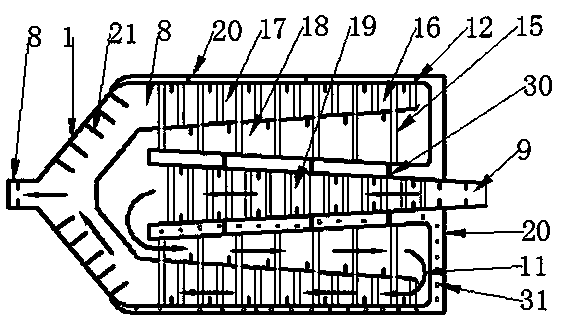

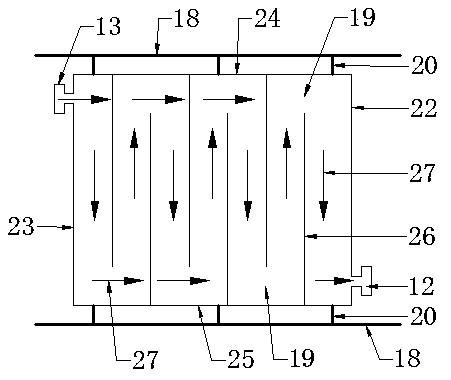

Heat pipe type heating device

InactiveCN109838988AImprove thermal conductivitySpeed up the cycleDrying machines with progressive movementsDrying solid materialsEngineeringThermal radiation

The invention discloses a heat pipe type heating device. The heat pipe type heating device comprises an upper heating plate, a lower heating plate, a support and a stirring device, wherein the upper heating plate and the lower heating plate are supported and fixed by the support, the stirring device is fixed below the upper heating plate, the upper heating plate comprises a top plate, a bottom plate, side plates, heat conduction pipes, heat conduction strips and heat conduction working media, and the lower heating plate comprises a top plate, a bottom plate, side plates, heat conduction pipes,heat conduction strips and heat conduction working media. According to the heat pipe type heating device, the heat conduction media carrying heat energy simultaneously conduct heat conduction and heat dissipation on materials through the upper heating plate and the lower heating plate, so that the heat conversion efficiency is high, the loss is low, the heat conduction heat exchange speed is increased, and the heat conduction working media do not generate water scale and oil dirt during long-time heat conduction and heating inside the heat pipe type heating device; and under the action of theconveying inertia of a conveying belt and under the guide of the stirring device, original static stacking of the materials is also changed when the materials are subjected to displacement, so that heat radiation and heat conduction type heating at different positions of the materials through heat energy can be improved due to the fact that the materials do left-right turnover motion in a small range, then the material drying efficiency is improved, and the material drying effect is optimized.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Vacuum belt drier

InactiveCN109813085AFacilitate waste heat utilizationPlay the role of dustDrying solid materials without heatDrying machines with progressive movementsEngineeringEnergy conversion efficiency

The invention discloses a vacuum belt drier. The vacuum belt drier comprises a drying bin, a belt conveyor, a heating plate, a vacuum unit, discharging valves and an air guide pipe, wherein one end ofthe air guide pipe is fixedly connected to an exhaust port of the drying bin, the other end of the air guide pipe is fixedly connected to the vacuum unit, the discharging valves are arranged on a feeding port and a discharging port of the drying bin, the belt conveyor is installed in the drying bin, the heating plate is installed below an upper layer conveying belt of the belt conveyor, a heat conduction pipe of a heating device of the heating plate is a straight pipe so that water scale and oil dirt can be conveniently removed through a descaling device, and a heat conduction working mediumdoes not generate water scale and oil dirt during long-time heat conduction and heating inside the heating plate. According to the vacuum belt drier, the heat conduction medium carrying heat energy isused for performing heat conduction and heat dissipation on materials on the upper layer conveying belt through the heating plate, the heat conversion efficiency is high, moreover, the loss is low, the heat conduction and heat exchange speed is improved, the effective utilization rate of heat energy conduction and heat exchange is high, the drying uniformity of the materials is improved, the material drying efficiency is improved, and the material drying effect are optimized.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Belt drier with material stirring function

InactiveCN109780838AStir wellReduce lossDrying machines with progressive movementsDrying solid materialsThermal radiationEngineering

