Heat pipe heating type disc dryer

A disc dryer and heating technology, applied in the direction of heating devices, drying solid materials, dry cargo handling, etc., can solve the problems affecting the dryer, insufficient effective heating area of the heating plate, and speed up the moving speed of materials, etc., to ensure smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

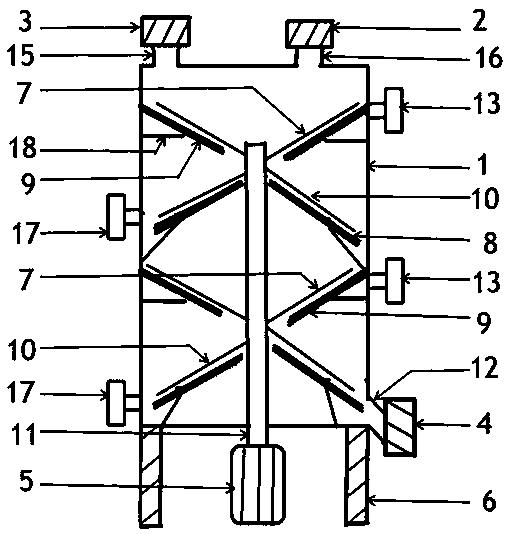

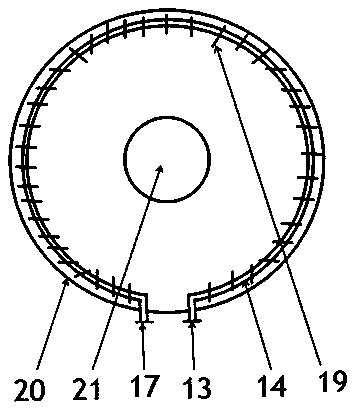

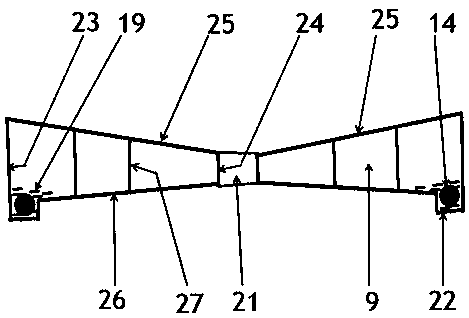

[0108] Such as figure 1 , figure 2 , image 3 , Image 6 A heat pipe heating type disc dryer is shown, including a drying chamber 1, an exhaust device 2, a feeding device 3, an unloading device 4, a variable speed motor 5, a support frame 18, a small heating plate 8, and a large heating plate 9, the lower rake bar 10, the transmission shaft 11, the upper rake bar 7, and the bracket 6.

[0109] The described drying bin 1 is supported and fixed on the ground by a bracket 6 .

[0110] The drying bin 1 includes a material inlet 15, a material outlet 12, an exhaust port 16, and a water outlet.

[0111] The condensed water flowing down from the chamber body in the drying chamber 1 is discharged from the drying chamber 1 through the vacuum drain valve installed on the water outlet.

[0112] The feeding device 3 is installed on the feeding port 15 of the drying bin 1 .

[0113] The feeding device 3 is a highly airtight air-tight device, the material to be dried is transported ...

Embodiment 2

[0195] Such as figure 2 , Figure 5 , Image 6 , Figure 8 , Figure 9 A heat pipe heating type disc dryer is shown, including a drying bin 1, an exhaust device 2, a feeding device 3, a variable speed motor 5, a support frame 18, a small heating plate 8, a large heating plate 9, and a lower rake bar 10, drive shaft 11, upper rake bar 7, bracket 6.

[0196] Such as Figure 9 The structure of the heat-pipe-heated tray dryer shown in Embodiment 2 is the same as the heat-pipe-heated tray dryer introduced in Embodiment 1, and the introduction will not be repeated.

[0197] Such as Figure 9 , Figure 8 When the material drying process of the heat pipe heating type disc dryer shown is a convective drying process: the discharge port 12 of the drying bin 1 is open.

[0198] The air outside the drying bin 1 can enter the inside of the drying bin 1 through the outlet 12 of the drying bin 1 .

[0199] The exhaust device 2 is installed at the exhaust port 16 of the drying chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com