Patents

Literature

52results about How to "Cause deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

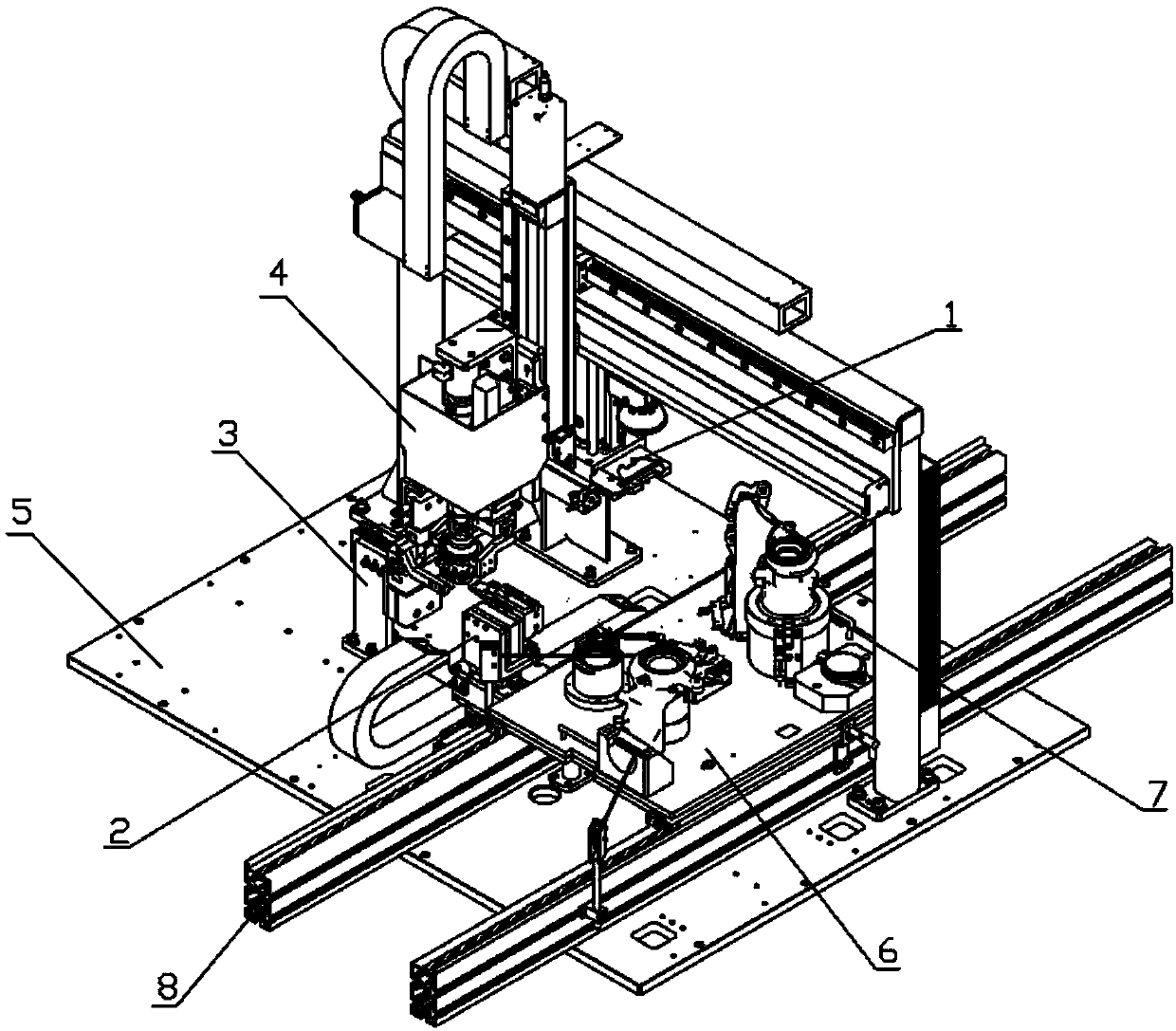

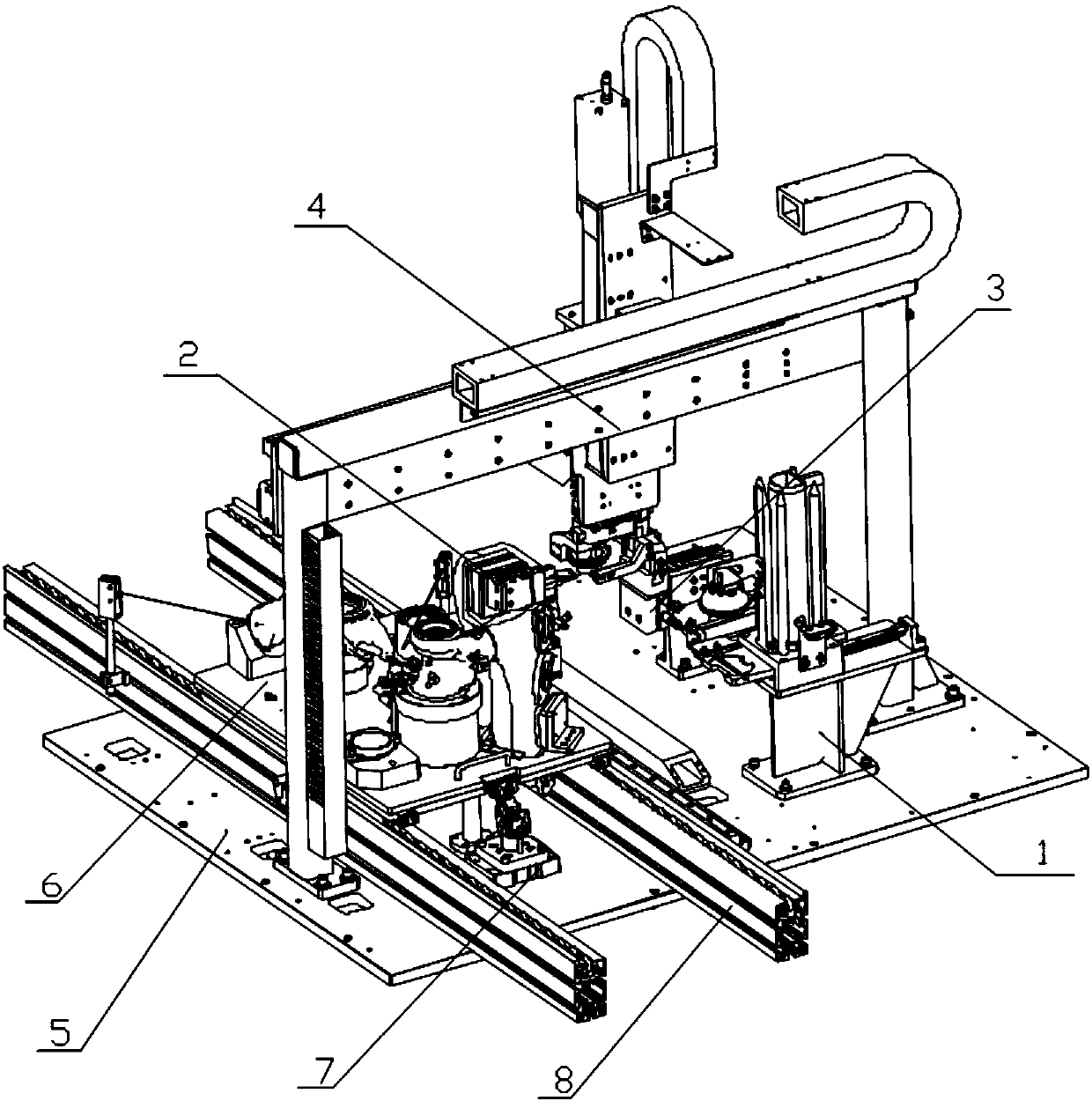

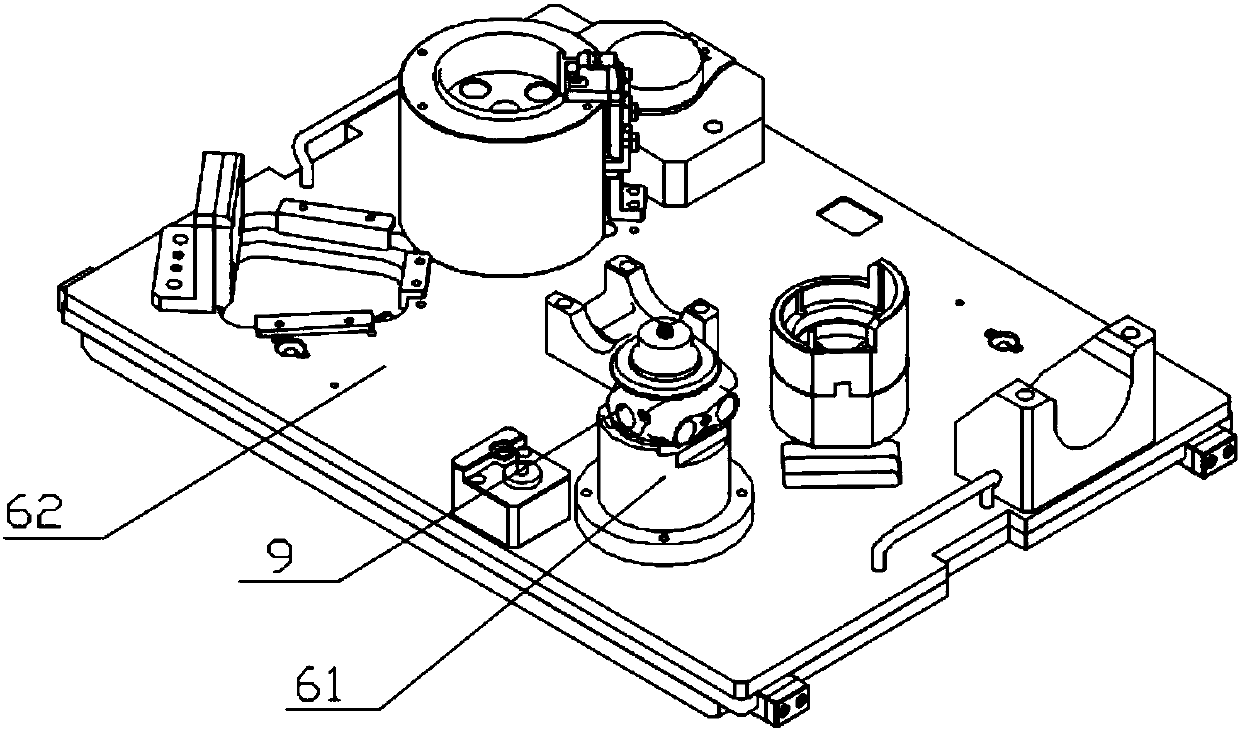

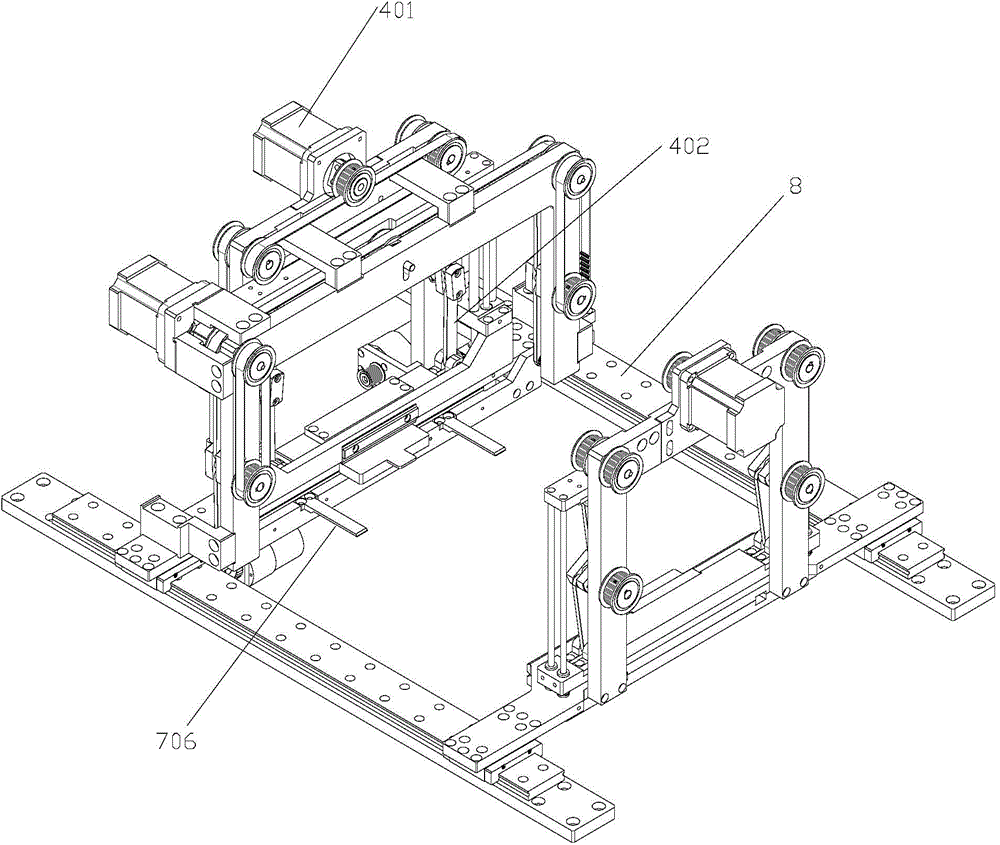

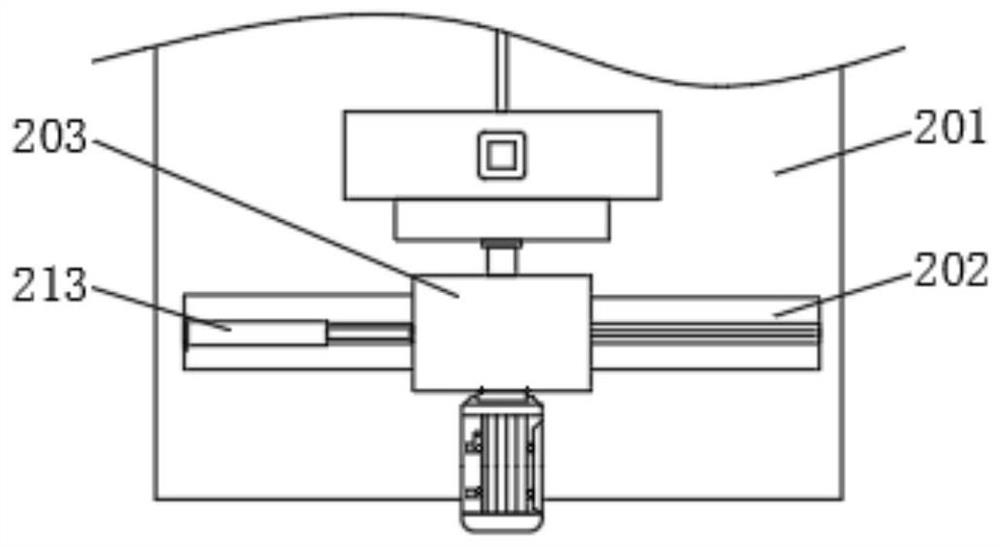

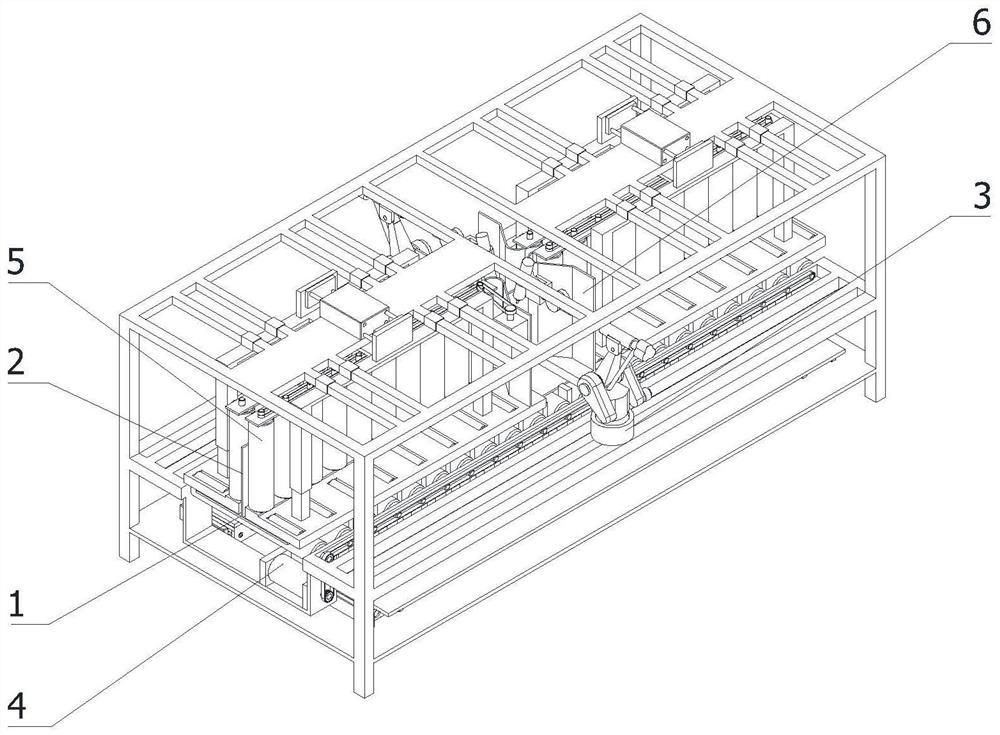

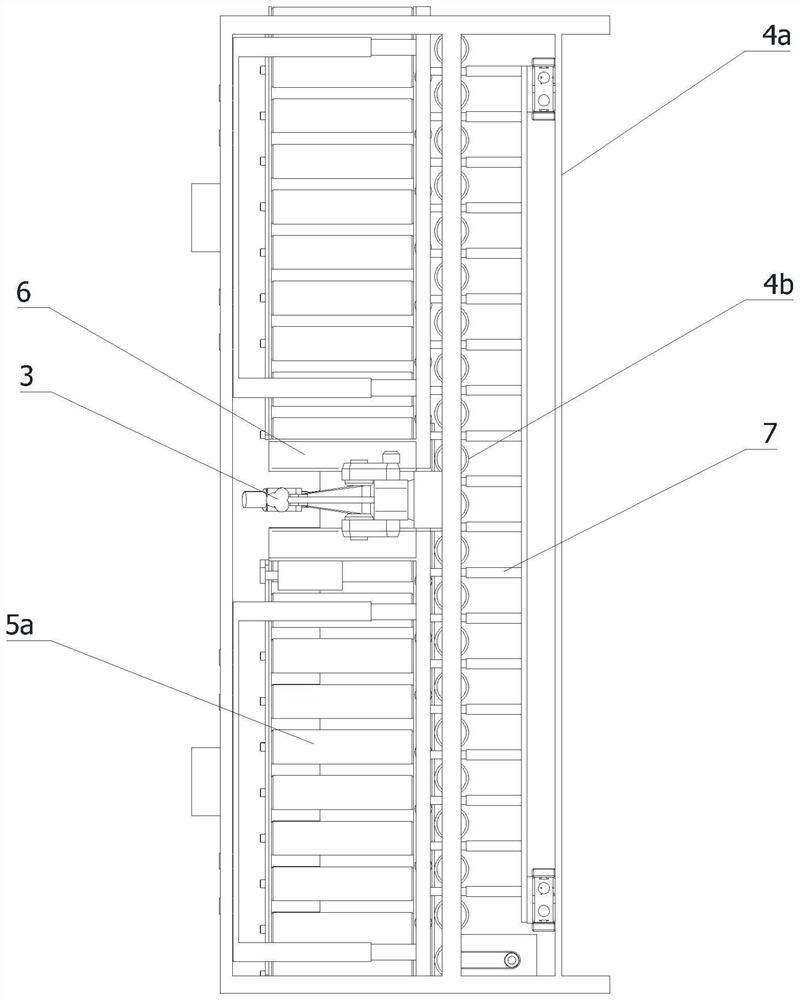

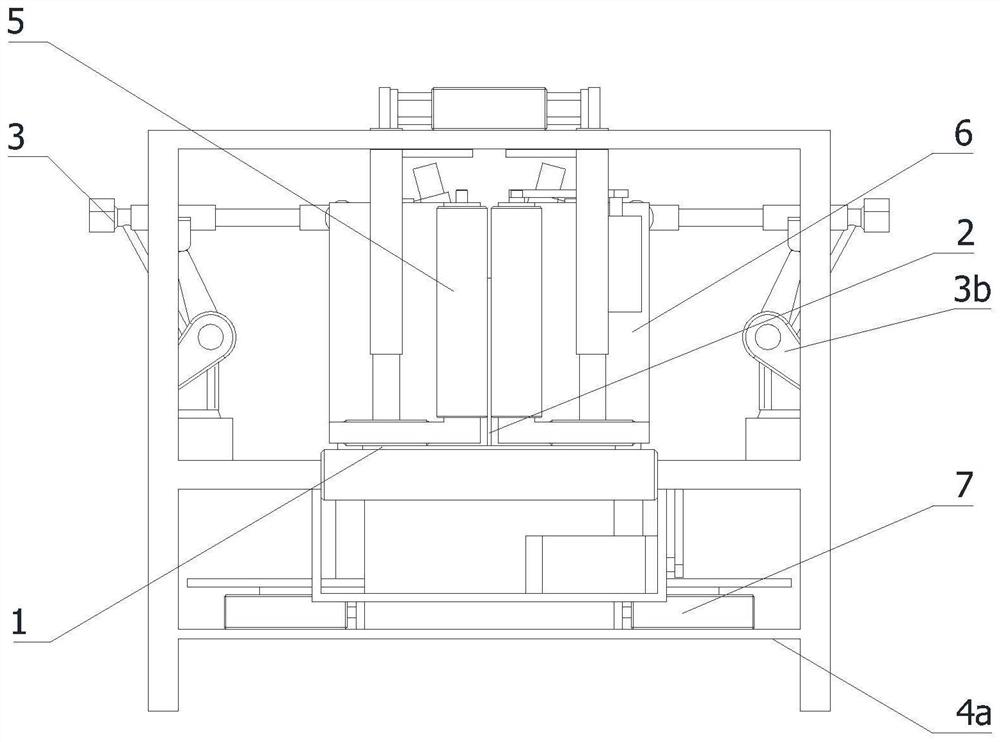

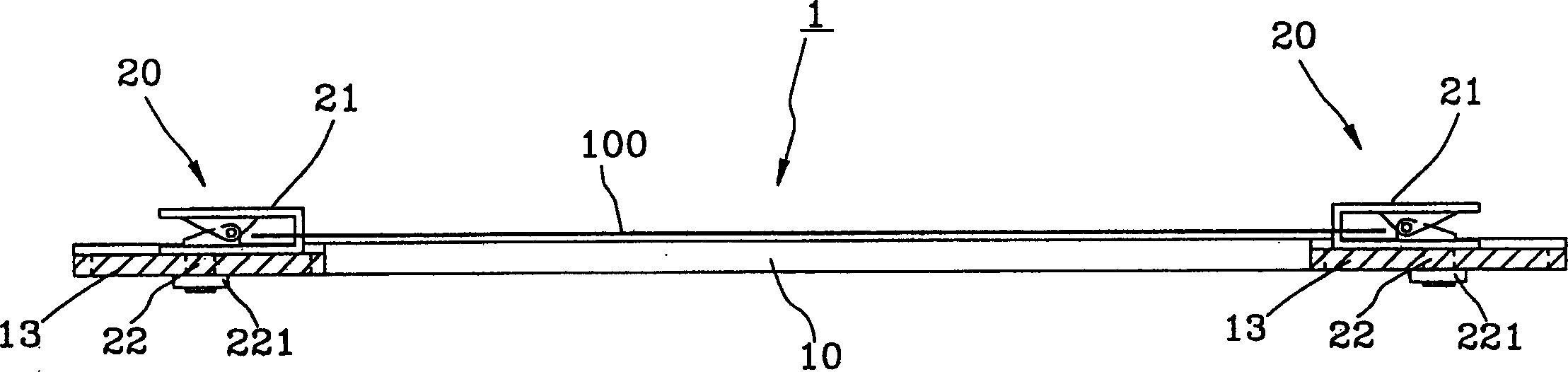

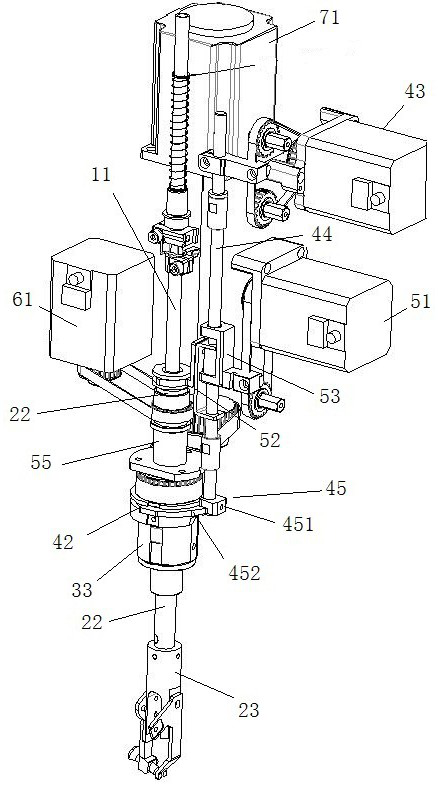

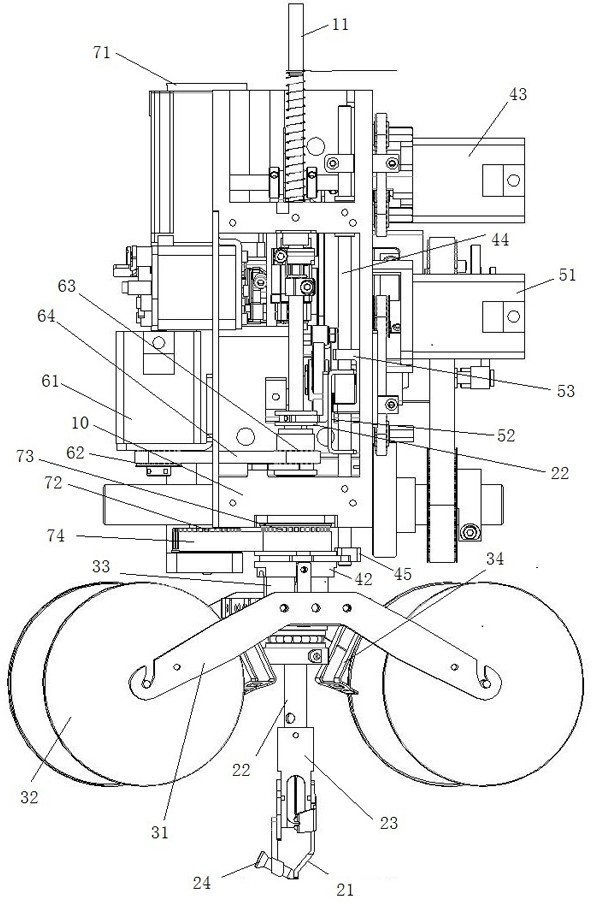

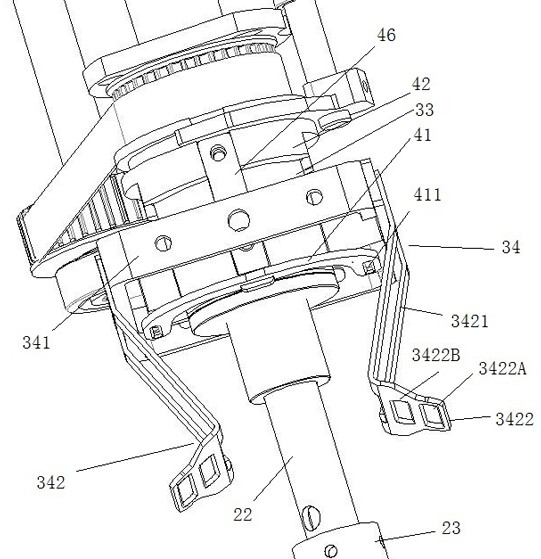

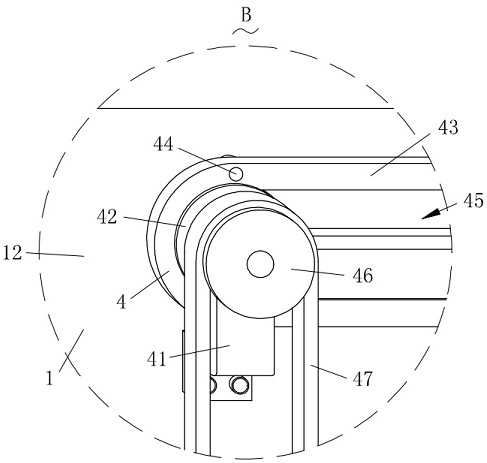

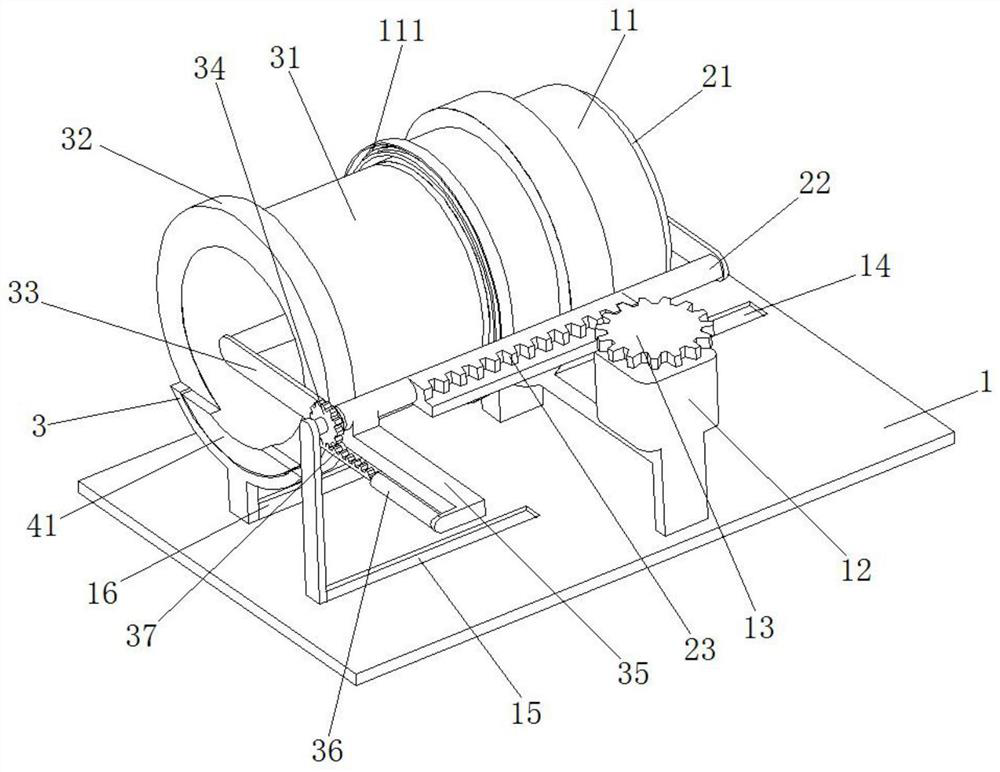

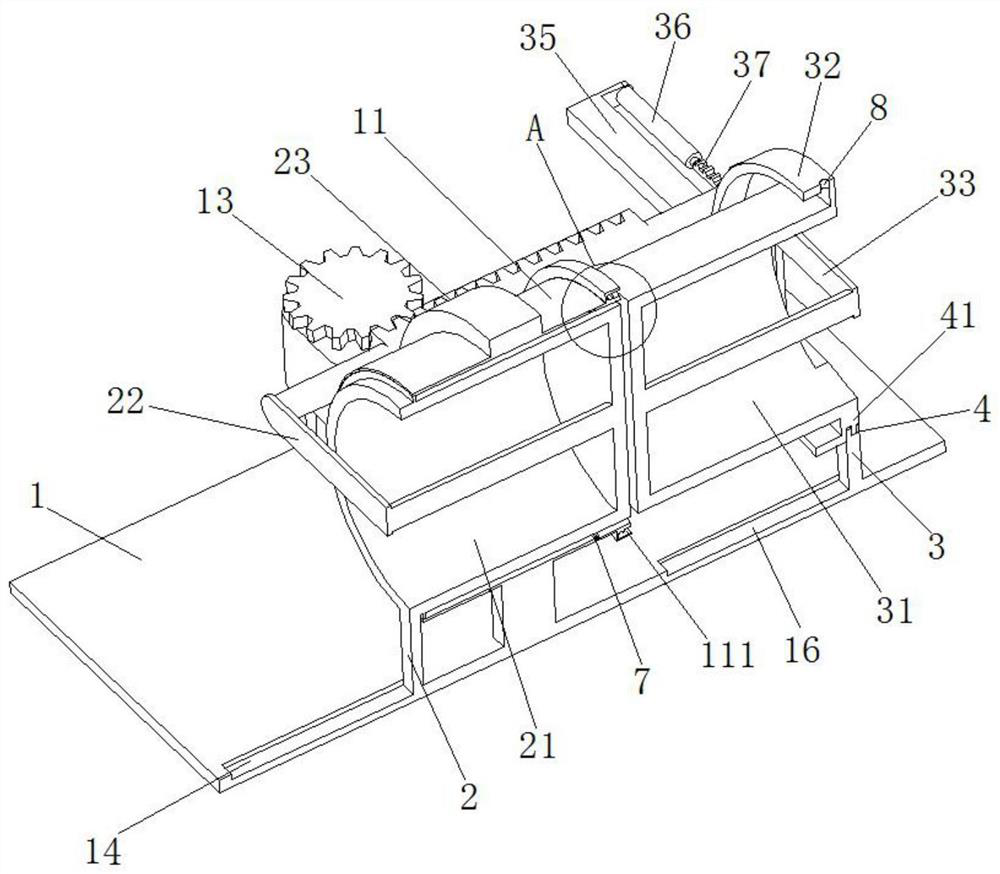

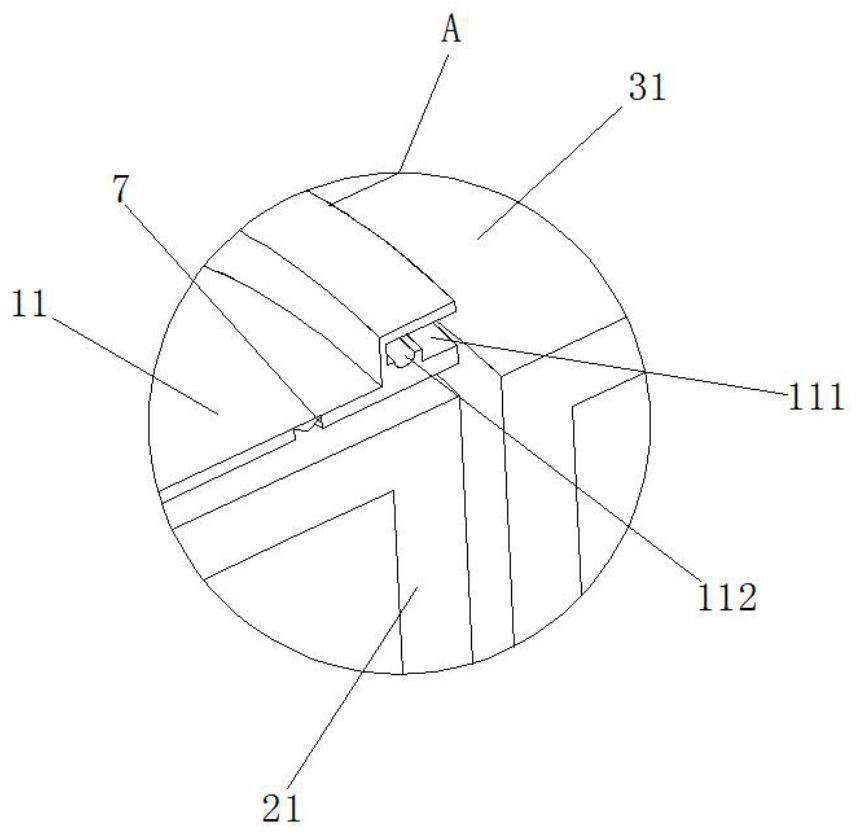

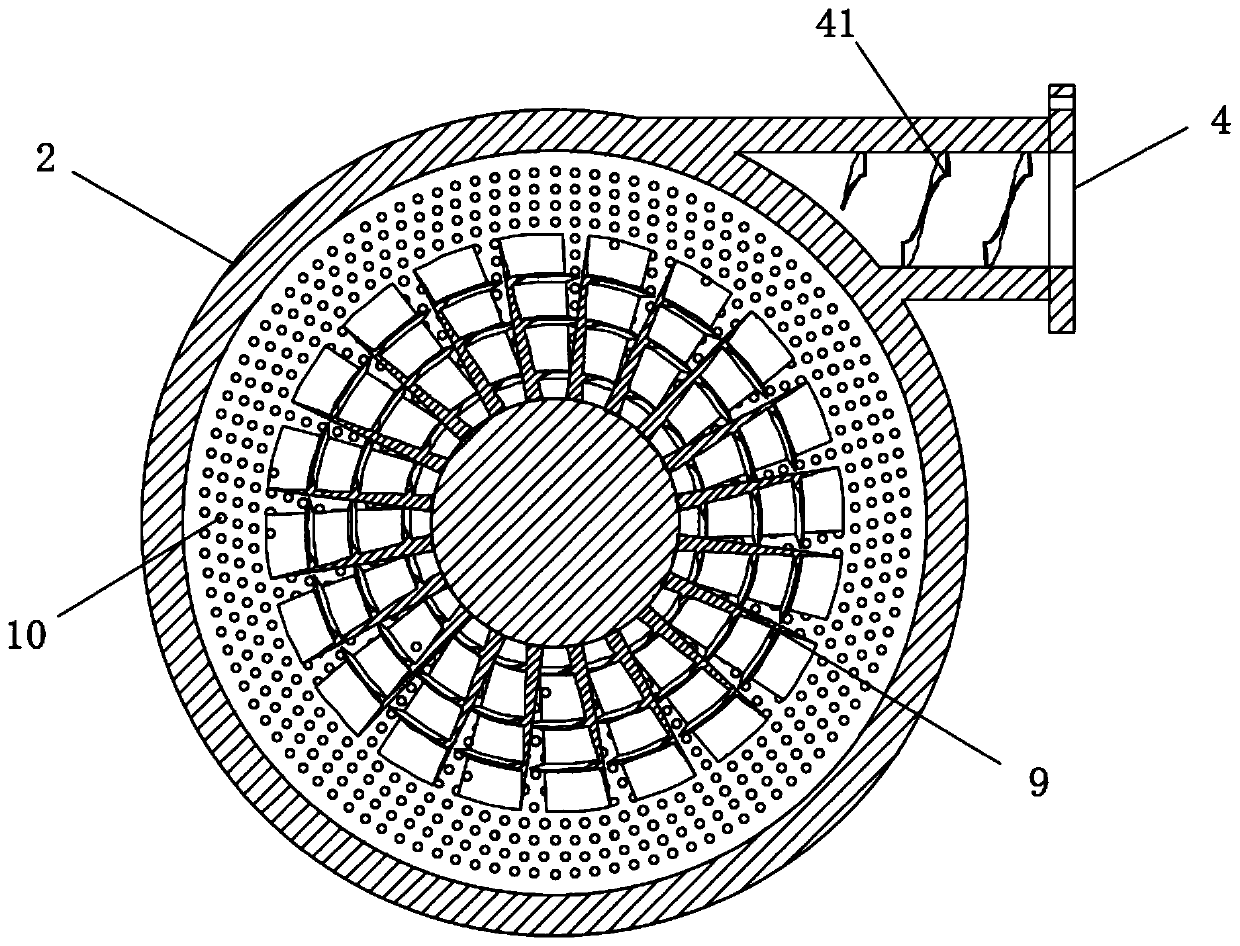

Automatic assembling mechanism of elastic clamping ring

ActiveCN109807615ACause deformationHigh degree of automationMetal working apparatusEngineeringTransfer mechanism

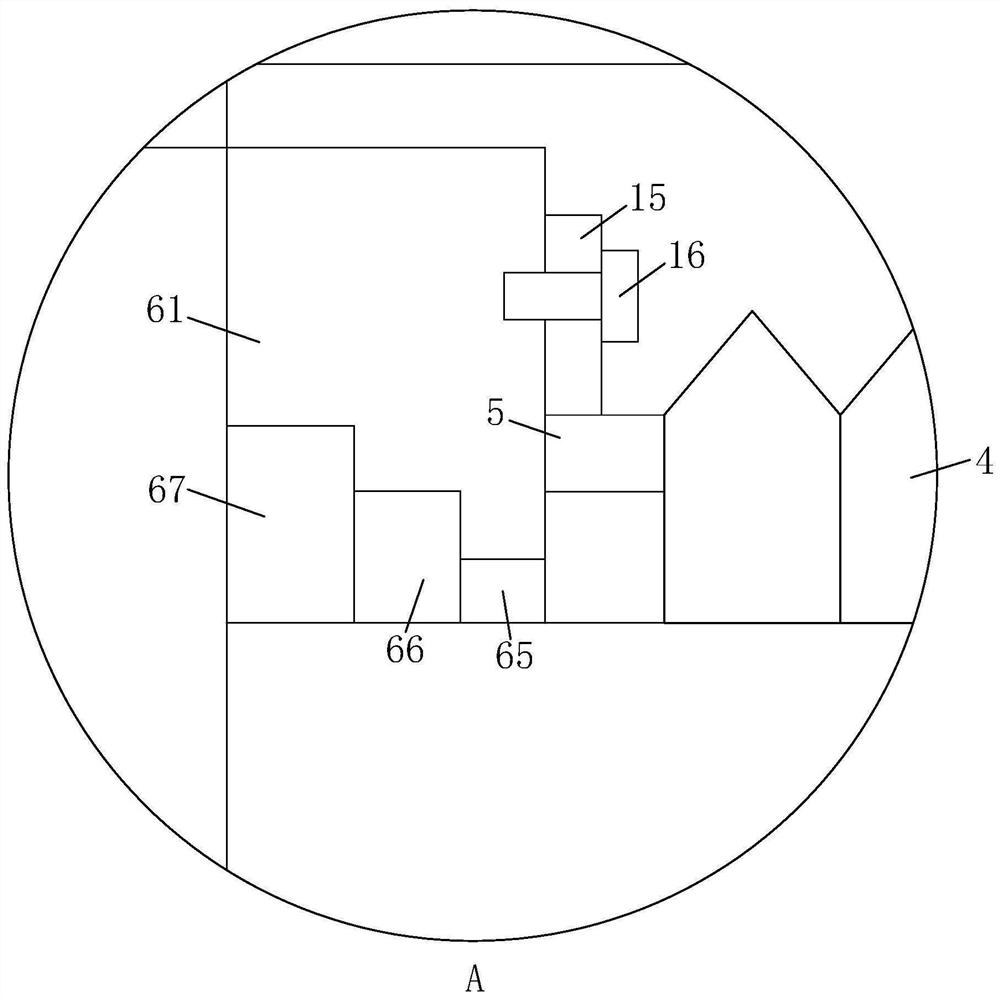

The invention relates to the technical field of turbocharger assembly, in particular to an automatic assembling mechanism of an elastic clamping ring. A clamping ring feeding mechanism is provided with a clamping ring feeding plate, A clamping ring clamping and transferring mechanism is provided with a clamping jaw, A clamping ring supporting opening mechanism is provided with an opening and positioning clamping jaw, a mechanical arm mechanism is provided with an auxiliary press-fitting mechanism and a clamping jaw assembly, the elastic clamping ring is connected to the picking position through the clamping ring feeding plate and is clamped and moved to an assembly position and is rotated to an assembly posture, the middle assembly is grabbed and moved to the assembly position through theclamping jaw assembly and is arranged in the opening of the elastic clamping ring, in the assembling process, the opening of the elastic clamping ring is supported by the opening and positioning clamping jaw, the elastic clamping jaw is rotated back to the initial position through the clamping jaw while the elastic clamping ring is opened and the clamping jaw