Vehicle-mounted drier

A dryer and vehicle-mounted technology, applied in dryers, drying, grain drying, etc., can solve the problems of inability to dry grains, dry wet grains, and mildew of grains, avoid breakage, and enhance durability. , the effect of increasing the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

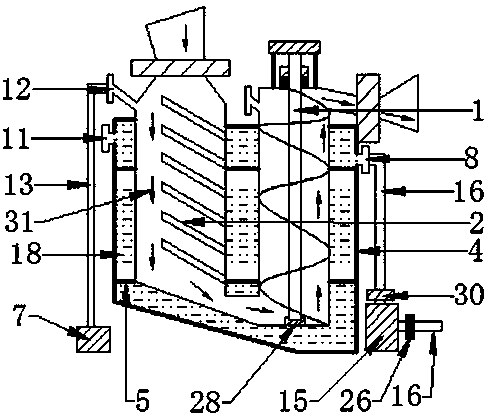

[0124] Such as figure 1 The vehicle-mounted dryer type A shown includes an auger hoist (1), a drying bin (2), a heating bin (4), a bracket (5), a vacuum unit (7), a heating device (15), Air duct (13), heat pipe (16), heat circulation pump (30).

[0125] The type A vehicle-mounted dryer is fixedly connected to the grain harvester.

[0126] The drying bin (2), the auger hoist (1) is installed in the bin of the heating bin (4).

[0127] The heating chamber (4) includes a chamber body (20) and a heat conducting medium (18).

[0128] The material of the chamber body (20) of the heating chamber (4) is a 3mm metal plate.

[0129] 1. The cross-sectional shape of the heating chamber (4) is rectangular.

[0130] 2. There is a thermal energy inlet (11) at the upper end of the heating chamber (4), and a thermal energy outlet (8) at the lower end of the heating chamber (4).

[0131] 3. A bracket (5) is installed outside the heating bin (4); the heating bin (4) is fixedly connected to ...

Embodiment 2

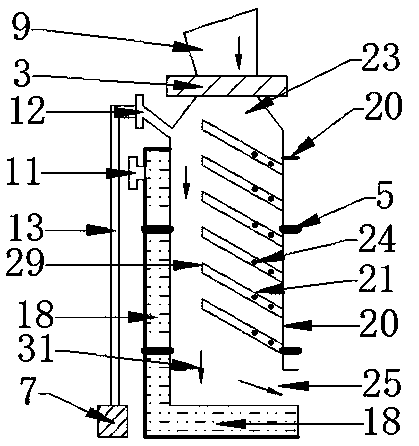

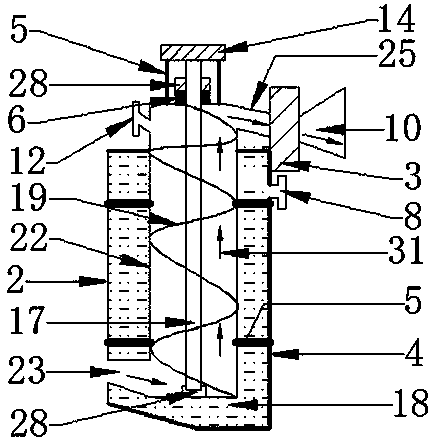

[0221] Such as Figure 4 , Figure 5 The vehicle-mounted dryer type B shown includes an auger hoist (1), a drying chamber (2), a heating chamber (4), a bracket (5), a vacuum unit (7), a heating device (15), and an air duct (13), heat pipe (16), heat circulation pump (30).

[0222] The combination structure of the vehicle-mounted dryer type B introduced in Embodiment 2 and the vehicle-mounted dryer type A introduced in Embodiment 1 will not be repeated in Embodiment 2.

[0223] The type B vehicle-mounted dryer is fixedly connected to the grain harvester.

[0224]The drying bin (2), the auger hoist (1) is installed in the bin of the heating bin (4).

[0225] The heat outlet (8) at the upper end of the heating chamber (4).

[0226] Such as Figure 4 , Figure 5 The shown drying bin (2) includes a bin body (20), a support (5), a heat exchange device (21), a discharge valve (3), and a feed hopper (9).

[0227] The heat exchange device (21) is a heat pipe heat exchanger.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com