Drying device for fluororesin particle production

A drying device and fluororesin technology, applied in the drying of granular materials, drying gas arrangement, drying solid materials, etc., can solve the problems of unconcentrated wind, low drying efficiency, low fluidity of resin particles, etc., to increase flow, improve Drying efficiency, the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

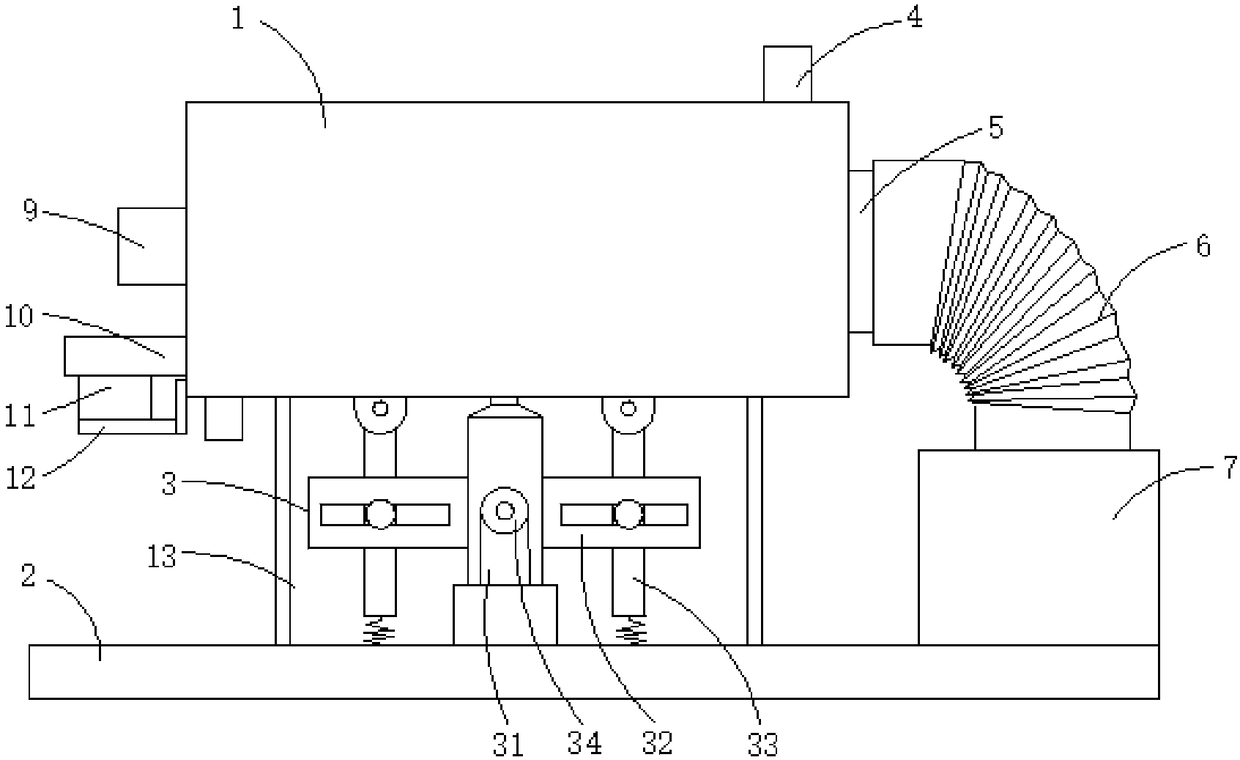

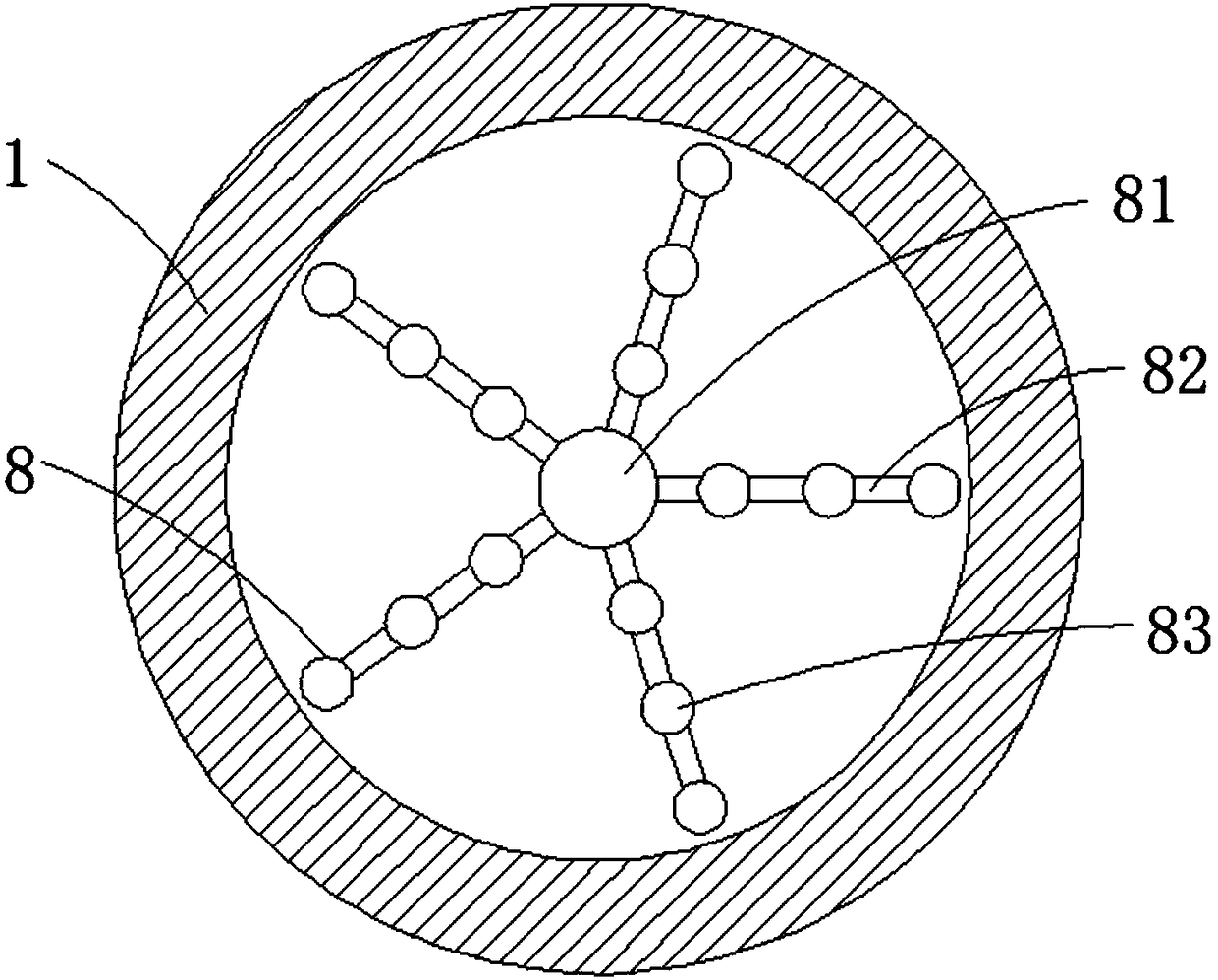

[0032] Add fluororesin particles into the drying cylinder 1 through the feed port 4, start the stirring motor 9, make the stirring shaft 81 rotate with the stirring rod 82 and the stirring ball 83, stir the fluororesin particles, the stirring rod 82 and the stirring ball 83 Rotation can increase the flow of fluororesin particles, and start the hot air blower 7 at the same time. The hot air blower 7 blows hot air into the drying cylinder 1 through the air inlet and 5 to dry the fluororesin particles. The hot air is sucked out through the air outlet 10, which increases the flow of the hot air in the drying cylinder 1, and at the same time can discharge the moisture out of the drying cylinder 1, so as to improve the drying speed of the fluororesin particles, with high drying efficiency and good effect.

