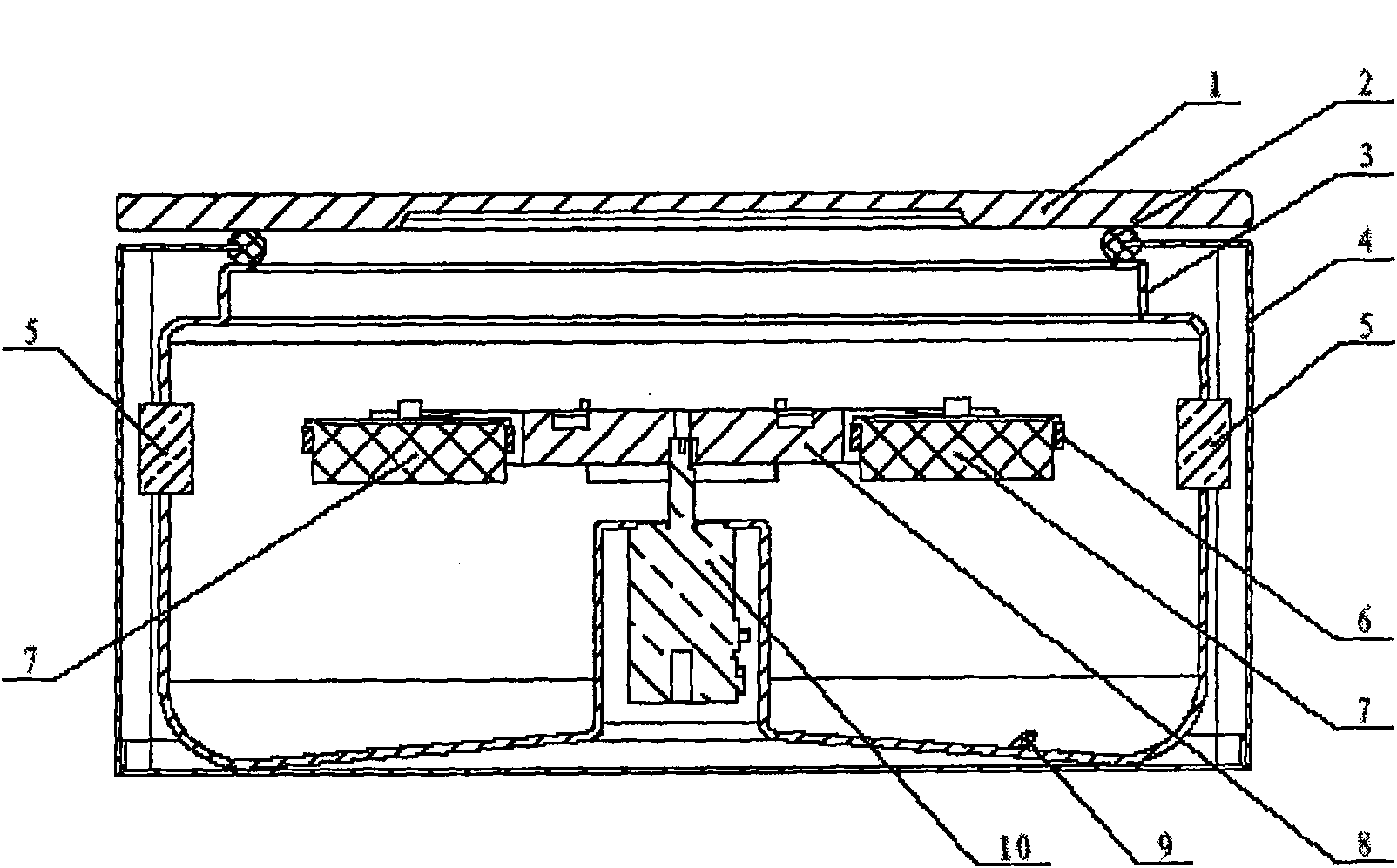

Hard matrix biochip drying tool

A biochip and chip technology, applied in the direction of non-progressive dryers, drying, drying machines, etc., can solve the problems of low production efficiency and no drying method for hard matrix biochips, so as to maintain consistency and reduce production Batch-to-batch difference, easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

