Patents

Literature

93results about How to "Unobstructed airflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mask

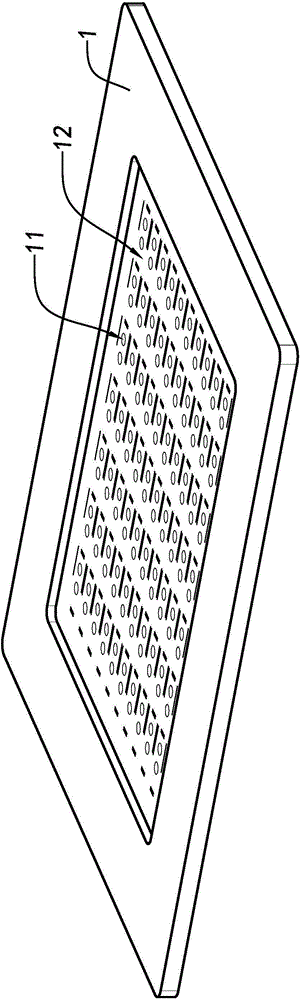

ActiveCN102763917AExtended service lifeEasy to wearProtective garmentRadiationSurface layerRespirator

Owner:周瓴 +1

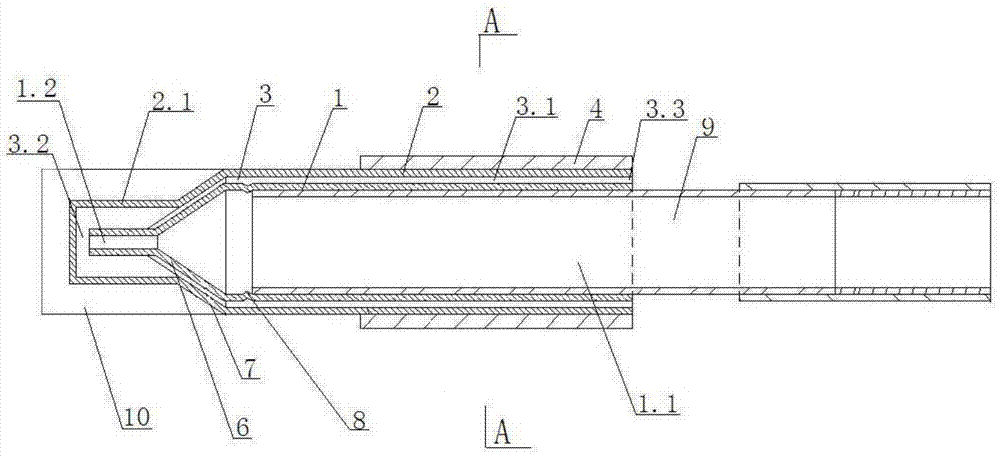

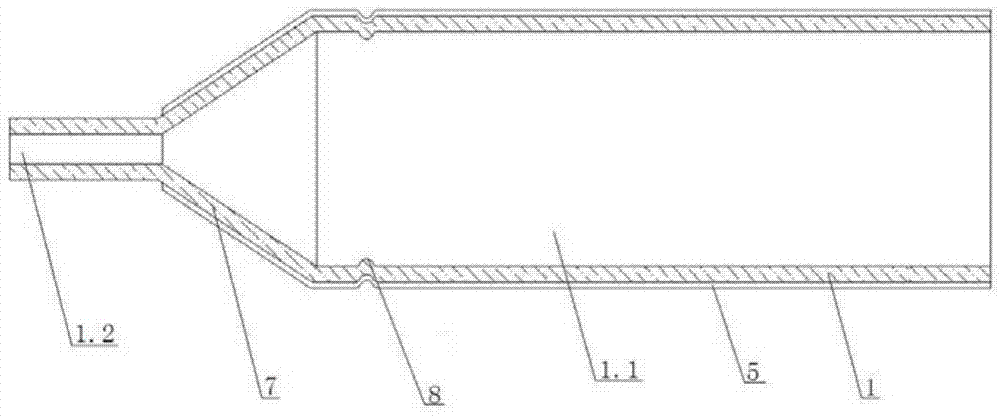

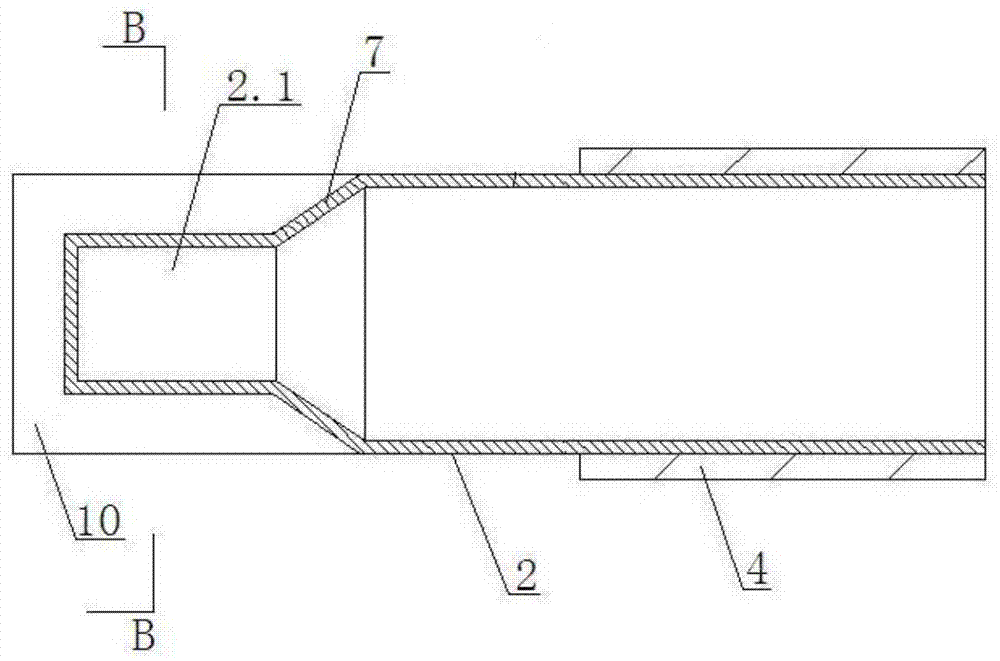

Rear air inlet type heat-conducting smoking device

ActiveCN103564657ATo achieve the effect of basic isolationEven heating in direct contactTobacco devicesHeat conductingEngineering

The invention discloses a rear air inlet type heat-conducting smoking device. The heat-conducting smoking device comprises an inner heat-conducting casing and an outer heat-conducting casing nested outside the inner heat-conducting casing, wherein an air inlet interlayer is formed between the inner heat-conducting casing and the outer heat-conducting casing; an airflow inlet is formed between the end part of the inner heat-conducting casing and the end part of the outer heat-conducting casing, a closed end of the outer heat-conducting casing is a heating part, a gap is formed between the heating part and an inner air inlet, and the air inlet interlayer and the gap are communicated to form an airflow passage; and the outer surface of the heating part is sleeved with a fuel part. According to the invention, an opening of the airflow passage is formed in the rear so as to form a certain distance with the fuel part, with the adoption of the arrangement, inlet air is basically isolated from waste gas generated by fuel, and the formula application range of the fuel is broadened; and with the adoption of the structure of the heat-conducting smoking device, the dry distillation effect is greatly improved, the opening of the airflow passage and the burning part of the fuel are isolated, and the application range of the fuel is extended.