Embodiment 2

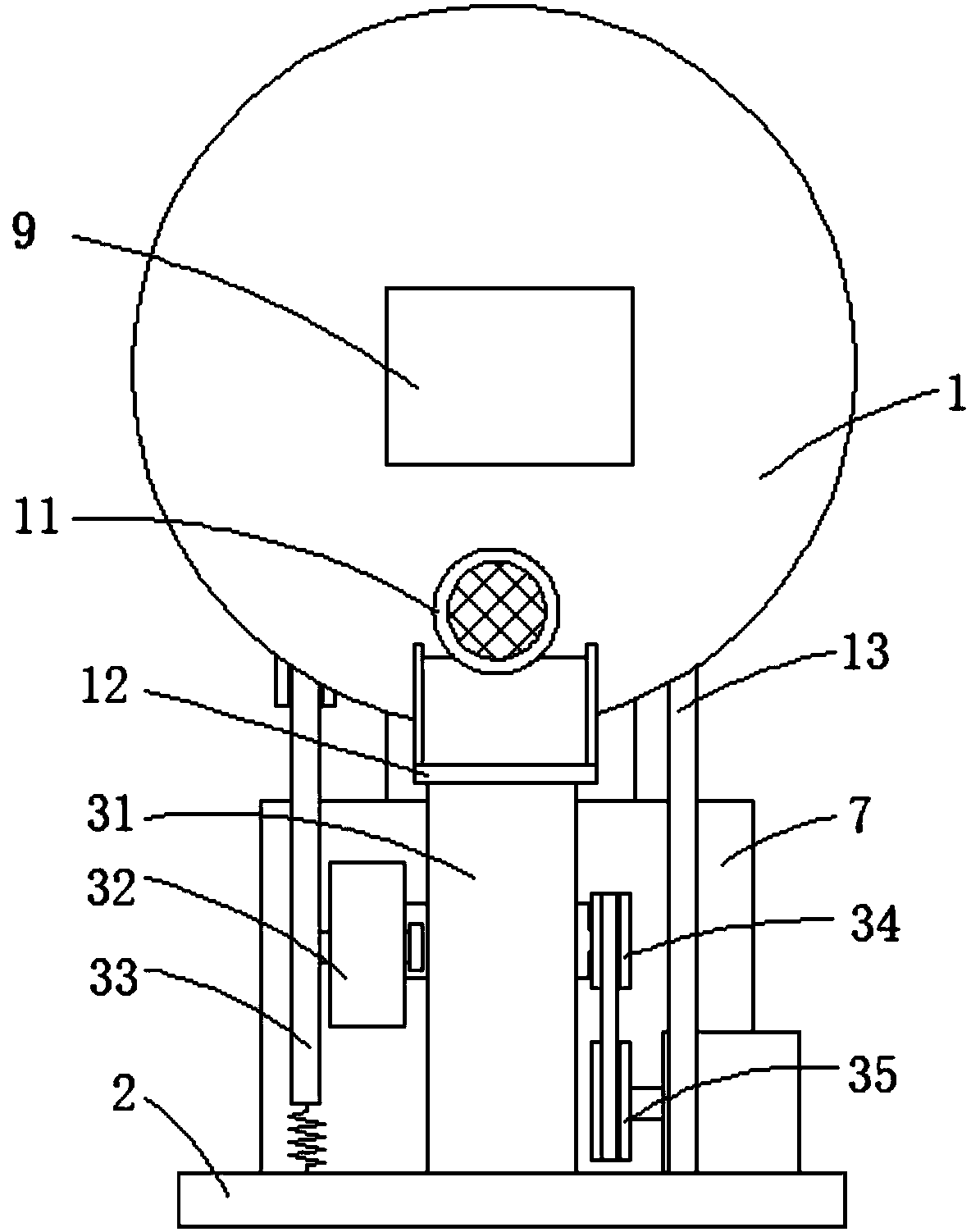

[0034] When the fluororesin particles are dried by hot air in the drying cylinder 1, start the driving motor, so that the driving pulley 35 drives the driven pulley 34 to rotate through the belt, and the forward and reverse directions rotate alternately, and the rotation of the driven pulley 34 The swing rod 32 can be driven to swing around the rotating rod, and the swing of the swing rod 32 can make the top pull rods 33 on both sides lift and pull down the drying cylinder 1, so that the drying cylinder 1 can swing and rotate around the top of the support column 31, further increasing The flow of fluororesin particles in the drying cylinder 1 is ensured, which helps to improve the drying efficiency.

[0035] Working process: fluororesin particles are added into the drying cylinder 1 through the feed port 4, and the hot air is blown into the drying cylinder 1 by the hot air blower 7 for drying, and the shaking of the drying cylinder 1 is increased by the swing device 3 to balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com