assembly is movably sleeved on a clamping groove of the middle assembly, then the elastic clamping ring is pressed and assembled through the auxiliary press-fitting mechanism. According to the automatic assembling mechanism of an elasticclamping ring, the automation degree is high, deformation of the elastic clamping ring is avoided, and the assembly efficiency and quality are improved.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

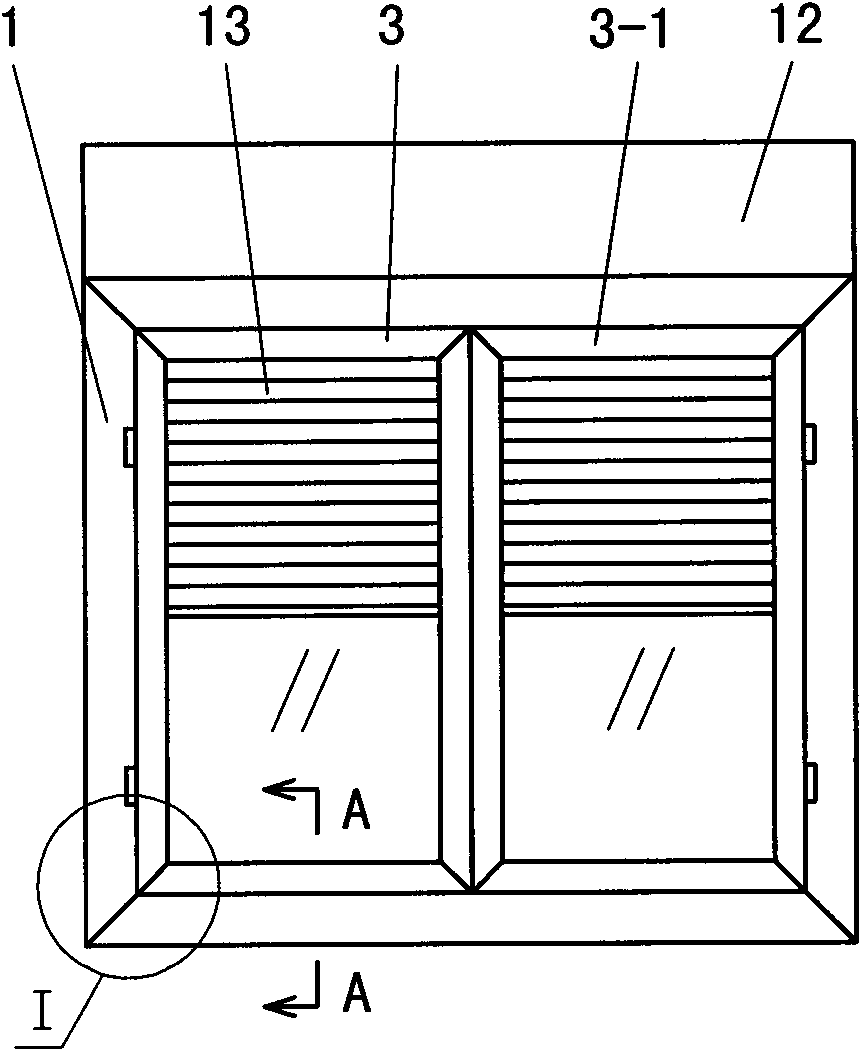

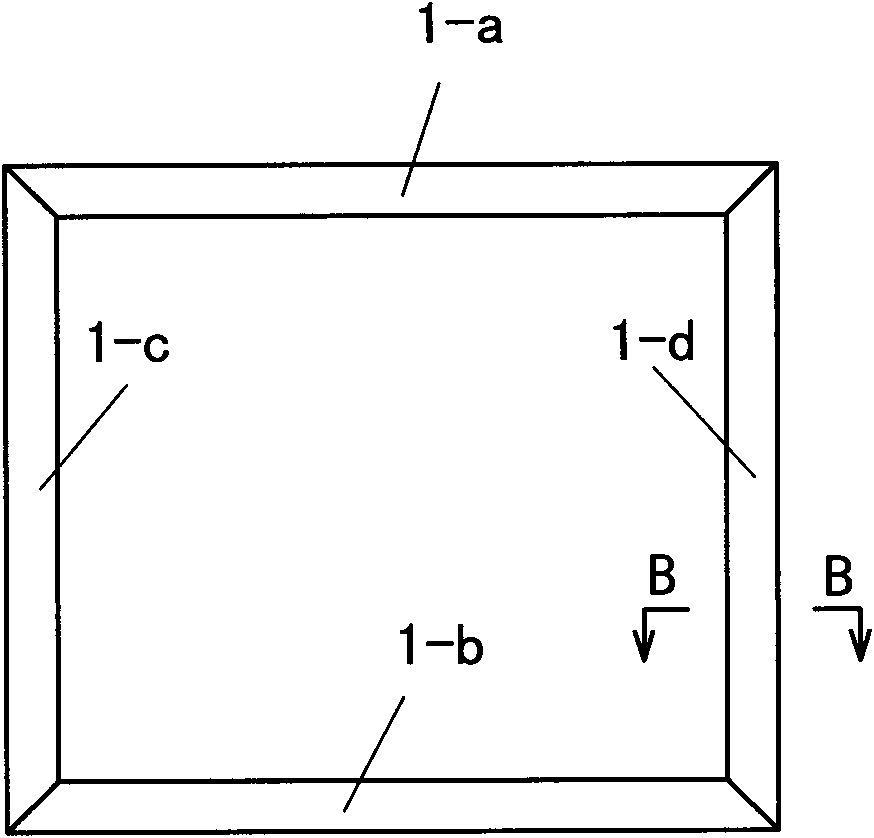

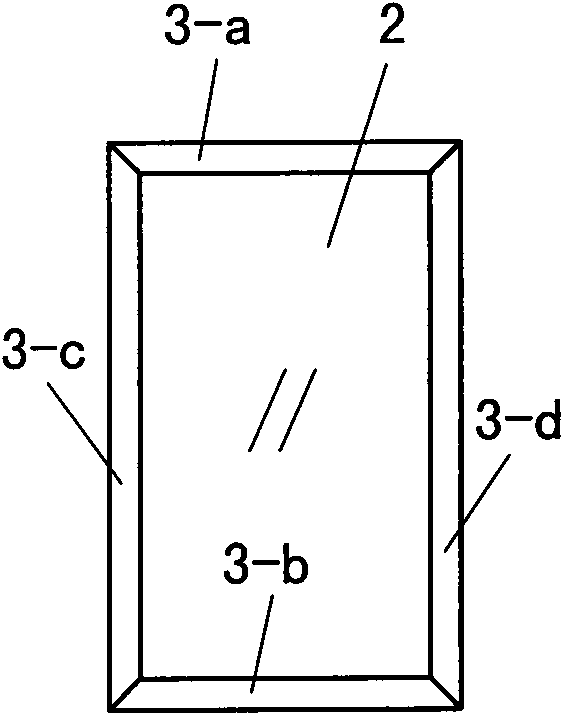

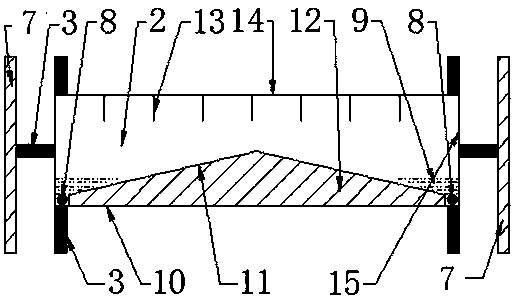

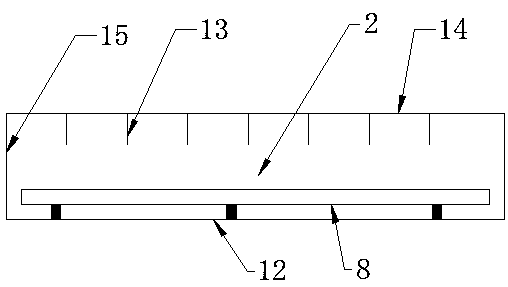

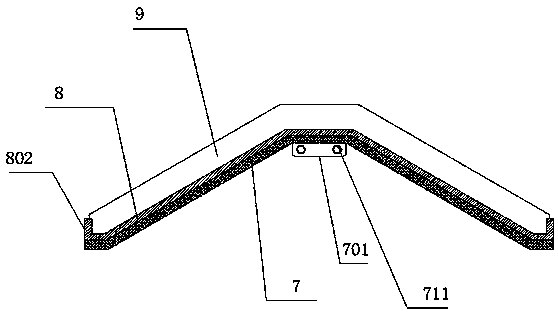

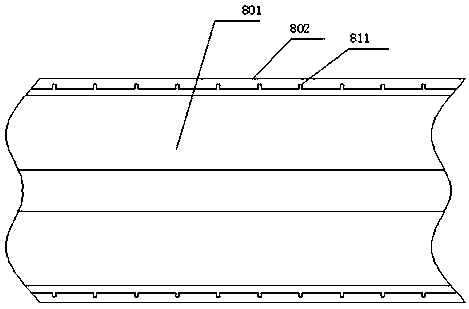

Energy-saving roller shutter

InactiveCN101929288AImprove thermal insulation performanceWith airtight sound insulationLight protection screensSealing arrangementsThermal insulationEngineering

The invention relates to a technical field of building doors and windows and discloses an energy-saving roller shutter. For solving the problem of the low heat-preservation performance of windows in the prior art, the invention puts forward a technical scheme that: the energy-saving roller shutter comprises a broken bridge aluminum window and an outer-layer sunshading roller blind device, wherein the broken bridge aluminum window comprises a frame (1), window slashes (3) with hollow glass, sealing strips, pads (5) and the like and is characterized by comprising the reinforced sealing strips (16) which are elastic strip objects with the outsides connected with a frame outer layer (8) and the lower sides connected with a frame broken bridge (7); each reinforced sealing strip (16) has more than two protruding sealing long strips (16-1) which are sealed with and pressed against a window slash broken bridge (10); and both the frame broken bridge (7) and the window slash broken bridge (10) have a multi-cavity structure with more than three cavities. The energy-saving roller shutter has the advantages of improving the heat-preservation and thermal-insulation performance obviously, producing remarkable airtight and sound-insulation effects, and the like.