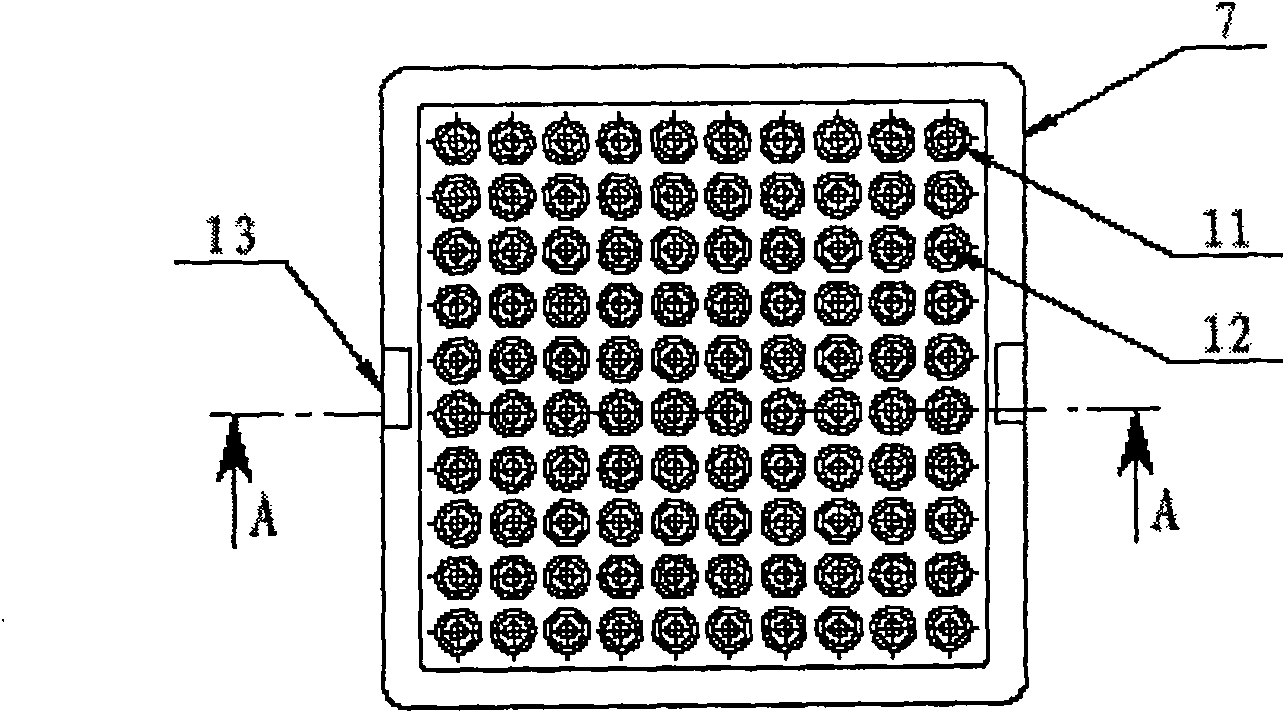

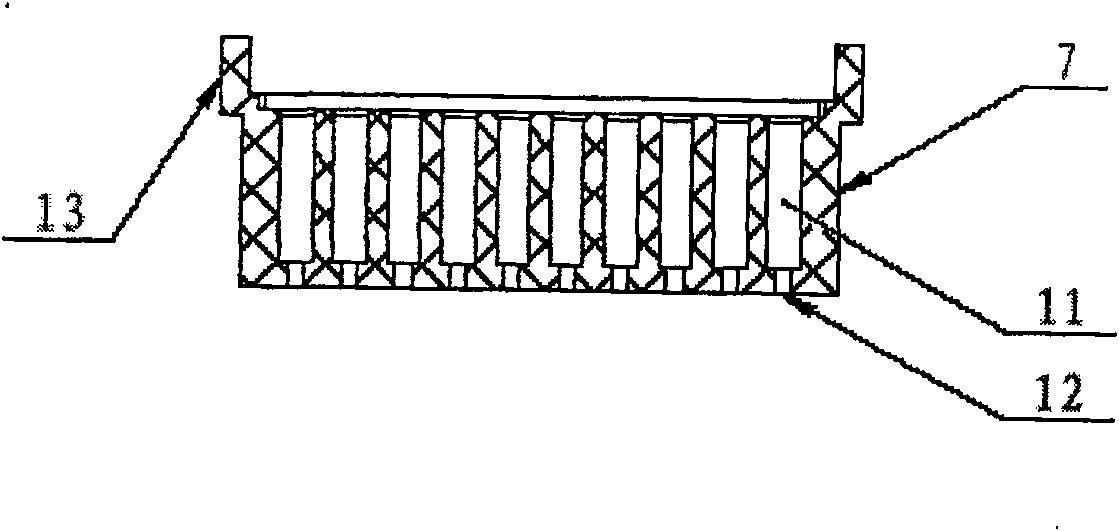

Method used

Image

Examples

Embodiment 1

[0015] (1) Turn on the chip drying tool, set the temperature at 22°C, and equilibrate for 8 minutes;

[0016] (2) Put the hard matrix biochip into the mold of the drying tool, and centrifuge at a speed of 2000 rpm for 5 minutes.

Embodiment 2

[0018] (1) Turn on the chip drying tool, set the temperature at 26°C, and equilibrate for 12 minutes;

[0019] (2) Put the hard matrix biochip into the mold of the drying tool, centrifuge at a speed of 2800 rpm, and centrifuge for 12 minutes.

Embodiment 3

[0021] (1) Turn on the chip drying tool, set the temperature at 28°C, and equilibrate for 15 minutes;

[0022] (2) Put the hard matrix biochip into the mold of the drying tool, centrifuge at a rotation speed of 3200 rpm, and centrifuge for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com