Automatic assembling mechanism of elastic clamping ring

An elastic snap ring and automatic assembly technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems affecting assembly quality, low efficiency, elastic snap ring deformation, etc., to improve assembly efficiency and quality, and automation The effect of high height and compact overall structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

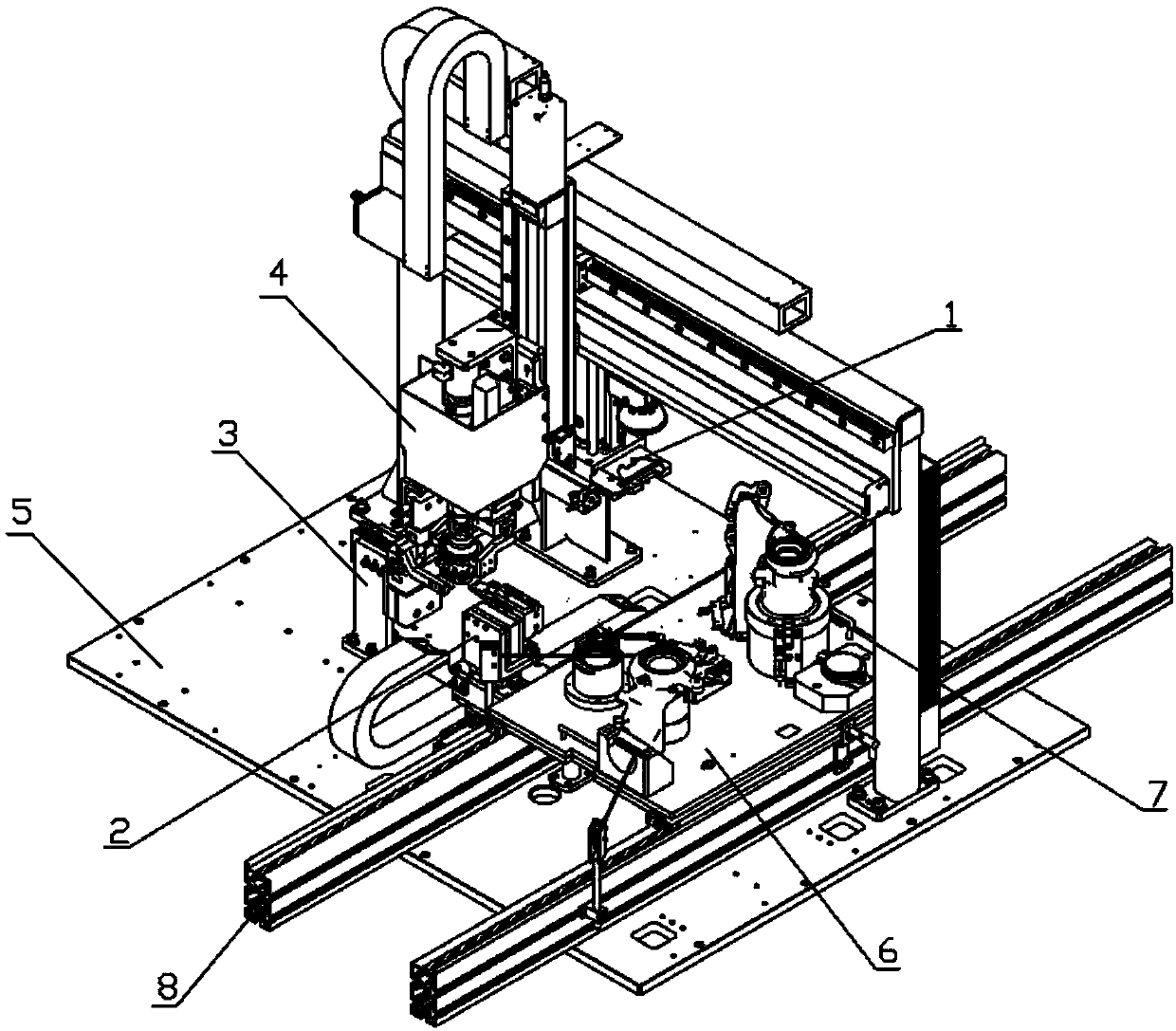

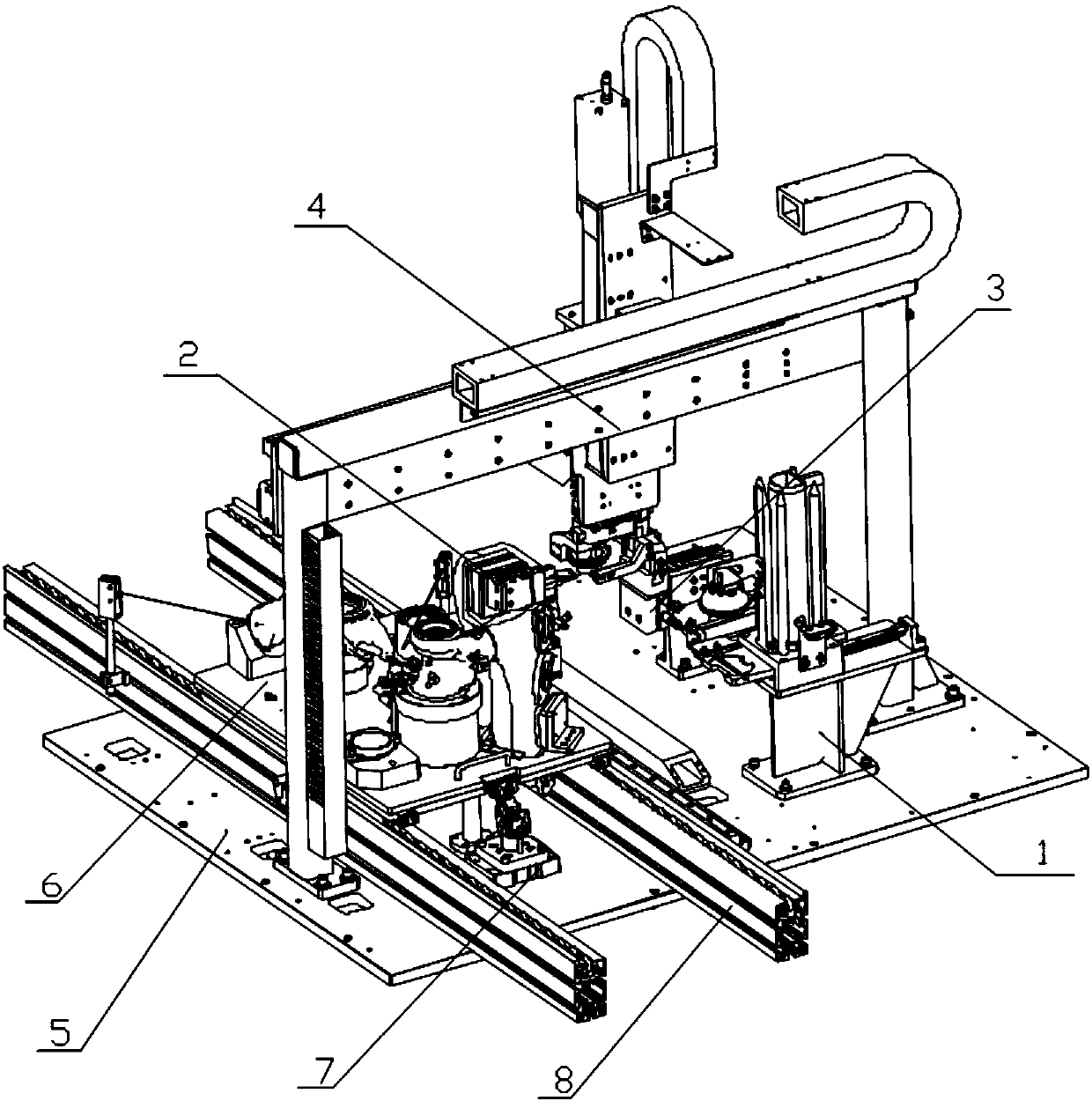

