Heating heat exchange device

A technology of heating devices and heating devices, which is applied in the direction of heating devices, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of low heat energy use efficiency, many dead spots for drying materials, and small heat exchange area, so as to increase the heat exchange efficiency. Heat dissipation area, optimization of drying quality, and improvement of heat conduction and heat transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

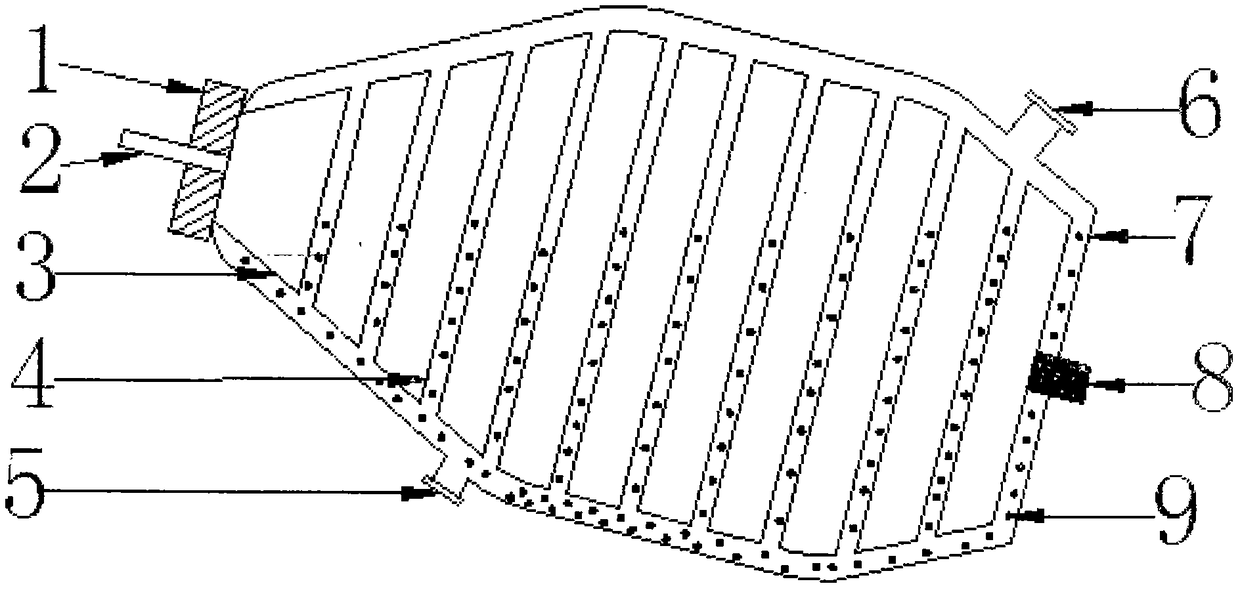

[0050] Such as figure 1 The shown heating and heat exchange device is composed of an outer shell (7), an inner chamber (3) and a heat-conducting working medium (9).

[0051] The exterior shape of the heating and heat exchange device is one end large and the other end small; the appearance shapes of the corresponding outer shell (7) and inner chamber (3) are also one end large and the other end small.

[0052] The material of the shell (7) is a metal plate, and the thickness of the metal plate is 2mm.