Owner:陈怡洁

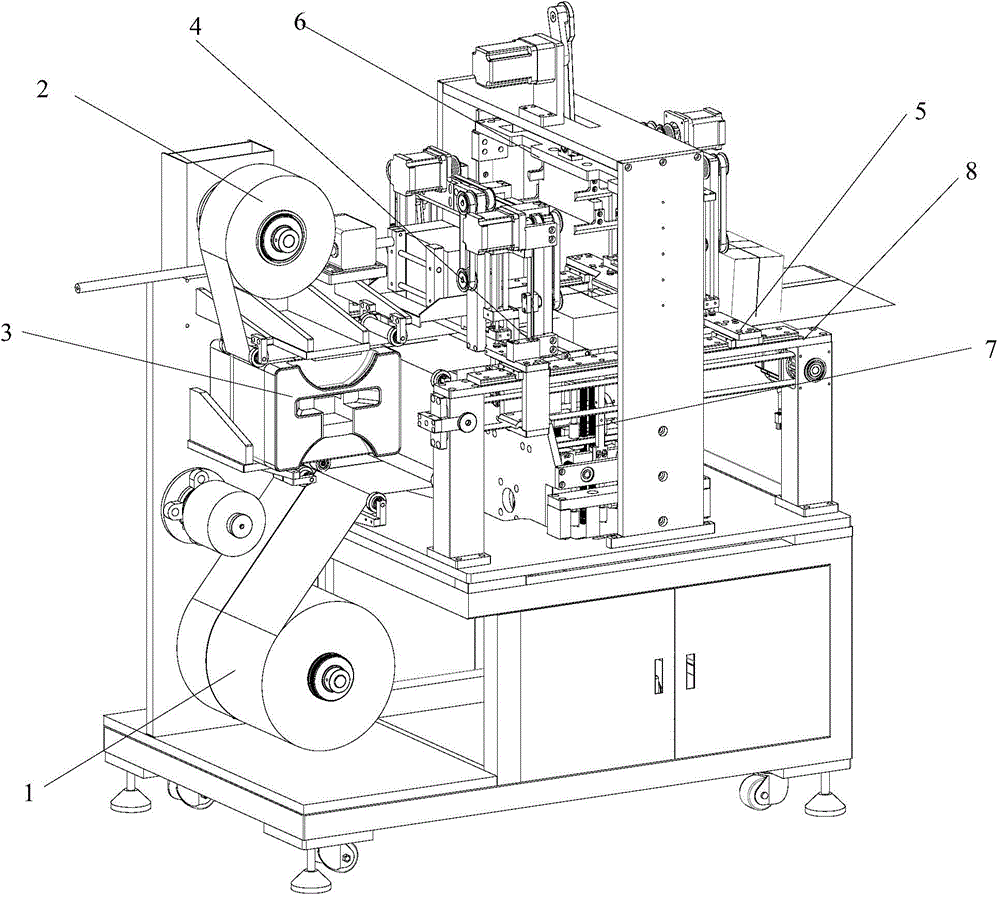

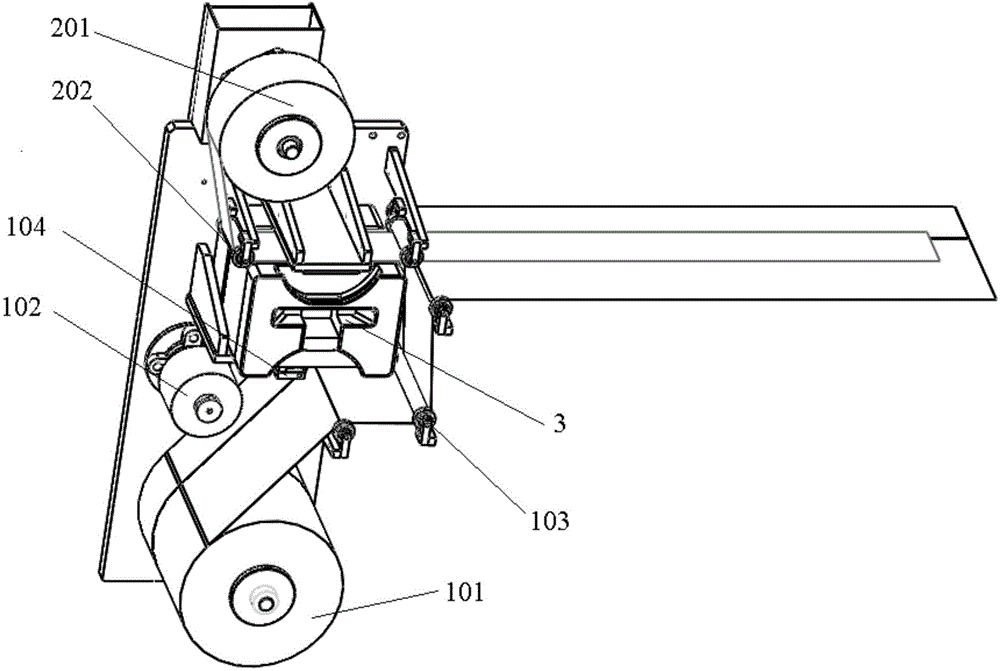

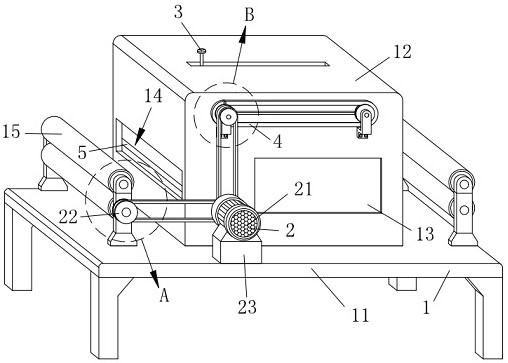

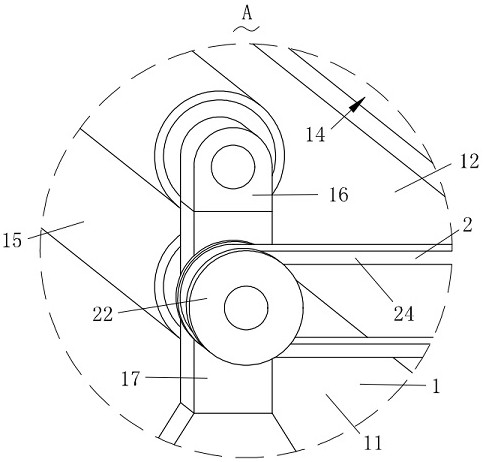

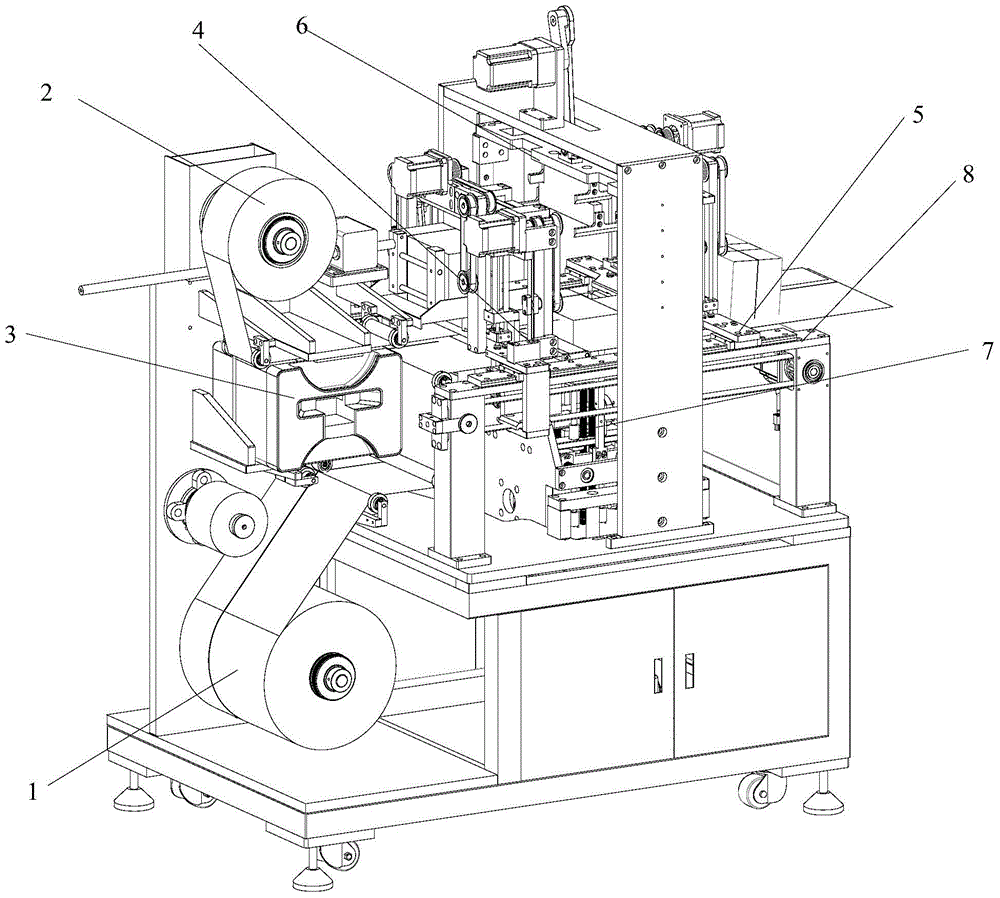

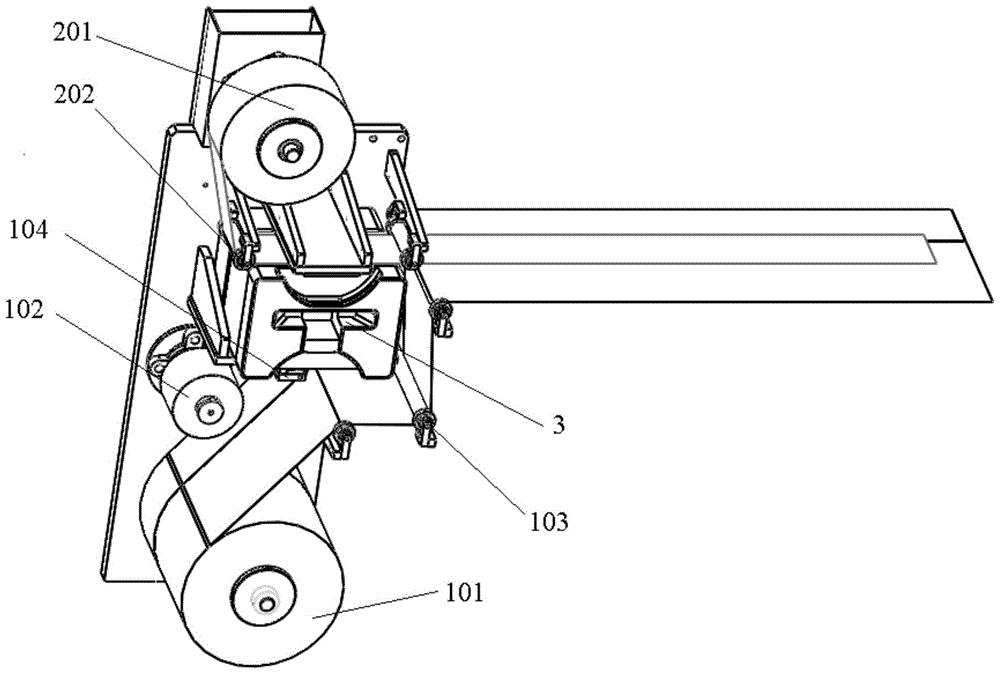

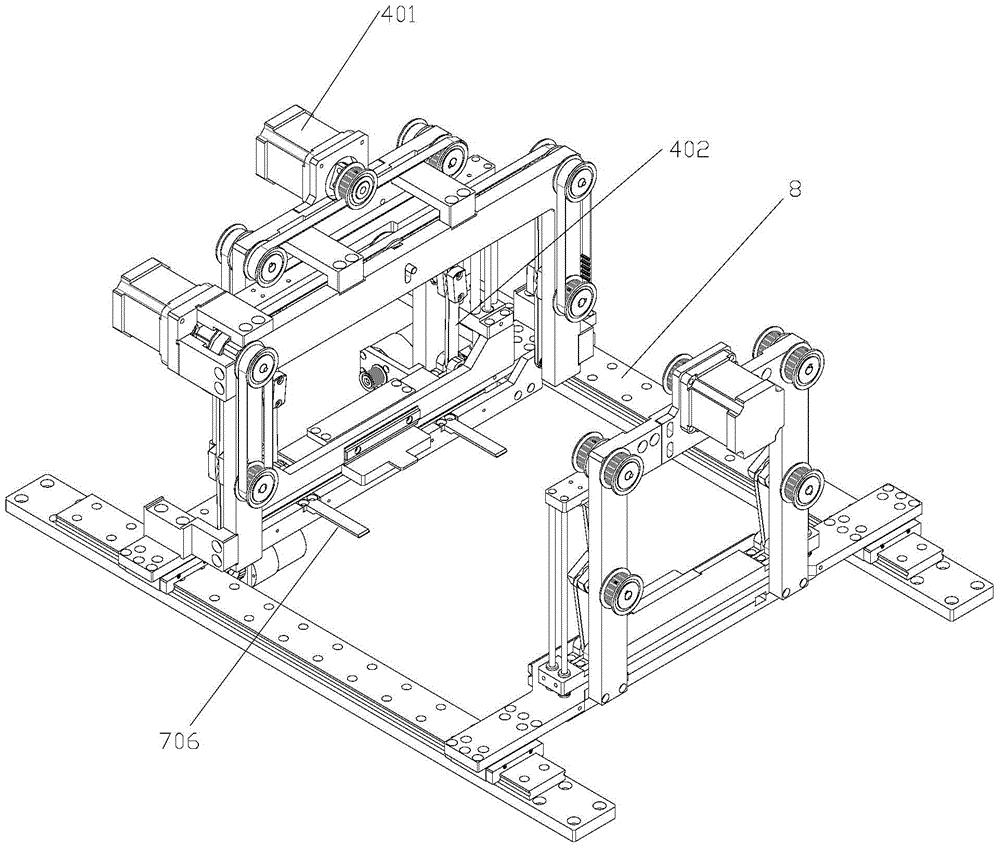

Banknote pre-enveloping and plastic-packaging mechanism and control method thereof

InactiveCN104670552ACompact structureReduce volumePaper article packagingWrappingPlastic packagingPaper tape

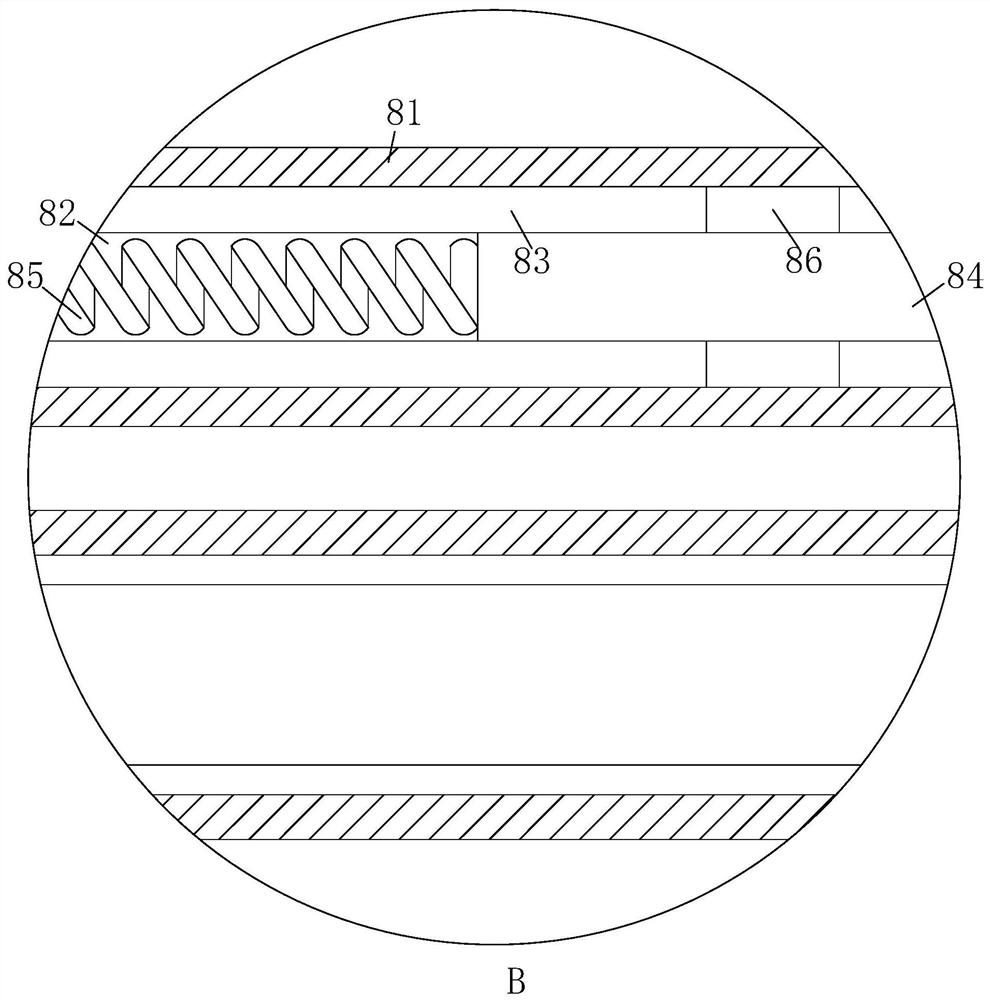

The invention discloses a banknote pre-enveloping and plastic-packaging mechanism and a control method thereof. The mechanism comprises a thermoplastic mechanism and a positioning mechanism, wherein the positioning mechanism comprises a pressing plate, a spring, a bearing plate and an edge folding device; the edge folding device is arranged on the periphery of the bearing plate; a piece of plastic-packaging film and a piece of paper tape film in preset length are arranged on the bearing plate, and the paper tape film is arranged on the plastic-packaging film; bundled banknotes are arranged on the paper tape film; the bundled banknotes and the bearing plate are pressed to a specified position by the pressing plate; the film is then cut off by a film cutting mechanism; the edge folding device is used for folding the plastic-packaging film and the paper tape film; the main body of the thermoplastic mechanism is arranged above the bearing plate; thermo-sealing pressing plates of the thermoplastic mechanism are arranged on the upper side and both sides of the bearing plate; when the paper tape film is folded, the thermo-sealing pressing plate in the corresponding direction carries out plastic sealing on the paper tape film; when the plastic-packaging film is folded, the thermo-sealing pressing plate in the corresponding direction carries out plastic sealing on the plastic-packaging film. The banknote pre-enveloping and plastic-packing mechanism and the control method thereof realize the effect that paper tape pre-enveloping and plastic packaging of the plastic-packaging film are carried out in one station; the structure is small, and the maintenance is convenient.

Owner:GUANGDONG DESOUL INTELLIGENT TECH CO LTD

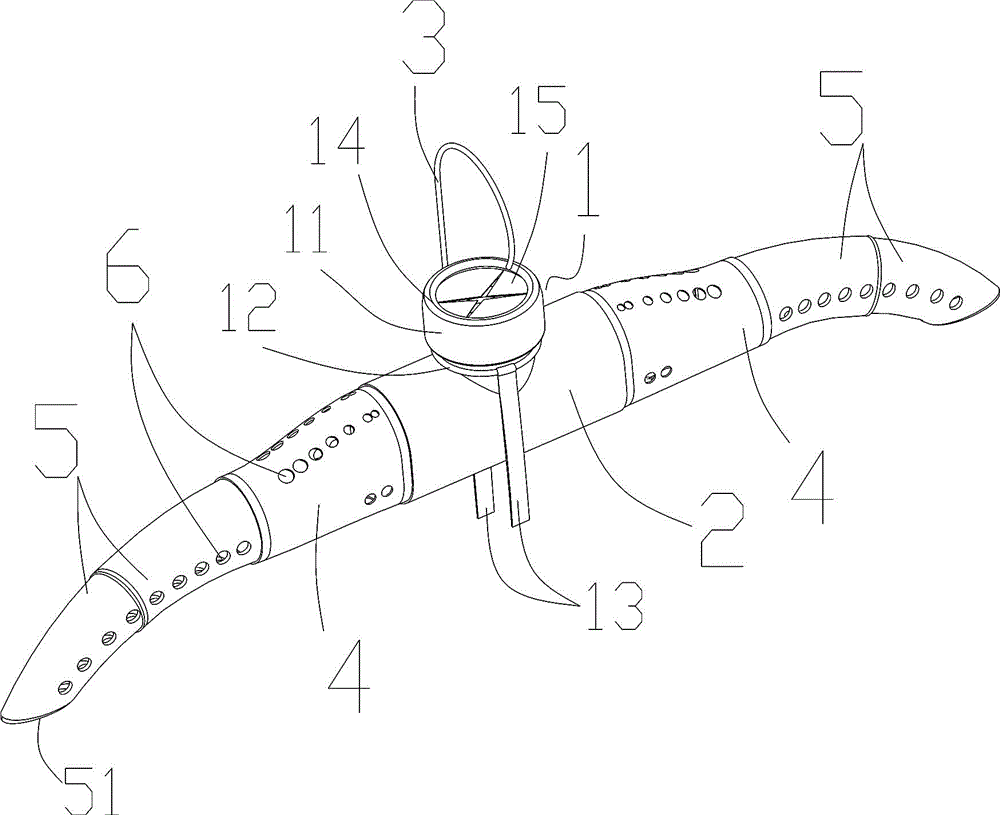

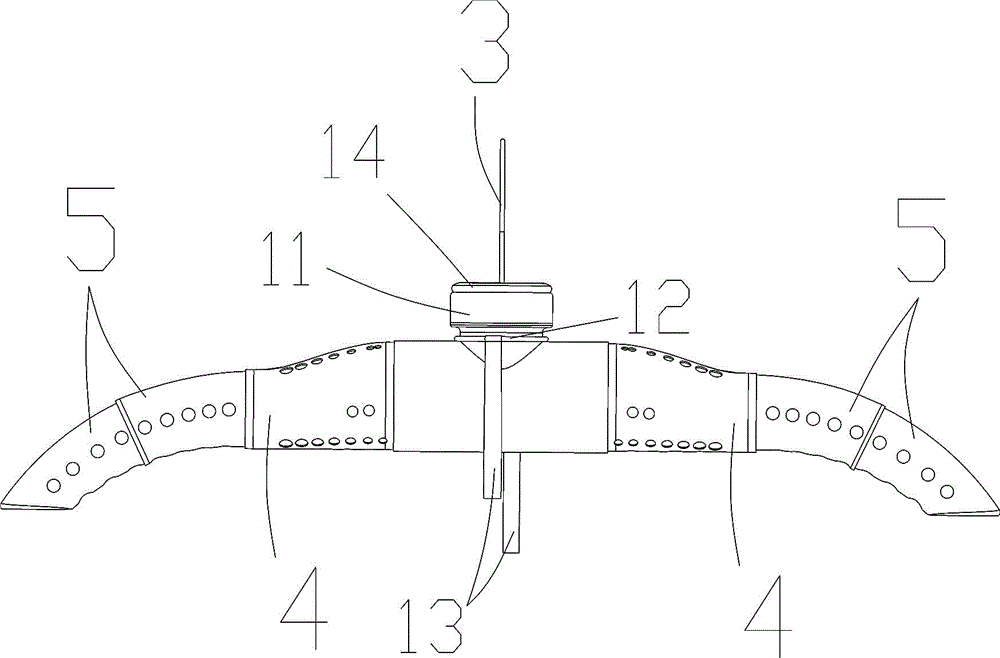

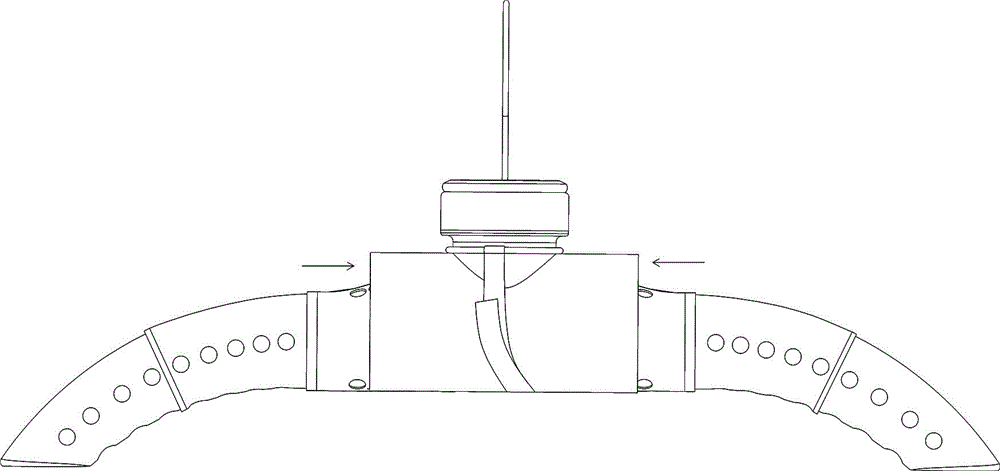

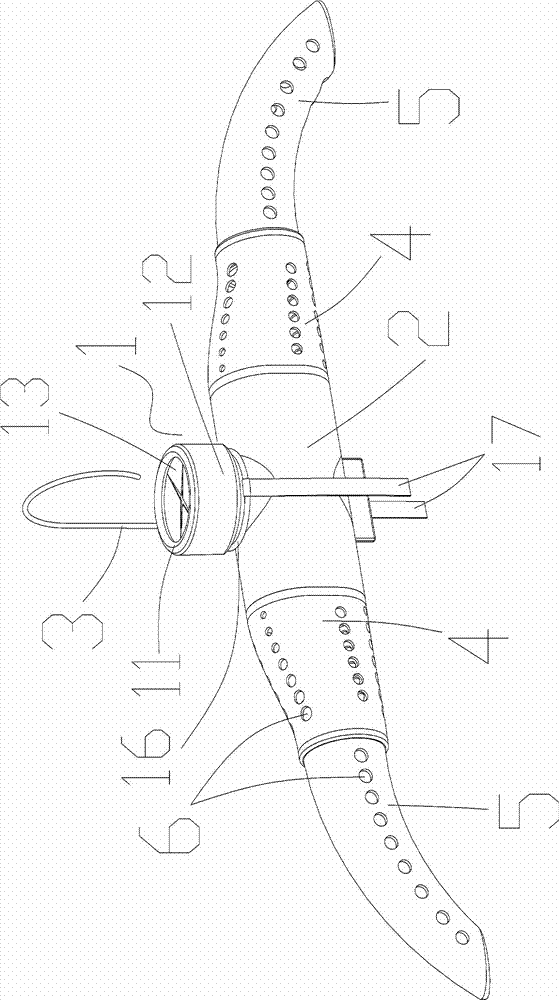

Stretching containing type portable clothes drying rack

InactiveCN102720046ASimple structureEasy to carryApparel holdersOther drying apparatusBiochemical engineeringMental detachment

The invention relates to a stretching containing type portable clothes drying rack which is characterized by comprising an air inlet base for inserting an electric hair drier, a main body connected with the air inlet base, a hanger hinged on the air inlet base or the main body, a stretching body fixed together with inner sleeves at two sides of the main body, and a tail body fixed together with the inner sleeves of the stretching body; air outlets are arranged on the walls of the stretching body and the tail body; an antiskid ring is circularly arranged on the inner side wall of the air inlet base and provided with a plurality of gaps, and a neck ring provided with a binding strip for fixing the electric hair drier is further sheathed at the periphery of the base body. The flexible containing type portable clothes drying rack is simple in structure, can be contained through detachment, is convenient to carry, and saves the cost of travel on official travel, thus being a best company of travel on official business, having certain novelty, creativity and stronger practicability, as well as wide market prospects, and being easy for batch production.