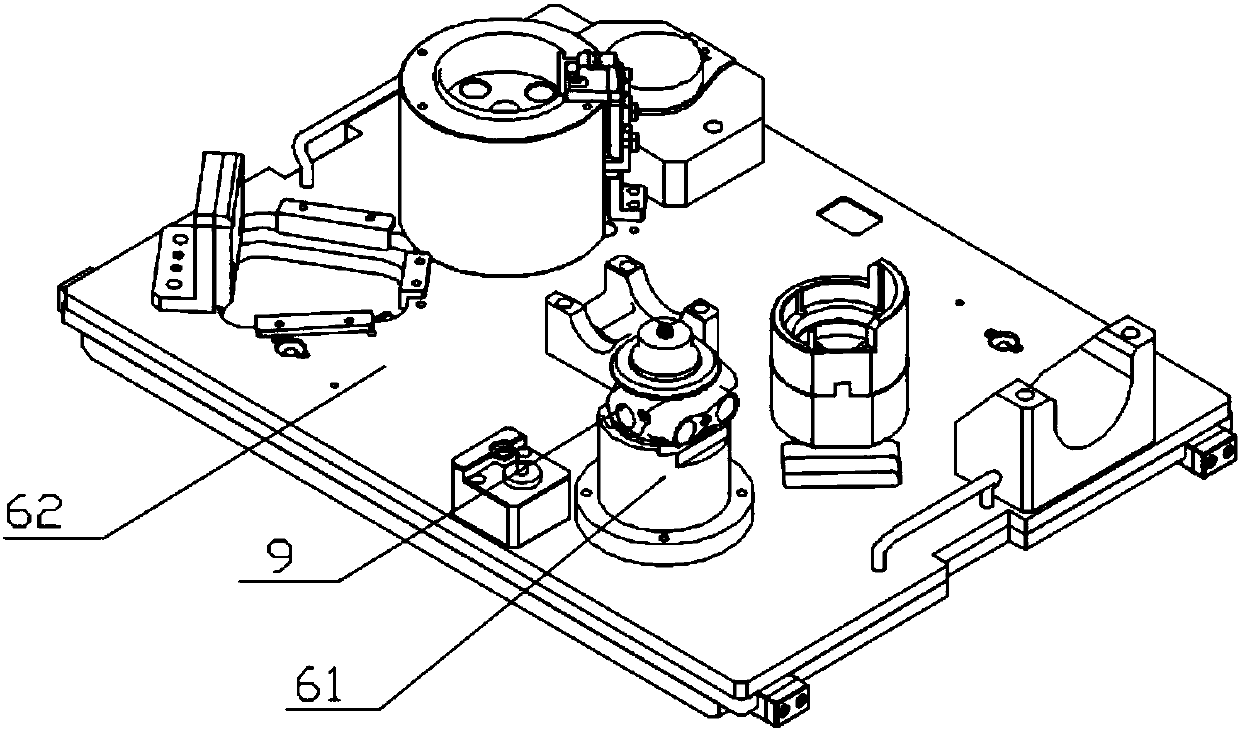

[0029] Such as Figure 1-9 As shown, the present invention includes a snap ring feeding mechanism 1, a snap ring clamping and transferring mechanism 2, a snap ring spreading mechanism 3 and a manipulator mechanism 4, wherein the snap ring feeding mechanism 1 is provided with a movable snap ring feeding mechanism Plate 13, the snap ring clamping and transferring mechanism 2 is provided with movable and rotatable clamping jaws 24, and the snap ring spreading mechanism 3 is arranged at the assembly position and is provided with movable stretching positioning jaws 33 , the manipulator mechanism 4 is provided with an auxiliary press-fit mechanism 46 and a movable jaw assembly 47, the elastic snap ring 10 to be assembled is approximately ring-shaped with one side opening, and the elastic snap ring 10 passes through the snap ring during assembly. The material plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com