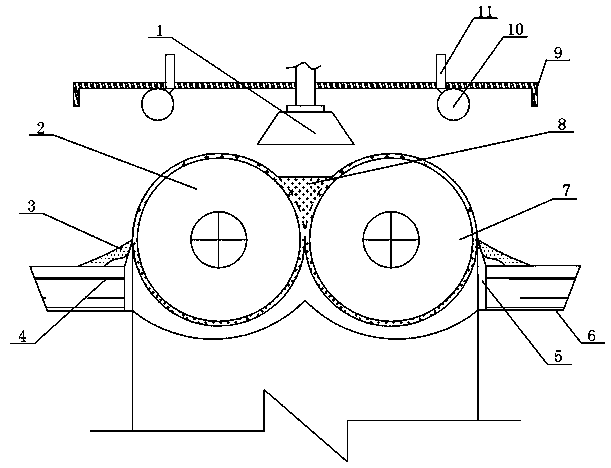

Double-roller dryer

A dryer and double-drum technology, applied in the direction of dryers, drying solid materials, drying, etc., can solve the problems of slow heat dissipation and inconvenient diameter of the control drum, so as to overcome the slow heat dissipation of the drum, improve drying efficiency, and facilitate falling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] As a preference, two suction fans and two steam exhaust ports are provided in this embodiment, and the two suction fans and steam exhaust ports are respectively arranged above the first drum 2 and the second drum 7 to ensure the smoothness of the slurry drying environment , the material is easy to be dried.

[0016] In this embodiment, the saturated steam pressure can reach 600kPa and the temperature can reach 150°C by heating steam entering the cylinder from one end of the central axis of the two cylinders respectively. When working, the slurry to be dried is sprayed between the first roller 2 and the second roller 7 below through the nozzle, and the two rollers rotate at the same speed and rotate in opposite directions. , is quickly heated and evaporated, and the dry flakes are continuously scraped off by the scraper 5, and the scraper 5 falls into the bin 6 along the guide groove 3, or the scraper 5, and then proceeds to the next step, wherein , The secondary steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com