Owner:HUBEI CHINA TOBACCO IND +1

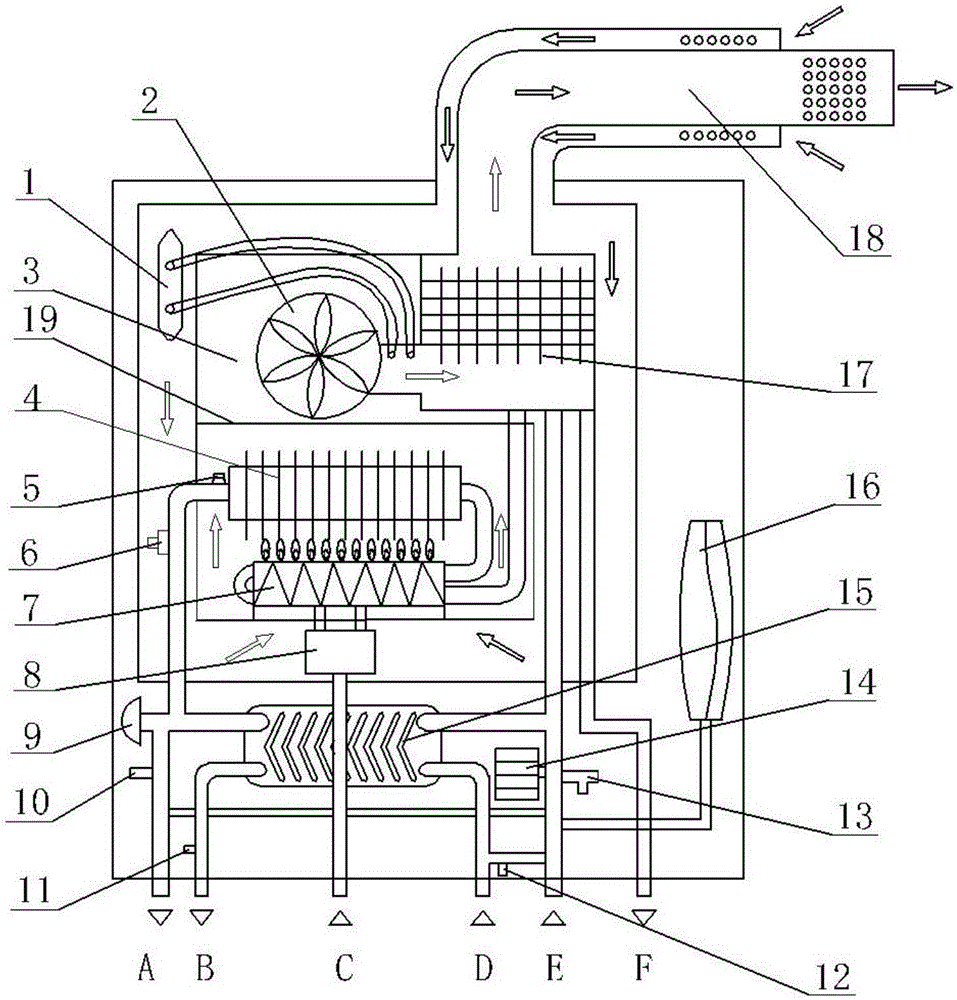

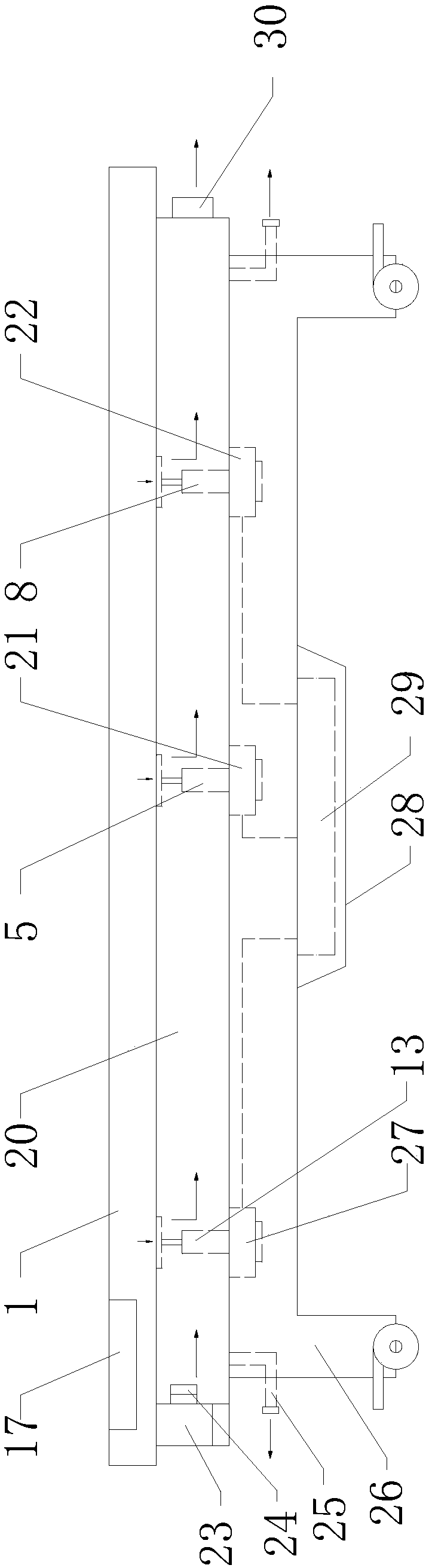

Low-nitrogen condensation wall-mounted furnace and application method thereof

The invention discloses a low-nitrogen condensation wall-mounted furnace and an application method thereof. The low-nitrogen condensation wall-mounted furnace comprises a draught fan, a fume collecting hood, a gas valve and a water-cooling combustor. An inner cavity of a gas distributing pipe of the water-cooling combustor is divided into two independent sections through a block plate, and each section is connected with a gas inlet joint. The gas valve is composed of a main on-off valve, a proportion regulating valve and two on-off valves, the main on-off valve is connected with a main gas inlet pipe, and outlets of the two on-off valves communicate with the two sections of the gas distributing pipe separately. The gas distributing pipe is sectioned, all fire rows or a part of fire rows on the gas distributing pipe are controlled to combust, small duty ratio is reduced, and the problems of flameout and too hot water temperature in summer can be solved. In addition, the constant-speed draught fan is adopted for the wall-mounted furnace, so the problem of corrosion of condensate water to a main heat exchanger can be solved. A ventilation baffle is further arranged at the bottom of the fume collecting hood to solve the problem of excessive CO emission under limit gas test conditions. Through experimental verification, when the small load regulation ratio of the wall-mounted furnace is between 0.35-0.5, the problems of flameout and too hot water temperature in summer can be solved.

Owner:MACRO THERMAL ENERGY TECH

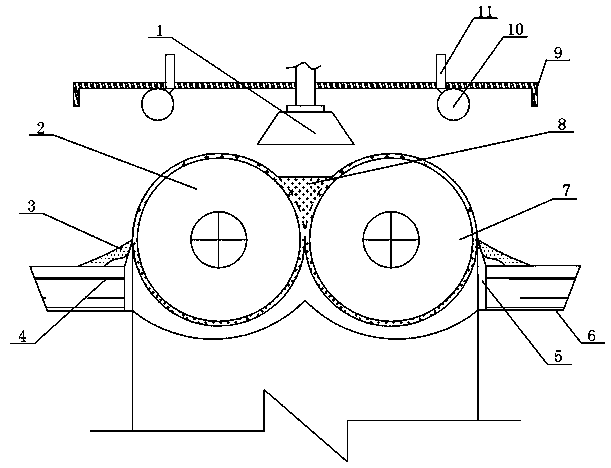

Double-roller dryer

InactiveCN104315829AImprove cooling effectKeep dryDrying solid materialsDrying machinesClassical mechanicsEngineering

The invention relates to the technical field of dryers, in particular to a double-roller dryer. The double-roller dryer comprises a first roller and a second roller, wherein the first roller and the second roller are arranged in parallel and are opposite in rotation direction, a material spraying device is arranged above the first roller and the second roller, a gap smaller than 5 cm is reserved between the first roller and the second roller, and the material spraying device is aligned to the gap. A material bin is arranged on the side opposite to the gap between the first roller and the second roller, a scraping plate is arranged on the material bin, the other end of the scraping plate is in circular contact with the periphery of the first roller and the periphery of the second roller, guide grooves are formed in the positions in contact with the first roller and the second roller, of the scraping plate, and the other end of each guide groove is connected with the inside of the material bin. By means of the technical scheme, the double-roller dryer enables materials to be dried easily and facilitates material discharge.

Owner:CHONGQING TENGHAN IND & TRADE

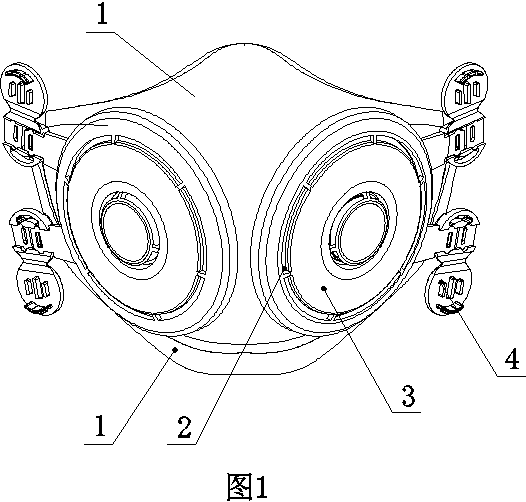

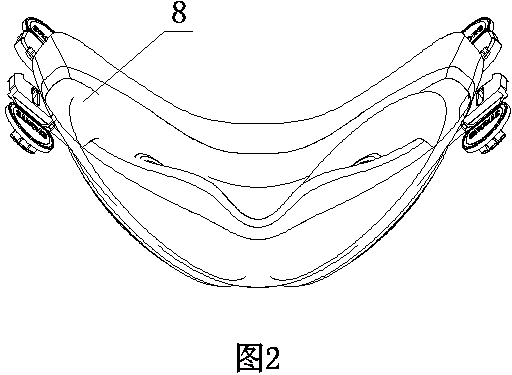

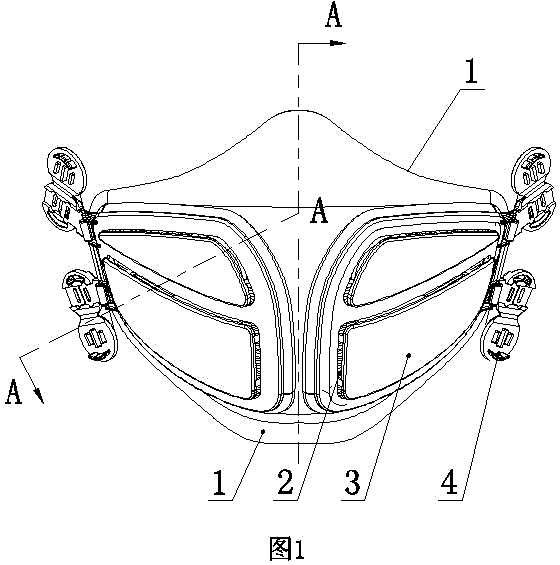

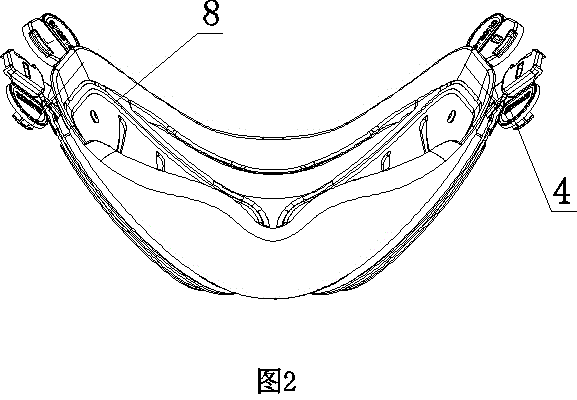

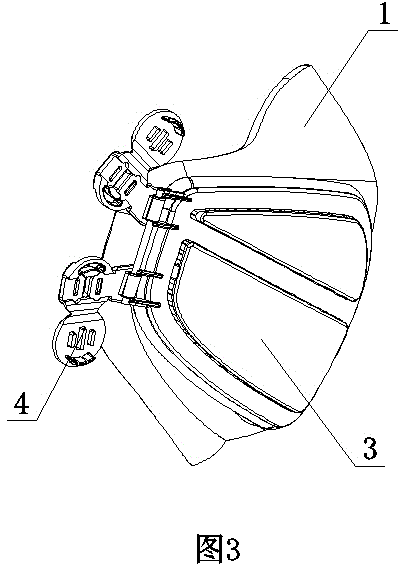

Anti-haze mask special for child

The invention relates to an anti-haze mask special for a child and belongs to the field of daily life protective articles of people. The anti-haze mask special for the child is composed of a silica gel mask, filer installing seats, a PM2.5 filter, fixing belt fasteners, an exhalation valve, a cover body, an inhalation valve, a filter layer and filter cotton. The cover body is arc-shaped and symmetrically provided with the filer installing seats, the exhalation valve and the inhalation valve are installed on the filer installing seats, the PM2.5 filter and the filter cotton are installed on the inhalation valve, and the fixing belt fasteners are installed on two sides of the cover body. The anti-haze mask adopts a structure that an exhalation channel, the filter and an inhalation channel are separated, flows are smooth, a user breathes smoothly after wearing the mask, the face adhesion effect and sealing effect are good, inhaled air is completely filtered and then is inhaled into a human body, the anti-haze effect is good, and the anti-haze mask is special for the child to wear. The problem that an existing anti-haze mask does not tightly attach to the face of the user, is poor in anti-haze effect and enable the user to feel oppressed and uncomfortable after being worn for a long period of time.