Owner:徐俏

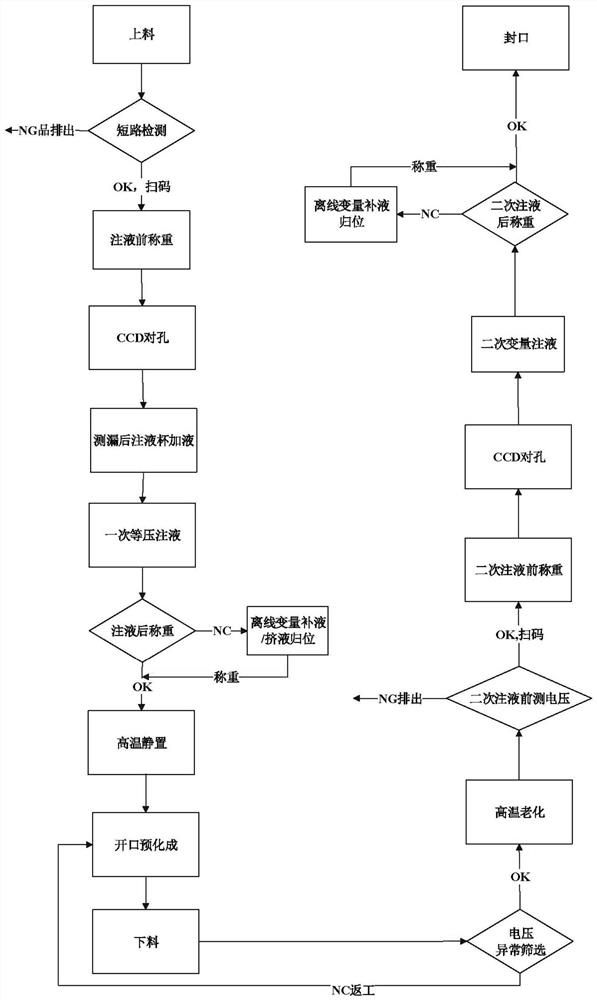

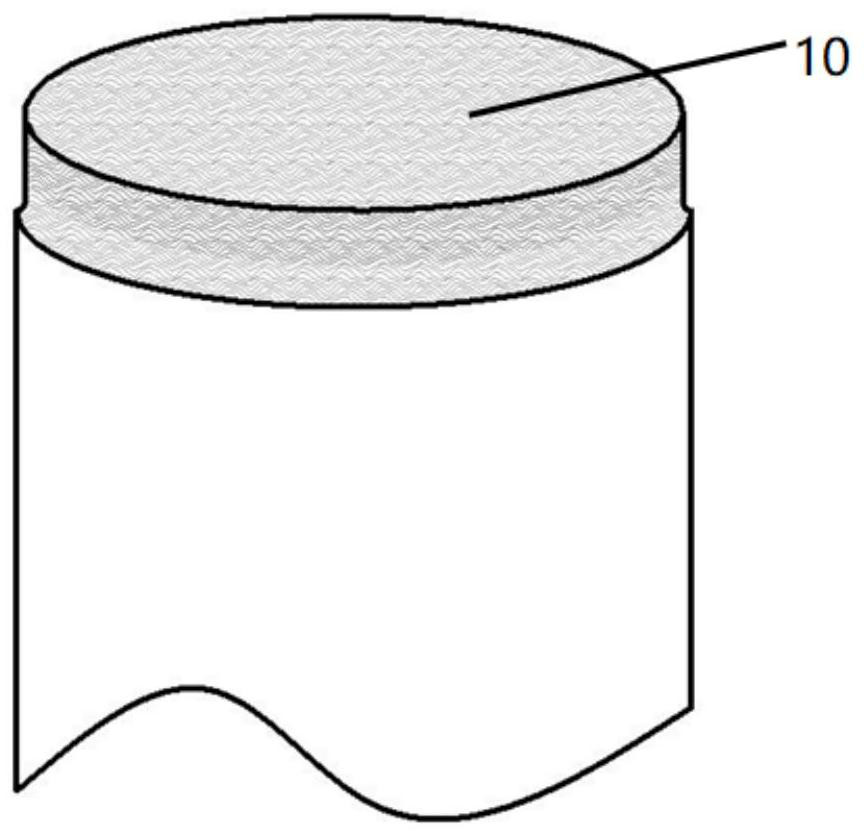

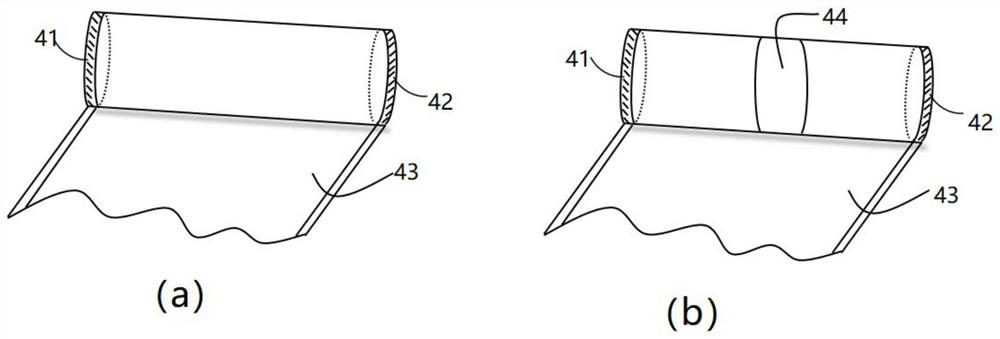

Liquid injection process of end face welding cylindrical lithium ion battery

InactiveCN112038562AImprove consistencyCause swellingFinal product manufactureCylindrical casing cells/batteryElectrolytic agentElectrical battery

The invention provides a liquid injection process of an end face welding cylindrical lithium ion battery, which comprises the following steps of battery feeding, short circuit detection, primary liquid injection, high-temperature standing, opening pre-formation, high-temperature aging, secondary liquid injection and sealing. The primary liquid injection adopts a vacuum and pressurization alternating mode to circularly carry out primary liquid injection; variable liquid injection is adopted for secondary liquid injection, the problem that electrolyte of the end face welding cylindrical lithiumion battery is difficult to permeate into the roll core can be effectively solved through the liquid injection process, and meanwhile the liquid injection percent of pass and the liquid injection consistency are improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

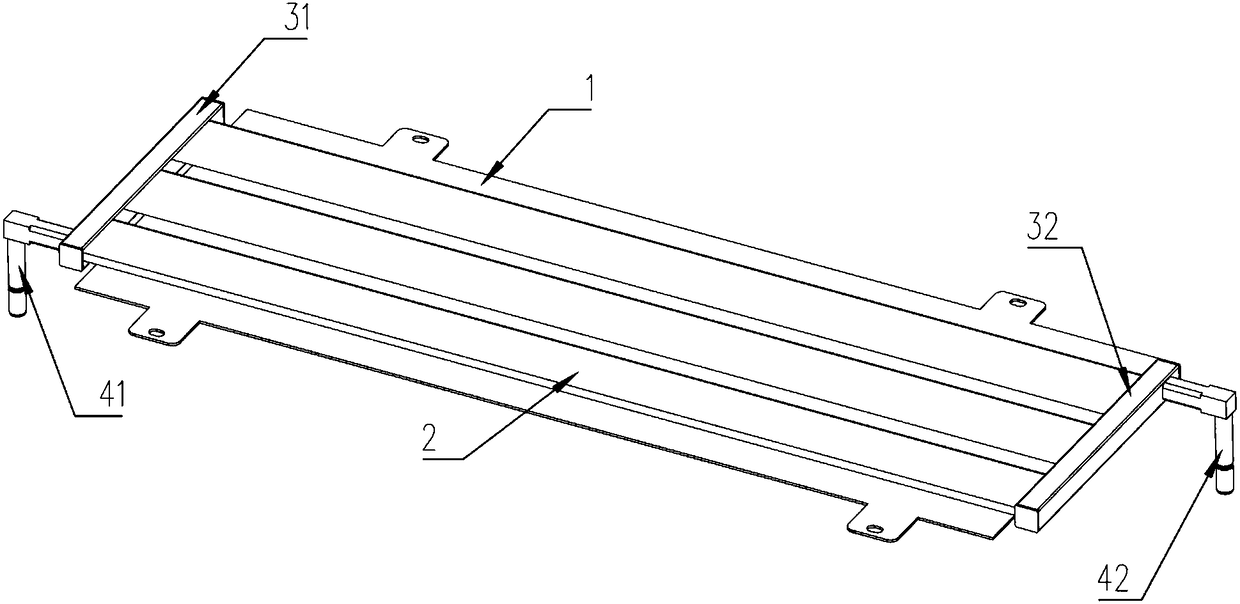

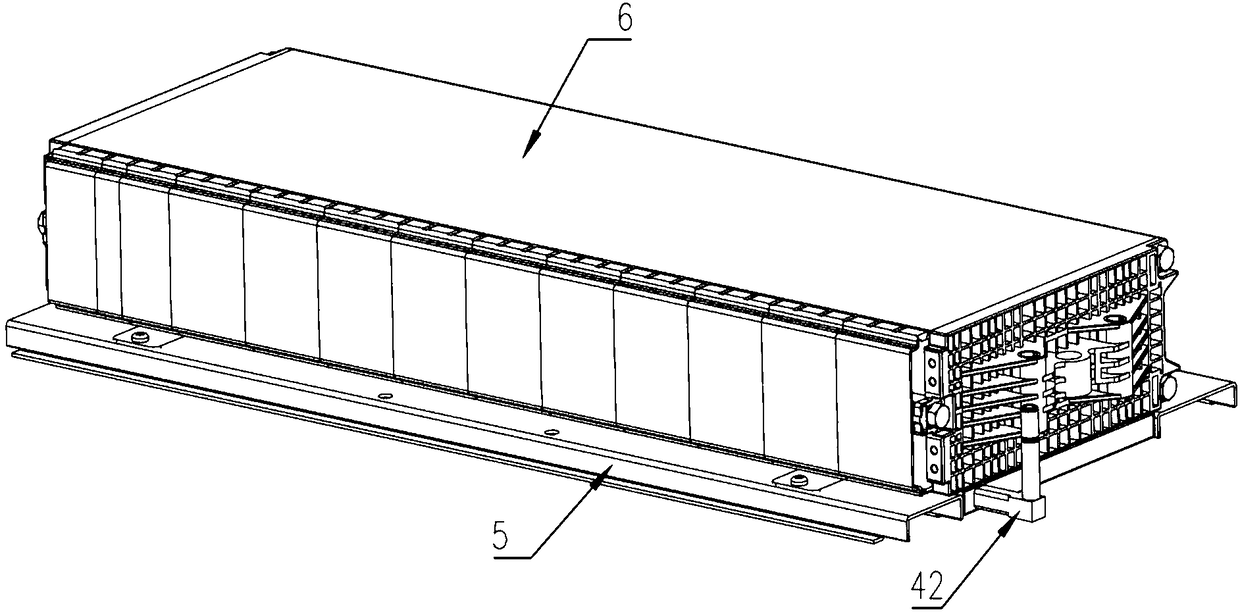

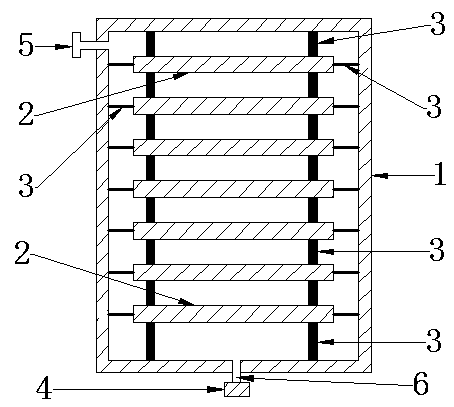

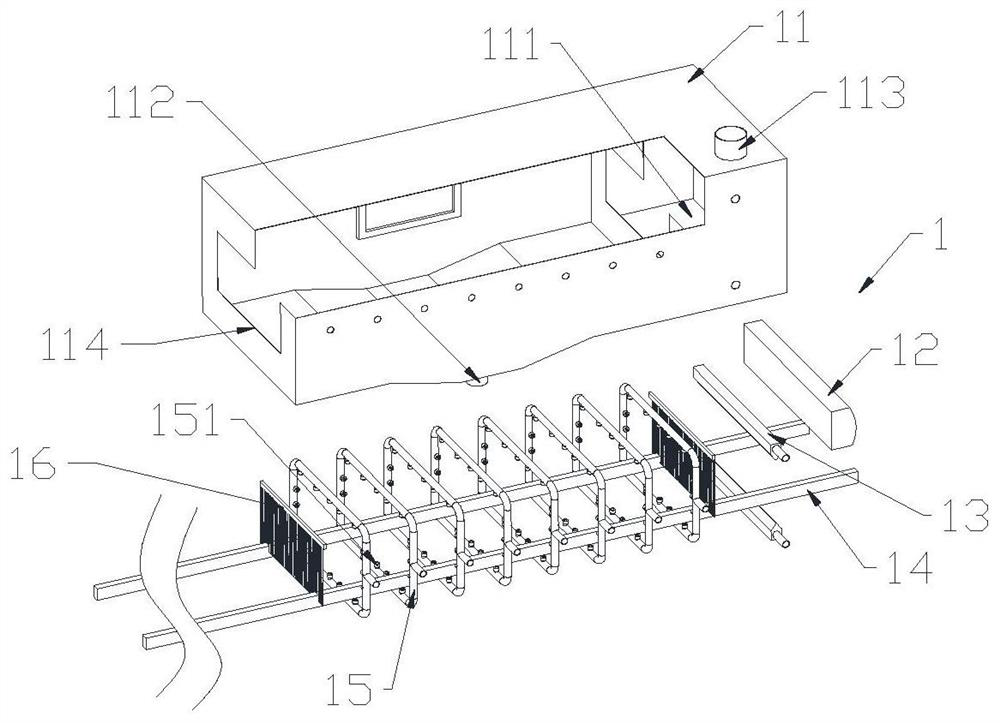

Novel uniform temperature liquid cold plate

InactiveCN108091963AReduce temperature differenceEasy to fixSecondary cellsBatteriesHeat conductingTemperature difference

The invention discloses a novel uniform temperature liquid cold plate. The liquid cold plate comprises a heat-conducting fixing plate, a plurality of diversion pipes, and two collecting pipes. The twoends of each collecting pipe are closed. The two collecting pipes are correspondingly an inlet collecting pipe and an outlet collecting pipe. The plurality of diversion pipes and the collecting pipesare communicated. The plurality of diversion pipes are arranged on a plate surface of the heat-conducting fixing plate, and The other side of the heat-conducting fixing plate is in close contact witha battery module. According to the novel uniform temperature liquid cold plate, the diversion pipes are connected with the heat-conducting fixing plate, the heat of the battery module is transferredfrom an aluminum plate to the diversion pipes, the heat-conducting fixing plate can uniformly distribute heat to an entire panel, and the heat is taken away by the diversion pipes to achieve uniform heat dissipation and to reduce temperature difference of the battery module.

Owner:桑顿新能源科技(长沙)有限公司

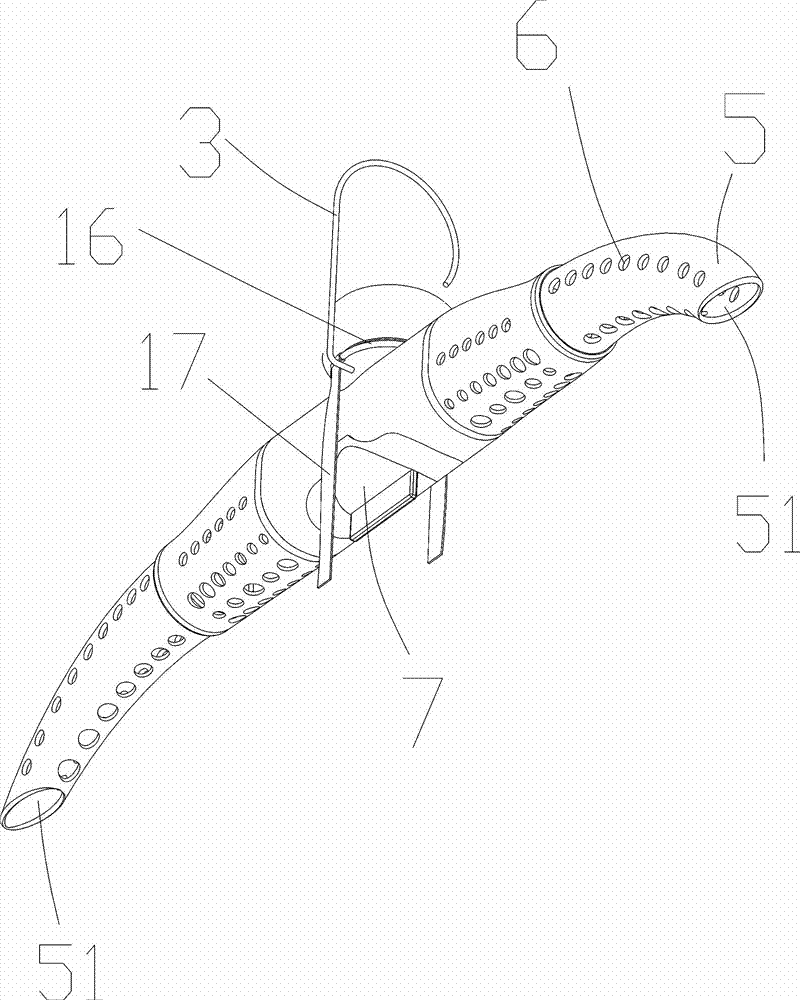

Portable clothes drying rack

InactiveCN102727059ASimple structureEasy to carryApparel holdersTextiles and paperEngineeringSlip ring

The invention discloses a portable clothes drying rack. The portable clothes drying rack comprises an air hole seat for an electric blower to insert, a main body connected with the air hole seat, a hanger hinged on the air hole seat or the main body, an extending body connected with the two sides of the main body, and a tail body connected with the extending body, wherein air outlet holes are formed in the body walls of the extending body and the tail body; the air hole seat consists of a cover ring, an elastic film and the anti-slip ring, wherein the elastic film is pressed between the cover ring and a seat body, the surface of the elastic film is provided with an opening, and the anti-slip ring is annularly arranged on the inner side wall of the seat body; a plurality of gaps are formed on the anti-slip ring; a neck ring of a binding strip for fixing the electric blower is also sleeved at the periphery of the seat body; the main body is connected with the extending body through a fastener or is integrally formed with the extending body; and the extending body is connected with the tail body through the fastener or a screw. The portable clothes drying rack is simple in structure, is dismountable and storable, and is convenient to carry; the cost of travel on official business can be saved, so that the portable clothes drying rack is the best friend for travel on official business; and the portable clothes drying rack has the advantages of certain novelty, creativeness and high practicality as well as wide market prospect, and is easy for batch production.

