Net belt dryer with double heating plates

A double-layer heating and drying technology, applied in dryers, heating devices, drying solid materials, etc., can solve the problems of low heat conversion efficiency, uneven drying moisture, and dead corners in materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with accompanying drawing:

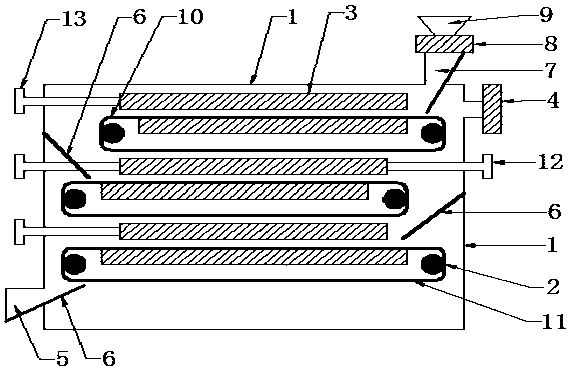

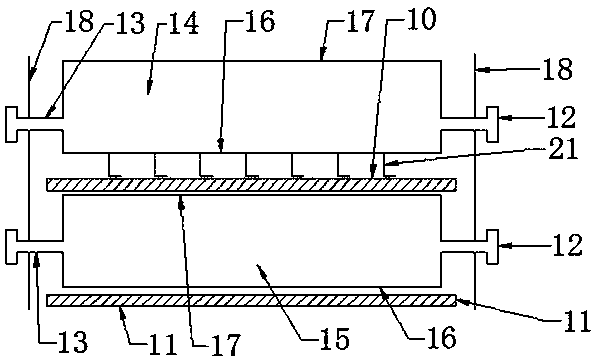

[0071] Such as figure 1 , figure 2 The mesh belt dryer with double-layer heating plate shown includes a drying bin 1, a mesh belt conveyor 2, a heating device 3, an exhaust device 4, a discharge valve 8, a feed hopper 9, a stirring plate 21, a guide Sheet 6.

[0072] The drying bin 1 is a cylindrical drying bin 1 .

[0073] The drying bin 1 has a feed inlet 7, a discharge outlet 5, and an exhaust port.

[0074] The exhaust device 4 is fixedly connected to the exhaust port of the drying chamber 1 .

[0075] The exhaust device 4 is an axial flow fan.

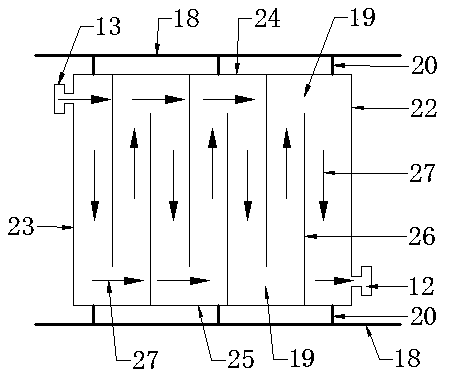

[0076] The air outside the drying bin 1 is affected by the suction of the exhaust device 4, and the air outside the drying bin 1 enters the drying bin 1 from the discharge port 5 of the drying bin 1; the air carries the air in the drying bin 1. The moisture generated when the material is dried is exhausted out of the dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com