Vacuum drying machine with cooling section

A vacuum dryer and cooling section technology, applied in non-progressive dryers, dryers, drying solid materials, etc., to achieve the effects of not being easy to agglomerate, optimizing the drying effect of materials, and shortening the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

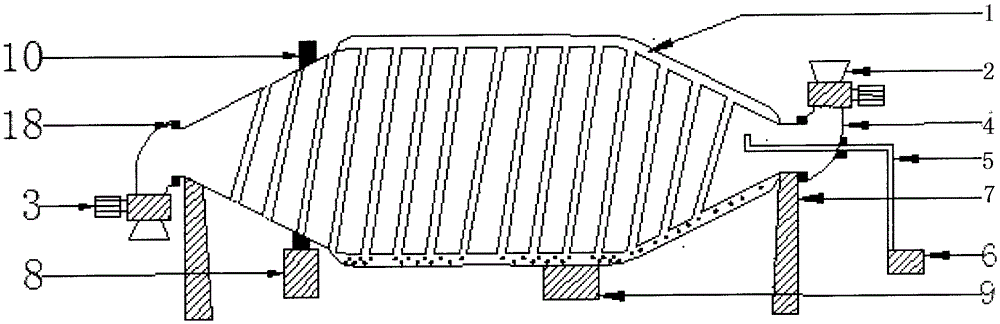

[0042] Such as figure 1 A kind of vacuum drier with cooling section shown is composed of drying chamber (1) with cooling section, hopper (2), unloading device (3), elbow (4), air duct (5), vacuum unit ( 6), a support (7), a driving device (8), a heating device (9) and a track (10).

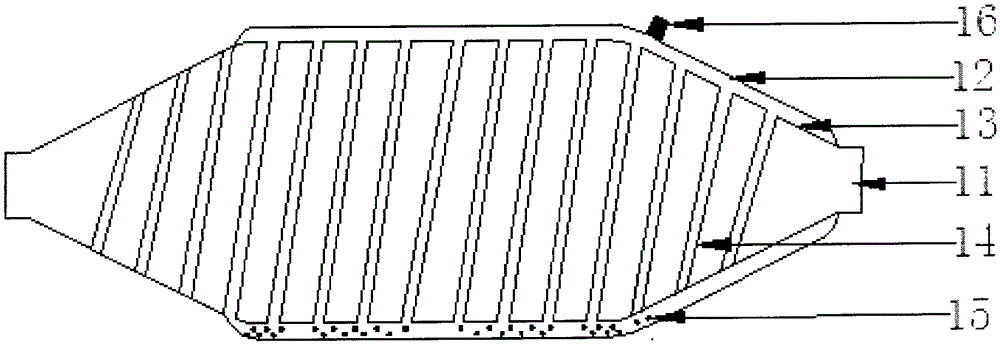

[0043] Such as figure 2 The shown drying chamber (1) with cooling section is a patent applied by me; the drying chamber (1) with cooling section is composed of outer shell (12), inner chamber (13), heat-conducting working medium (15) and safety valve (16) )composition.

[0044] The outer casing (12) of the inner chamber (13) has a heat-conducting working medium (16) in the cavity between the outer casing (12) and the inner chamber (13).

[0045] The end of the inner bin (13) with the outer shell (12) is a drying section; the end of the inner bin (13) without the outer shell (12) is a cooling section.

[0046] There are 2 safety valves (16) on the described casing (12).

[0047] The outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com