Drum Vacuum Dryer

A vacuum dryer and drum type technology, which is applied in the direction of non-progressive dryers, dryers, drying chambers/containers, etc., to achieve the effects of not being easy to agglomerate, accelerating heat transfer, and increasing heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

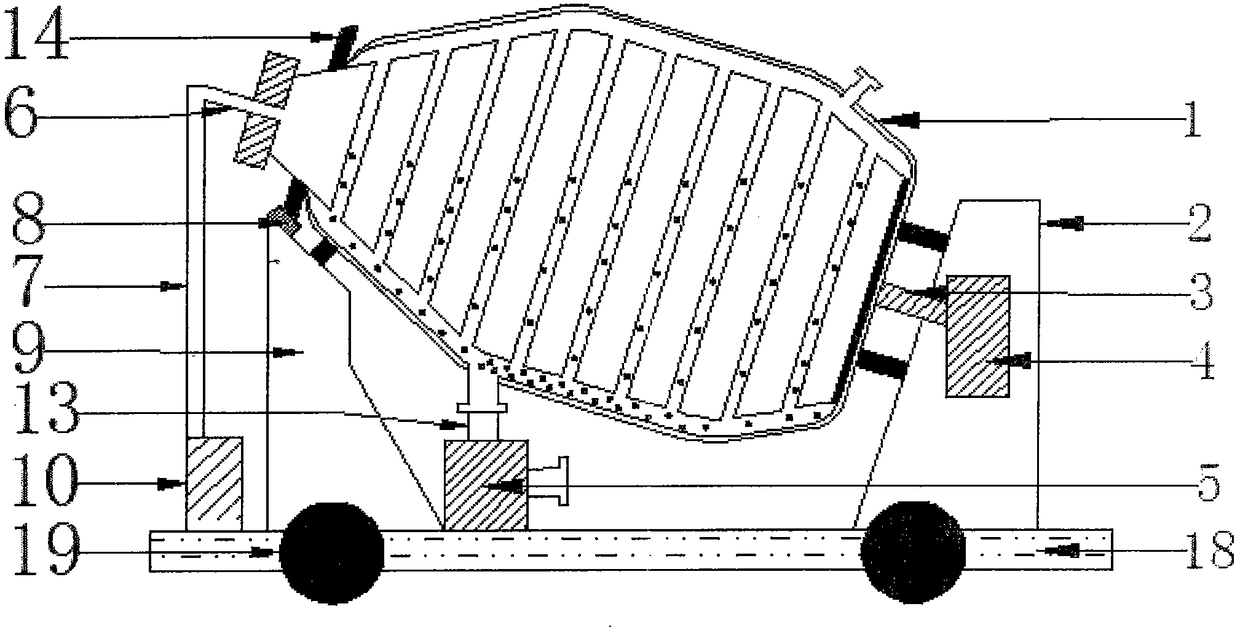

[0051] Such as figure 1 The drum-type vacuum dryer shown is composed of a heating heat exchange device (1), a rear bracket (2), a vacuum unit (10), a heating device (5), a driving device (4), an air duct (7), a roller Road (14), front support (9), chassis (18), wheels (19), conduit (13) and supporting wheel (8).

[0052] Described chassis (18) is metal base.

[0053] Wheels (19) can be arranged below the described chassis (18).

