Heat-pipe type three-cylinder dryer

A technology of heat pipe type and drying machine, which is applied in non-progressive drying machines, dryers, drying solid materials, etc., can solve the problems of low heat exchange efficiency of heat energy, uneven drying moisture, etc. Optimize the drying effect of materials and the effect of reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

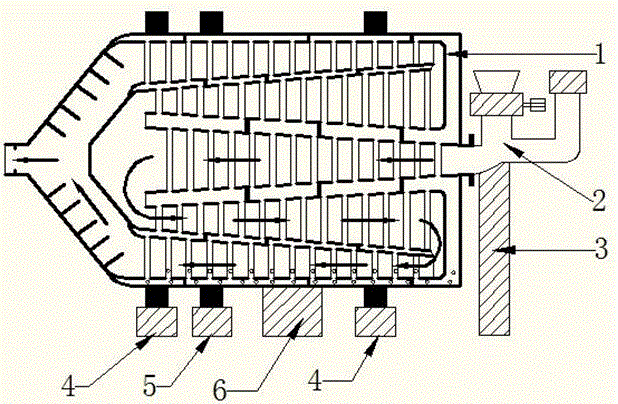

[0049] Such as figure 1 The heat pipe type three-cylinder dryer type A shown includes a heat pipe type three-cylinder drying chamber (1), feeding and exhausting device (2), support (3), idler support (4), driving device (5), heating device (6).

[0050] The heat pipe type three-cylinder dryer type A is fixed after installation.

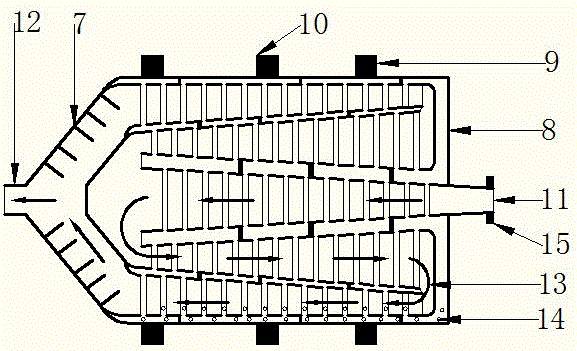

[0051] Such as figure 1 , figure 2 The shown heat pipe type three-tube drying bin (1) includes a casing (8), a composite drying bin (7), a raceway (9), a gear ring (10), and a heat-conducting medium (14).

[0052] The heat pipe type three-cylinder drying bin (1) has a material inlet (11) and a material outlet (12).

[0053] There is a flange joint (15) on the feed inlet (11) of the heat pipe type three-cylinder drying bin (1).

[0054] The composite drying chamber (7) includes an inner cylinder, an outer cylinder, a middle cylinder, a bracket, a baffle, a cooling pipe, and a deflector.

[0055] The heat-conducting medium (14) is in the cavity b...

Embodiment 2

[0084] Such as Figure 5 A heat pipe type three-cylinder dryer type B shown includes a heat pipe type three-cylinder drying chamber (1), a feeding exhaust device (2), a support (3), a roller support (4), and a driving device (5) , heating device (6), mobile device (21).

[0085] The combination structure of the heat pipe type three-cylinder drying chamber type B introduced in the second embodiment and the heat pipe type three-cylinder dryer type A introduced in the embodiment 1 will not be repeated in the embodiment 2.

[0086] Such as Figure 5 The heat pipe type three-cylinder dryer type B shown is different from the heat pipe type three-cylinder dryer type A introduced in Example 1 in that the heat pipe type three-cylinder dryer B adds a moving device (21).

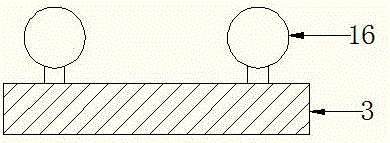

[0087] The mobile device (21) is a platform made of metal with wheels (22).

[0088] The heat-pipe three-cylinder drying machine type B has a heat-pipe three-cylinder drying chamber (1), a bracket (3), a roller supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com