Owner:陈思敏 +1

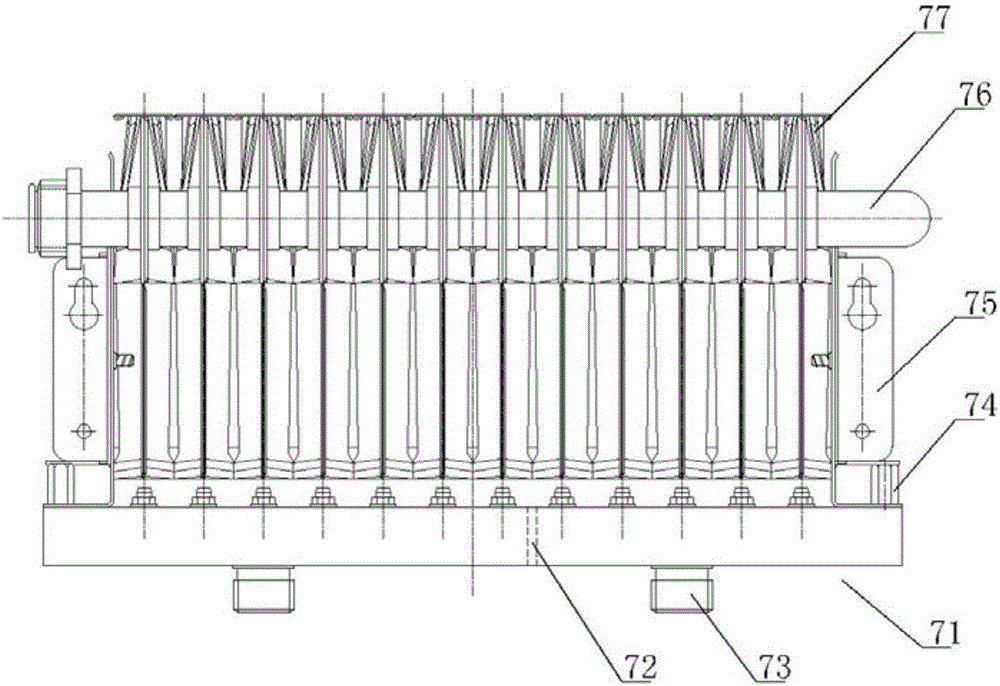

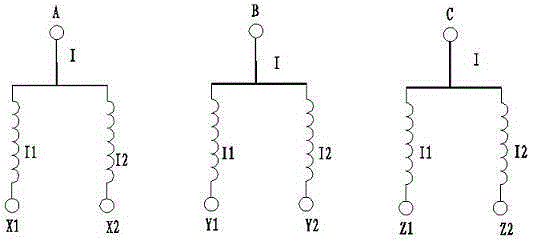

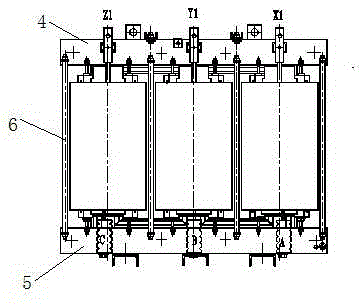

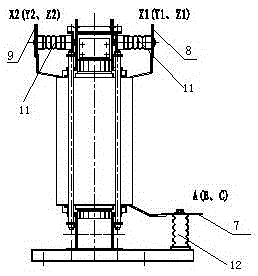

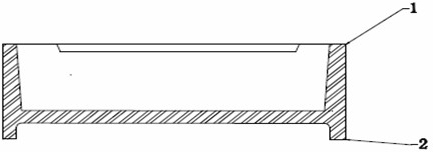

Iron core-type split reactor

ActiveCN105428040AReduce lossReduce Flux LeakageTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringShort circuit

The present invention relates to an iron core-type split reactor. The iron core-type split reactor comprises a rack; the rack is provided with at least one reactor unit; the reactor unit comprises at least two coaxially arranged split coils with axes extending vertically; each split coil comprises a wire inlet end used for and provided in a same main circuit and a wire outlet end used for connecting to a corresponding branch circuit respectively; and an inner side of an innermost split coil is provided with an iron core being coaxial with the split coil. The wire inlet ends of the split coils are disposed in the same main circuit, the outlet ends are connected to the corresponding branch circuits respectively to limit a short circuit current, and the inner side of the innermost coil is provided with the iron core, so that the iron core-type split reactor is low in loss, small in flux leakage and small in volume.