The invention discloses a belt drier with a material stirring function. The belt drier with the material stirring function comprises a drying bin, a belt conveyer, a heating device, an air exhaust device, an unloading valve, a charge hopper, a material stirring device, a material guide plate and a material guide side plate. The air exhaust device is fixedly connected to an air exhaust port of thedrying bin, and the unloading valve is installed on a charge port of the drying bin. An upper-layer conveying belt of the belt conveyer passes through the space between the heating device and a heating plate below, and the distance between the bottom plate of the heating device and the space above the upper-layer conveying belt is 30-55mm; and a heat-conducting medium carrying heat energy carriesout heat conduction and heat dissipation on materials on the upper-layer conveying belt while passing through the heating device, the material stirring device and the heating plate below, and high heat conversion efficiency, low loss, and high effective use rate of conduction and heat exchange for the heat energy are achieved. The materials carry out small-range left-right overturning movement under the guide of the material stirring device and under the conveying inertia effect of the conveying belt, and the heat-radiation and heat-conduction heating of the heat energy for the different positions of the materials can be improved, so that the material drying efficiency is increased and the material drying effect is optimized.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Roller vacuum drying bin with cooling section

InactiveCN109323535AReduce heat lossDoes not affect normal useDrying solid materials without heatDrying machines with non-progressive movementsEngineeringPhase change

The invention provides a roller vacuum drying bin with a cooling section. The roller vacuum drying bin comprises a heating bin, a drying bin, heat conduction work media and a gear ring. An externallyarranged driving device drives the gear ring on the drying bin, and the gear ring can drive the drying bin to rotate. The heating bin is arranged on the outer surface of the drying bin. The drying bincomprises a bin body, a heat dissipation vertical pipe, heat pipes, screw blades and a fixing bar. The heat pipes are an independent whole overall welded to the part, in a drying section of the drying bin, of a bin body. The two ends of the heat dissipation vertical pipe are fixed to the parts, in a cooling section of the drying bin, of the bin body. The heat conduction work media in the heat pipes are heated by heat energy carried by the heat conduction work media in the heating bin to generate phase change gasification, the heat energy carried by the gasified heat conduction work media conducts heat conduction and heat exchange through heat pipe feed, the heat conduction and heat exchange speed of the heat energy is increased through the enlarged heat exchange area, the material dryingefficiency is improved, and the purpose of fast material drying is achieved. During material drying, the screw blades have stirring and pushing functions, materials are not likely to be agglomerated when being dried in the drying bin, and the dried materials are cooled in the cooling section of the drying bin.

Owner:程长春

Four cylinder drying machine

InactiveCN107588648AImprove drying uniformityImprove drying efficiencyDrying chambers/containersDrying solid materialsHeat conductingEngineering

The invention relates to a four cylinder drying machine. The four cylinder drying machine comprises a four cylinder drying bin, a feeding exhaust device, a gear ring, a heating device, a support, a supporting wheel bracket and a driving device. Under the drive of the driving device, the four cylinder drying bin can rotate to work under the support of supporting wheels on the supporting wheel bracket. Heat energy generated by the heating device conducts heating and heat conduction on a heat-conducting medium in a heating bin through a bin body of the heating bin. The heat energy carried by theheat-conducting medium is used for conducting heat conduction and heat exchange on heat pipes in a double cylinder bin through an outer cylinder body and an inner cylinder body of an inner cylinder bin. The heat conversion efficiency is high, the loss is small, and the heat conduction and heat exchange speed is increased. When the four cylinder drying machine dries materials, excess heat air is not needed, the heat loss taken away by exhaust can be ignored, the overall effective utilization rate is 80%-90%, the exhaust device exhausts moisture out of the four cylinder drying bin, a guide platestirs and pushes the materials in the drying process, the drying uniformity of the materials is improved, by means of continuous drying, the material drying efficiency is improved, and the material drying effect is optimized.

