Forage processing and refining device for livestock breeding

A pasture and rotary drum technology, applied in the field of animal husbandry, can solve the problems of limited crushing range, inability to achieve comprehensive crushing and refining effect of grain feed, etc., and achieve the effects of improving crushing efficiency, avoiding sticking, and quickly turning and crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

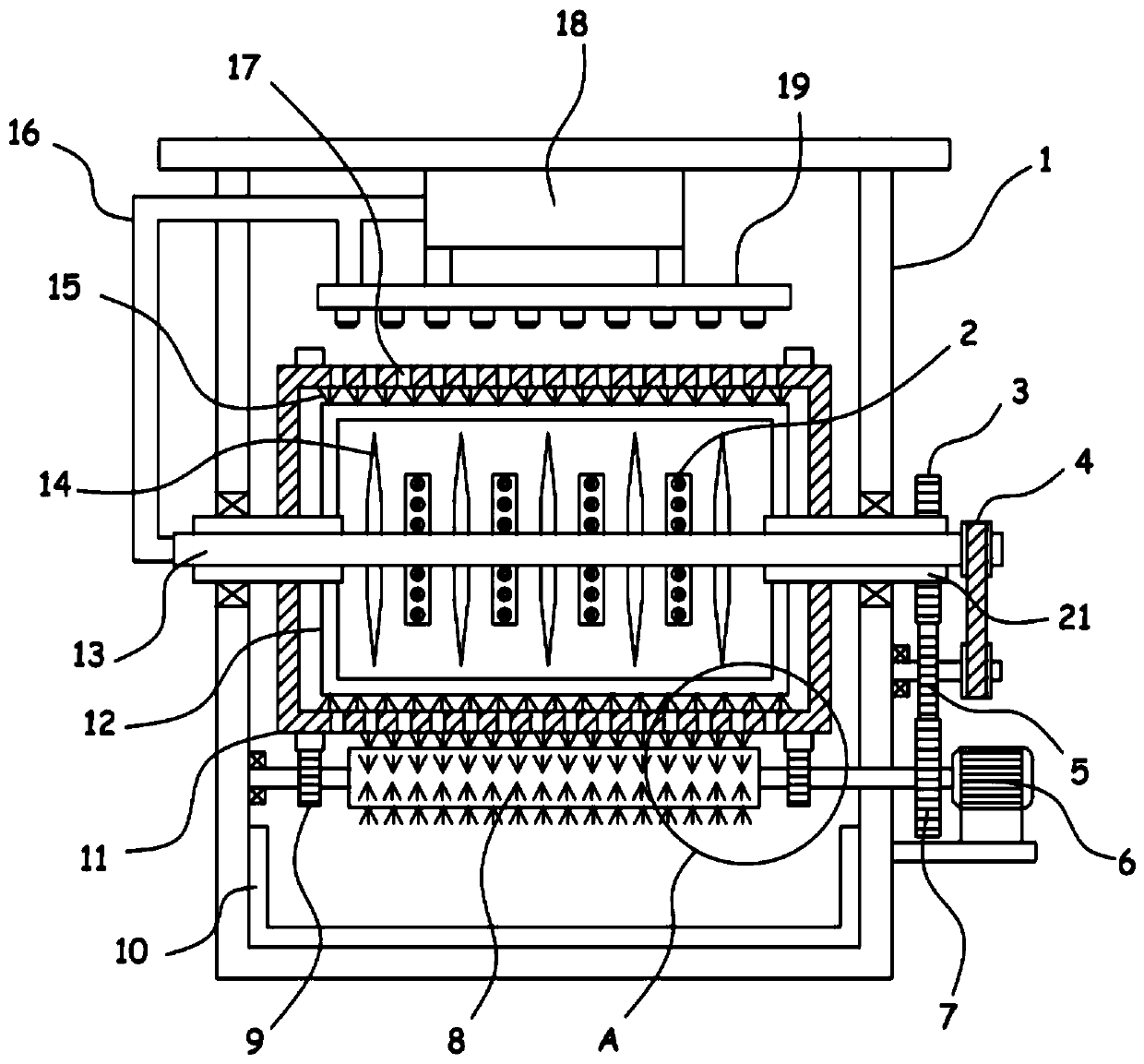

[0022] see Figure 1-4 , a pasture processing refinement device for animal husbandry, comprising a fixed frame 1, on which a rotating cylinder 11 is connected through a drive mechanism, and a plurality of discharge holes 17 are evenly opened on the side wall of the rotating cylinder 11, on the fixed frame 1 A rotating sleeve 21 extending into the rotating drum 11 is pivotally connected, and a hollow tube 13 that rotates coaxially with the rotating drum 11 through a transmission mechanism is installed in the rotating sleeve 21. The side wall of the hollow tube 13 is fixed with several pairs of spaced Broken blade 14 and rotating plate 2, a cleaning mechanism for cleaning the discharge hole 17 is fixed on the rotating sleeve 21, and a drying mechanism for drying pasture is arranged above the rotating drum 11.