Owner:徐俏

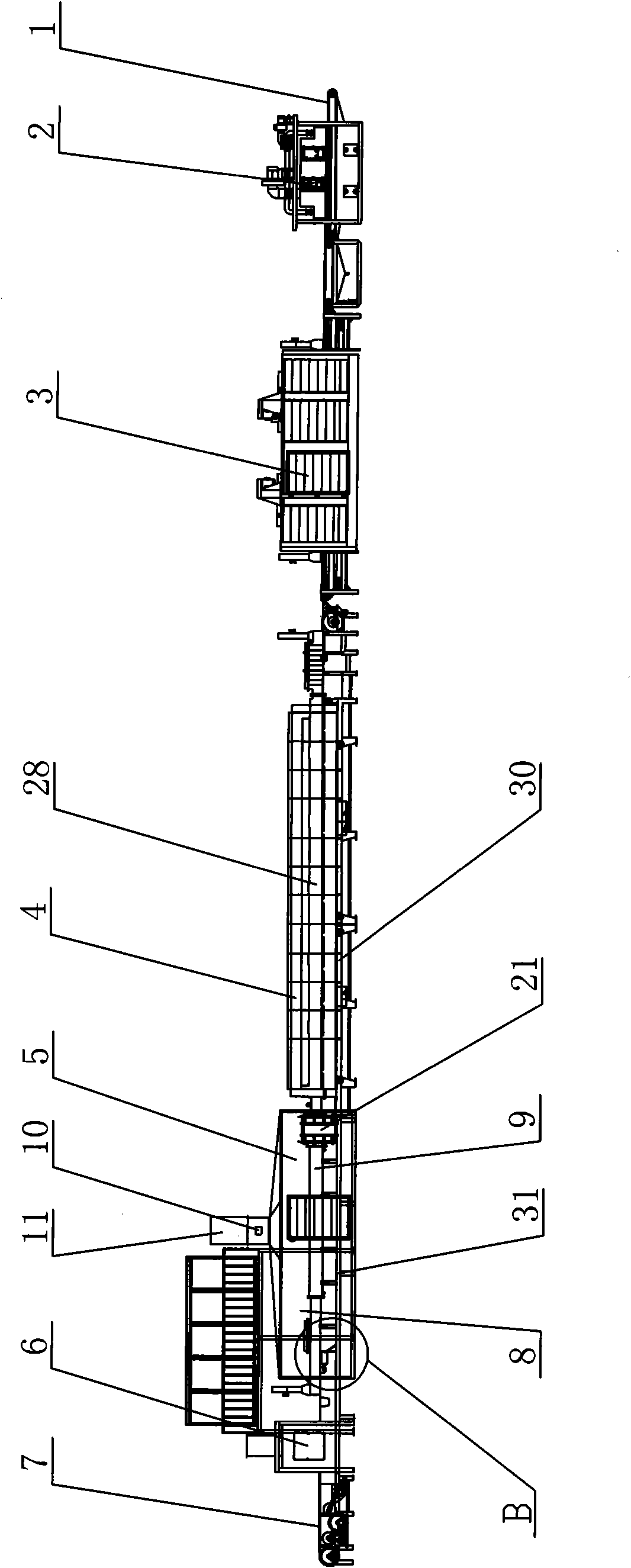

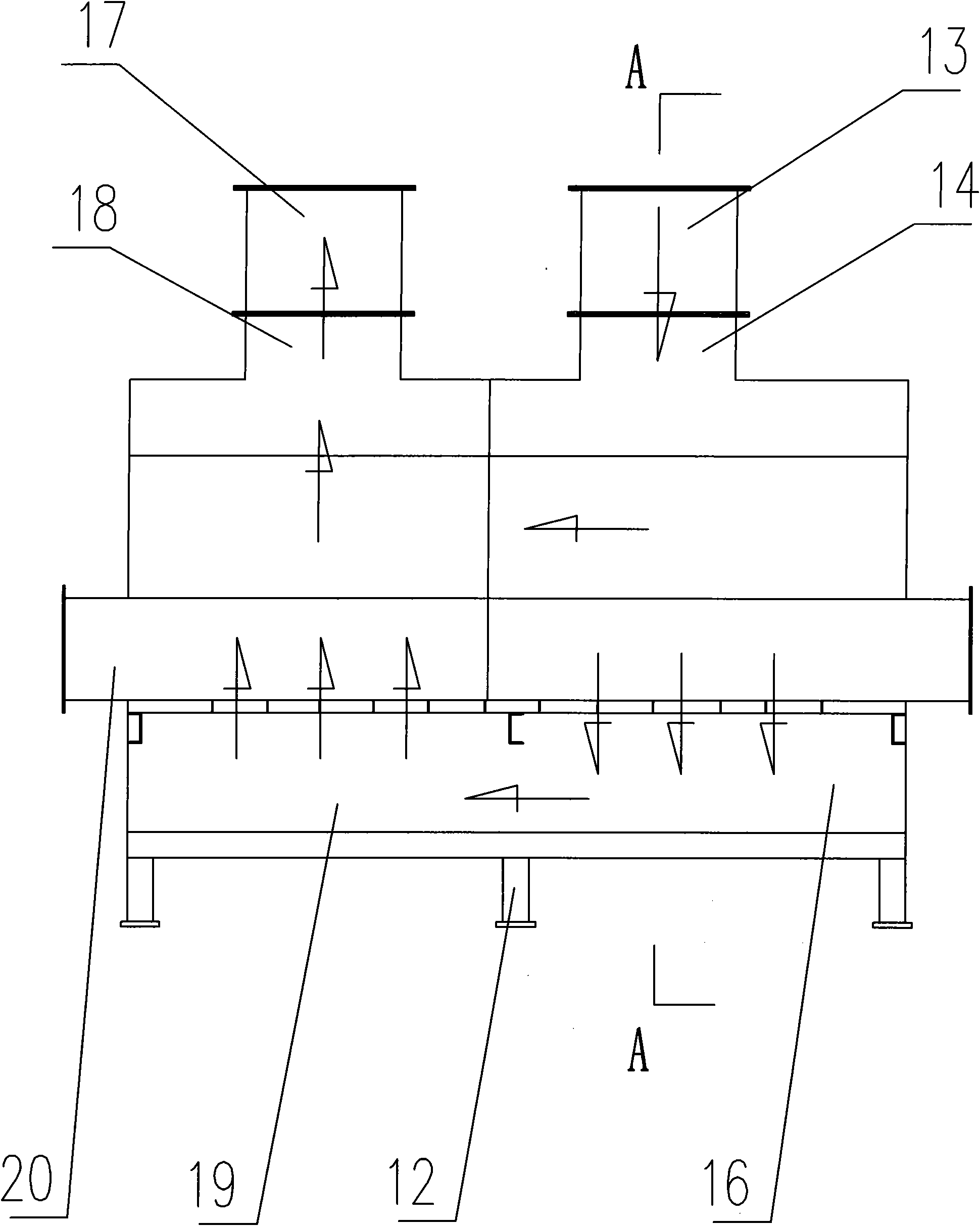

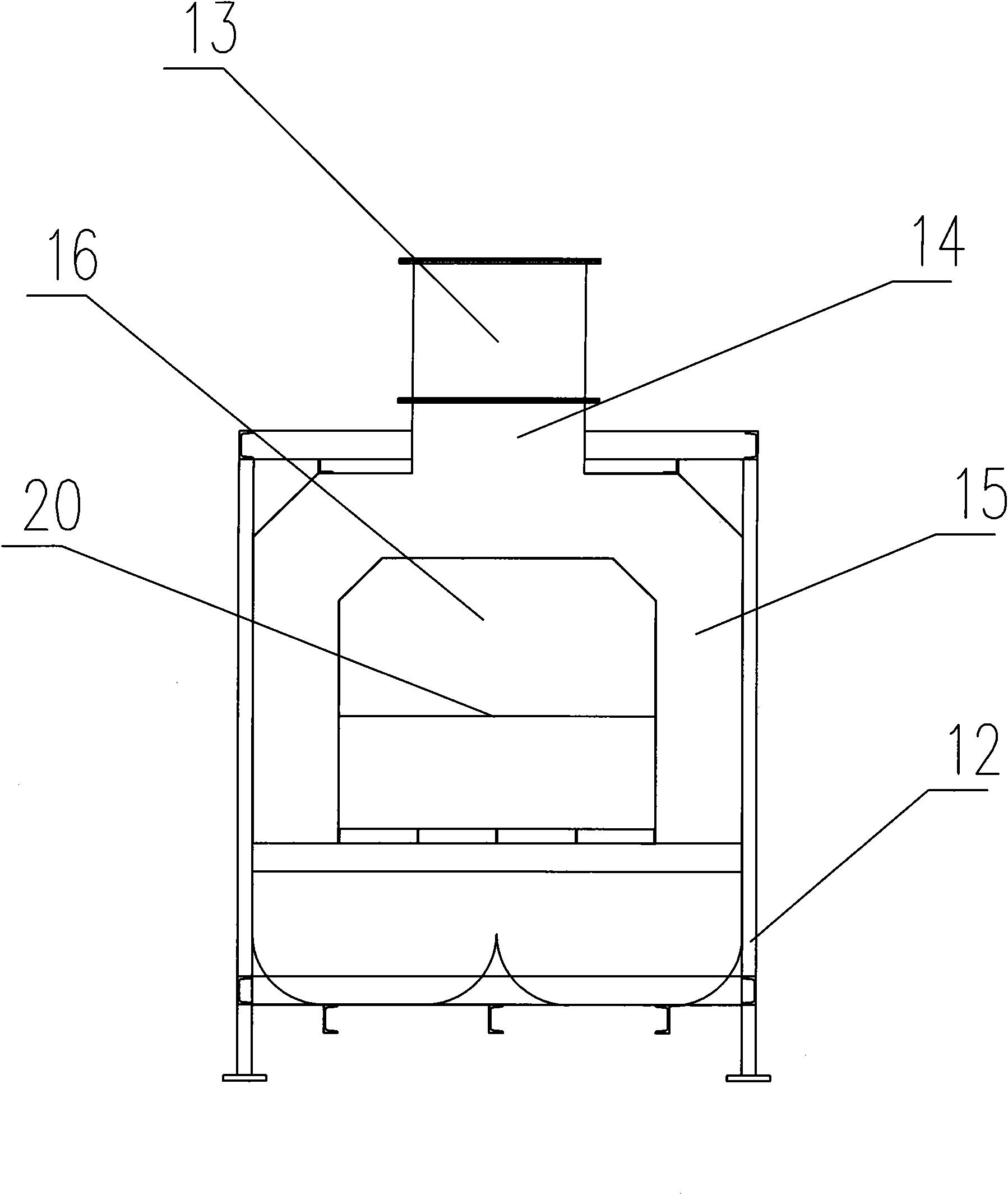

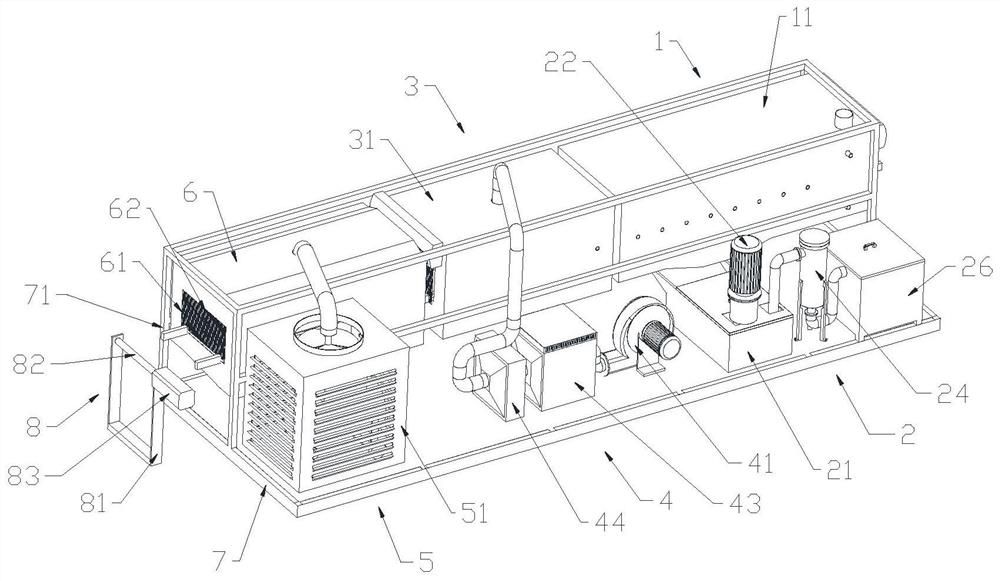

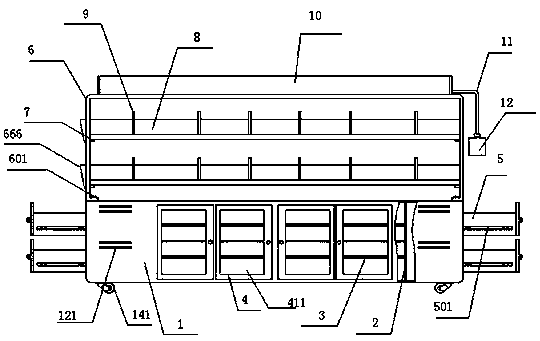

Aluminum brazing furnace

The invention discloses an aluminum brazing furnace which has the advantages of safe use and good cooling effect at a pre-cooling region. When the temperature in an air cooling chamber is higher than a set temperature, a control device can control a circulating fan to be automatically started; the air speed at a forced cooling region is uniform, the cooling effect of a furnace lining at the forced cooling region is good and the cooling area is relatively large; a slag removal chamber is reserved, so that brazing crystals can be immediately cleaned up without manual periodic cleaning, the labor intensity is reduced, the using cost is reduced, the working efficiency is improved, and the influence on the brazing effect is prevented because the shaking of a conveyer belt caused by the accumulation generated by the brazing crystals can be prevented; meanwhile, the slag removal device is also provided with an access door, so that the aluminum brazing furnace can be conveniently examined and repaired; when the furnace lining is subjected to linear expansion, the furnace lining can be helped to quickly move towards one side so as to perform the liner expansion well, reduce the resistance during the expansion and ensure high safety and high reliability for the running of the aluminum brazing furnace; and thus the distance for every linear expansion of the furnace lining is the same, and deformation of the furnace lining caused by the difference in distance of the linear expansion of the furnace lining is prevented.

Owner:JIANGSU KANGJIE MACHINERY

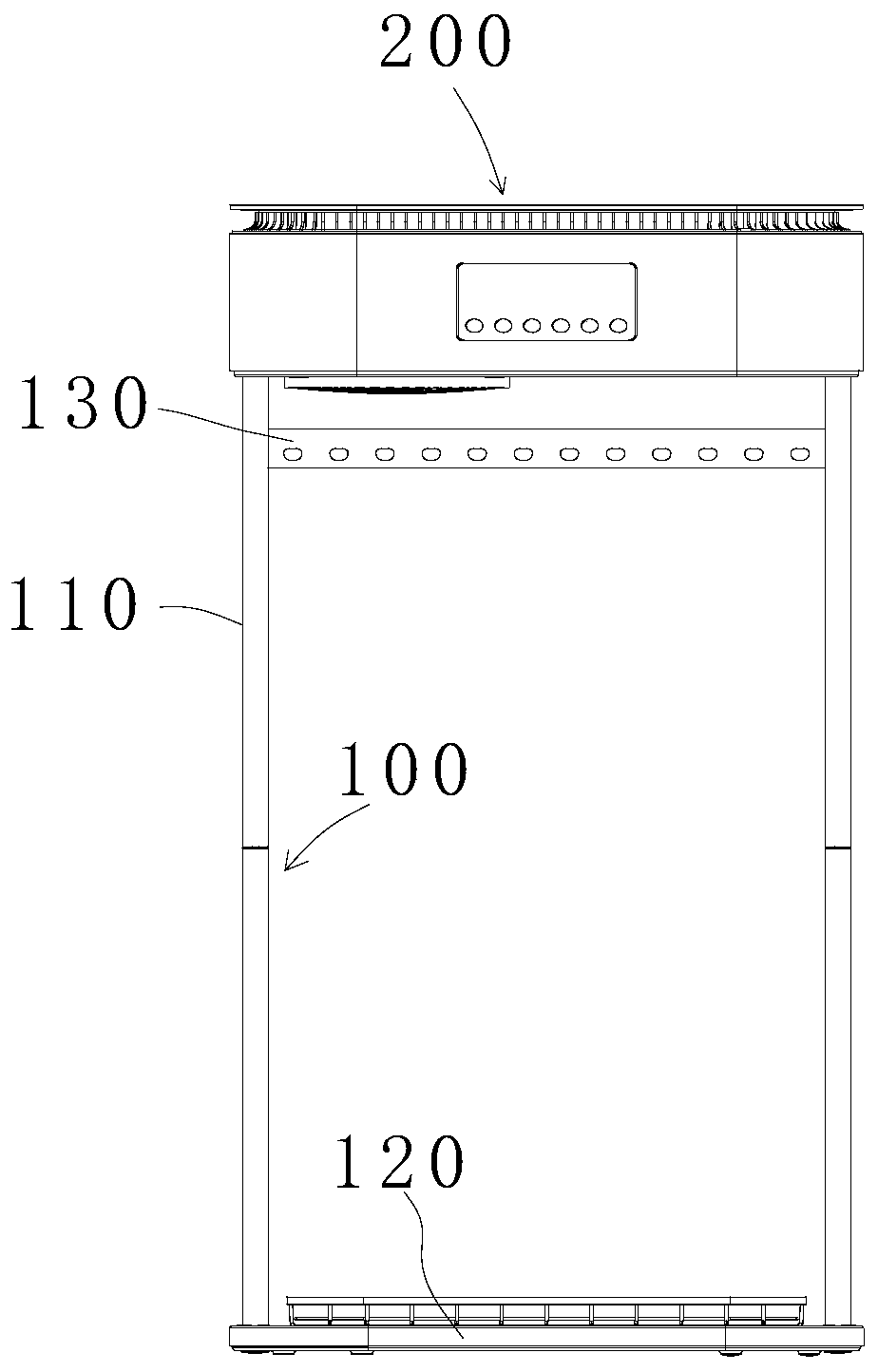

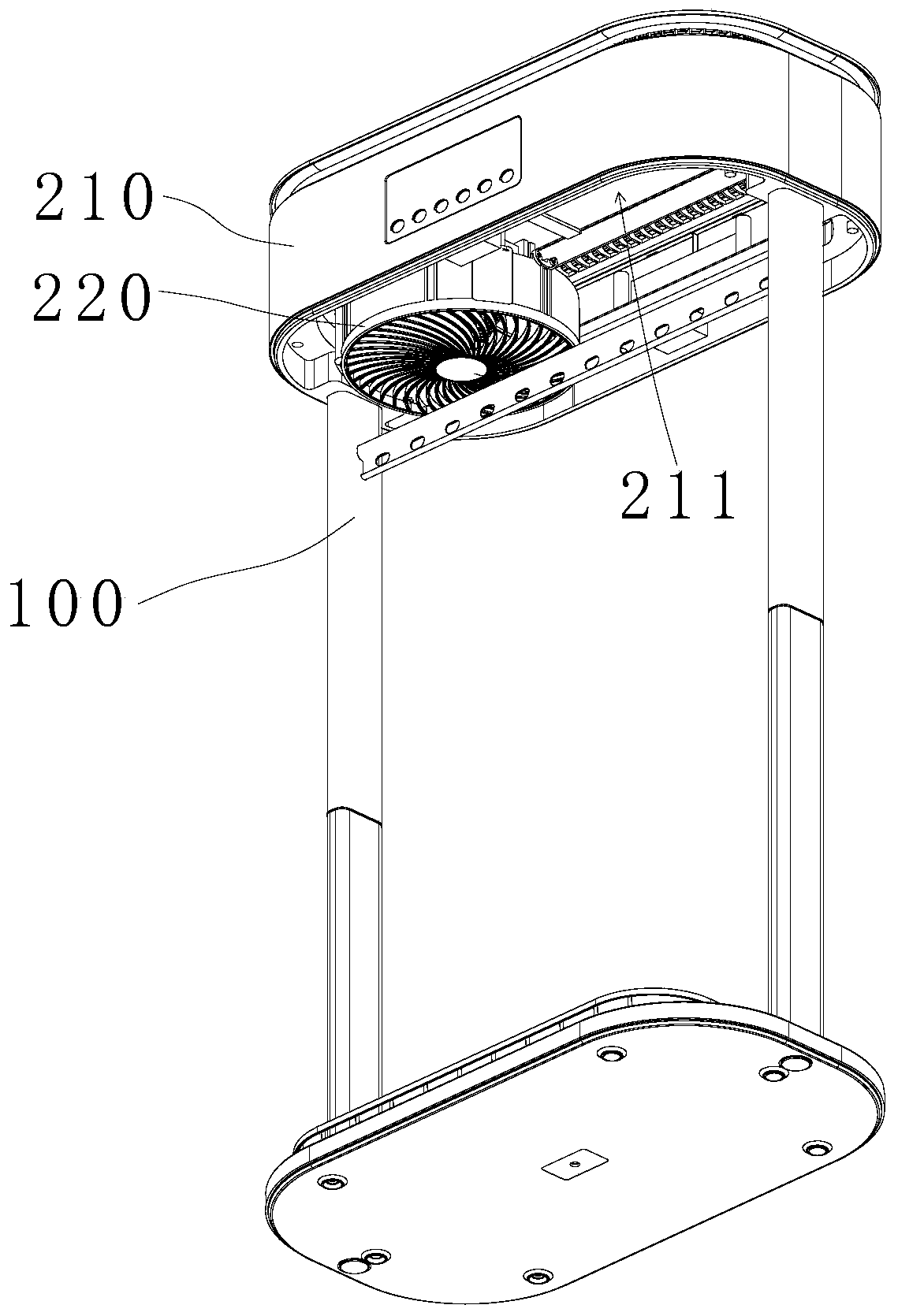

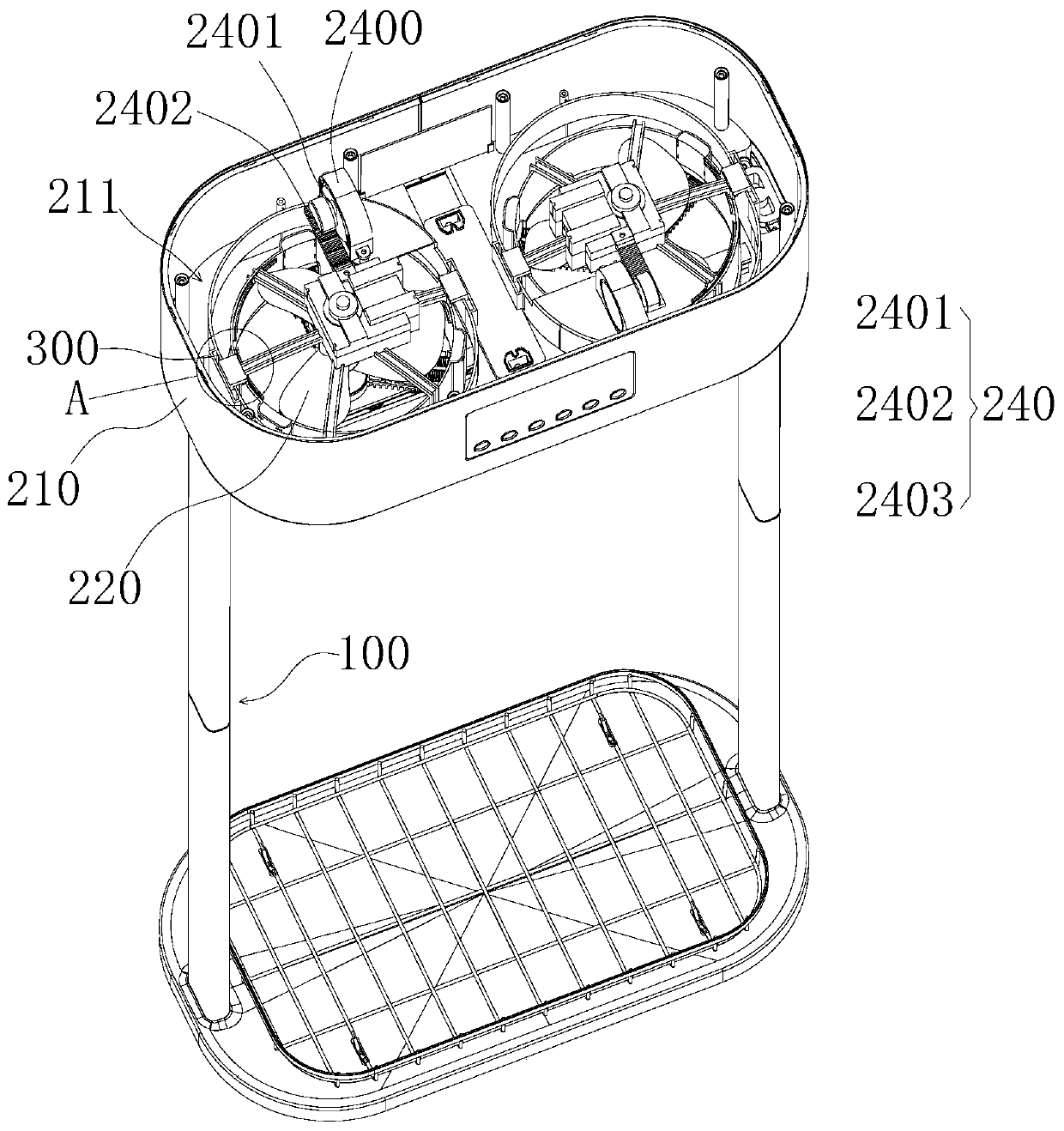

Clothing care machine with movable drying function

PendingCN109944040AAchieve dryingAvoid deformationTextiles and paperLaundry driersPulp and paper industry

The invention relates to the field of clothing care machines, in particular to a clothing care machine with a movable drying function. The clothing care machine comprises a supporting rack and a drying machine which is arranged at the upper end of the supporting rack, and the drying machine blows air downwards to dry clothing under the drying machine; the drying machine comprises a machine hood, ablower, a heating device and a driving mechanism. The driving mechanism drives the blower to do reciprocating translation movement in the machine hood; a clearance hole is formed in the bottom of themachine hood so as to avoid the air flow which the blower blows downwards; the heating device is fixedly arranged at the air inlet end or an air outlet of the blower. By means of the clothing care machine, it is avoided that hot air is blown to the same position of clothing all the time, it is avoided that the clothing is deformed even damaged due to long-time heating, in the moving process of the blower, after the hot air leaves, part heat of the clothing can be dispersed into air, and the protection effect on the clothing is achieved.

Owner:中山巾管家电器科技有限公司

Efficient cleaning method of spinneret plate for mesophase pitch melt spinning

InactiveCN110820055AExtend your lifeShorten drying timeSpinnerette packsArtificial thread manufacturing machinesMolten saltMelt spinning

The invention belongs to the technical field of spinneret plate cleaning in chemical fiber manufacturing industry and discloses an efficient cleaning method of a spinneret plate for mesophase pitch melt spinning. The method includes: cooling the spinneret plate dismantled on site, scraping mesophase pitch on the surface of the spinneret plate, and subjecting the spinneret plate to high-temperaturetreatment in inert gas; cooling the spinneret plate, scraping the mesophase pitch on the surface of the spinneret plate, and subjecting the spinneret plate to salt bath treatment; cooling the spinneret plate, removing molten salt on the surface of the spinneret plate, subjecting the spinneret plate to ultrasonic treatment, and using compressed air to blow the surface of the spinneret plate; drying the spinneret plate, and inspecting. The method has the advantages that the treatment steps in the method are effective solutions for actual problems instead of simply listed and added steps, the cleaning efficiency of the method is much higher than that of existing methods, and adverse influence such as spinneret plate deformation can be avoided. Tests show that the qualification rate of the spinneret plates cleaned by the method can reach 100%.

Owner:上海高强高模新材料科技有限公司

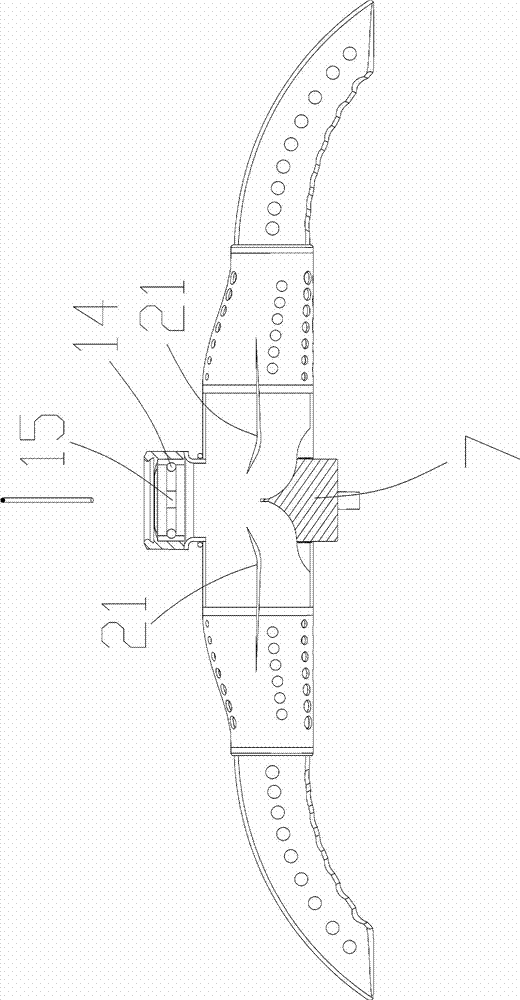

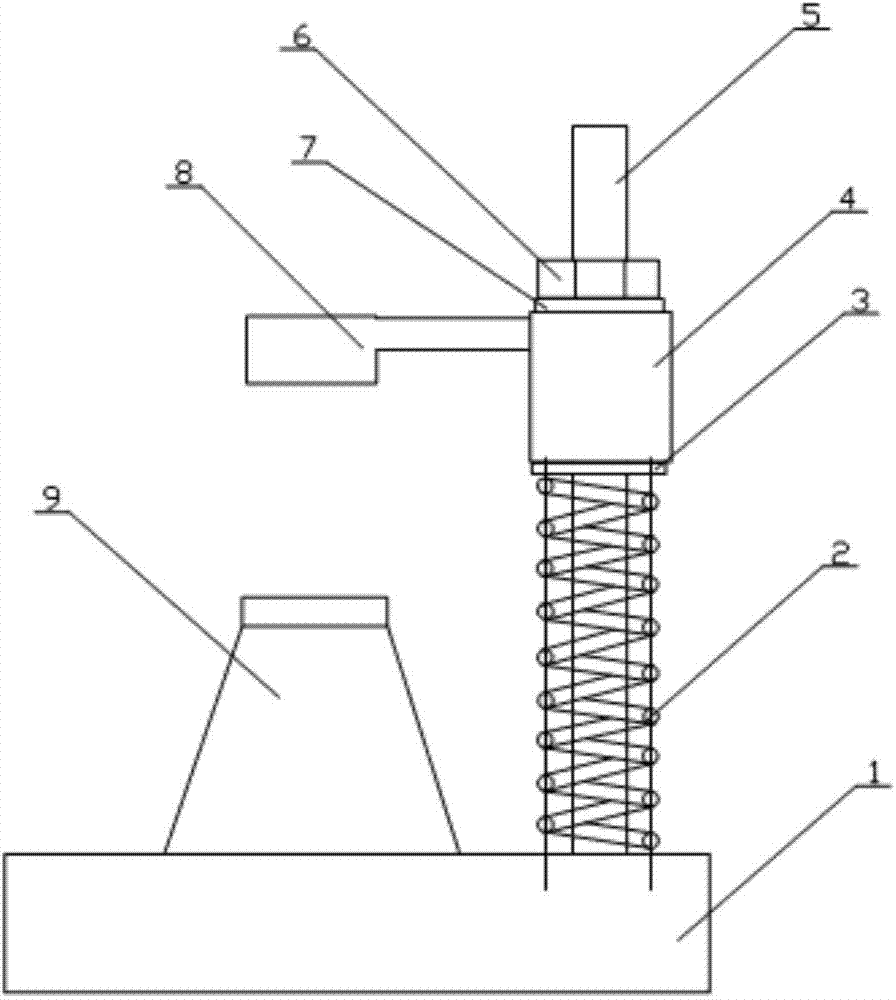

Adjustable caterpillar track section clamping device

InactiveCN103481222ACausing deformationCause deformationWork holdersMetal chainsIndustrial engineeringGasket

The invention relates to the technical field of caterpillar track section clamping, in particular to an adjustable caterpillar track section clamping device. The adjustable caterpillar track section clamping device comprises a base, a spring, a supporting plate, a movable part, a supporting rod, a locating nut, a spacer and an upper pressing plate. The supporting rod is arranged at the upper end of the base, the supporting rod is sleeved with the spring, the supporting plate is arranged at the upper end of the spring, the movable part is arranged at the upper end of the supporting plate, the locating nut is arranged on the supporting rod and presses the movable part through the spacer, and the upper pressing plate is arranged on one side of the movable part and directly faces the base. The locating nut is adjusted to enable the movable part to drive the upper pressing plate to move downwards to press a work-piece. The spring supports the movable part through the supporting plate so that appropriate clamping force can be exerted on the work-piece, and the work-piece is protected against deformation caused by the excessively large or small clamping force.