Owner:张海娟

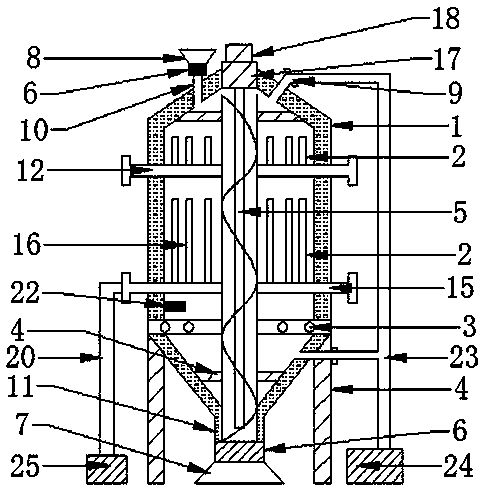

Thermal tube type vacuum drier capable of utilizing afterheat

ActiveCN105423721AShorten drying timeUniform drying qualityDrying using combination processesDrying machines with non-progressive movementsVertical tubeHelical blade

The invention discloses a thermal tube type vacuum drier capable of utilizing afterheat. The thermal tube type vacuum drier consists of a thermal tube drying cabin capable of utilizing afterheat, an air guide pipe, a bracket, a vacuum unit, a heating device, a driving device, rails and a vacuum charging and discharging device, wherein the rail on the thermal tube drying cabin capable of utilizing afterheat is mounted on the bracket; the driving device is used for driving the rail on an inner cabin; one end of the air guide pipe is connected to the vacuum unit after passing through the vacuum charging and discharging device; the other end of the air guide pipe is connected to the inside of the inner cabin; the inner cabin of the drying cabin adopts three-dimensional heat conduction by a cabin body and a cooling vertical tube, so the heat conduction speed and the heat exchange speed are increased; a cooling tube and a helical blade have a stirring function; no dead corner exists in material drying; the material drying time is shortened, so that the material can be dried uniformly; the material drying efficiency is improved; the material drying effect is optimized; the material can be cooled during a vacuum drying process; heat energy released in cooling of the material is also utilized, so continuous vacuum material drying can be realized.

Owner:常州奕诺梵节能科技有限公司

Heat-pipe type three-cylinder dryer

ActiveCN106091630ACompact structureSimple structureDrying chambers/containersDrying solid materialsHeat conductingPulp and paper industry

The invention discloses a heat-pipe type three-cylinder dryer comprising a heat-pipe type three-cylinder drying bin, a feeding exhaust device, a support, a heating device, a driving device, a roller rack and a moving device. The heat-pipe type three-cylinder drying bin comprises a shell, a combined-type drying bin, 2-5 sets of roller paths, 1-2 sets of gear rings and a heat-conducting medium; the heat-conducting medium is in the inner cavity between the shell and the combined-type drying bin; the feeding exhaust device comprises a vacuum feeding and discharging device, a ventilation pipe and an exhaust device; the roller paths and the gear rings are arranged on the shell of the heat-pipe type three-cylinder drying bin. Under the driving of the driving device, the heat-pipe type three-cylinder drying bin can rotate to operate under the support of rollers on the roller rack; materials are fed or discharged from the heat-pipe type three-cylinder drying bin through the vacuum feeding and discharging device, humidity is discharged from the combined-type drying bin through the exhaust device, and the materials can be continuously dried, so that drying efficiency of the materials is improved, and drying effect of the materials is optimized.

Owner:龙南县赣钇精细化工有限公司

Heat pipe type vacuum drying box

PendingCN110243148AWill not polluteReduce heat lossDrying solid materials without heatDrying gas arrangementsEngineeringVacuum drying

The invention discloses a heat pipe type vacuum drying box. The heat pipe type vacuum drying box comprises a drying box body, a heating device, a support and a water draining valve. A heat energy inlet, a heat energy outlet, an exhaust opening and a water draining opening are formed in the drying box boxy, the water draining valve is arranged on the water draining opening of the outer face of the drying box, the heating device is fixedly mounted on a box main body of the drying box body through the support, and the heating device comprises a top plate, a bottom plate, side plates, a heating pipe, a fixed strip, and a heat conduction working medium, the heat conduction working medium rapidly transmits the heat to the top plate and the bottom plate of the heating device through the gas and liquid phase change, balance temperature on the four corners and the periphery of the top plate and the bottom plate of the heating device ensures the material water drying uniformity, the upper and the lower of the heating device carry out simultaneous heating, the heat conduction and exchange speed of the heat energy is improved, the material drying speed is improved, and the heat working media cannot generate water scale and oil scale in the heating device, and the heat pipe type vacuum drying box flexibly selects vacuum low-temperature drying or air convection drying.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Heat pipe type heat exchanger

PendingCN110243209AImprove heat conduction and heat exchange speedImprove heat conduction and heat exchange efficiencyIndirect heat exchangersEvaporationEngineering