[0023] When the device is performing pasture crushing and processing, the pasture is placed inside the drum 11, and the rotating drum 11 is driven to rotate by the set dr...

Embodiment 2

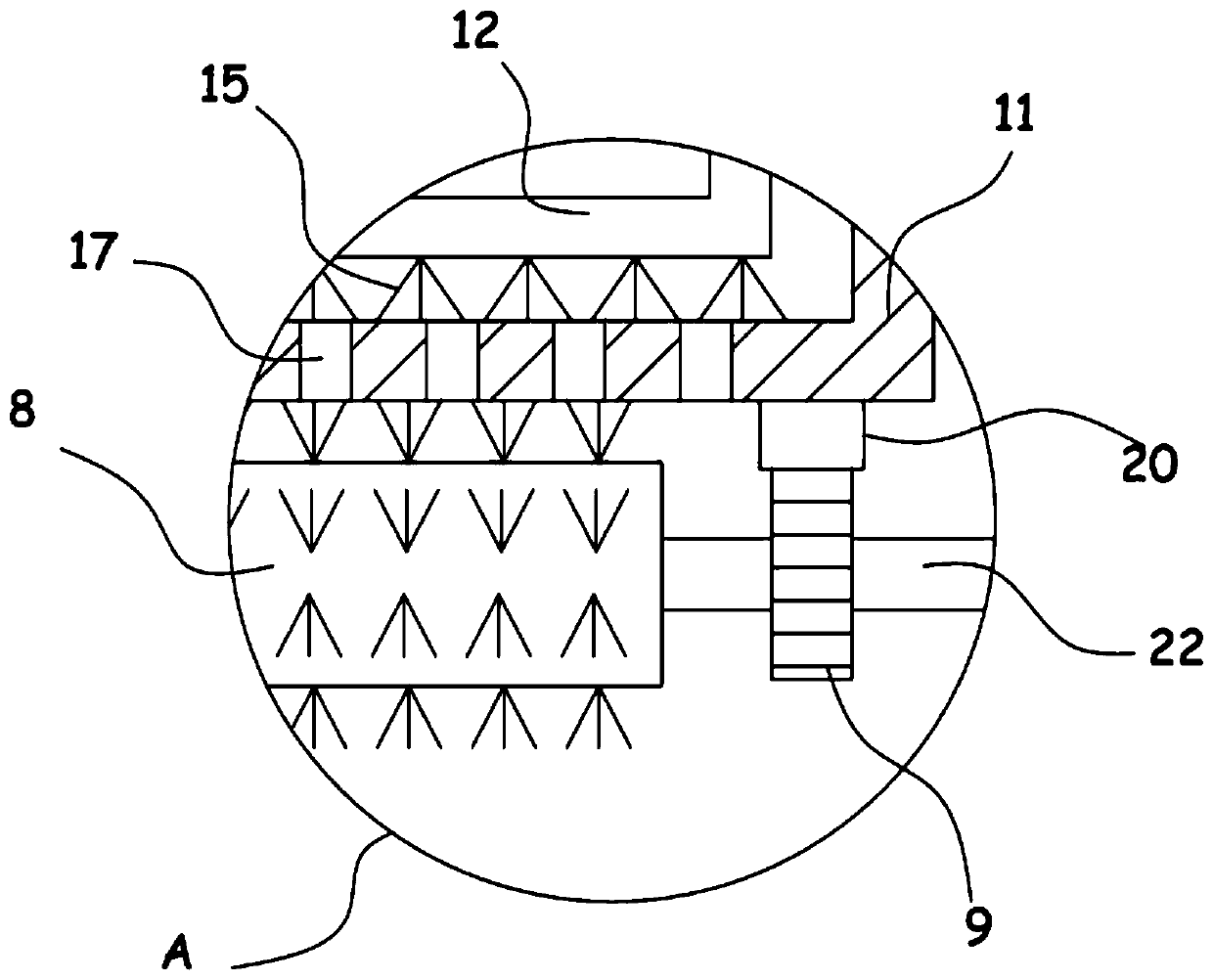

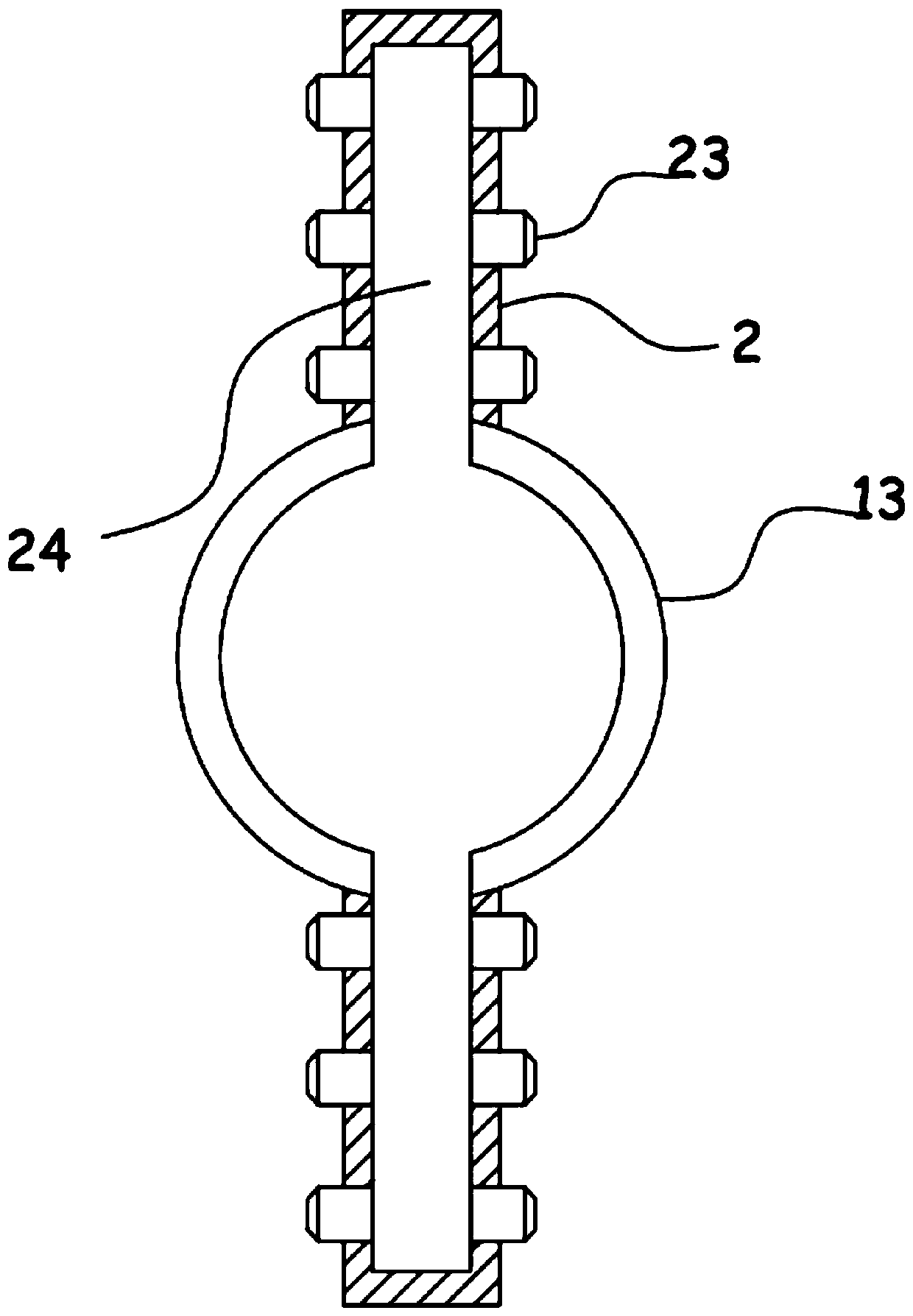

[0029] The pasture thrown into the drum 11 usually has more moisture. In order to improve the pasture in the process of cutting and thinning, the pasture will not be bonded and aggregated to cause the reduction of the cutting effect of the crushing blade 14. For this reason, in the embodiment 1, in addition, this device is also provided with a drying mechanism, which includes a hot air blower 18, the outlet end of the hot air blower 18 is connected with a conveying pipe 16 extending into the hollow pipe 13, and the rotating plate 2 is provided with a hollow pipe 13 communicates with the cavity 24 inside, and the side wall of the rotating plate 2 is embedded with a nozzle 23 communicated with the cavity 24 .

[0030] The hot air generated by the hot air blower 18 is transported through the delivery pipe 16, and the hot air enters the inside of the hollow tube 13. Since the inside of the hollow tube 13 communicates with the cavity 24 of the rotating plate 2, the hot air can be di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com