Quick drying granulator for organic fertilizer

A rapid drying and granulator technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of wet organic fertilizer granules and reduce the quality of organic fertilizer, so as to help dry and increase the tumbling time , Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

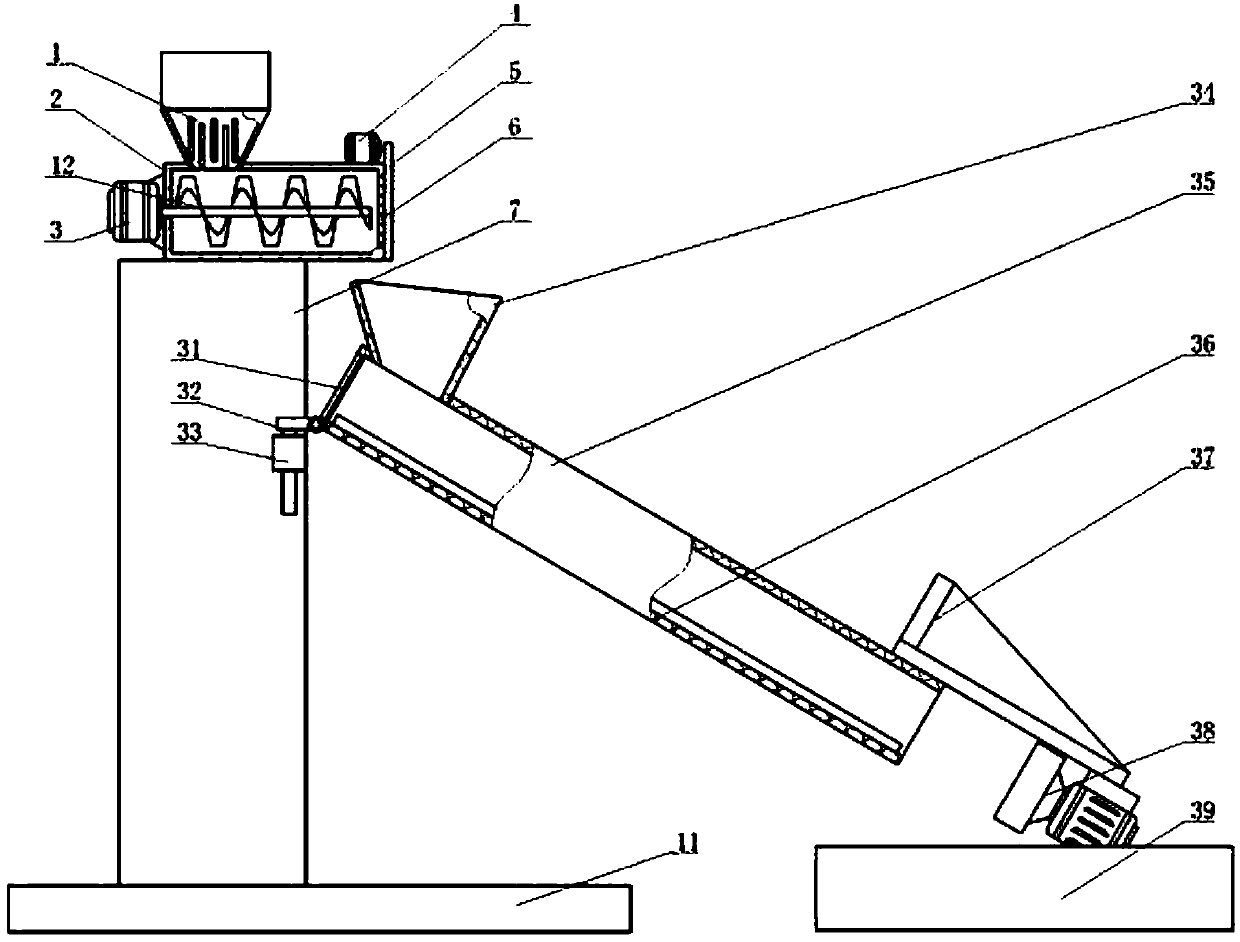

[0013] Organic fertilizer quick drying granulator, such as figure 1 As shown, it includes a fixed seat 11, a granulation device is installed on the top of the fixed seat 11, a fixed frame 7 and a storage box 10 of the granulated device, an extrusion pipe 2 is installed on the top of the fixed frame 7, and a flow guide is arranged on the top of the extrusion pipe 2 Cover 1, the inside of the shroud 1 communicates with the inside of the extrusion tube 2, the extrusion tube 2 is a tubular shell with two ends sealed, one end of the extrusion tube 2 is installed with a stirring motor 3, and the output shaft of the stirring motor 3 is installed with a twist The dragon 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com