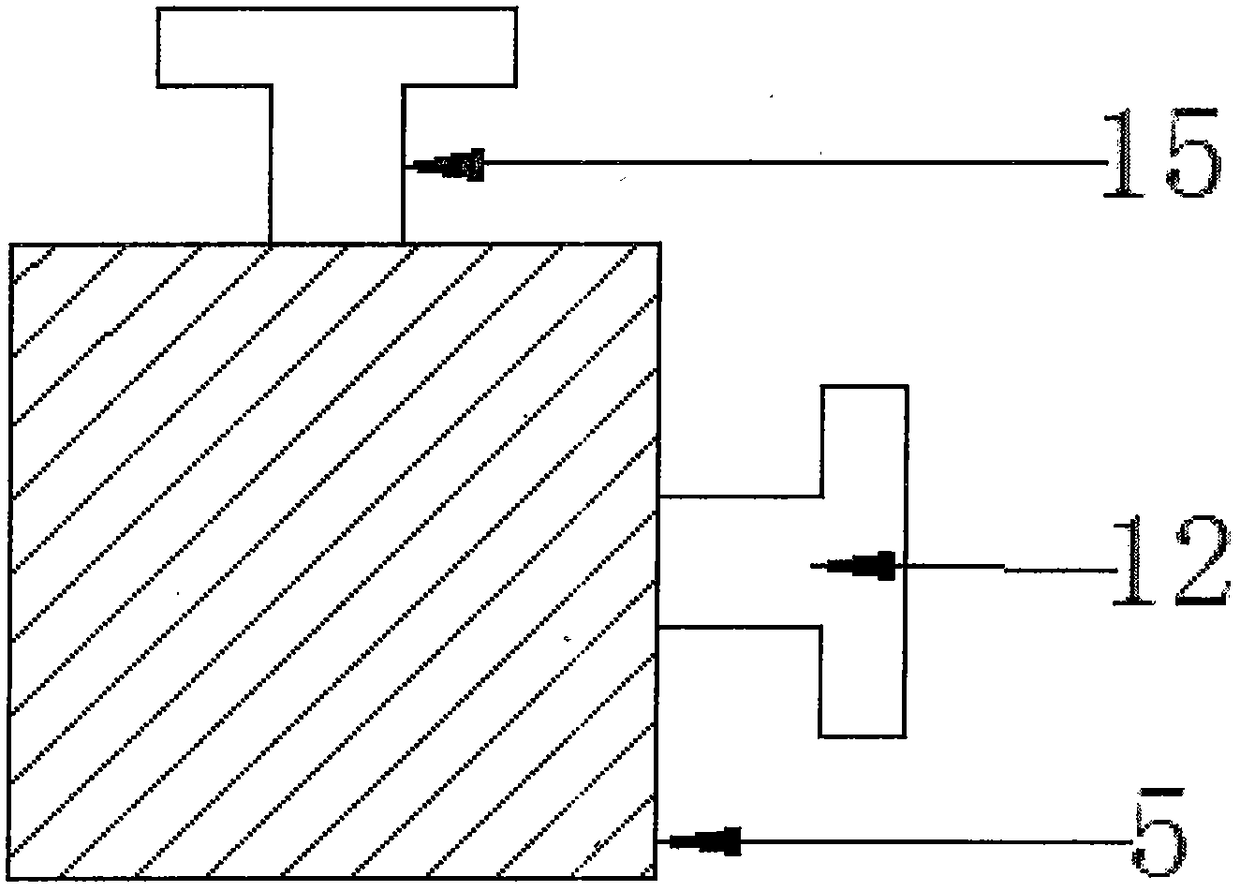

[0054] The front support (9), rear support (2), vacuum unit (10) and heating device (5) are fixedly installed on the chassis (18).

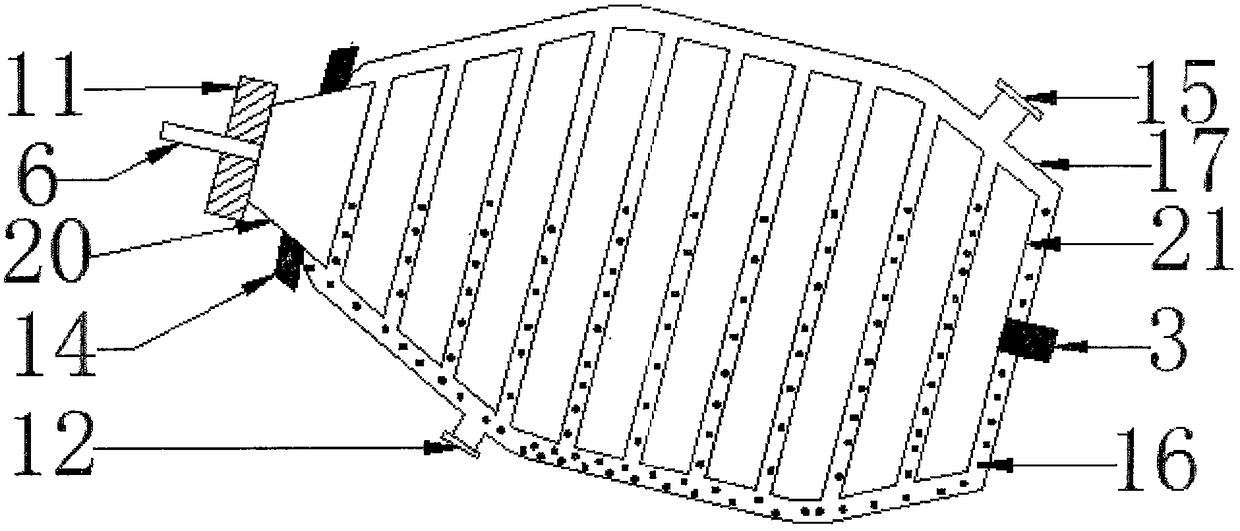

[0055] Such as figure 2 The shown heating heat exchange device (1) is a patent applied by myself.

[0056] The heating and heat exchange device (1) is composed of an outer shell (17), an inner chamber (21) and a heat-conducting working medium (16).

[0057] Such as figure 1 , figure 2 The shell (17) of the shown heating and heat exchange device (1) is fixed on the rear support (2) and the front support (9); the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com