The invention discloses a heat pipe type heat exchanger. The heat pipe type heat exchanger comprises a heat conduction device, a heating device and a heat pipe. The heat pipe comprises a metal pipe, a flow guide device, a heat conduction working medium and fins; and the flow guide device which is integrally formed by an evaporation flow guide cover, a condensation flow guide cover and a support is arranged inside the metal pipe. The heat conduction area of a pipe body of the metal pipe of an evaporation section of the heat pipe in the heating device increases the heat conduction heat exchange speed of the heat energy; and the heat conduction heat exchange speed of the heat energy is increased by the pipe body of the metal pipe at the evaporation section of the heat pipe. The metal pipe body, decreasing the heat conduction working medium, of a condensation section of the heat pipe in the heating device increases the heat conduction heat exchange of the heat energy on the condensation section, so that the heat energy on the condensation section of the heat pipe is conveniently to carry out heating and heat conduction on the heat conduction medium outside the heat pipe. Through guide flowing of the heat conduction working medium in the heat pipe by the guide flow device, the heat conduction heat exchange efficiency of the heat energy is improved, and the heat conduction heat exchange speed of the heat energy is expanded.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

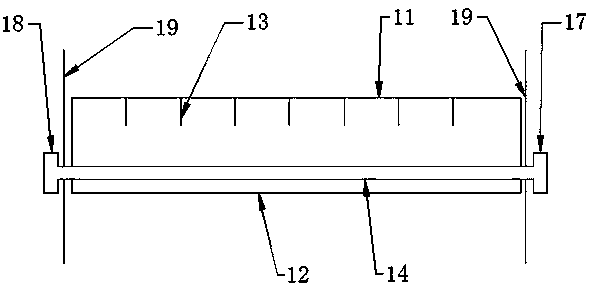

Net belt dryer with double heating plates

InactiveCN109751857AImprove effective utilizationImprove drying uniformityDrying solid materialsHeating arrangementHeat conductingHeat losses

The invention provides a net belt dryer with double heating plates. The net belt dryer comprises a drying chamber, a net belt conveyor, a heating device, an exhaust device, a discharge valve, a feed hopper, mixing plates and guide plates. The exhaust device is fixedly connected to an exhaust port of the drying chamber. The discharge valve is mounted on a feed port of the drying chamber. The heating device is fixedly mounted on a chamber body of the drying chamber through supports. The heating device is composed of the upper heating plate and the lower heating plate. An upper conveyor belt passes through the space between the upper heating plate and the lower heating plate of the heating device. A high-temperature heat conducting medium passes the upper heating plate and the lower heating plate to conduct conduction drying on a material on the upper conveyor belt. The heat conversion efficiency is high, and heat loss is small. The heat conduction and heat exchange speed is increased. The availability of heat energy during heat conduction and heat exchange is high. Original static stacking of the material is changed under the action of conveying inertia of the conveyor belt and guidance of the mixing plates while displacement occurs to the material, the material is turned over and move left and right within a small range, the drying efficiency of the material is improved, and thedrying effect of the material is optimized.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Heat pipe heating type disc dryer

PendingCN110836594AReduce lossHigh heat conversion efficiencyDrying solid materialsHeating arrangementThermodynamicsElectric machine

The invention discloses a heat pipe heating type disk dryer. The heat pipe heating type disk dryer includes a drying bin, an air exhaust device, a feeding device, a variable speed motor, a support frame, a small heating plate, a large heating plate, a lower rake rod, a transmission shaft, an upper rake rod, and a support. The material drying process of the heat pipe heating type disc dryer is a vacuum drying process or a convection drying process. A heat-conducting working medium carries thermal energy and performs heat conduction and heat exchange to the material through top plates of the large heating plate and the small heating plate. The material on the top plate of the heating plate of the large heating plate conveniently moves from the top plate which is higher on the outside and lower on the inside in an internal rotation mode from the outside to the inside, and the material on the top plate of the heating plate of the small heating plate conveniently moves from the top plate which is higher in the inside and lower on the outside in an external rotation mode from the inside to the outside; the material is covered on the top plates of the large heating plate and the small heating plate under the guidance and diversion paving of a rake blade device, the upper and lower heating intensities of the material are improved, drying uniformity of the material water content is improved, and the effective heating area of the top plates of the large heating plate and the small heating plate are greater than 90%.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com