Vacuum belt drier

A vacuum belt drying and vacuum unit technology, applied in progressive dryers, dryers, drying solid materials, etc., can solve the problems of affecting heat transfer and heat transfer, not easy to clean and descaling, and complex internal structure of the heating plate. , to achieve the effect of improving circulation speed and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

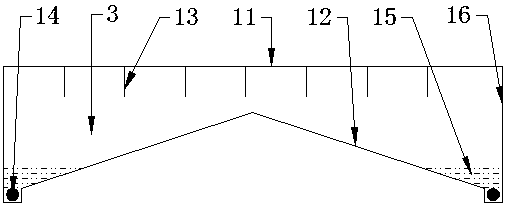

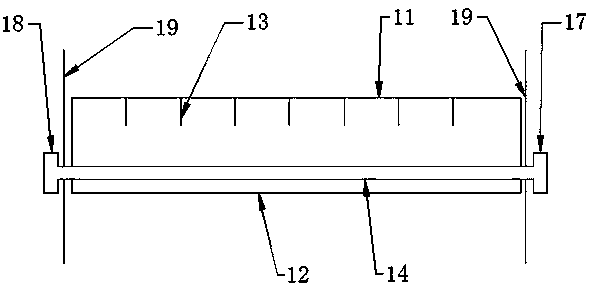

[0072] The present invention will be further described below in conjunction with accompanying drawing:

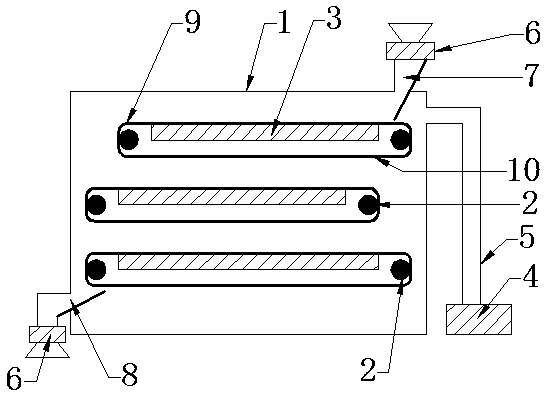

[0073] Such as figure 1 The shown vacuum belt dryer includes a drying bin 1 , a belt conveyor 2 , a heating plate 3 , a vacuum unit 4 , a discharge valve 6 , and an air duct 5 .

[0074] Described drying warehouse 1 is a box-type drying warehouse.

[0075] The drying bin 1 has a feed inlet 7, a discharge outlet 8, and an exhaust port.

[0076] One end of the air guide tube 5 is fixedly connected to the exhaust port of the drying chamber 1 , and the other end of the air guide tube 5 is fixedly connected to the vacuum unit 4 .

[0077] The vacuum unit 4 includes a dust treatment device, a condenser, and a vacuum pump.

[0078] The vacuum pump extracts the gas in the drying bin 1 and the moisture generated when the material is dried; the gas in the drying bin 1 and the moisture generated when the material is dried enters the vacuum unit 4 through the air duct 5, and the moi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com