Owner:XUJI GRP +2

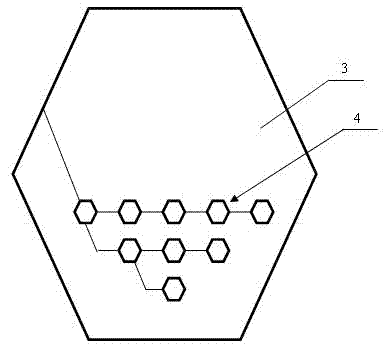

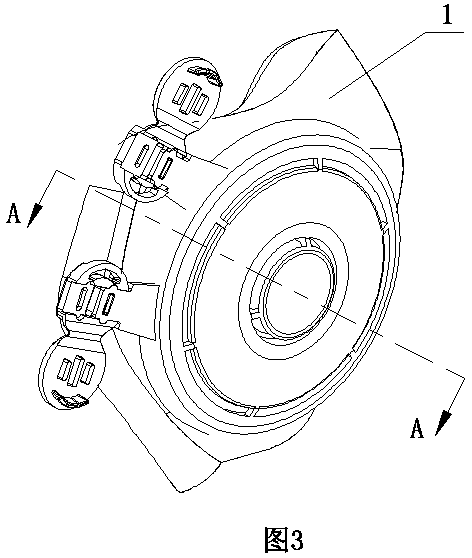

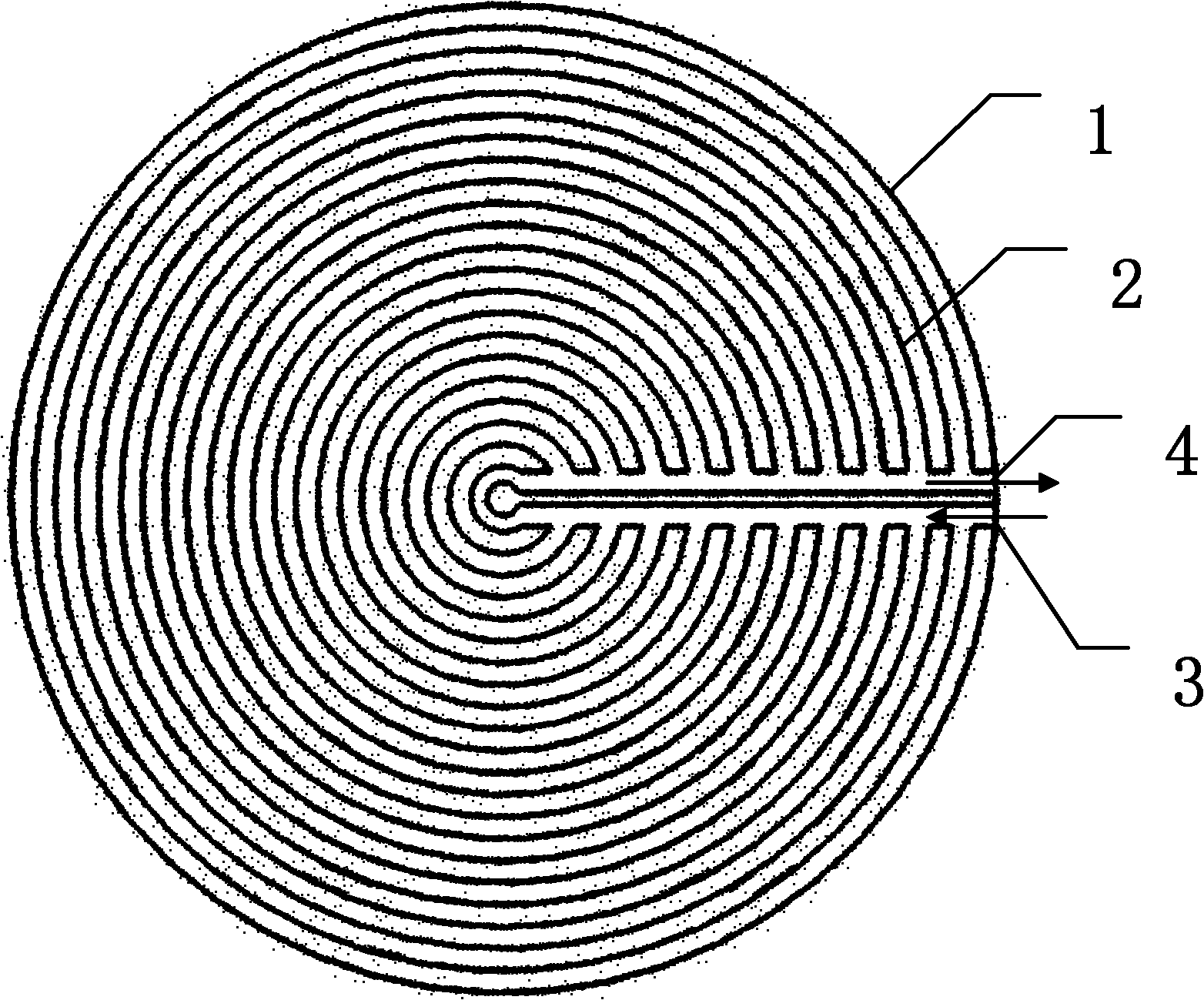

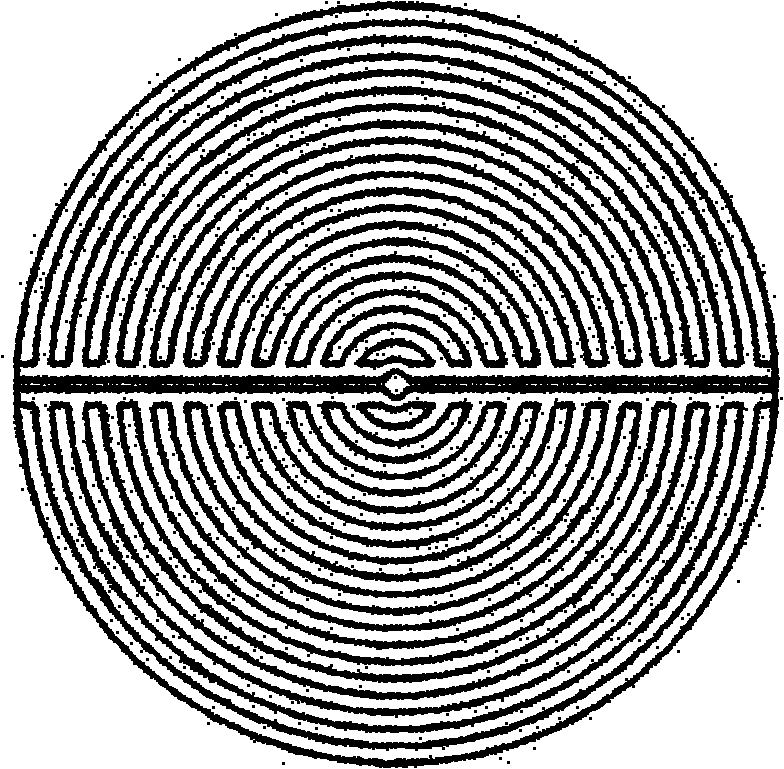

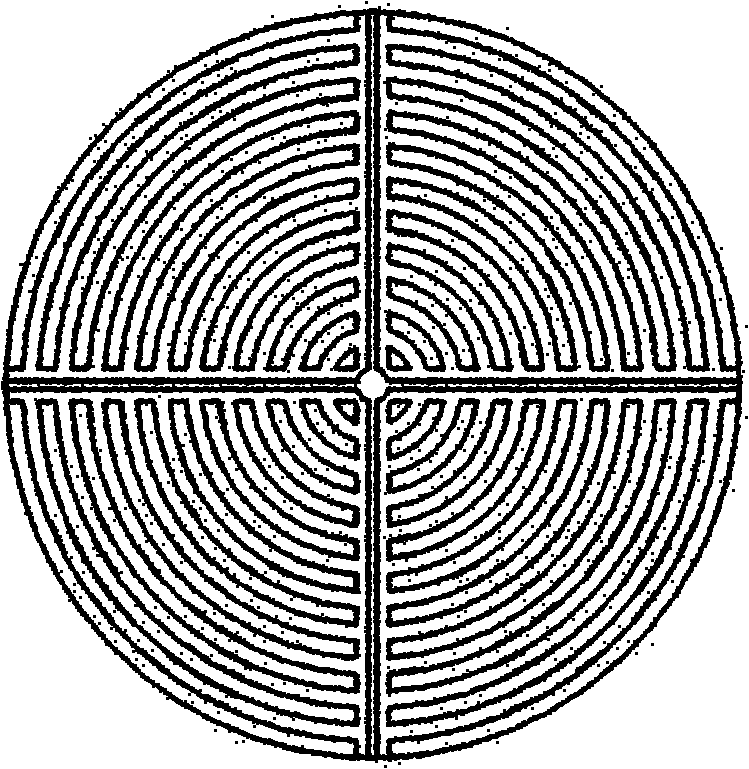

Bipolar plate with mosquito incense type flow field distribution structure

InactiveCN102104150ASmall inlet pressure dropReduce contact resistanceCell electrodesEngineeringMultiple layer

The invention relates to a bipolar plate with a mosquito incense type flow field distribution structure, comprising a bipolar plate body, the bipolar plate body is provided with a fuel and oxidant gas inlet and a tail gas outlet and in the shape of a cylinder; the surface of the cylinder is provided with an annular flow channel; the annular flow channel comprises multiple layers of annular flow channel units which are arranged from a circle center to an outer circle and mutually separated; the fuel and oxidant gas inlet is communicated with inlets of the annular flow channel units; the outlets of the annular flow channel units are communicated with the tail gas outlet; and the fuel and oxidant gas inlet and the tail gas outlet are radially arranged. The bipolar plate with the mosquito incense type flow field distribution structure has uniform distribution and effectively enhances the battery performance.

Owner:ZHEJIANG UNIV OF TECH

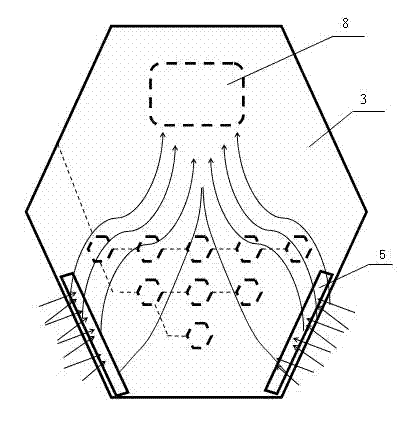

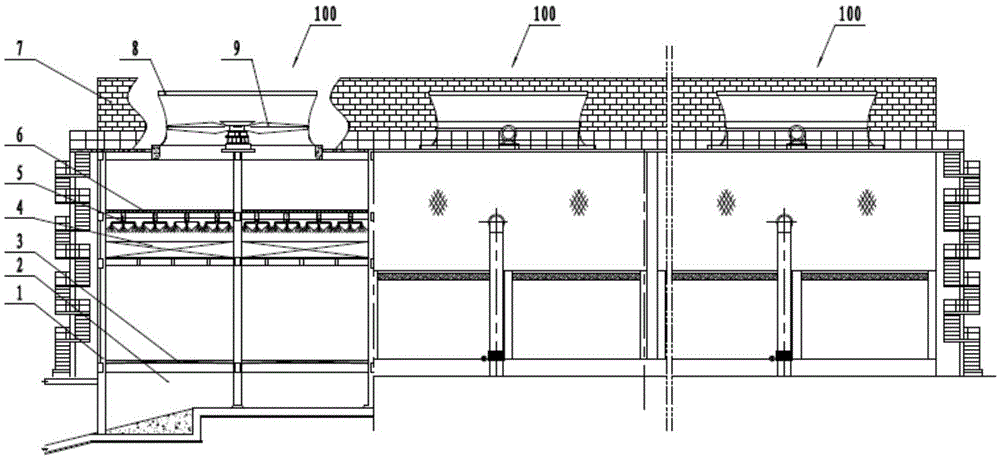

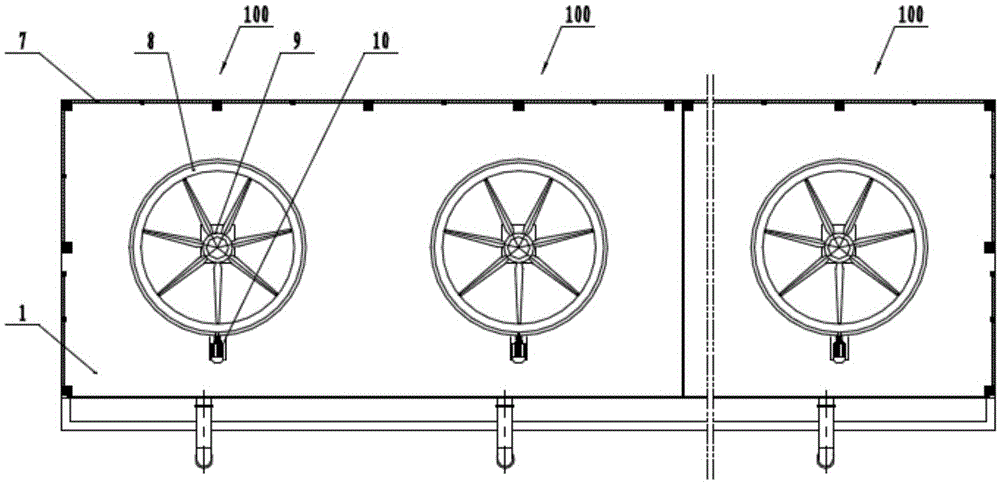

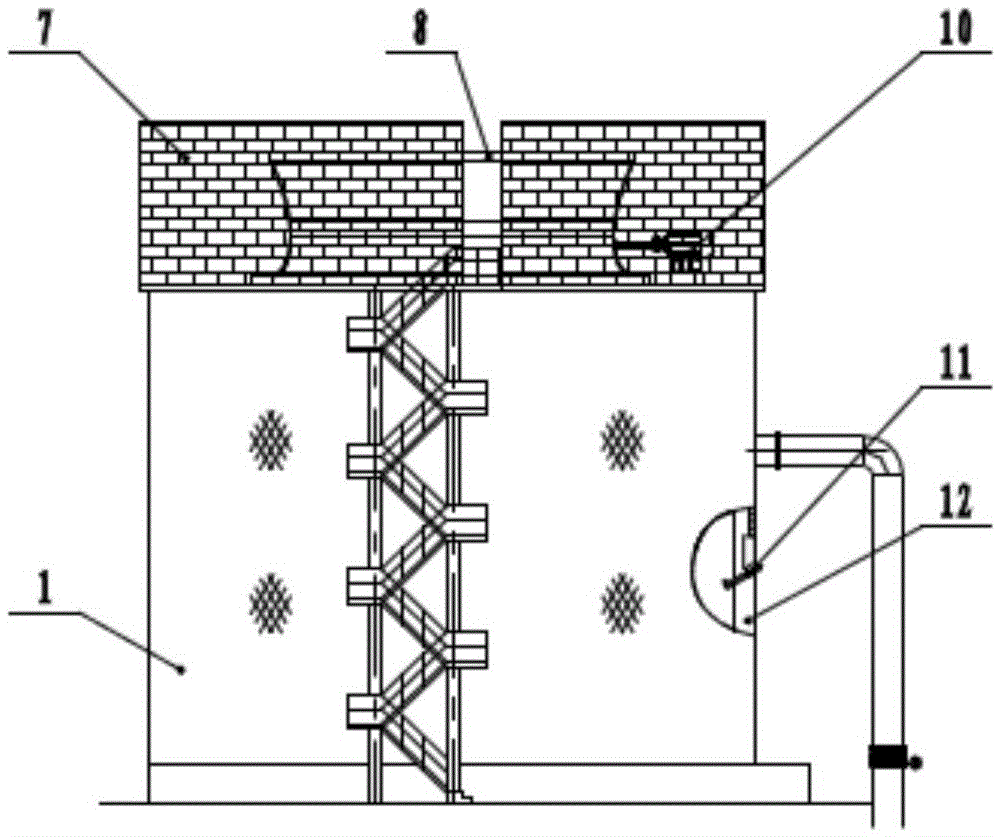

Low-noise cooling tower system

InactiveCN105486105AUnobstructed airflowReduce the wind resistance areaTrickle coolersDistribution systemThe chokes