Owner:KUNSHAN KAINUOER METAL PROD

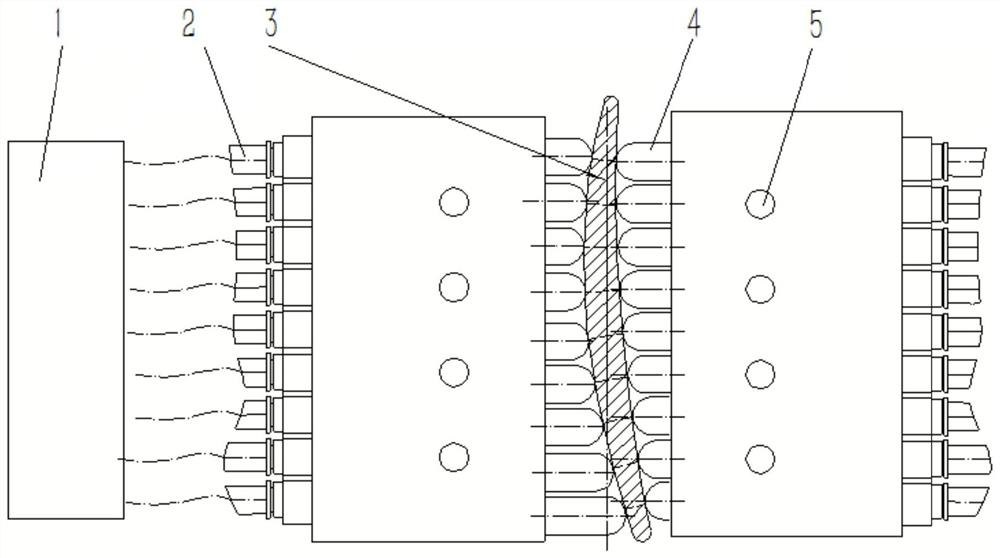

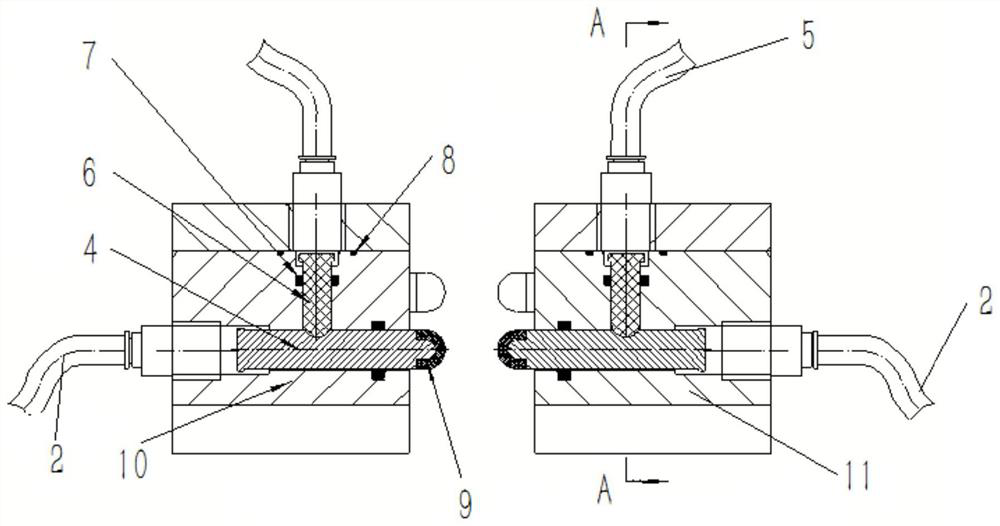

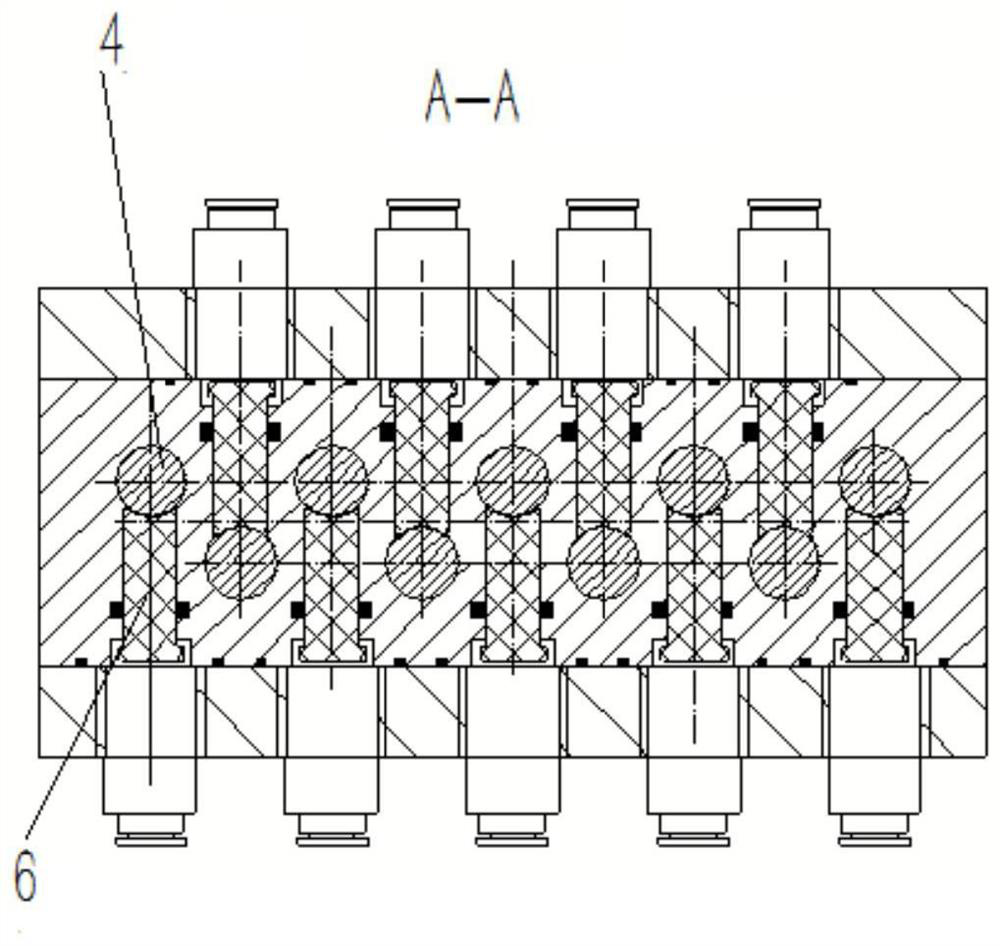

Pneumatic self-adaptive clamp and using method thereof

ActiveCN114536062ACause deformationAvoid scratchesFinal product manufactureWork clamping meansEngineeringMechanical engineering

The invention provides a pneumatic self-adaptive clamp and a using method thereof.The pneumatic self-adaptive clamp comprises a left clamp base body, a right clamp base body and at least one pair of clamping contacts, the left clamp base body and the right clamp base body are provided with the same number of clamping contact mounting holes, and the clamping contact mounting holes in the left clamp base body and the right clamp base body are arranged in a one-to-one opposite mode; two clamping contacts in each pair of clamping contacts are installed in two opposite clamping contact installation holes in the left clamp base body and the right clamp base body respectively, a clamping air cylinder is arranged at the rear end of each clamping contact, the two clamping air cylinders at the rear ends of each pair of clamping contacts form a pair of clamping air cylinders, and the clamping air cylinders are connected with a pneumatic system. The pneumatic system independently drives each pair of clamping cylinders to work, and enables the clamping contacts to extend out one by one from a point with high rigidity to a point with low rigidity under the driving of low-pressure gas according to the rigidity of each clamped point on a clamped piece, so that the deformation of the clamped piece caused by the contact between the clamping contacts and the clamped piece is avoided.

Owner:聊城大学东昌学院

Electric heating type drying box

PendingCN110243149AImprove stress resistanceCause deformationDrying machines with local agitationDrying machines with materials at restElectricityHeat conducting

The invention discloses an electric heating type drying box. The electric heating type drying box comprises a drying box, heating devices, a bracket and a drainage valve. The drainage valve is mounted in a drainage port on the outer surface of the drying box. The heating devices comprise top plates, base plates, side plates, electric heating pipes, fixed strips and heat conducting working mediums. The heating devices are fixedly mounted on a box body of the drying box through brackets. The electric heating pipes provide a heat source to the liquid-state heat conducting working mediums; the heat conducting working mediums transfer heat onto the top plates and the base plates of the heating devices through gas-liquid phase change; the heating devices on the upper and lower layers synchronously heat materials in trays up and down; through balanced temperature at four angles and the peripheries of the top plates and the base plates of the heating devices, the water drying uniformity of the materials is guaranteed, and the transfer drying of the materials is performed; and through up-down synchronous heating by the heating devices, the heat conduction and exchange speed of heat energy is accelerated. The electric heating type drying box flexibly selects vacuum low-temperature drying or air convection drying to improve the material drying efficiency and to optimize the material drying effect.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Surface cutting device for metal casting machining

ActiveCN114589529AEasy clampingEasy to cutFeeding apparatusPositioning apparatusEngineeringStructural engineering

The surface cutting device for metal casting machining comprises a machining box, a clamping mechanism is fixed to the bottom end of the interior of the machining box through supporting legs, the clamping mechanism comprises a base, moving plates are slidably connected to the two sides of the top of the base, and side plates are slidably connected to the tops of the moving plates; overturning rods are rotationally connected to the sides, close to each other, of the two side plates, overturning plates are fixed to the ends, away from the side plates, of the overturning rods, a cutting mechanism is arranged above the clamping mechanism, a recycling mechanism is fixed to the bottom end of the interior of the machining box, and cooling mechanisms are fixed to the two sides of the interior of the machining box. The problems that in an existing patent, after a metal casting is clamped, the metal casting cannot be driven to move and rotate in multiple directions, repeated dismounting and clamping are needed when different positions of the metal casting are cut, and the time cost is increased are solved; and meanwhile, when the cutting fluid is recycled, chippings in the cutting fluid cannot be separated, and environmental protection and recycling of the cutting fluid cannot be achieved.

Owner:江苏诺丰科技有限公司

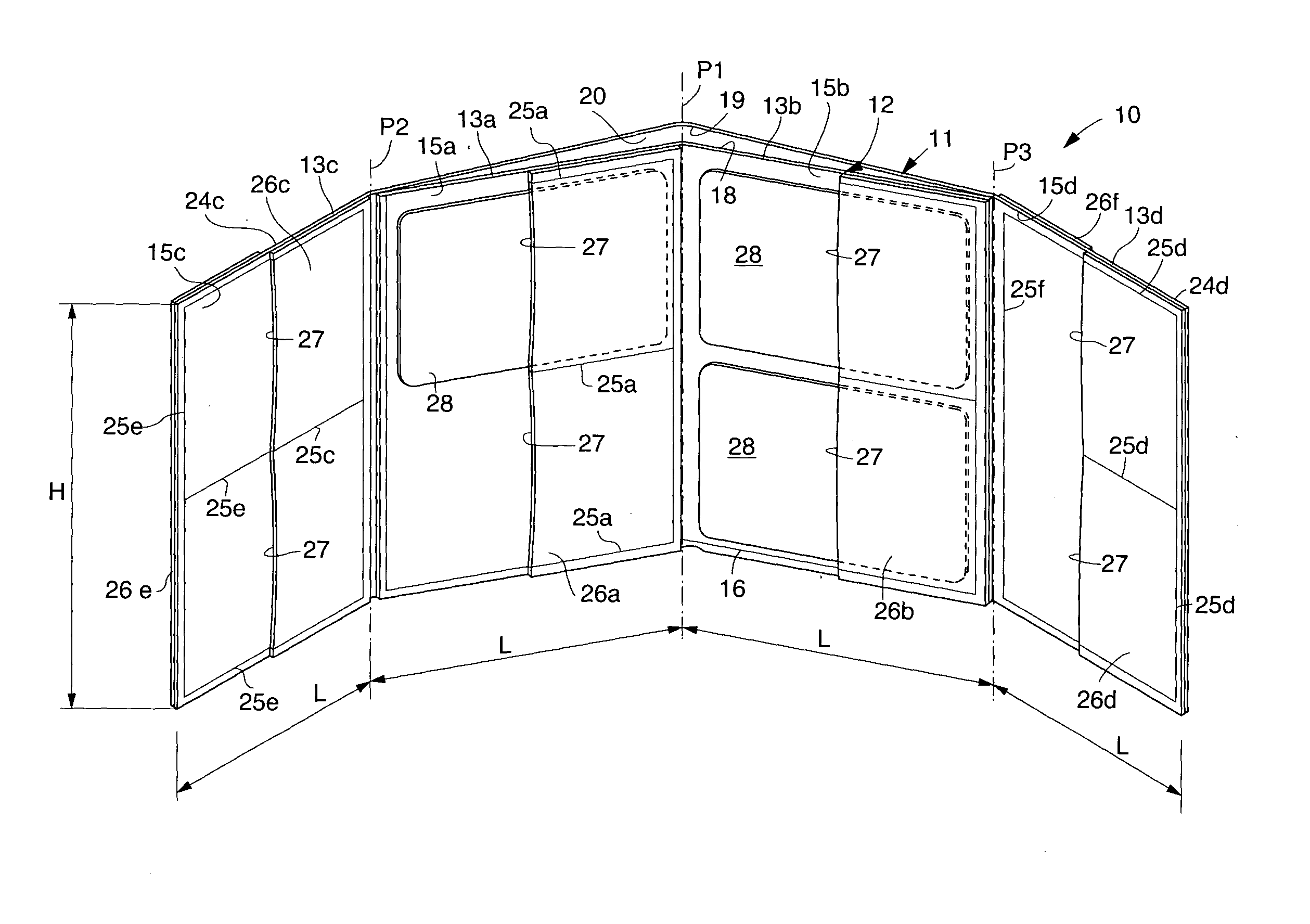

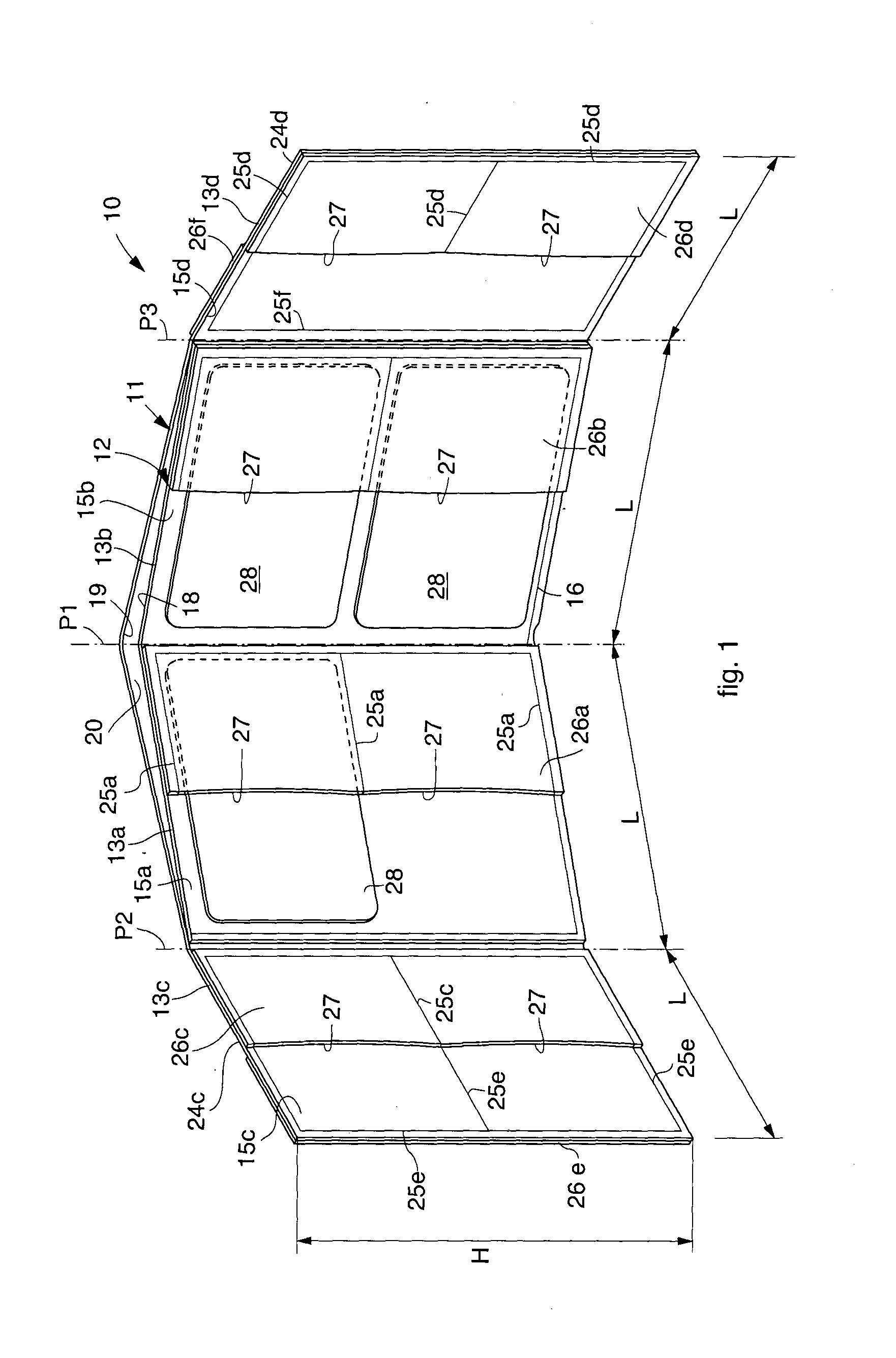

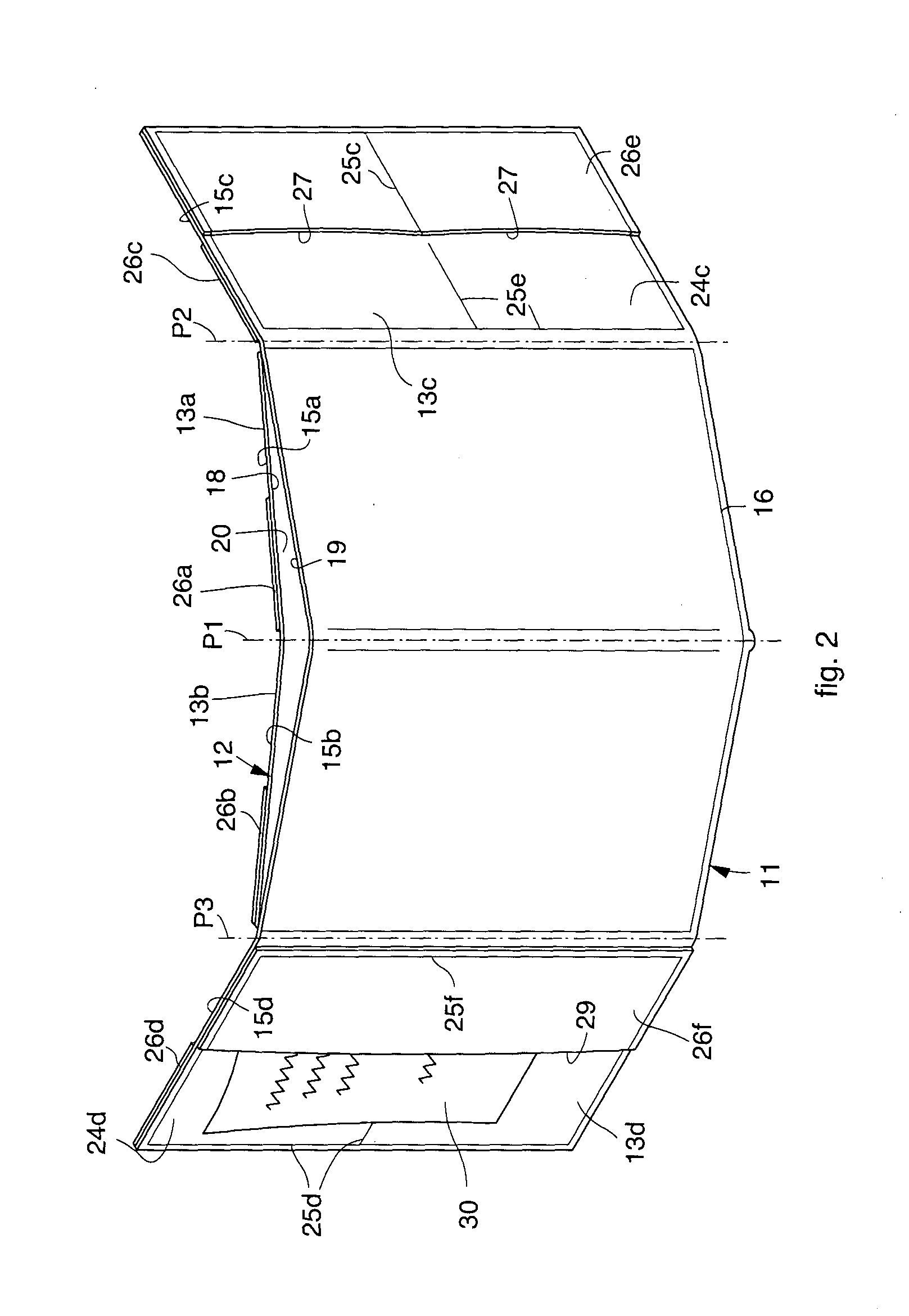

Wallet

Owner:DELLE VEDOVE GAETANO

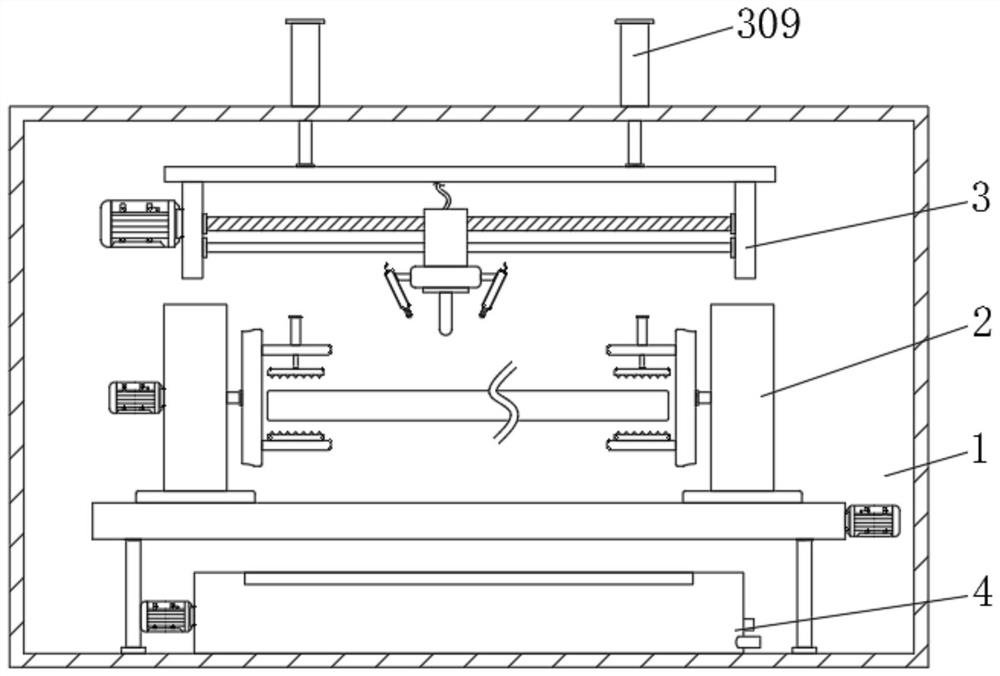

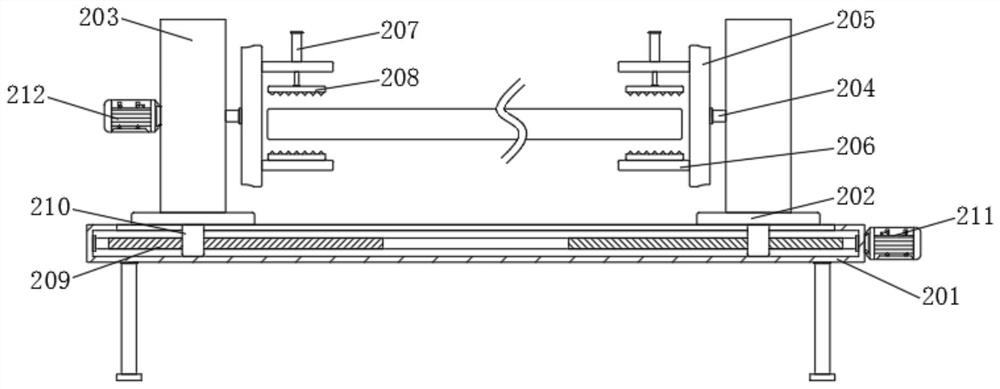

T-shaped steel intelligent welding workstation

ActiveCN114799628ATransport stableGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to the technical field of welding equipment, in particular to a T-shaped steel intelligent welding workstation which comprises a wing plate conveying assembly for horizontally conveying wing plates, web plates are vertically placed on the wing plates, web plate positioning assemblies for clamping the web plates are arranged on the two sides of the web plates, and the two ends of the wing plate conveying assembly are each provided with two web plate positioning assemblies. A certain gap is formed between the web positioning assemblies, the working end of the welding device conducts welding towards the connecting position of a wing plate and a web between the web positioning assemblies, arc-shaped baffles are arranged on the opposite sides of the web positioning assemblies, and the working ends of the web positioning assemblies and the working end of the welding device are separated through the arc-shaped baffles. According to the technical scheme, the technical problems of how to position and machine section steel webs and wing plates of different sizes and ensuring that welding spatter cannot be attached to other parts during machining are solved.

Owner:大同宏鑫钢制品有限责任公司

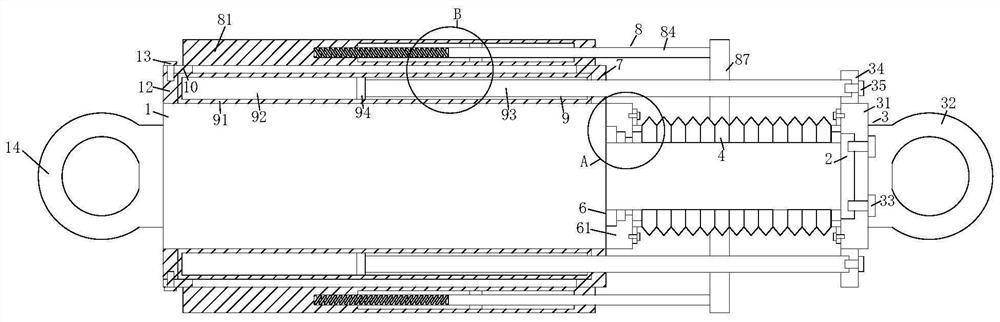

Tunneling hydraulic cylinder

PendingCN112178005ACause deformationAvoid damageEngine sealsFluid-pressure actuatorsHydraulic cylinderEngineering

The invention relates to the field of hydraulic cylinders, in particular to a tunneling hydraulic cylinder which comprises a hydraulic cylinder body. A piston rod of the hydraulic cylinder body is located on one side of the hydraulic cylinder body, a mounting plate is fixedly connected to the moving end of the piston rod, a connector is mounted on the mounting plate, and the piston rod of the hydraulic cylinder body is sleeved with a dustproof pipe. Connecting rings are fixedly connected to the two ends of the dustproof pipe, the circumferential outer walls of the connecting rings are both fixedly connected with second fixing rings in a sleeved mode, and the second fixing rings are both in threaded connection with fourth bolts. Auxiliary mechanisms and protection mechanisms are arranged outside the hydraulic cylinder body; when the hydraulic cylinder is in use, sliding rods of the auxiliary mechanisms and protection rods of the protection mechanisms surround the outer portion of the piston rod of the hydraulic cylinder body; and when the hydraulic cylinder is subjected to external impact, acting force generated during impact can act on the sliding rods and the protection rods firstly, the sliding rods and the protection rods can buffer the acting force, and the situation that since external impact force directly acts on the piston rod of the hydraulic cylinder body, the pistonrod of the hydraulic cylinder body deforms is prevented.

