Continuous heat pipe drying machine

A heat pipe type and dryer technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of low exhaust efficiency, dead corners of materials, low heat conduction and heat dissipation efficiency, etc., to improve drying quality. , Strengthen the drying efficiency, the effect of not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

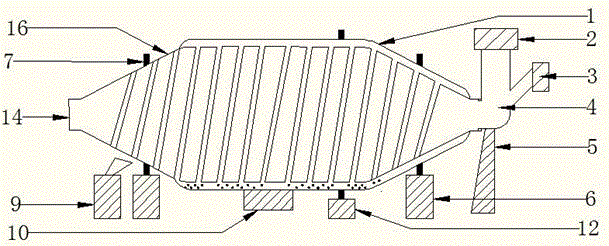

[0060] Such as figure 1The shown continuous heat pipe dryer includes drying bin (1), exhaust device (2), feeding device (3), tee pipe (4), bracket (5), roller bracket (6) , fan (9), heating device (10), sealing device (11), driving device (12).

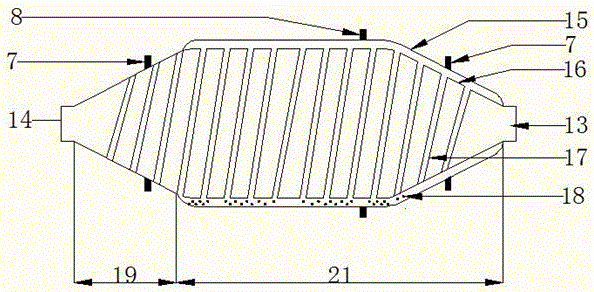

[0061] Such as figure 1 , figure 2 The appearance shape of the shown drying bin (1) is cylindrical.

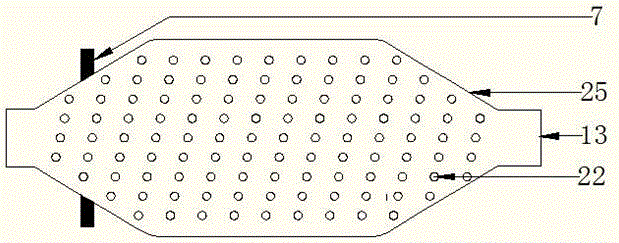

[0062] The drying chamber (1) includes an inner chamber (16), an outer shell (15), and a heat-conducting working fluid (18).

[0063] The shell (15) is outside the inner bin (16), and the two ends of the outer shell (15) are fixedly welded as a whole at the positions where the inner bin (16) and the body (25) of the inner bin (16) are in contact.

[0064] The heat-conducting working medium (18) is in the inner cavity between the outer casing (15) and the inner chamber (16).

[0065] The heat-conducting working medium (18) is water.

[0066] The heating device (10) heats the shell (15) of the drying chamber (1).

[0067] The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com