The invention relates to a low-noise cooling tower system. The low-noise cooling tower system comprises at least two cooling towers which are arranged side by side, wherein each cooling tower comprises a vertical tower body, an air duct is arranged at the top of the tower body, a fan is mounted in the air duct, a water collector and a water distribution system are mounted at the upper part inside the tower body, a heat exchange filler layer is mounted below the water distribution system, and a water pool is arranged at the lower part inside the tower body; an air inlet is formed in the side wall of each tower body and located between the corresponding heat exchange filler layer and the corresponding water pool; silencing filler layers are arranged above the water pools of at least the two cooling towers located at two ends. According to the low-noise cooling tower system, the single-side air inlet reverse-flow type cooling towers are adopted, water spraying noise and air entering from the air inlets form convection, air flow in the towers is smooth, the choke area is small, and noise transmission is reduced; the silencing filler layers arranged in the towers can effectively eliminate the water spraying noise.

Owner:WUXI BLUE SKY GAS TURBINE COGENERATION CO LTD

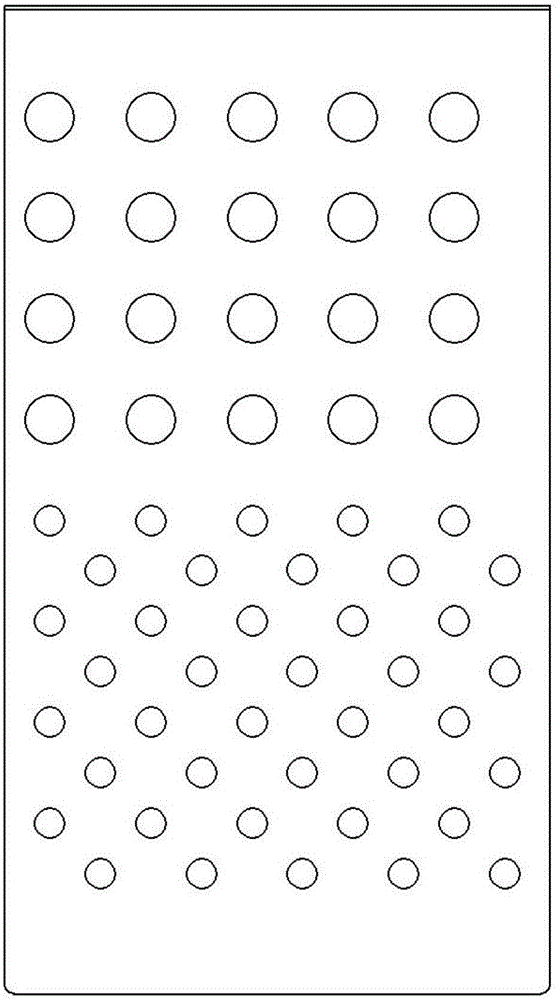

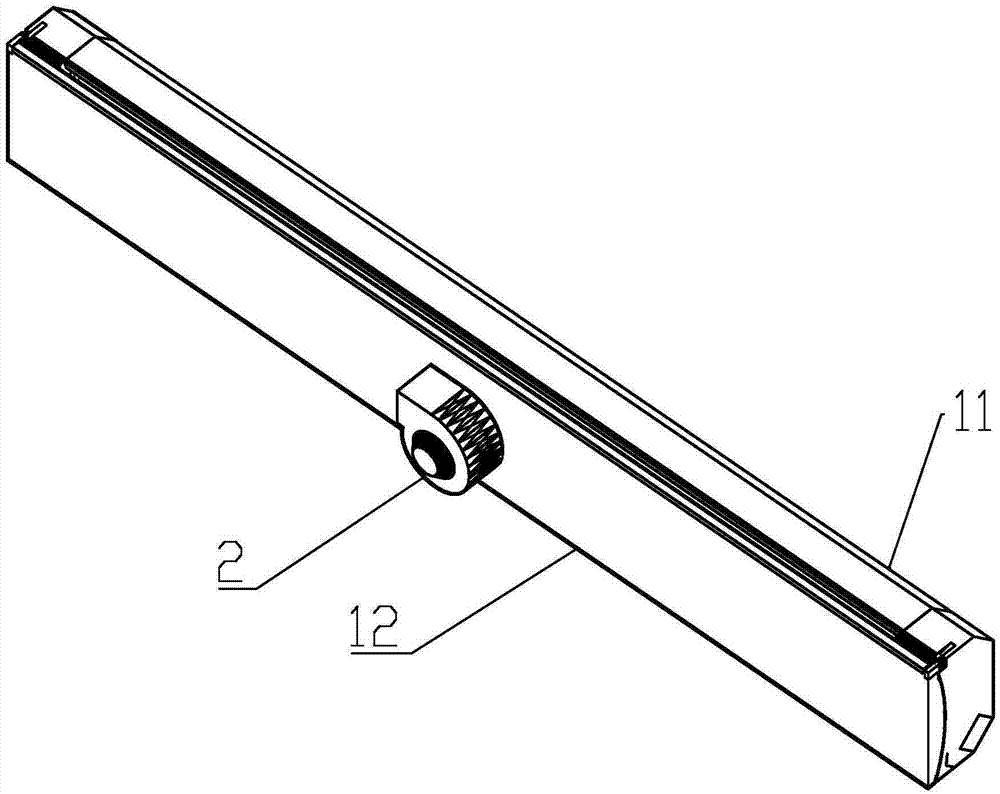

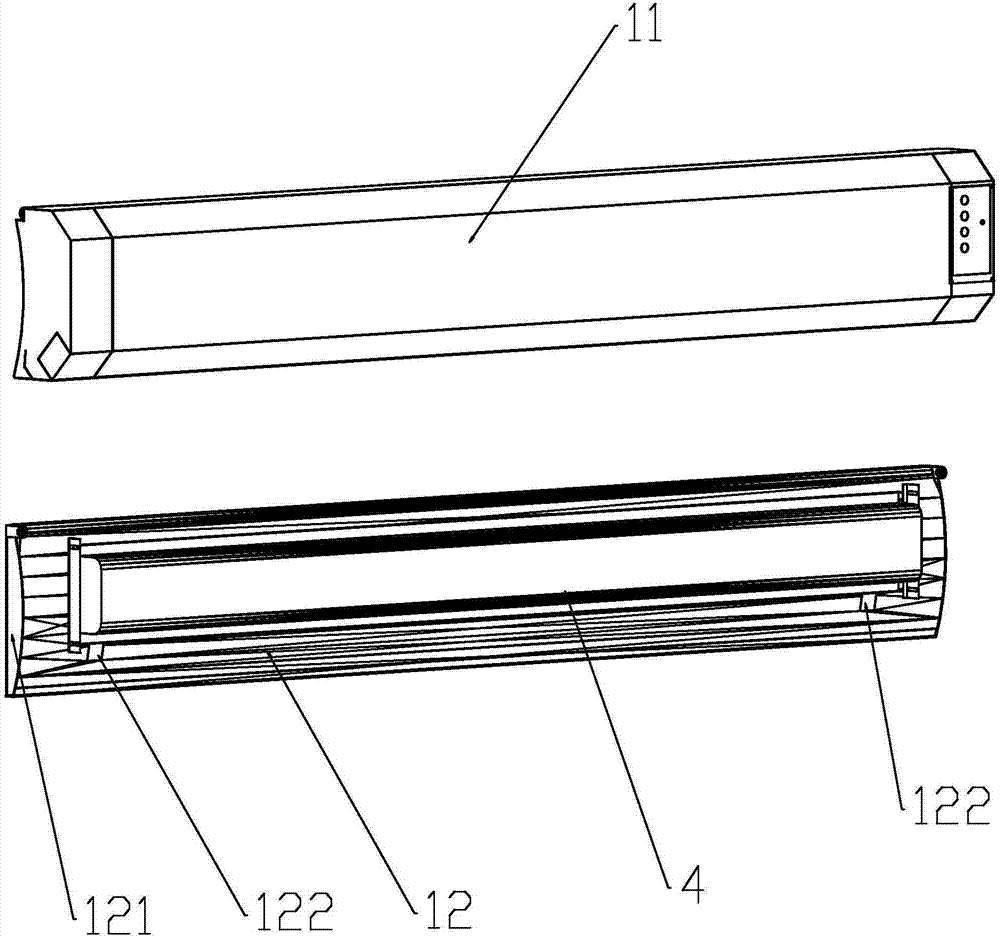

Cropping locating jig capable of preventing cropping pollution, and dust exhaust structure and method thereof

ActiveCN106181053AEfficient dischargeSmooth air flowDirt cleaningLaser beam welding apparatusMechanical engineeringPollution

A cropping locating jig capable of preventing cropping pollution, and a dust exhaust structure and method thereof are disclosed. The dust exhaust structure comprises: a cropping locating jig having a mounting groove formed in a front face thereof, a communicating groove formed in a back face thereof, and a plurality of air exhaust holes formed therein to communicate the mounting groove with the communicating groove, with the mounting groove being suitable for mounting a PCB panel, and an air suction device having a plurality of air suction holes and facing the bottom of the jig to allow at least one of the air suction holes to communicate with the communicating groove, wherein when the PCB panel is cropped, polluting dust generated is suited to reach the communicating groove via the air exhaust holes and further be sucked out via the air suction holes from the communicating groove.

