Roller vacuum drying bin with cooling section

A technology of drum vacuum and drying warehouse, used in drying solid materials, non-progressive dryer, drying solid materials without heating, etc. Connection firmness, negative pressure resistance and anti-flattening, ensuring the effect of anti-flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

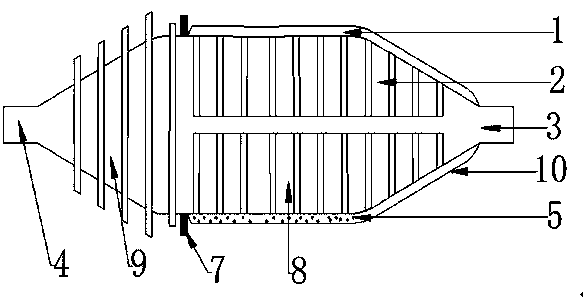

[0099] Such as figure 1 , figure 2 The shown drum vacuum drying chamber with a cooling section includes a heating chamber (1), a drying chamber (2), a heat-conducting working fluid (5), and a gear ring (7).

[0100] The exterior shape of the drum vacuum drying chamber with cooling section is cylindrical.

[0101] The heating chamber (1) is outside the drying chamber (2); the chamber body (10) at both ends of the heating chamber (1) and the chamber body (10) of the drying chamber (2) are fixedly connected as a whole.

[0102] The interior of the heating chamber (1) is sealed and airtight.

[0103] The appearance shape of the heating chamber (1) is cylindrical.

[0104] 1. The diameter of the heating chamber (1) is 1800mm.

[0105] 2. The length of the heating chamber (1) is 400mm.

[0106] When the length of the heating bin (1) exceeds 1500 mm, the bin body (10) of the heating bin (1) and the bin body (10) of the drying bin (2) are fixedly supported by brackets.

[0107]...

Embodiment 2

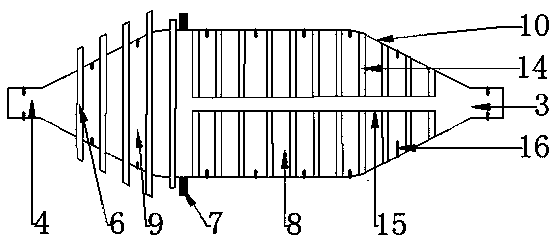

[0163] The combined structure of a drum vacuum drying chamber with a cooling section shown in Embodiment 2 is the same as that described in Embodiment 1, and the similarities will not be repeated.

[0164] A drum vacuum drying chamber with a cooling section includes a heating chamber (1), a drying chamber (2), a heat-conducting working medium (5), and a gear ring (7).

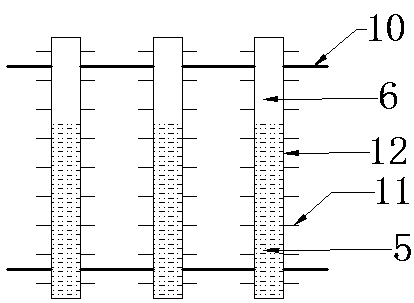

[0165] The drying bin (2) includes a bin body (10), a cooling standpipe (6), a heat pipe (14), a spiral blade (16), and a fixing strip (15).

[0166] The heat dissipation riser (6) includes a metal tube (12) sealed at both ends, fins (11), and a heat-conducting working fluid (5).

[0167] Both ends of the heat dissipation standpipe (6) are fixed on the chamber body (10) inside the cooling section (9) of the drying chamber (2).

[0168] 1. Fix and weld the two ends of the cooling standpipe (6) to the chamber body (10) of the cooling section (9) of the drying chamber (2) by an electric welding machine.

[0169]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com