Owner:韩振华

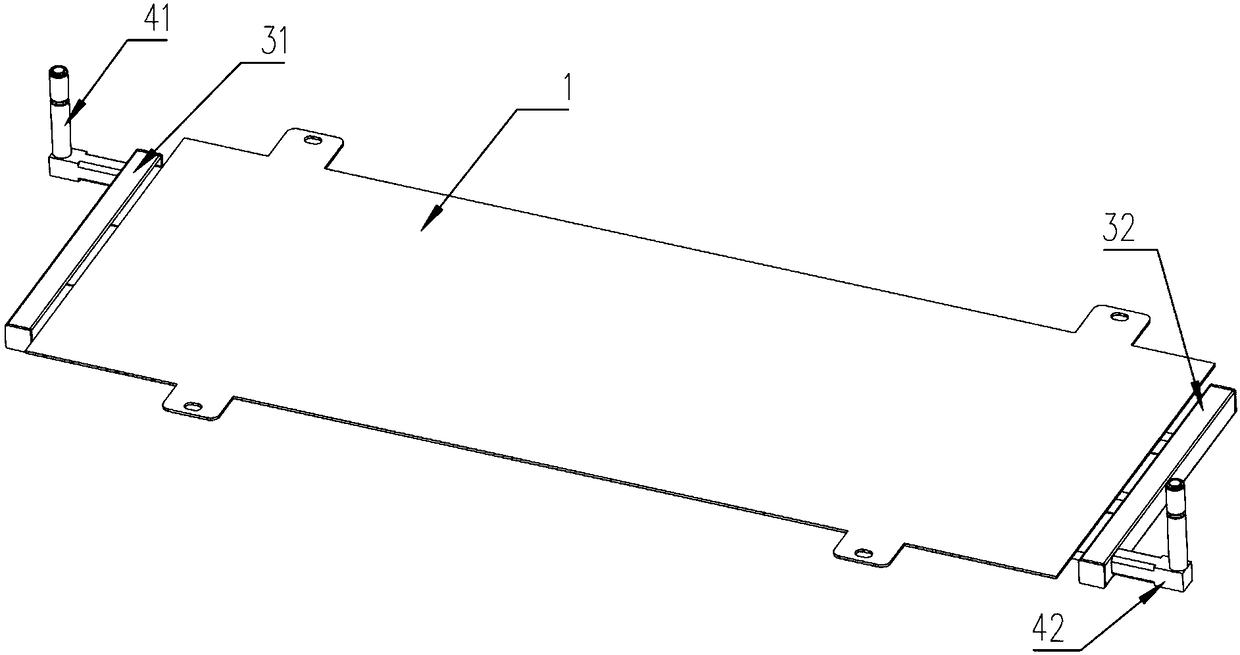

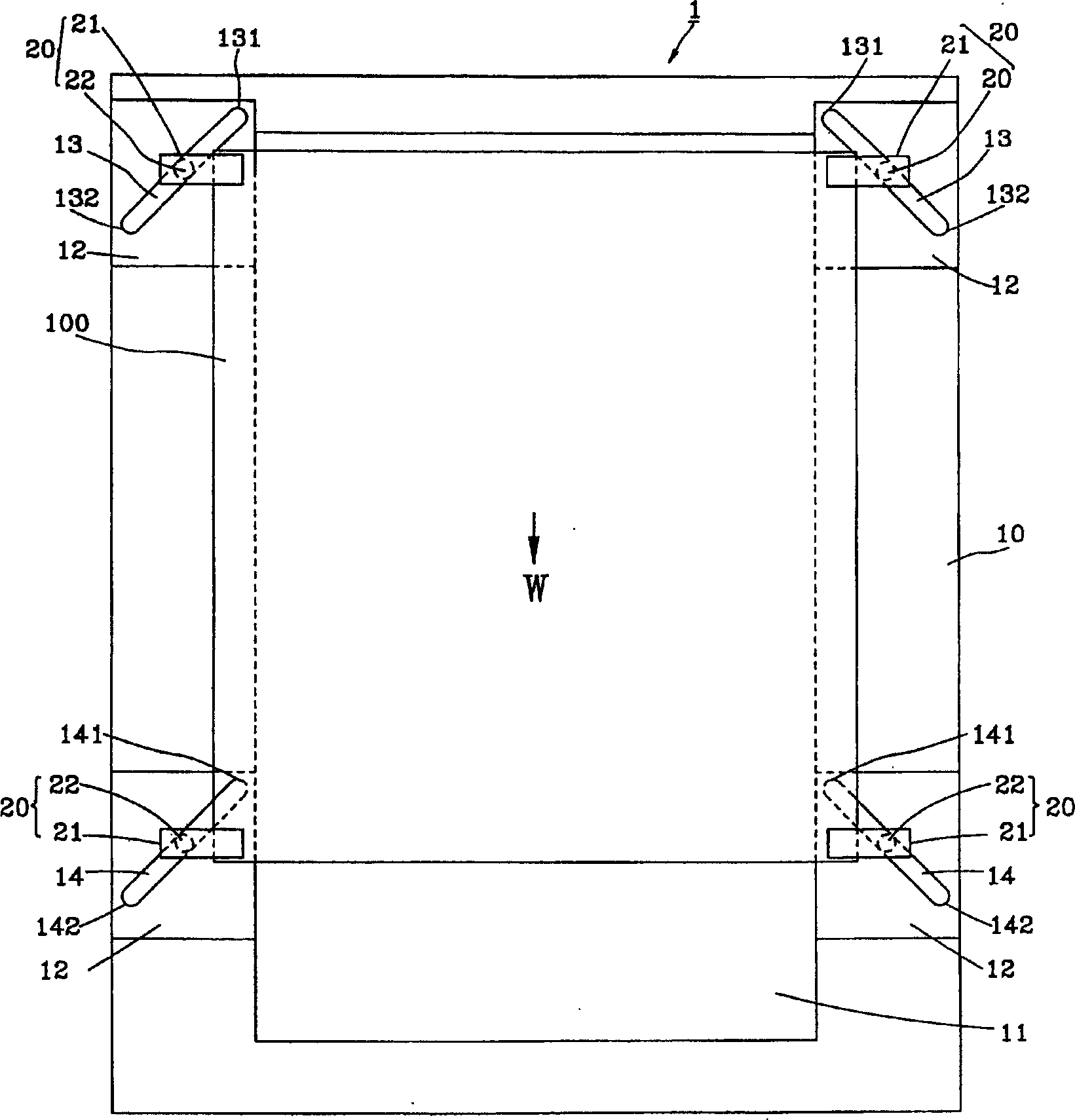

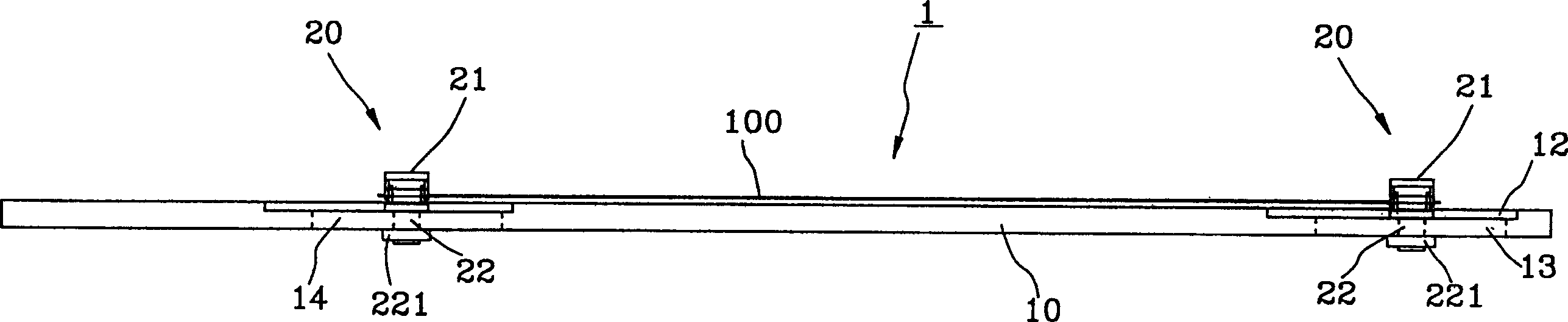

Apparatus for fixing platy object or flaky object

Owner:UNITED TEST CENTER INC

Fixed shoe airing rack

The invention discloses a fixed shoe airing rack, which comprises a main supporting rod (1), a hook head and hook head fastening switch (2), hanging clips (3) and annular hanging hooks (4) and is characterized in that the upper end of the main supporting rod (1) is provided with the hook head and hook head fastening switch (2), the middle of the main supporting rod (1) is symmetrically provided with the hanging clips (3), and the lower end of the main supporting rod (1) is symmetrically provided with the hanging hooks (4); the hook head and hood head fastening switch (2) can rotate by 360 degrees around the main supporting rod (1). The fixed shoe airing rack has the beneficial effects that the fixed shoe airing rack is simple in structure and convenient to use, the inner side of a hook head is zigzag, has an antiskid function and can be prevented from being blown away by wind when the hook head is hung outdoors, the hanging clips clamp shoe tongues to expand a shoe airing range, the interior of a shoe can better receive sunlight and a sterilizing effect is achieved.

Owner:邢士昂

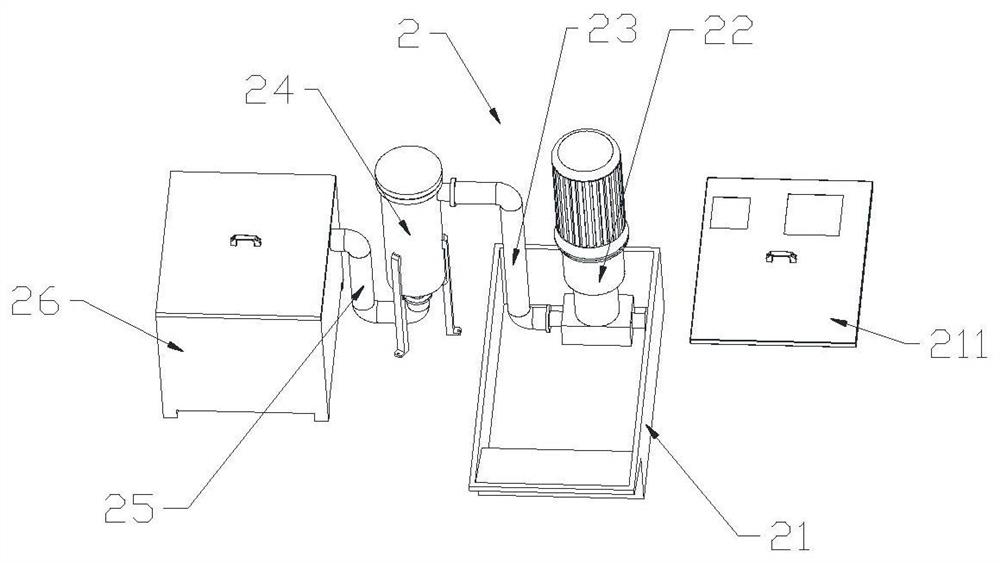

Cleaning and drying equipment for non-woven fabric production

InactiveCN112268419AReliable structureFunctionalDrying gas arrangementsDrying chambers/containersProcess engineeringWoven fabric

The invention discloses cleaning and drying equipment for non-woven fabric production. The cleaning and drying equipment for non-woven fabric production comprises a base, wherein a waste liquid treatment assembly is arranged on the base, a hot air assembly is arranged on one side of the waste liquid treatment assembly, a cold air assembly is arranged on one side of the hot air assembly, and the hot air assembly and the cold air assembly are also fixed to the base, a bracket is arranged on the base, a cleaning assembly is arranged in the bracket, a drying box assembly is arranged at one end ofthe cleaning assembly, a cooling box is arranged at one end of the drying box assembly, the drying box assembly and the cooling box are also fixed in the bracket, and a collecting assembly is arrangedat one end of the base. The cleaning and drying equipment for non-woven fabric production is reliable in structure and practical in function. Circulating water is adopted for cleaning, so that waterresources are saved to a great extent. The cleaning cost is effectively reduced, the cleaning and drying speed is high, a cooling structure is further arranged, non-woven fabric can be rapidly cooled,and non-woven fabric deformation caused by high temperature is prevented.

Owner:黄桂荣

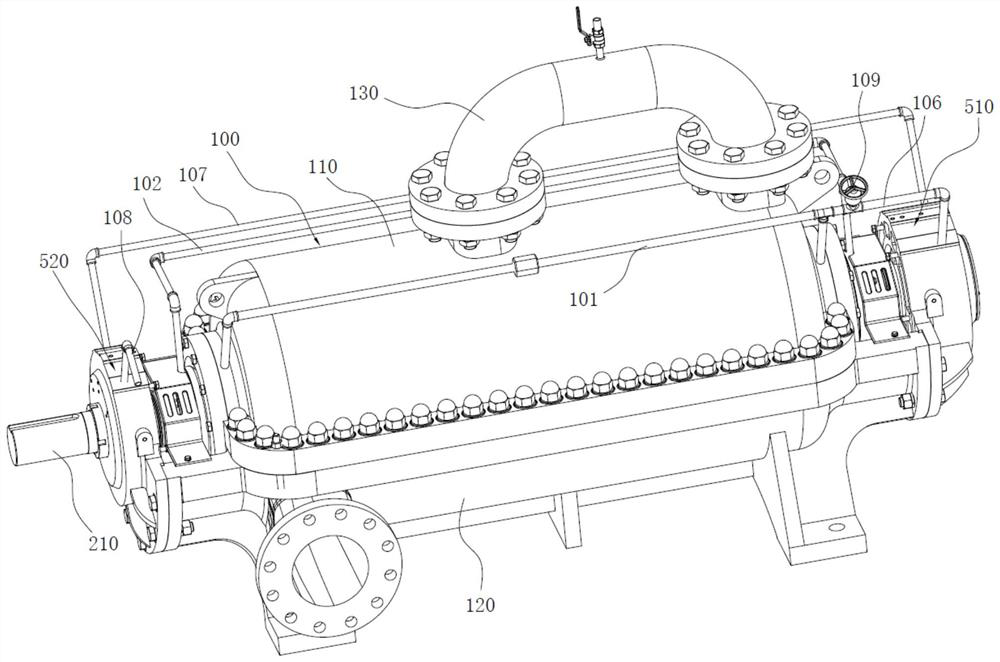

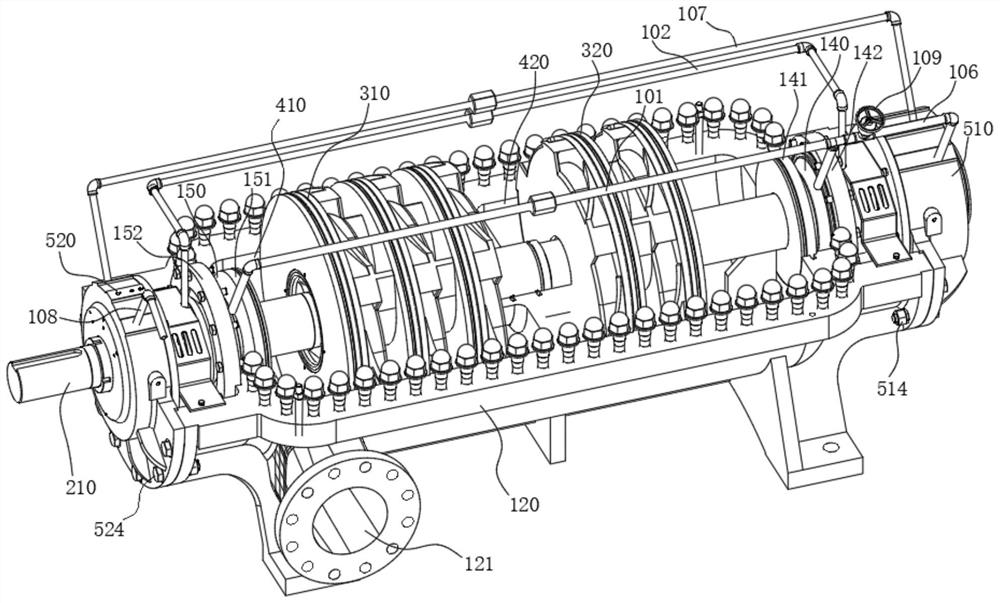

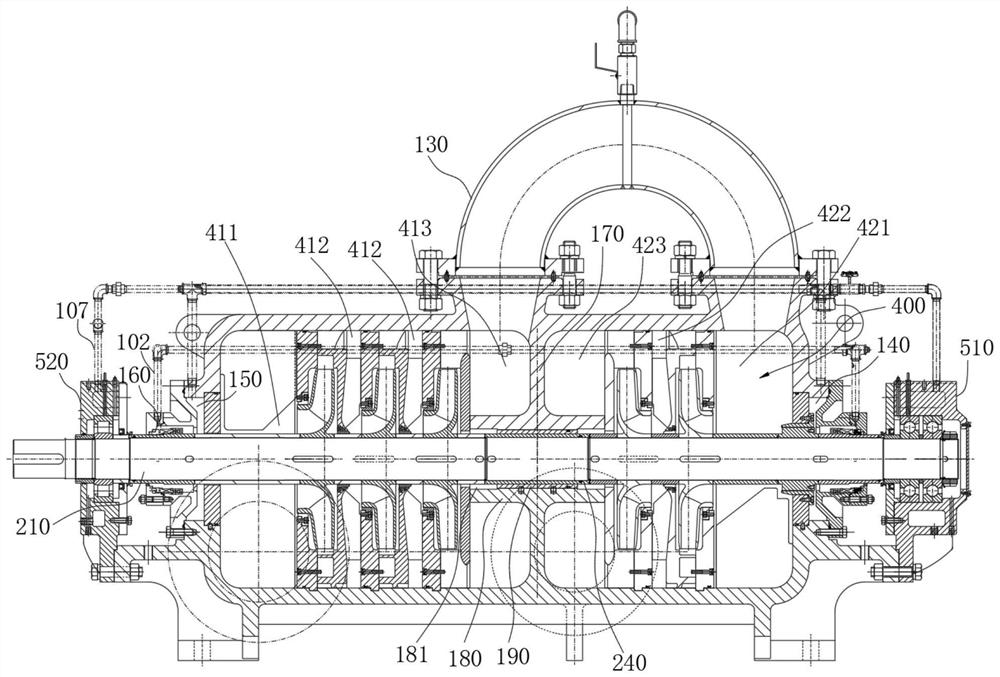

Self-balancing multi-stage axially split pump equipment

PendingCN114483593AReduce risk of frictionExtended service lifePump componentsRadial flow pumpsPhysicsImpeller

The invention discloses self-balancing multi-stage axially split pump equipment which comprises a pump shell body, a pump shaft, a forward guide vane assembly and a reverse guide vane assembly, a supporting plate is arranged in the pump shell body and divides a pump cavity into a first cavity and a second cavity, a first baffle is arranged in the first cavity of the pump shell body, and a second baffle is arranged in the second cavity of the pump shell body. A second baffle is arranged in the pump shell body and the second cavity, a limiting block is arranged on the upper shell, the first baffle is arranged close to one forward guide vane assembly, and the limiting block is arranged close to one reverse guide vane assembly. The first baffle is arranged in the pump shell body to limit the forward guide vane assembly located in the first cavity, and the second baffle is arranged in a matched mode to reduce energy loss in the liquid conveying process; and then the limiting block is used for limiting the reverse guide vane assembly, so that deformation of the guide vane assembly caused by acting force applied to the guide vane assembly when the liquid flows in the pump cavity is avoided, the friction risk between the impeller and the guide vane assembly is reduced, and the service life of a product is prolonged.

Owner:HUNAN CREDO PUMP

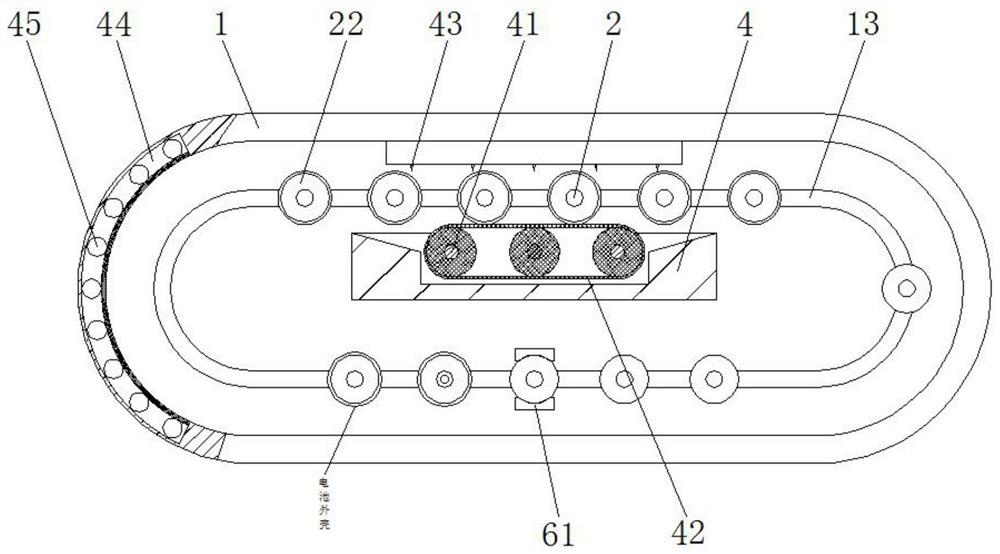

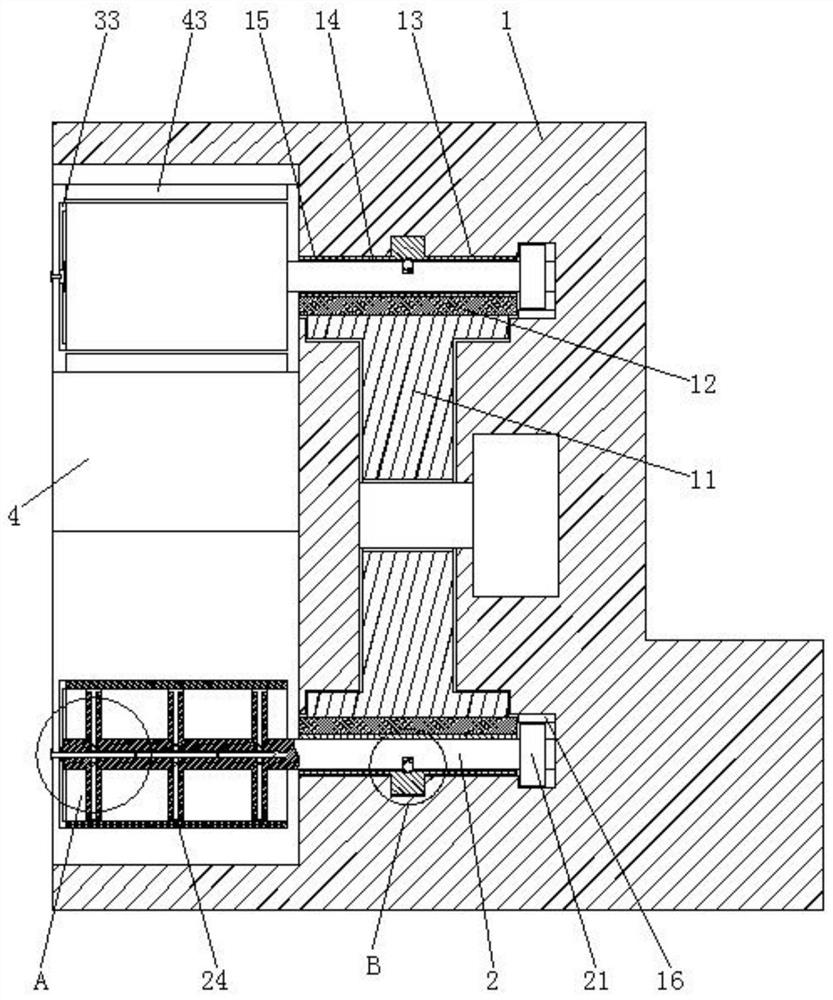

Battery case surface protection treatment process

InactiveCN111940245ACause deformationImprove yield ratePretreated surfacesCoatingsStructural engineeringMechanical engineering

The invention relates to the field of battery processing, and particularly relates to a battery case surface protection treatment process. The battery case surface protection treatment process uses abattery case treatment device, the battery case treatment device comprises a base and fixing frames, transmission gears are symmetrically arranged in the base, a conveying belt is arranged between thetransmission gears, a conveying groove with an annular structure is formed in the base, the conveying groove and the conveying belt are symmetrically arranged and communicate, a plurality of socketsare symmetrically and fixedly installed on the side, away from the transmission gears, of the conveying belt, through grooves are formed in the sockets, the plurality of fixing frames are inserted into the through grooves, a rotating gear is fixedly installed at one end of each fixing frame, and racks are fixedly installed in the conveying groove. the rotating gears and the racks are symmetricallyarranged, the ends, away from the rotating gears, of the fixing frames extend out of the conveying groove and are fixedly provided with a plurality of supporting plates with circular structures. Thebattery case surface protection treatment process can coat multiple battery cases at the same time, and is suitable for popularization.

Owner:合肥集知匠心科技发展有限公司

Tapping embroidery device and taping embroidery feeding control method

ActiveCN113584748ASimple installation structureCause deformationAutomatic machinesControl engineeringElectrical and Electronics engineering

The invention discloses a taping embroidery device and a taping embroidery feeding control method, and belongs to the technical field of embroidery machines. The taping embroidery device comprises a machine shell, a presser foot part, a tray part and a rotary driving mechanism; the presser foot sleeve vertically penetrates through the machine shell, a fixing sleeve and a shaft sleeve sequentially sleeve the presser foot sleeve, and the fixing sleeve is fixed to the machine shell; the rotary driving mechanism drives a tray rack to rotate; the taping embroidery device further comprises a feeding frame and a feeding lifting driving mechanism; a feeding sleeve sleeves the shaft sleeve, and the feeding frame is installed on the feeding sleeve; the feeding lifting driving mechanism is used for driving the feeding frame to ascend or descend in the vertical direction or swing transversely; and the rotary driving mechanism is used for driving the feeding frame to rotate. The taping embroidery feeding control method is realized based on the taping embroidery device, and comprises the following steps that firstly a machine needle is controlled to move to lock a rope or a belt, then the feeding frame is controlled to lift, then the machine needle is controlled to pull out, a tabouret is controlled to move, the feeding frame is controlled to descend, and the machine needle is controlled to move again until the taping embroidery operation is finished. According to the taping embroidery device and the taping embroidery feeding control method, the problem of poor embroidery caused by pulling deformation of the embroidery is solved.

Owner:浙江镨美科智能刺绣设备有限公司

Cloth drying device for novel textile machine

ActiveCN113587610AEasy to hold and transferQuality improvementDrying chambers/containersDrying machines with progressive movementsProcess engineeringTextile

The invention relates to the technical field of cloth drying, in particular to a cloth drying device for a novel textile machine. The cloth drying device comprises a conveying mechanism, two symmetrical guide mechanisms are mounted in the conveying mechanism, a driving mechanism is mounted on the conveying mechanism, and a drying mechanism is connected in the conveying mechanism; two sliding mechanisms are arranged on the conveying mechanism; cloth with different thicknesses can be conveniently conveyed and flattened through power transmission of the driving mechanism to the conveying mechanism, the cloth in the conveying process can be guided and supported under the action of the guide mechanisms, the cloth is made to have flexibility, and pulling damage is prevented; and the cloth in the conveying process can be dried under the action of the drying mechanism, fine adjustment is facilitated, the drying efficiency is improved, and the sliding mechanisms can work under the action of the driving mechanism, so that the drying mechanism repeatedly moves back and forth in the conveying mechanism, and the drying efficiency is improved.