Owner:NINGBO SUNNY OPOTECH CO LTD

Special mask for preventing haze

The invention relates to a special mask for preventing haze, and belongs to the field of protective appliances for everyday life of people. The special mask comprises a silicone face mask, filter mounting seats, PM.2.5 (Particulate Matter 2.5) filters, fixed belt fastening parts, exhalation valves, a mask body, inhalation valves and filtering layers; the mask body is arc-shaped, and the filter mounting seats are symmetrically mounted on the mask body; the exhalation valves are mounted on the cover body at the upper parts of the filter mounting seats; the inhalation valves and the PM2.5 filters with the filtering layers are mounted on the filter mounting seats; the fixed belt fastening parts are movably mounted at two sides of the mask body. According to the special mask for preventing the haze, the structure that an exhaling channel, filters and an inhaling channel are separated is adopted, and thereby, smooth airflow is ensured, a user can breathe smoothly after wearing, the mask can fit the face well, the sealing effect is great, the inhaled air can be completely filtered before entering a human body, and as a result, good haze preventing effect is realized. With the adoption of the special mask for preventing the haze, the problems of the existing haze mask that the mask cannot tightly fit the face of a people, obvious haze preventing effect is not realized, and people feels oppressed and uncomfortable after long-time wearing, can be solved.

Owner:陈思敏 +1

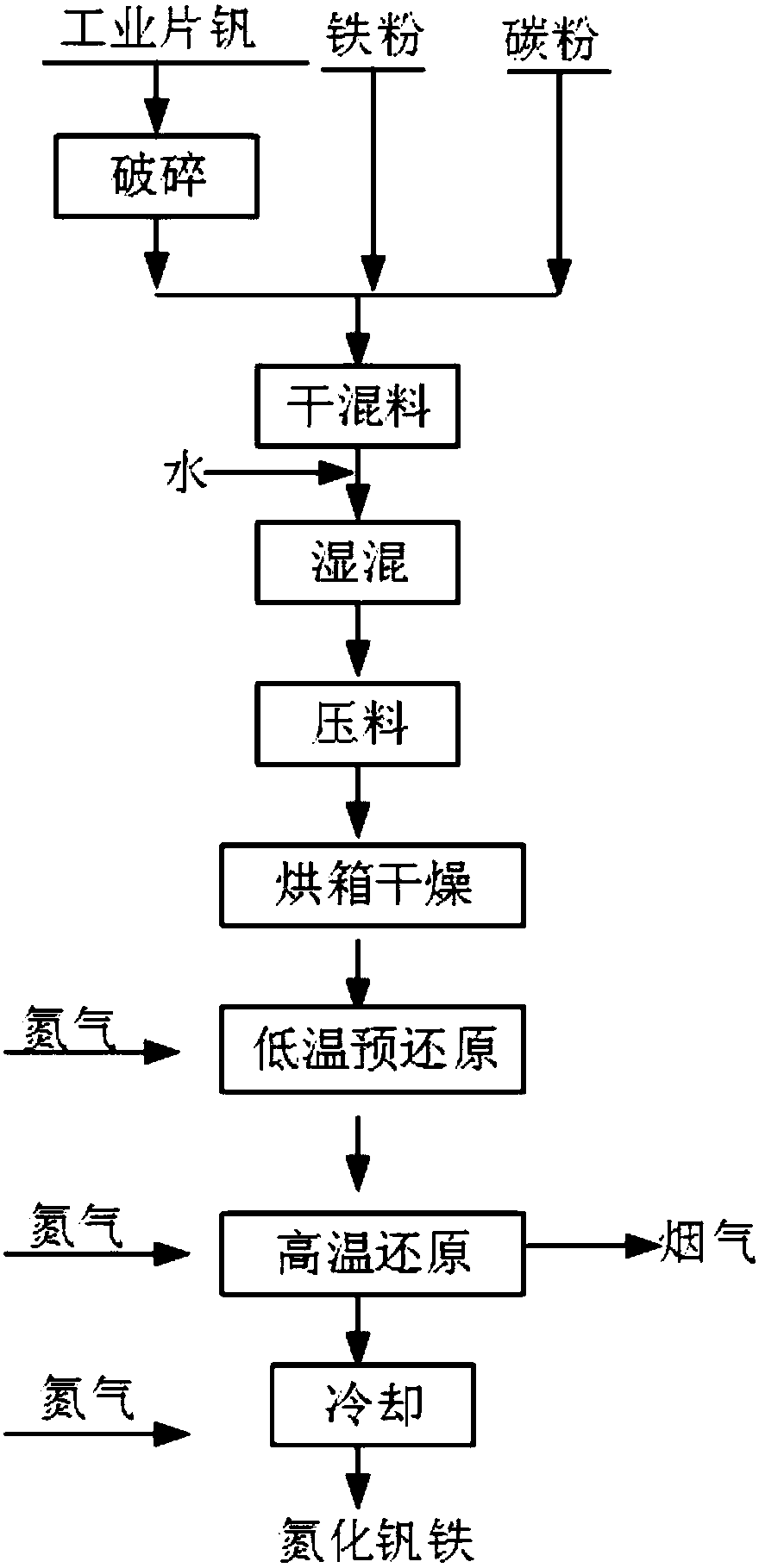

Method for preparing nitrided ferrovanadium

The invention discloses a method for preparing nitrided ferrovanadium. The method comprises the following steps that (1), a sample fabricated by uniformly mixing and pressing vanadium oxide powder, iron powder and carbon powder is subjected to prereduction through the nitrogen gas in a heating furnace, in the prereduction process, the temperature in the heating furnace is 650 + / -20 DEG C, the nitrogen gas flow is 150-180 L / h, and the heat preservation time of the heating furnace is 3-5 hours; (2), after heat preservation in step (1) is finished, the temperature of the heating furnace is then increased to 1200-1500 DEG C to perform final reduction on the sample, in the final reduction process, the nitrogen gas flow in the heating furnace is 150-180 L / h, and the heat preservation time of theheating furnace is 2-3 hours; (3), after heat preservation in step (2) is finished, the sample is cooled along with the furnace in the atmosphere of the nitrogen gas, and an obtained product is the nitrided ferrovanadium. According to the method, the vanadium oxide powder serves as the raw material, the iron powder serves as the iron source, the carbon powder serves as a reducing agent, the nitrogen gas is introduced into the heating furnace for reaction, and the method has the advantages that the procedure is simple, no vanadium slag is generated, the vanadium utilization rate is high, resources are saved, the environment is protected, and the production cost can be lowered.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

