Hot pipe type three-barrel vacuum drier

A vacuum dryer and heat pipe technology, which is used in dryers, drying solid materials, drying chambers/containers, etc., can solve the problems of rising vacuum water vaporization temperature, low heat conduction and heat dissipation efficiency, and unutilized waste heat. , to achieve the effect of improving heat conduction and heat exchange speed, compact structure and shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

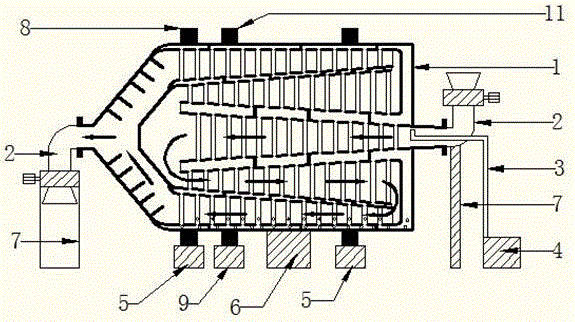

[0050] like figure 1 The heat-pipe three-cylinder vacuum dryer type A shown includes a heat-pipe three-cylinder drying chamber (1), a vacuum feeding and discharging device (2), an air duct (3), and a vacuum unit ( 4), idler bracket (5), heating device (6), bracket (7), driving device (9).

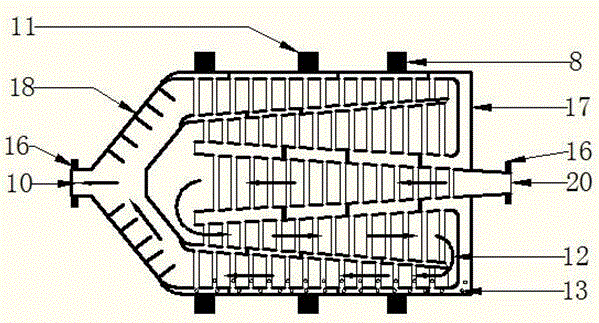

[0051] like figure 2 The shown heat pipe type three-tube drying bin (1) includes a casing (17), a composite drying bin (18), a raceway (8), a gear ring (11), and a heat-conducting medium (13).

[0052] The heat-conducting medium (13) is in the cavity between the shell (17) and the composite drying chamber (18).

[0053] The heat conduction medium (13) is a composite liquid.

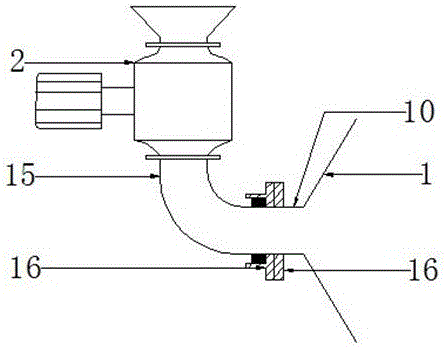

[0054] like figure 2 A flange joint (16) is fixedly installed on the outlet (10) of the heat pipe type three-cylinder drying warehouse (1) shown; Flange joint (16).

[0055] The vacuum feeding and discharging device (2) includes a discharging device, a conveying pipe (15), a flange joint (16), a sealing device,...

Embodiment 2

[0083] like Image 6 The heat pipe type three-cylinder vacuum dryer type B shown includes a heat pipe type three-cylinder drying chamber (1), a vacuum feeding and discharging device (2), an air duct (3), a vacuum unit (4), and a roller bracket (5 ), heating device (6), support (7), driving device (9), mobile device (19).

[0084] The combined structure of the heat pipe type three-cylinder drying chamber type B introduced in the second embodiment and the heat pipe type three-cylinder vacuum dryer type A introduced in the embodiment 1 will not be repeated in the embodiment 2.

[0085] like Image 6 The heat pipe type three-cylinder vacuum dryer type B shown is different from the heat pipe type three-cylinder vacuum dryer type A introduced in Example 1 in that the heat pipe type three-cylinder vacuum dryer B is added with a moving device (19) .

[0086] The mobile device (19) is a mobile platform made of metal with wheels (21).

[0087] The vacuum unit (4), idler bracket (5),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com