Vacuum dryer for cereals

A grain vacuum and drying machine technology, which is applied in the direction of drying machines, grain drying, drying, etc., can solve the problems of large vehicle-mounted dryers, lack of equipment for synchronous dryers, and drying of wet grains, etc., to achieve Effects of increasing firmness, increasing heat conduction speed, and reducing air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

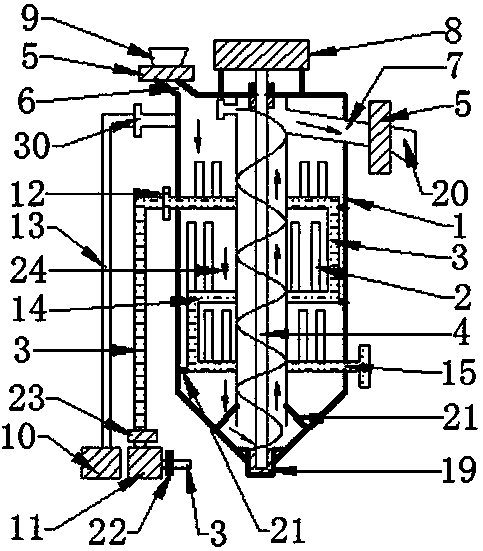

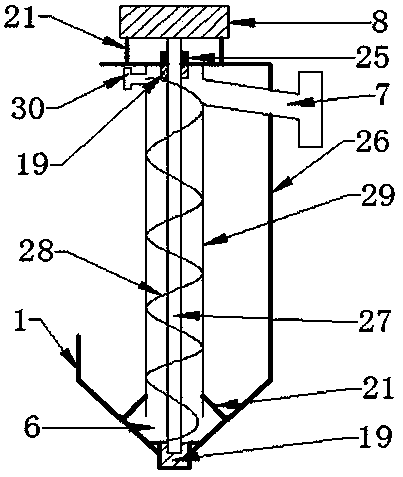

[0151] like figure 1 The grain vacuum dryer shown includes drying chamber (1), heat exchange device (2), heat pipe (3), lifting device (4), discharge valve (8), wet material bin (9), vacuum unit (10), heating device (11), air duct (13), dry feed bin (20), support (21), heat circulation pump (23).

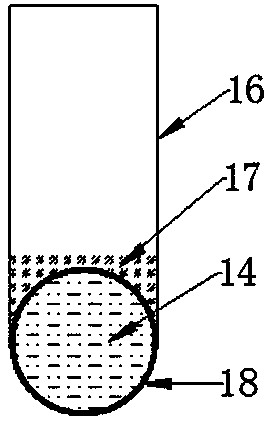

[0152] The dry bin (1), the wet bin (9), and the bin body (26) of the dry bin (20) are made of 6mm metal plates.

[0153] 1. The appearance of the drying bin (1) is a cylindrical shape with both ends closed, and the lower end of the drying bin (1) is conical.

[0154] 2. The outside of the bin body (26) of the drying bin (1) is wrapped with an insulating layer to keep warm.

[0155] The wet hopper (9) has a material inlet and a material outlet; the dry hopper (20) has a material inlet and a material outlet.

[0156] The upper end of the drying bin (1) has a feed port (6).

[0157] 1. A discharge valve (5) is installed on the feed port (6) at the upper end of the drying chamber (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com