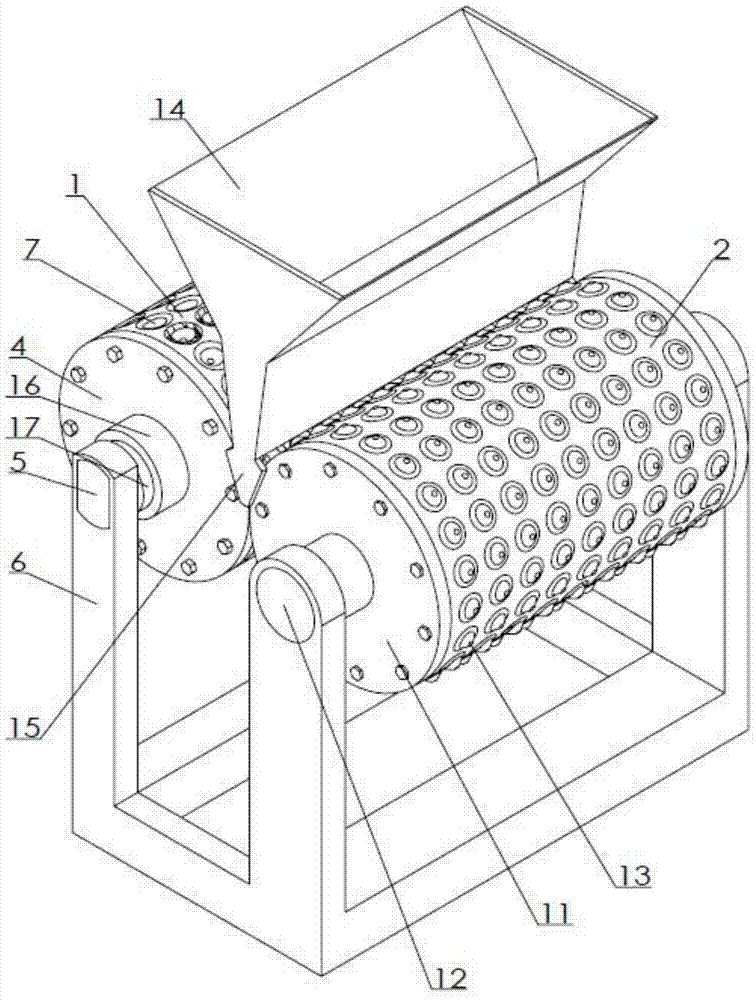

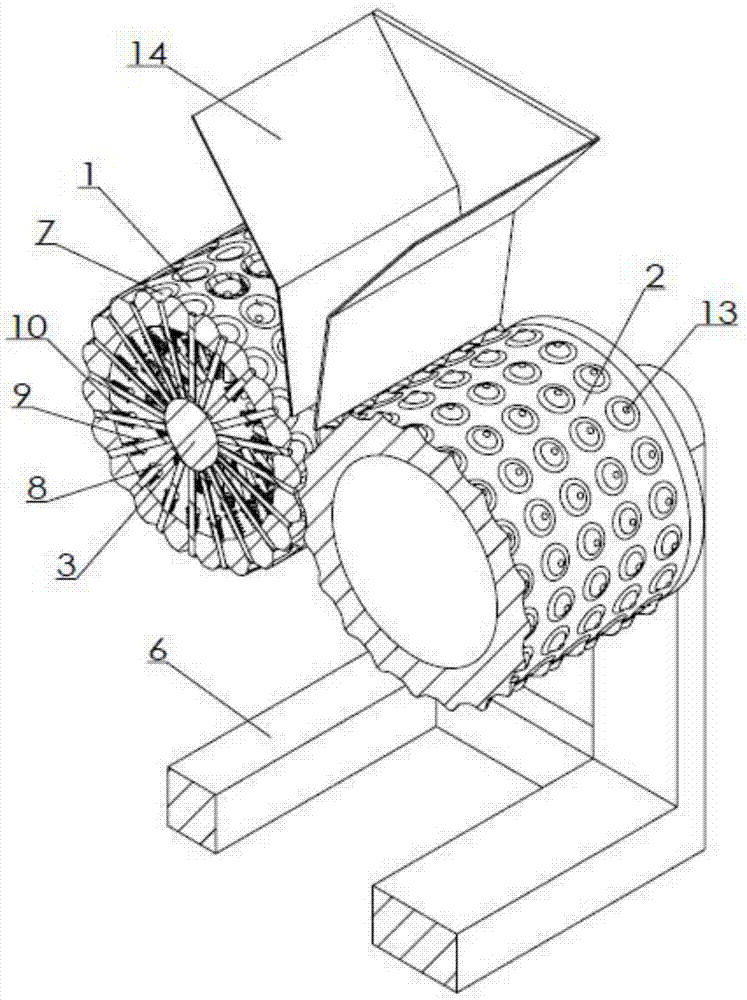

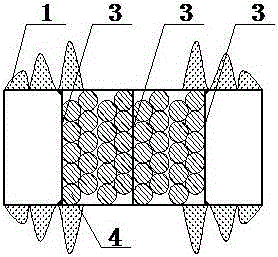

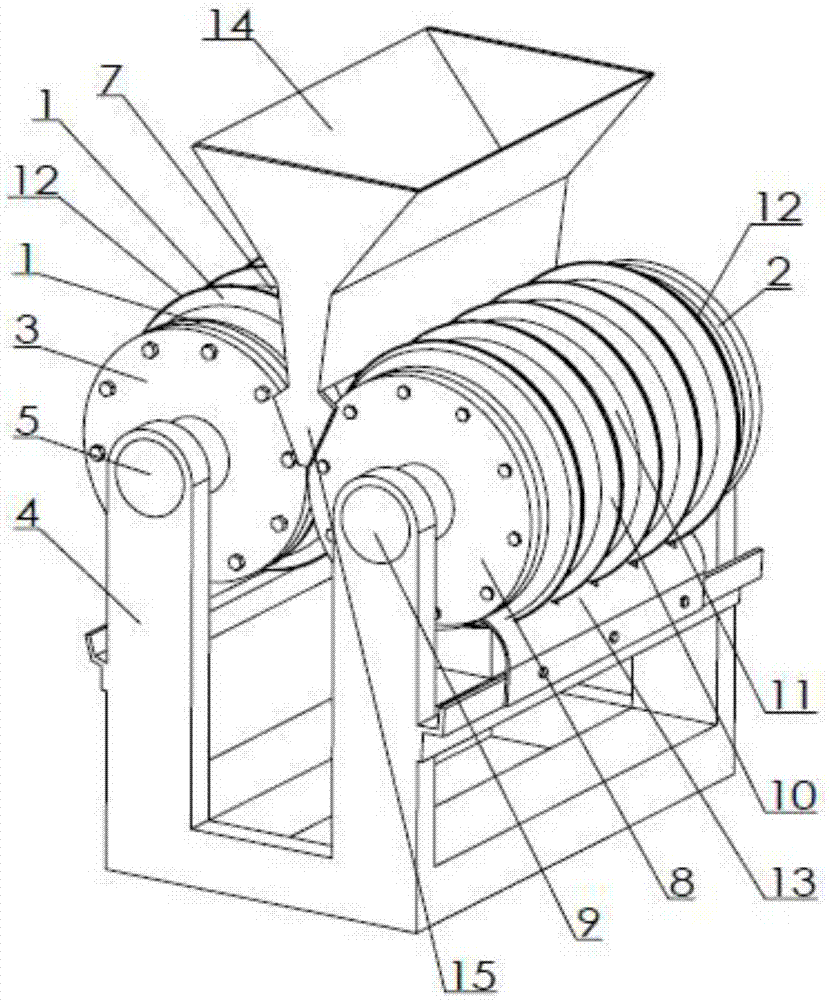

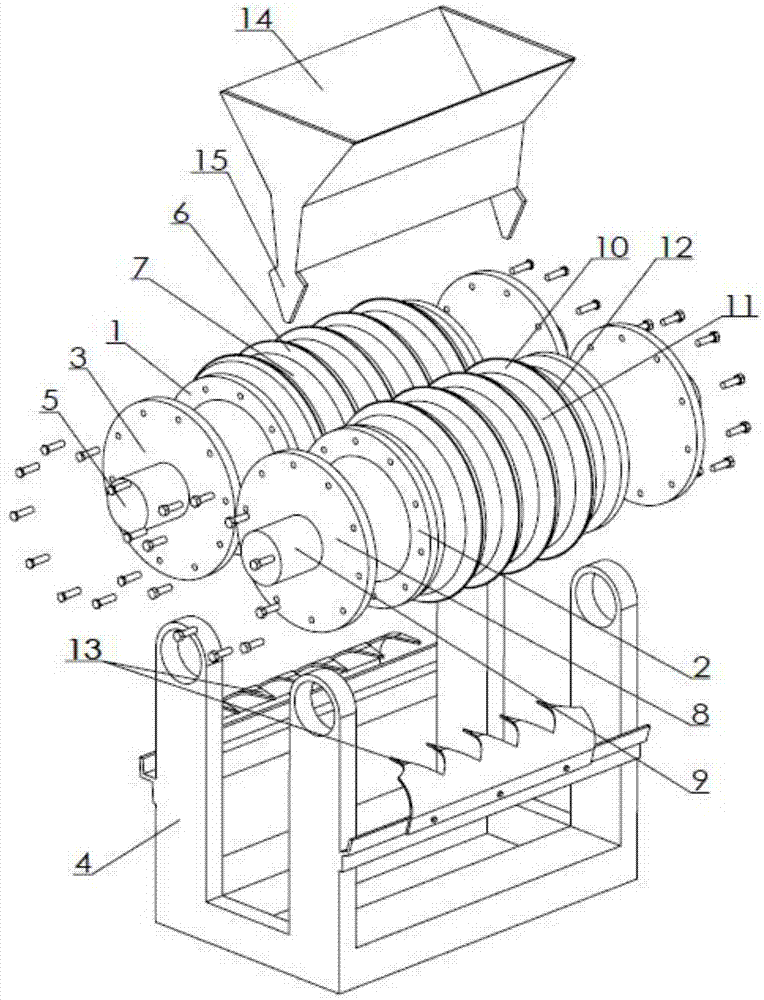

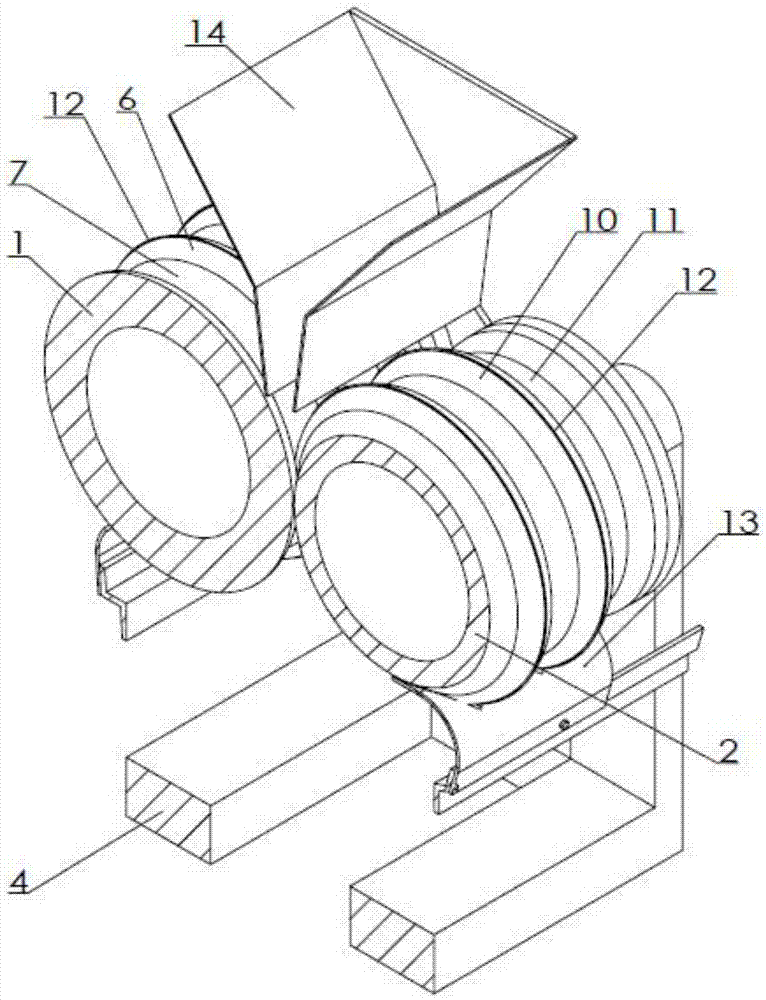

Roll compression device for bio-fuels

The invention discloses a roll compression device for bio-fuels. The roll compression device for the bio-fuels is characterized by comprising a main roll and a synchronous roll, wherein the main roll is barrel-shaped; a fixed shaft rod is arranged at an axis position; a cam shaft with a downwards-projecting part is arranged at a position aligned with the main roll, of the middle section of the shaft rod; polished shafts coaxial with the main roll are arranged at the two ends of the shaft rod; a shaft sleeve sleeves each polished shaft; each shaft sleeve is connected with a main end plate connected with the corresponding end surface of the main roll; the polished shafts at the two ends are connected with a location shaft respectively; each location shaft is fixedly connected with a support; peripherally-distributed recessions are arranged on the surface of the main roll; a hole penetrating through the sidewall of the main roll is arranged in the bottom of each recession; an ejection rod is fitted in each hole; and the inner end of each ejection rod is ejected onto the cam shaft. According to the invention, the pressed and broken particles have large gaps after being accumulated, a gas flow is smooth and combustion is vigorous after a boiler is filled with the particles, and moreover, the gaps can be furthest reserved through thoroughly combusting thin ash, thus promoting combustion.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

Efficient exhaust gas catalytic combustion process

InactiveCN110779031AExtended service lifeImprove purification efficiencyIncinerator apparatusFlame arresterPtru catalyst

The invention discloses an efficient exhaust gas catalytic combustion process. The process involves an electric control device, an induced draft fan, a purification device, a heat exchanger, a catalytic bed, an electric heating element and a dust removal flame arrestor, the process comprises the following steps that an organic gas source is fed into the purification device through the action of the induced draft fan, the organic gas source passes through a dust removal flame arrestor system firstly, then enters the heat exchanger, and is fed into a heating chamber, the combustion reaction temperature of gas is achieved through the electric heating element, then the organic gas is decomposed into carbon dioxide and water through the action of the catalytic bed, and then enters the heat exchanger, and heat exchange is carried out between the organic gas and low-temperature gas, so that the temperature of the entered gas is increased to reach the reaction temperature. According to the efficient exhaust gas catalytic combustion process, noble metal such as palladium, and platinum plating is adopted to be used as catalysts on a honeycomb ceramic carrier, the purification efficiency reaches up to 95% or above, the service life of the catalysts is long, the airflow is unobstructed, the resistance is small, automatic control is achieved through PLC control, watching of special people is not needed, and the process safety is improved through the arranged dust removal flame arrestor.