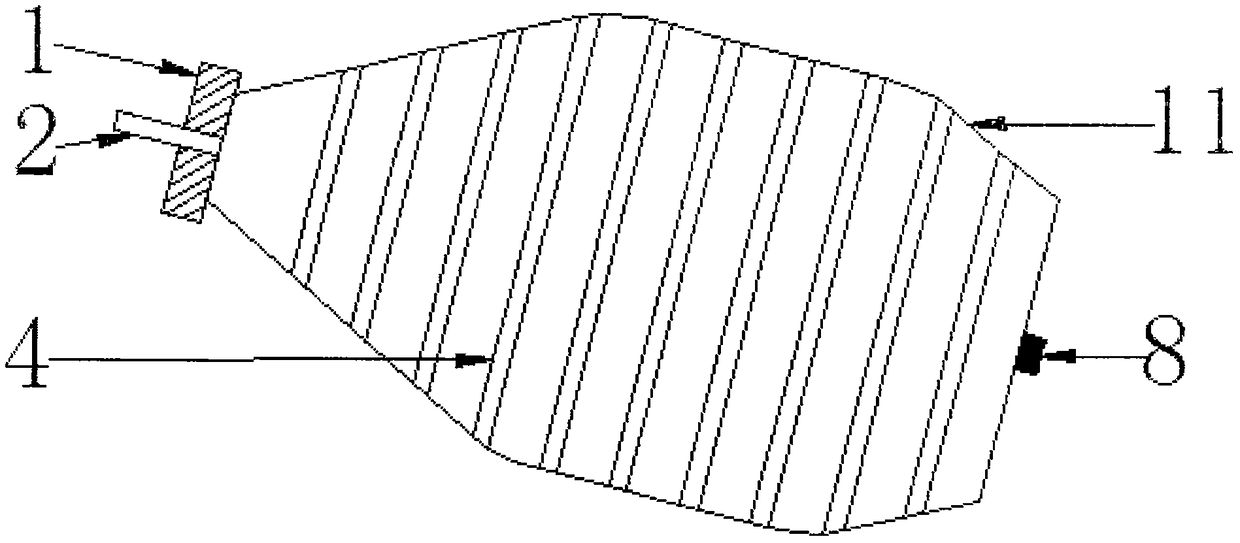

[0053] The warehouse body (11) of the inner warehouse (3) is made of metal plate, and the thickness of the metal plate is 2mm.

[0054] The outer casing (7) is wrapped on the outside of the inner compartment (3).

[0055] 1. The distance between the shell (7) and the inner chamber (3) is 80mm.

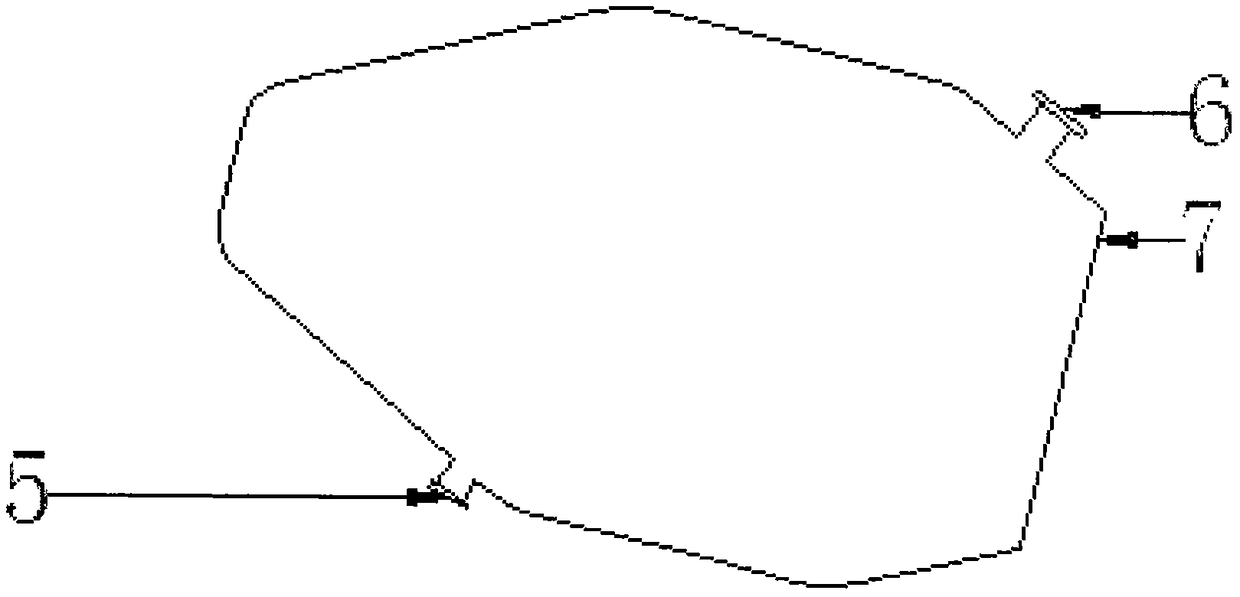

[0056] Such as figure 2 , Figure 4 The shown inner bin (3) is composed of a bin body (11), a cooling standpipe (4), a sealing cover (1), a conduction shaft (8) and a spiral blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com