A recycling and reuse glass wine bottle drying line

An assembly line and wine bottle technology, applied in drying, dryers, progressive dryers, etc., can solve the problems of poor drying effect and low drying efficiency of glass wine bottles, so as to facilitate water re-collection and improve Drying efficiency, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

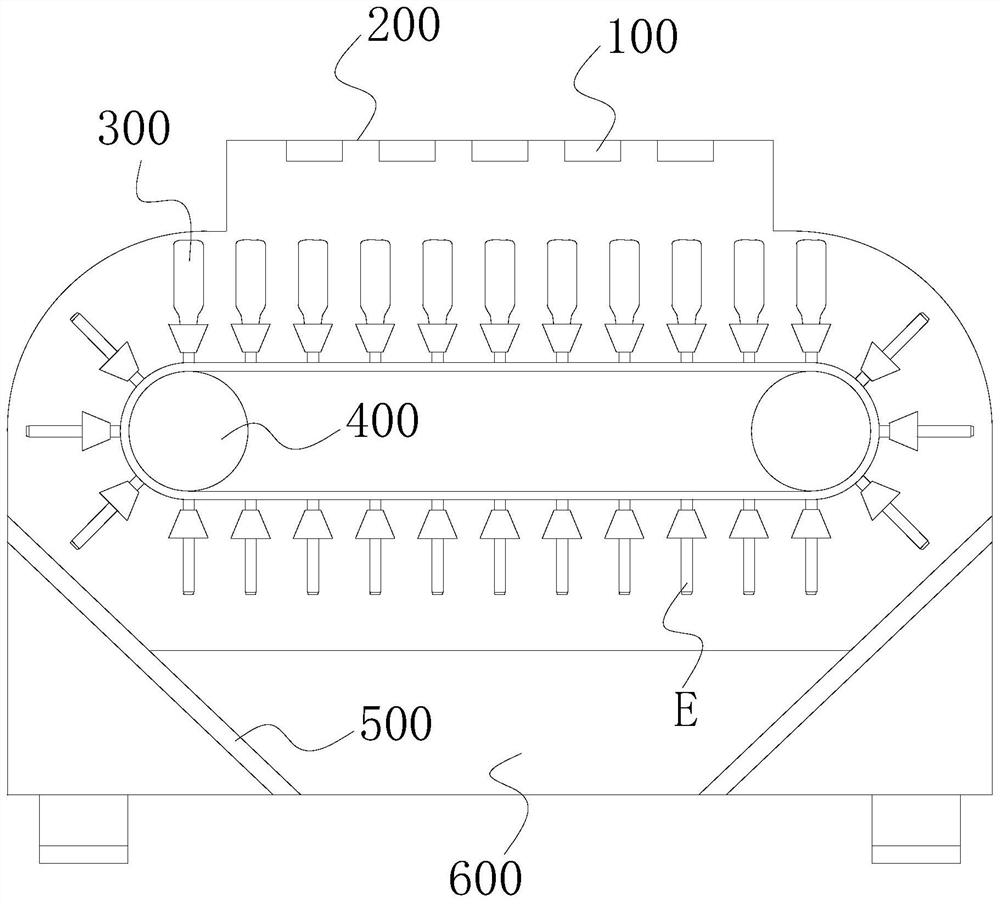

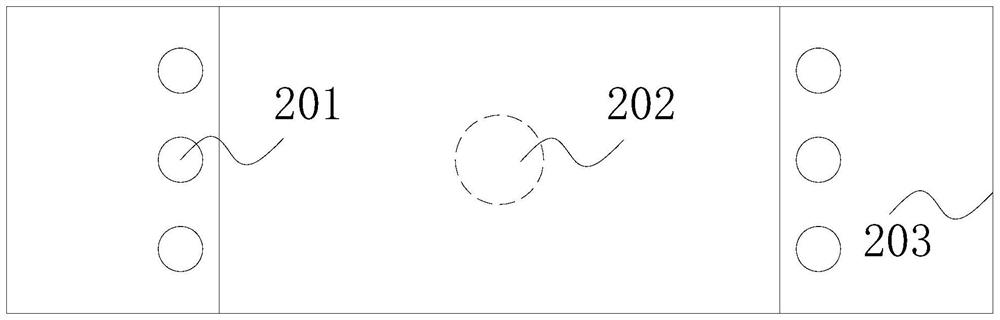

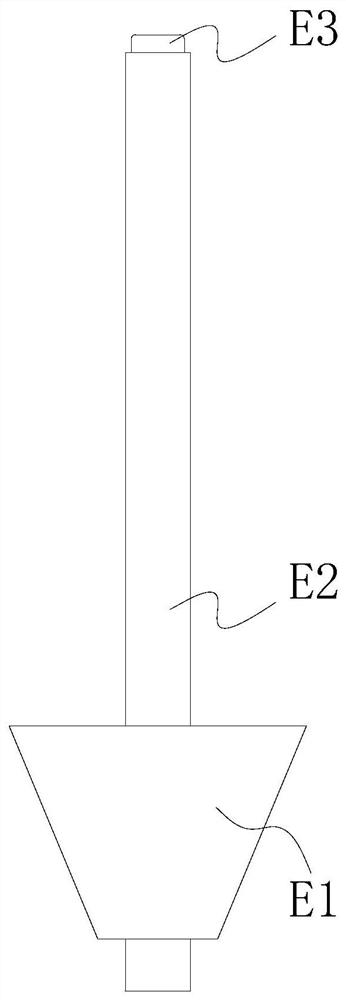

[0030] see Figure 1-4 , the present invention provides a technical solution for recycling glass wine bottle drying line: its structure includes blower 100, drying body 200, glass wine bottle 300, chain plate conveyor 400, inclined plate 500, water collection tank 600, The dryer body 200 is provided with a chain plate conveyor 400, and the chain plate conveyor 400 is provided with a blower 100, and the blower 100 is installed on the inner top surface of the dryer body 200, and the chain plate conveyor There are two inclined plates 500 connected to the dryer body 200 under the 400. The two inclined plates 500 and the inner wall of the dryer body 200 form a water collection tank 600, and the water collection tank 600 is located directly below the chain conveyor 400. , the chain plate conveyor 400 is provided with a glass wine bottle 300 placed upside down, the inclined plate 500 is set to facilitate water entering the water collection tank 600, and the water collection tank 600 ...

Embodiment 2

[0036] see figure 1 , 2 , 3, 5, 6, the present invention provides a technical solution for recycling glass wine bottle drying assembly line: its structure includes blower 100, dryer body 200, glass wine bottle 300, chain plate conveyor 400, inclined plate 500, the water collection tank 600, the chain conveyor 400 is arranged inside the dryer body 200, the chain conveyor 400 is provided with a blower 100, and the blower 100 is installed on the inner top surface of the dryer body 200, The chain conveyor 400 is provided with two inclined plates 500 connected to the dryer body 200, the two inclined plates 500 and the inner wall of the dryer body 200 form a water collection tank 600, and the water collection tank 600 is arranged on the chain plate Directly below the conveyor 400, the chain conveyor 400 is provided with glass wine bottles 300 placed upside down, the inclined plate 500 is set to facilitate water entering the water collection tank 600, and the water collection tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com