Owner:响水县嘉亿纺织有限公司

Food paper-plastic packaging box manufacturing and forming mold

InactiveCN111676738AImprove production and processing efficiencyAvoid deformationCleaning using toolsTextiles and paperPlastic packagingElectric machine

The invention relates to the field of food packaging, and in particular, relates to a food paper-plastic packaging box manufacturing mold comprising a fixed base; a fixed frame is fixedly connected tothe fixed base; the fixed frame is of a cylindrical hollow structure, and one end of the fixed frame is fixedly connected with an edge groove; an arc-shaped inner groove is formed in the side groove;a rotating motor is fixedly connected to the fixed base; the output end of the rotating motor is fixedly connected with a first gear; a first sliding groove, a second sliding groove and a third sliding groove are symmetrically formed in the fixed base; a first support is slidably connected into the first sliding groove, the top of the first support is fixedly connected with a bottom groove of a concave structure, the bottom groove is inserted into the fixed frame, a movable frame is fixedly connected into the bottom groove, a tooth groove is formed in the movable frame, the tooth groove and the first gear are symmetrically arranged and engaged, and one end of the movable frame is inserted into the second sliding groove. The production efficiency of a paper-plastic packaging box can be improved, meanwhile, the yield of the paper-plastic packaging box is guaranteed, and the paper-plastic packaging box manufacturing mold is suitable for popularization.

Owner:合肥德胜包装材料有限公司

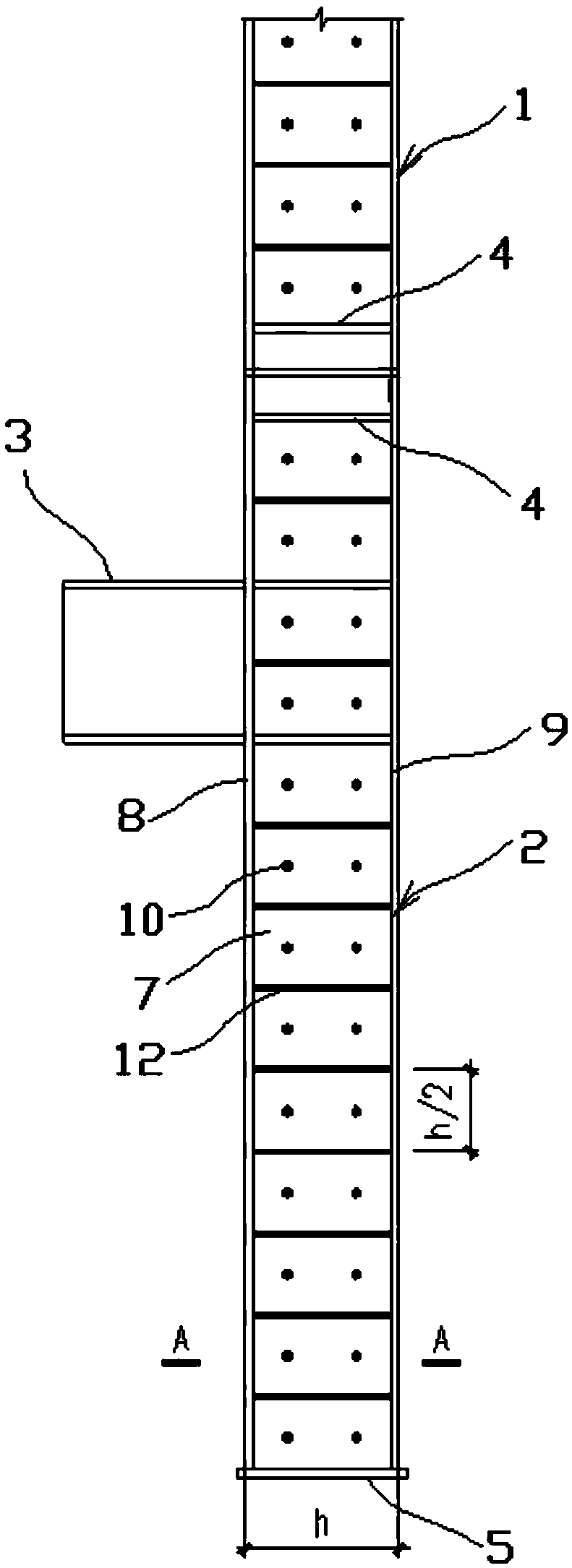

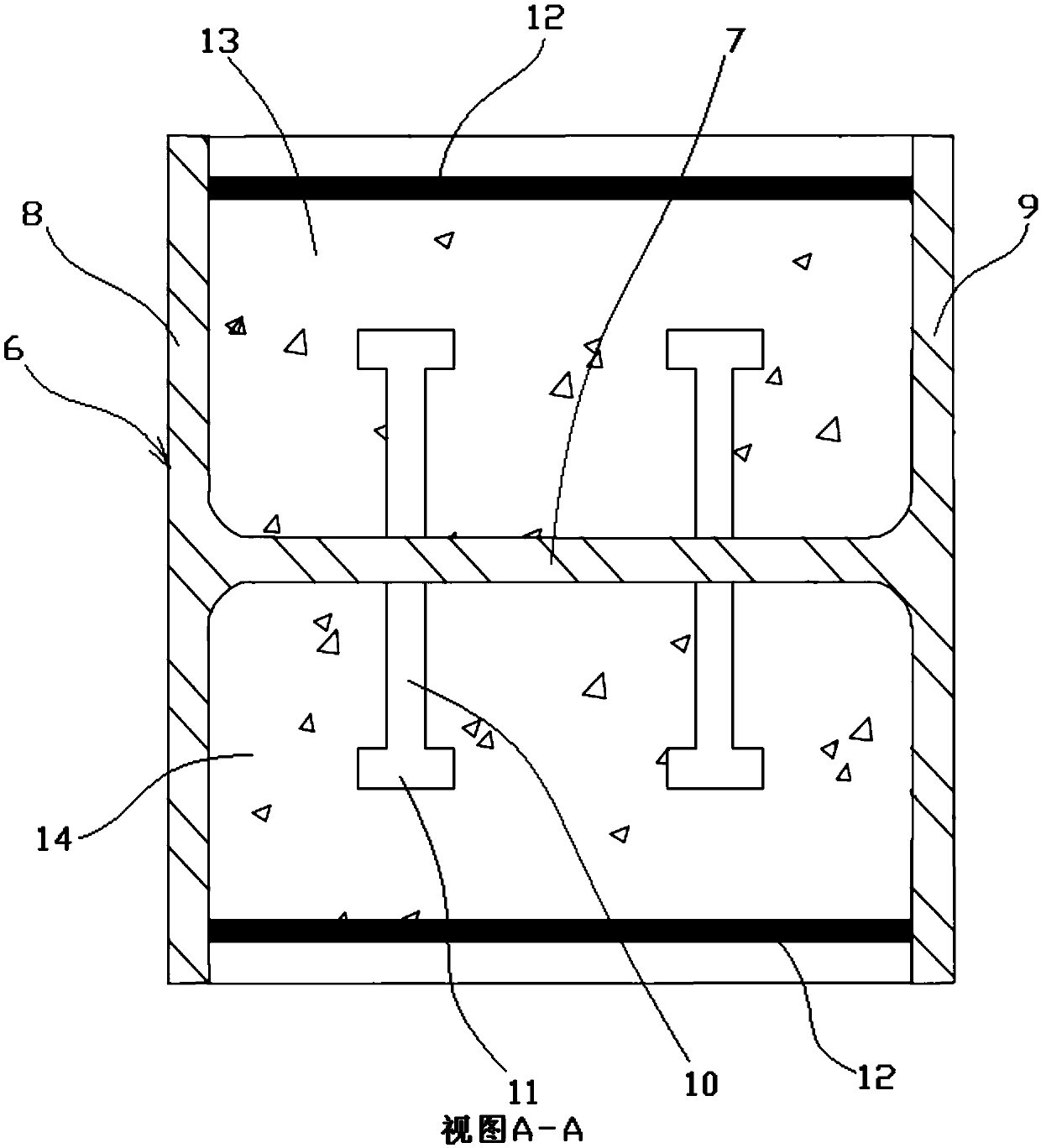

Prefabricated supporting column based on H-shaped steel and construction method of prefabricated supporting column

PendingCN109555268AAvoid deformationCause deformationStrutsPillarsEngineeringUltimate tensile strength

The invention relates to a prefabricated supporting column based on H-shaped steel and a construction method of the prefabricated supporting column. A first structural piece and a second structural piece are arranged in a first U-shaped space and a second U-shaped space of the H-shaped steel, concrete is further poured into the first U-shaped space and the second U-shaped space, the first structural piece and the second structural piece are both embedded into the concrete, thus the concrete can be firmly combined with the first structural piece and the second structural piece together, thus the bearing capacity of the H-shaped steel supporting column is enhanced substantially, the second structural piece is connected between a first wing plate and a second wing plate, and deformation of the H-shaped steel due to concrete expansion can be prevented. When the prefabricated supporting column based on the H-shaped steel is constructed, the prefabricated supporting column can be prefabricated in a factory and then overall transported to a construction site to be assembled. Thus it can be seen that the prefabricated supporting column based on the H-shaped steel is high in strength and stiffness, and fabricated construction is easy.

Owner:上海电气电站环保工程有限公司

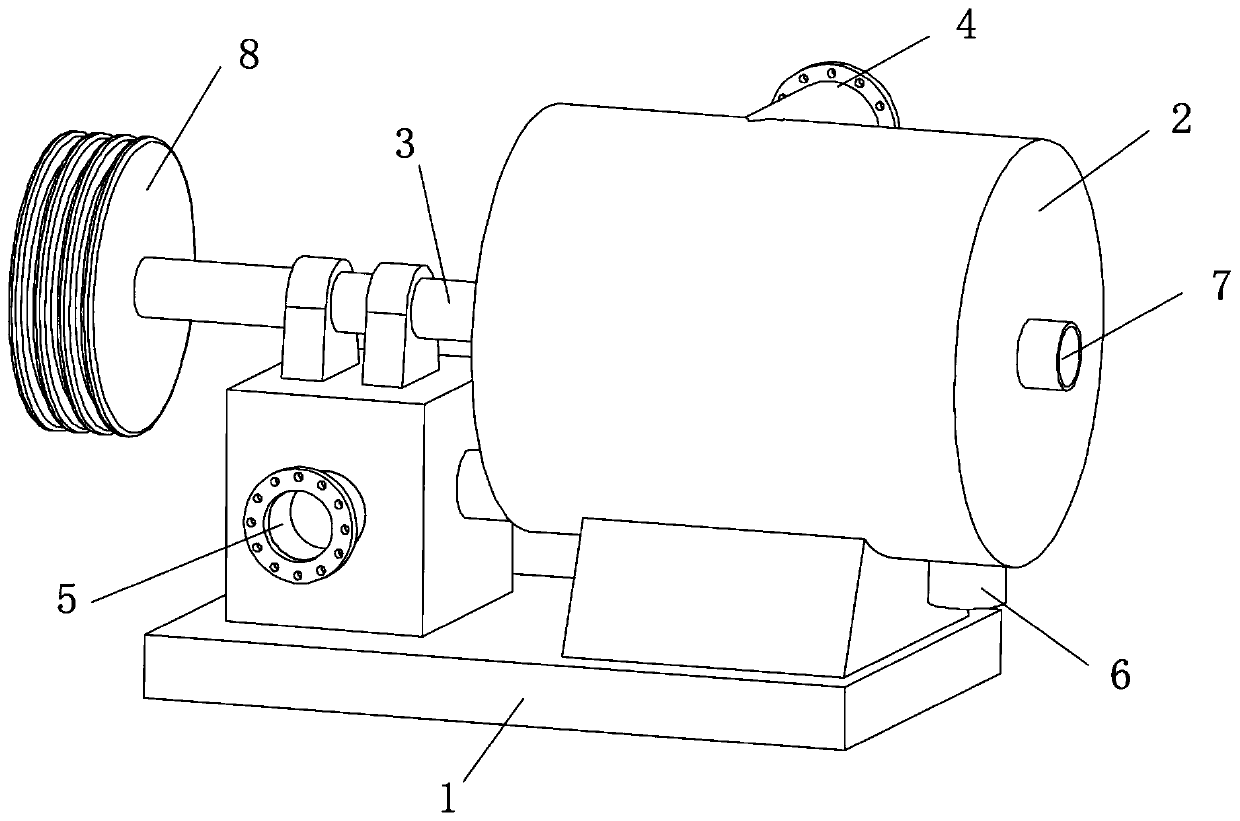

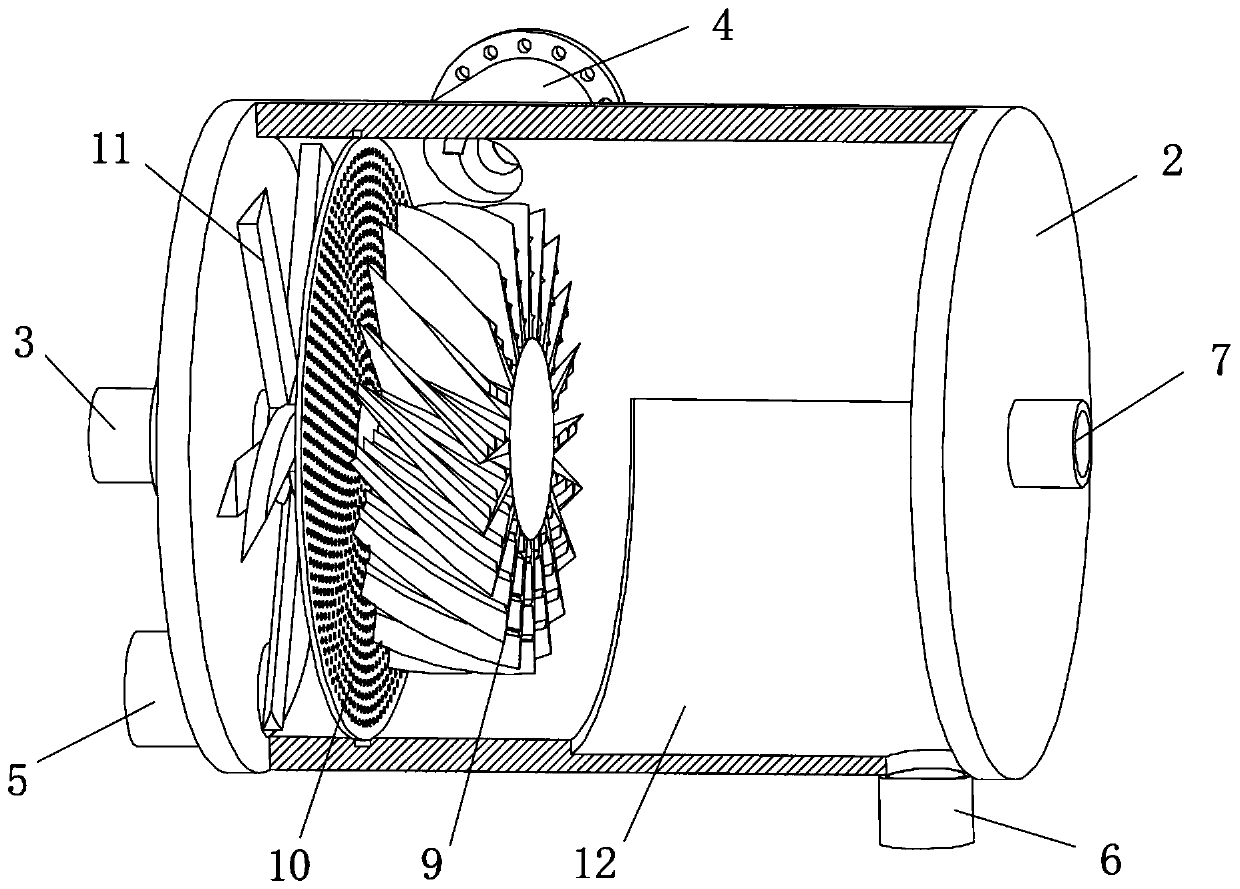

Fiber separator

ActiveCN111074659AGood separation effectImprove impact performancePaper recyclingRaw material divisionFiberImpeller

The invention relates to the technical field of papermaking, and discloses a fiber separator. The fiber separator includes a base, wherein a tank body is fixedly mounted on the front of the top of thebase; a rotating shaft is fixedly mounted in the middle of the back surface of the tank body and extends into the tank body; a slurry inlet is tangentially formed in the top of the tank body; a slurry outlet is formed in the bottom of the back of the tank body; a heavy impurity outlet is formed in the bottom of the tank body; a light impurity outlet is formed in the center of the front surface ofthe tank body; a belt wheel is fixedly installed at the end of the rotating shaft; the end, located in the tank body, of the rotating shaft is movably sleeved with an impeller; a sieve plate structure is movably installed at the position, located on the back surface of the impeller and in the tank body, of the rotating shaft; and a shearing device is arranged at the position, between the sieve plate structure and the back surface in the tank body, of the rotating shaft. According to the fiber separator, by improving the structures of the impeller and the sieve plate, the effect of defiberingand separating waste paper pulp is improved, and the service lifetime of the sieve plate is prolonged.

Owner:山东建丰纸业有限公司

Banknote pre-wrapping and plastic sealing mechanism and its control method

InactiveCN104670552BCompact structureReduce volumePaper article packagingWrappingPlastic packagingPaper tape

The invention discloses a banknote pre-enveloping and plastic-packaging mechanism and a control method thereof. The mechanism comprises a thermoplastic mechanism and a positioning mechanism, wherein the positioning mechanism comprises a pressing plate, a spring, a bearing plate and an edge folding device; the edge folding device is arranged on the periphery of the bearing plate; a piece of plastic-packaging film and a piece of paper tape film in preset length are arranged on the bearing plate, and the paper tape film is arranged on the plastic-packaging film; bundled banknotes are arranged on the paper tape film; the bundled banknotes and the bearing plate are pressed to a specified position by the pressing plate; the film is then cut off by a film cutting mechanism; the edge folding device is used for folding the plastic-packaging film and the paper tape film; the main body of the thermoplastic mechanism is arranged above the bearing plate; thermo-sealing pressing plates of the thermoplastic mechanism are arranged on the upper side and both sides of the bearing plate; when the paper tape film is folded, the thermo-sealing pressing plate in the corresponding direction carries out plastic sealing on the paper tape film; when the plastic-packaging film is folded, the thermo-sealing pressing plate in the corresponding direction carries out plastic sealing on the plastic-packaging film. The banknote pre-enveloping and plastic-packing mechanism and the control method thereof realize the effect that paper tape pre-enveloping and plastic packaging of the plastic-packaging film are carried out in one station; the structure is small, and the maintenance is convenient.

Owner:GUANGDONG DESOUL INTELLIGENT TECH CO LTD

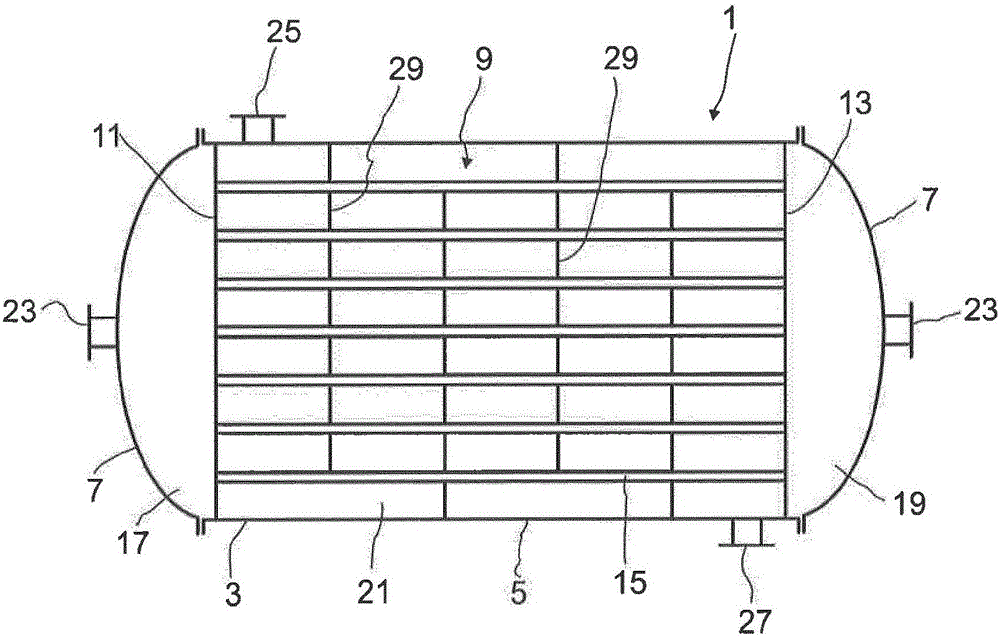

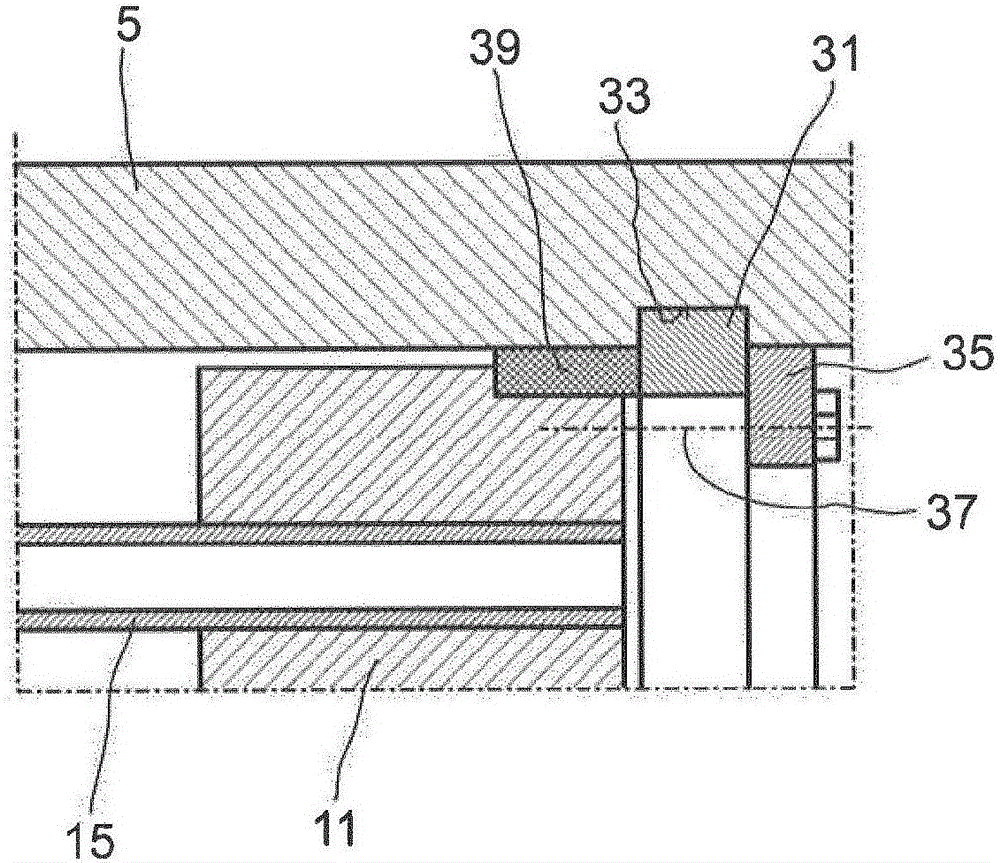

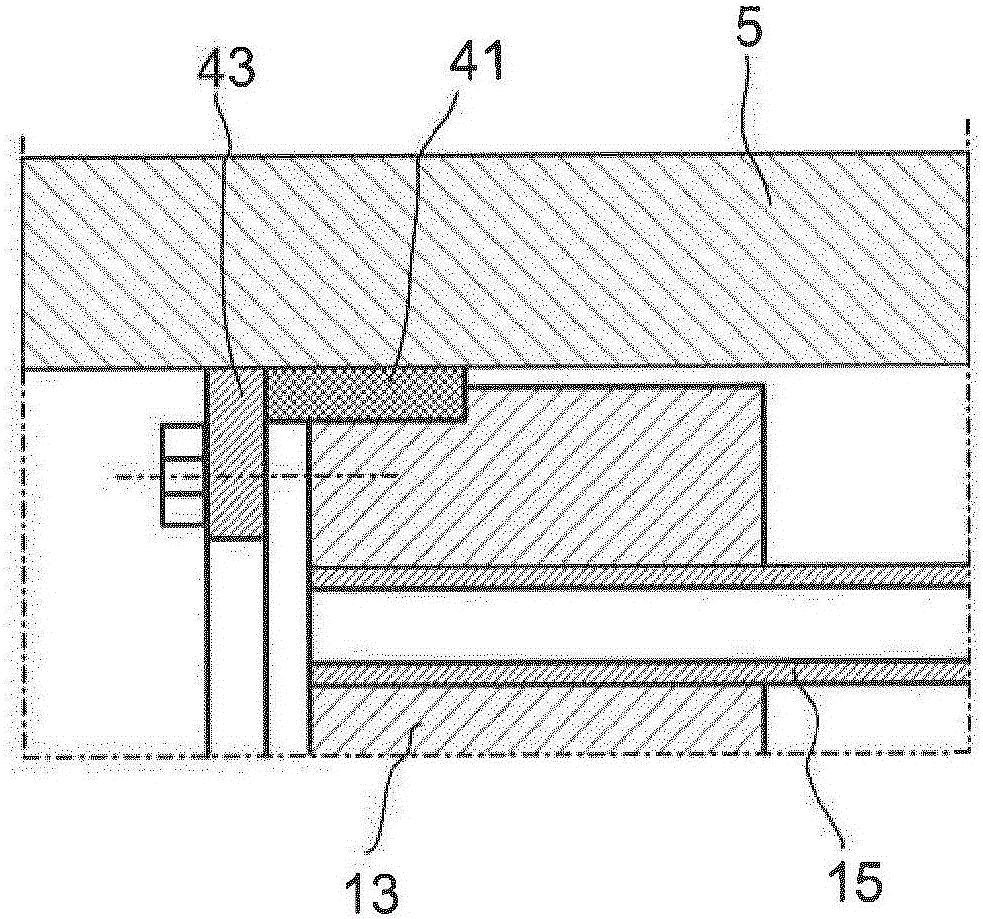

Tube bundle device and use thereof

ActiveCN105121990AHeating fastWon't cause mixingHeat exchanger casingsStationary tubular conduit assembliesEngineering

Owner:BASF SE

Medicine rack for dispensary for western medicine

InactiveCN108113252ACause deformationImplement partitionChestsDressing tablesWestern medicineMedicine

The invention discloses a medicine rack for a dispensary for western medicine. The medicine rack comprises a cabinet body, a support is cooperatively arranged on the upper portion of the cabinet body,screws are cooperatively arranged between the support and the cabinet body, multiple support rods are symmetrically arranged on the left and the right of the inner side of the support, medicine racksupport plates are cooperatively arranged between every two symmetrically arranged support rods, the support rods are each shaped like an inverted V, the medicine rack support plate is matched with the support rods, the medicine rack support plates form two inclined planes used for guiding out the medicine, the front side faces and the rear side faces of the medicine rack support plates are all bent upwards to form flange parts, connecting plates are arranged at the bottoms of the support rods, first screws are cooperatively arranged between the connecting plates and the support, division plates are cooperatively arranged between the flange parts on the two sides, and slots used for allowing the division plates to be inserted are formed in the tops of the flange parts. Accordingly, the space can be divided flexibly, the space utilization rate is increased, and meanwhile the structure is simple, and convenience is brought to disassembling and assembling.

Owner:陈为娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com