Rotary drying chamber with cooling section

A technology of rotary drying and cooling section, which is applied in the field of drying chamber, can solve problems such as complicated manufacturing process, and achieve the effects of enhancing drying efficiency, improving drying quality and fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

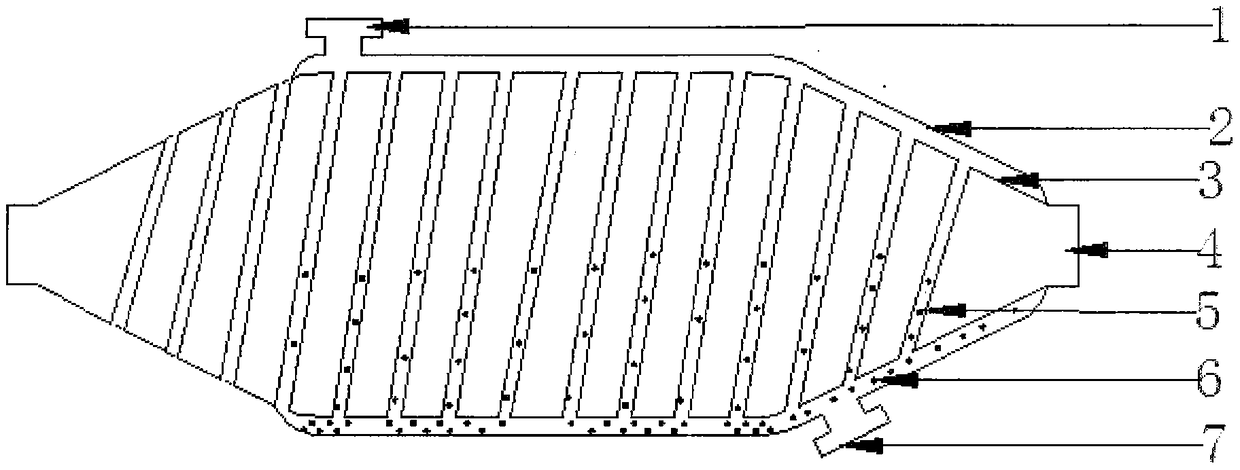

[0049] Such as figure 1 The shown rotary drying chamber with a cooling section is composed of an outer shell (2), an inner chamber (3) and a heat-conducting working fluid (6).

[0050] The appearance shape of the rotary drying bin with the cooling section is cylindrical, and the two ends are tapered.

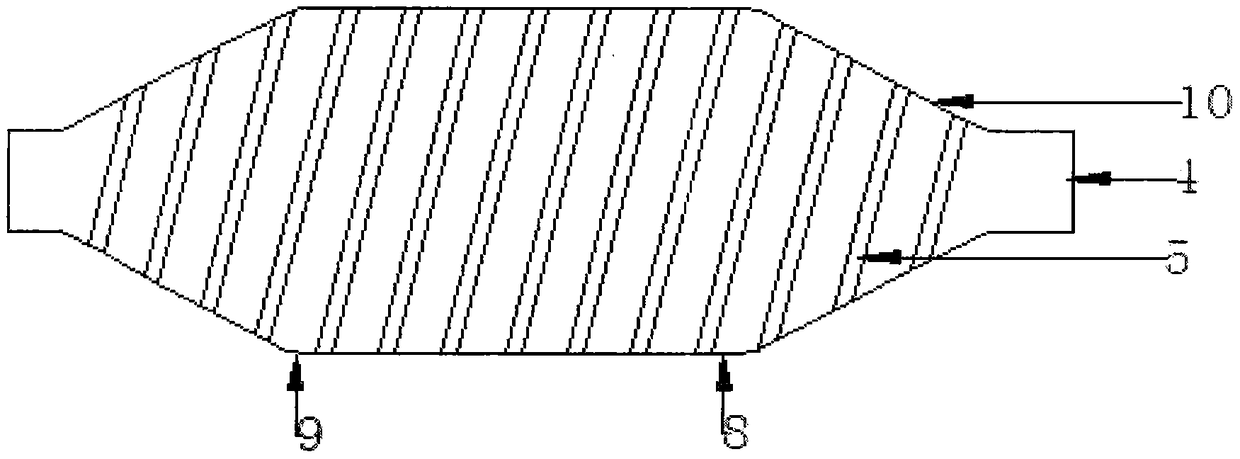

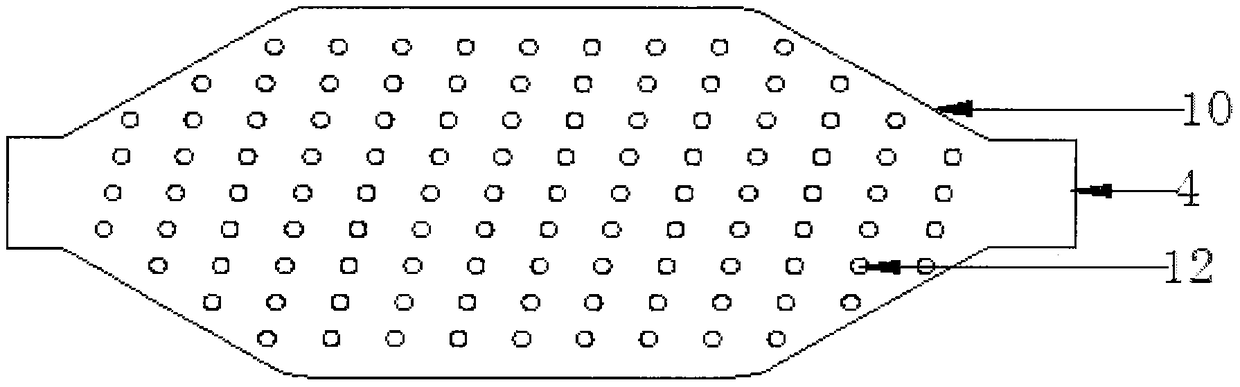

[0051] Such as figure 1 , figure 2 The outer casing (2) shown is outside the inner bin (3); the positions where the two ends of the outer casing (2) contact the inner bin (3) and the bin body (10) are sealed as a whole with a sealing device.

[0052] The inner chamber between the outer shell (2) and the inner chamber (3) is closed and airtight.

[0053] 1. The distance between the shell (2) and the inner compartment (3) is 100mm.

[0054] 2. The length of the outer casing (2) is 2000mm less than the length of the inner chamber (3).

[0055] 3. The diameter of the outer casing (2) is 200mm larger than that of the inner chamber (3).

[0056] The exterior shape of the shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com