Modularized multifunctional dryer

A dryer and multi-functional technology, applied in dryers, drying, progressive dryers and other directions, can solve the problems of low drying efficiency, low cooling efficiency, easy to return to moisture, etc., to improve drying efficiency and production. The effect of high efficiency, reduced turnaround space and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

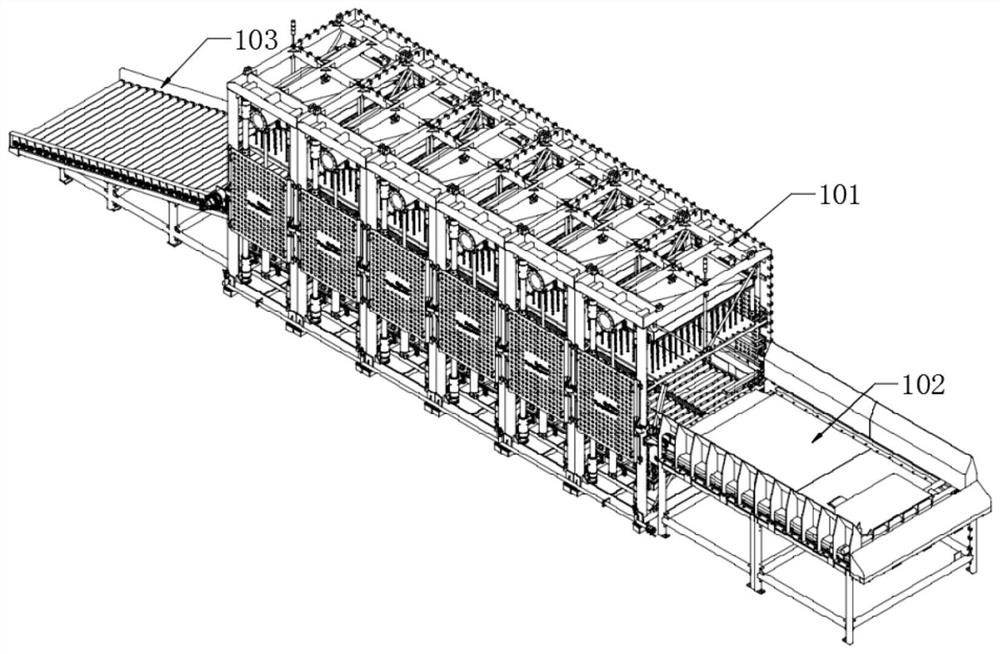

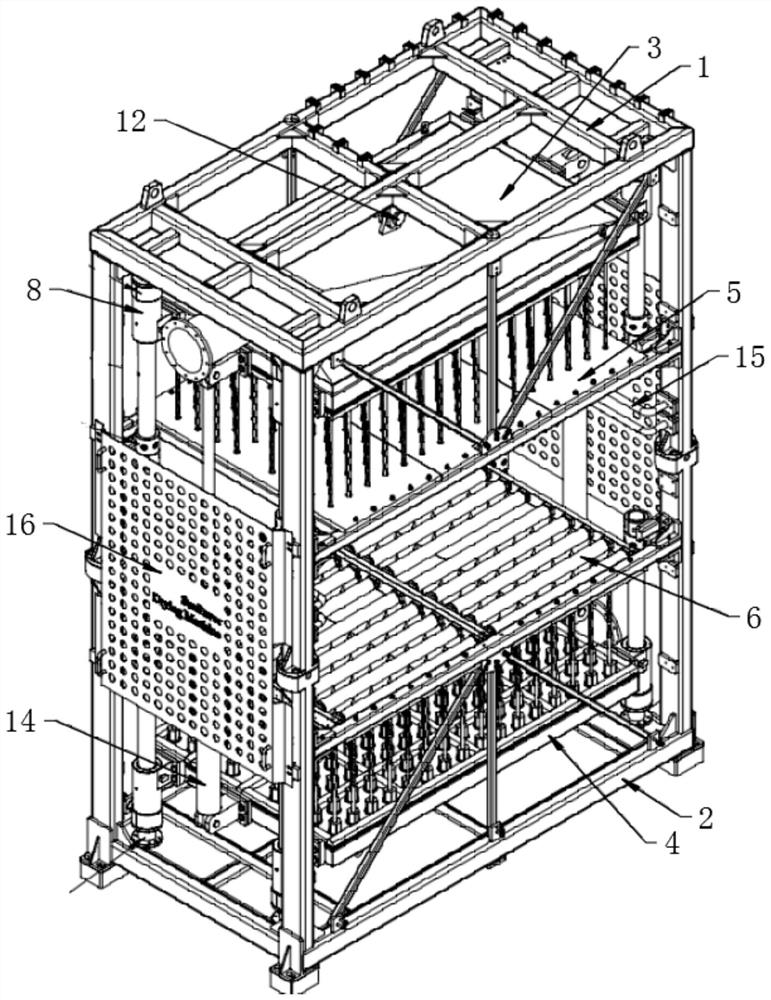

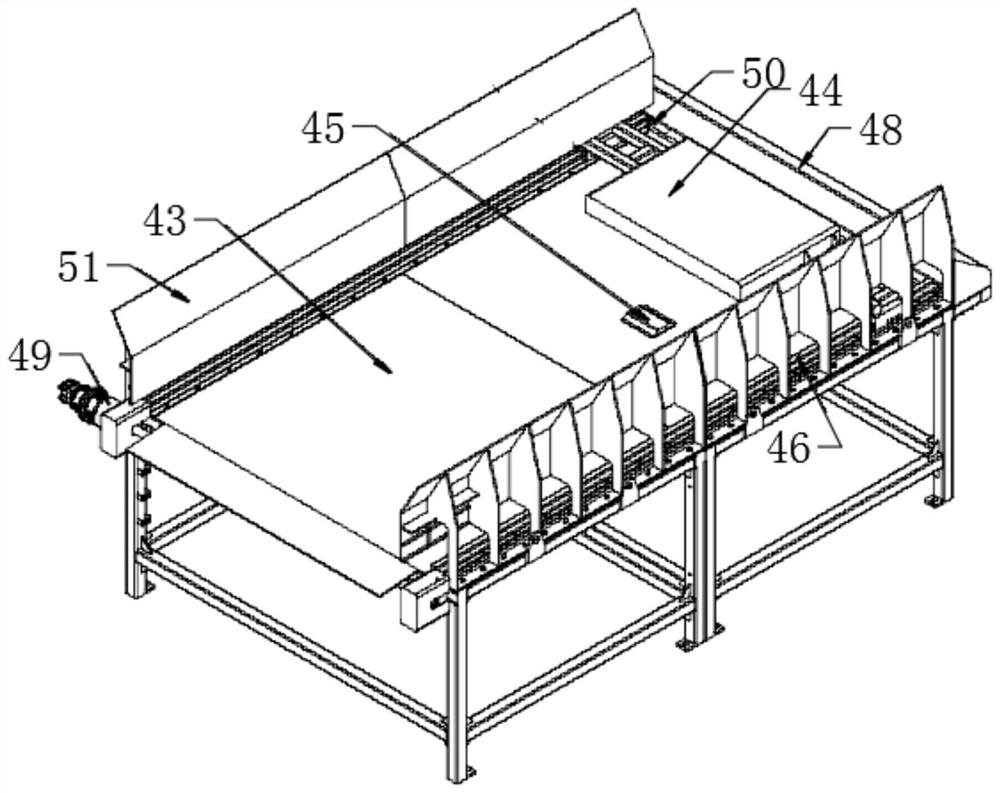

[0037] refer to Figure 1-11 In this embodiment, a modular multi-functional dryer is proposed, including a dryer body 101, a feeding device 102, and a discharging device 103. The dryer body 101 is assembled by multiple groups of functional modules connected in series. The functional module includes an upper frame 1 and a lower frame 2 fixedly connected together, and an upper air outlet mechanism 3 and a lower air outlet mechanism 4 are respectively slidably installed in the upper frame 1 and the lower frame 2, and the upper air outlet mechanism 3 and the lower air outlet mechanism The air outlet mechanism 4 is distributed in a mirror image. The upper frame 1 and the lower frame 2 are respectively fixed with a guide mechanism 5 and a conveying mechanism 6. The guide mechanism 5 is located on the upper and lower sides of the conveying mechanism 6. The feeding device 102 and the discharging device 103 are respectively Located on both sides of the dryer body 101 .

[0038] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com