Owner:苏州联滔环保设备有限公司

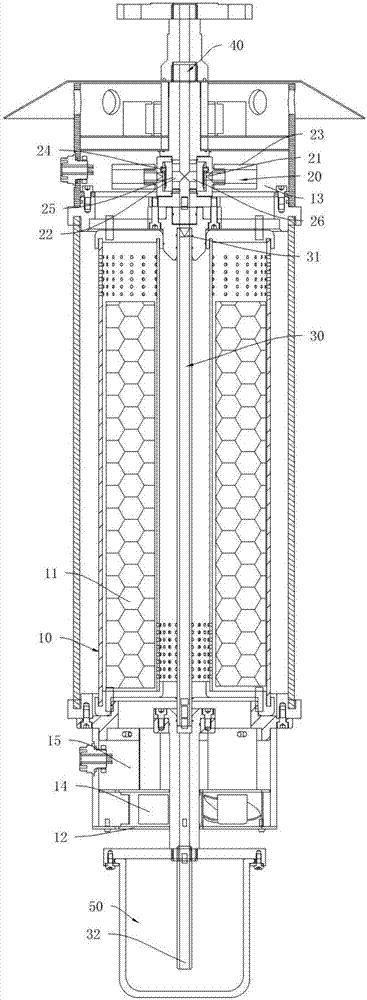

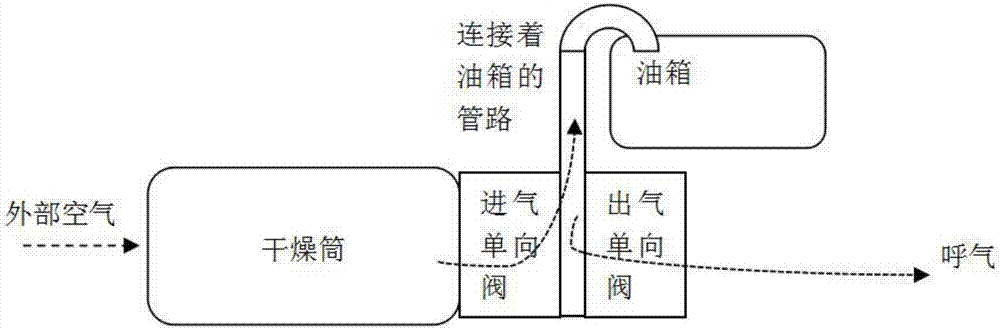

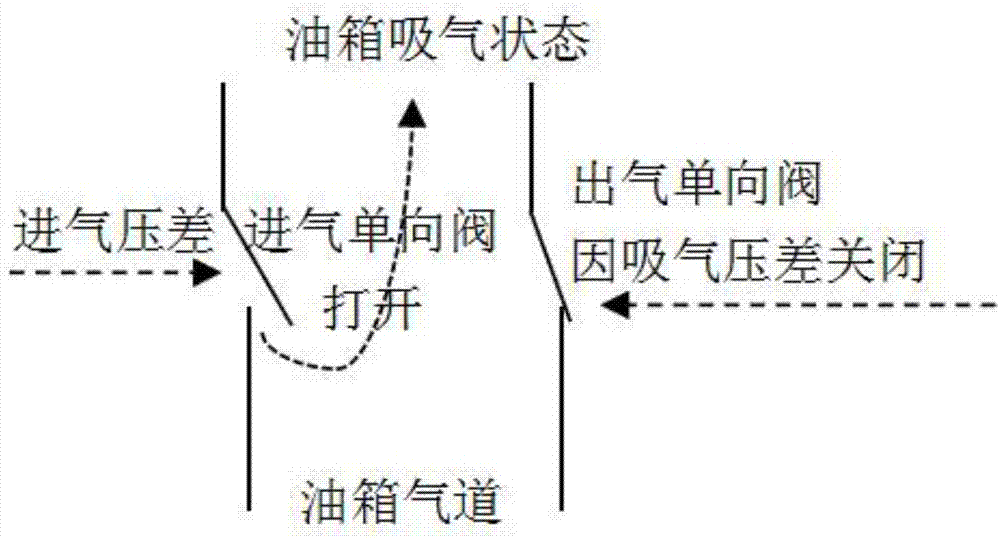

Breather for transformers

PendingCN107452473AGuaranteed pureExtended service lifeTransformers/inductances coolingTransformer oilElectrical and Electronics engineering

The invention discloses a breather for transformers and solves the problem that since exhaust and suction passages of an existing breather for transformers are not separated, oil-bearing gas exhausted by an oil tank of a transformer passes by a drying barrel and contaminate a drying agent. The breather comprises a drying barrel and also comprises an intake passage and an exhaust passage, the suction passage is communicated with a gas passage of an oil tank, the intake passage is provided with an intake one-way valve that has a flow direction from the outside of the breather toward the gas passage of the oil tank, the intake passage is communicated with the drying barrel, the exhaust passage is provided with an exhaust one-way valve that has a flow direction from the gas passage of the oil tank toward the outside of the breather, one end of the exhaust passage is communicated with the gas passage of the oil tank, the other end of the exhaust passage is communicated with the outside of the breather, and the exhaust passage is isolated from the drying agent in the drying barrel. The breather has the advantages that the intake passage and the exhaust passage are separated in order to directly discharge oil-bearing gas exhausted by the oil tank of the transformer out of the breather, the service life of the drying agent is greatly extended, smoothness of a gas flow in the breather is maintained for long time, and maintenance cost is reduced.

Owner:HANGZHOU KELIN ELECTRIC POWER EQUIP

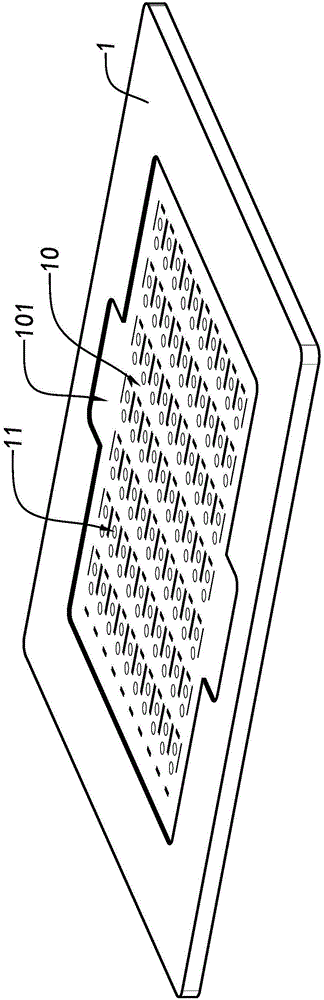

Saggar for roasting electronic elements and electronic materials

InactiveCN102519262AUniform heating and cooling atmosphereBottom airflowCharge supportsElectronic materialsMaterials science

A saggar for roasting electronic elements and electronic materials belongs to a container made of refractory materials and comprises a saggar body. Supporting lugs are disposed at the bottom of the saggar body, so that when used in a kiln, the saggar is heated and cooled uniformly, airflow at the bottom of the saggar is smooth, influence of contact stress concentration between the saggar and a push plate is low, possibility of crack of the bottom of the saggar is reduced, the service life of the saggar is prolonged, and service cost is lowered.

Owner:江苏三恒高技术窑具有限公司

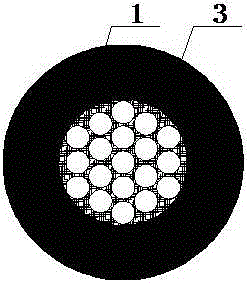

Buffering and pressure reduction earplug

InactiveCN105287102ADoes not affect hearingUnobstructed airflowEarplugsAmbient pressurePulp and paper industry

The invention relates to a buffering and pressure reduction earplug which comprises rubber sealing rings, a sleeve, filter nets and a plurality of small light elastic balls. The rubber sealing rings are arranged on the outer sides of the two ends of the sleeve. External air is prevented from entering the auditory meatus. The filter nets are arranged at the two ends and the middle of the inner side of the sleeve. The multiple small light elastic balls are arranged at the intervals between every two of the three filter nets. The middle filter net can move leftwards and rightwards. The buffering and pressure reduction earplug can well protect the hearing organ against influences of ambient pressure changes on the condition that the audition is not affected, and the wide application prospect and obvious economic effects are achieved.

Owner:SHANGHAI UNIV

Dustproof cover dust removal device

InactiveCN107854921ASimple structureAvoid enteringDispersed particle filtrationRubber ringArchitectural engineering

The invention relates to the field of dustproof equipment and provides a dustproof cover dust removal device. The dustproof cover dust removal device comprises a fan, wherein a dustproof cover is arranged on the upper part of the fan; the upper part of the inner side of the dustproof cover is hinged to the top of a telescopic rod of a telescopic device; the bottom of the telescopic device is fixedly arranged at the lower part of the inner side of the dustproof cover; one side of the dustproof cover is movably connected with a casing of an equipment main body; a control device is arranged at the inner side of the dustproof cover; the telescopic device is electrically connected with the control device; a filtering screen and a dust collection hopper are arranged in the dustproof cover; the filtering screen is in a V shape; a dustproof rubber ring is arranged at the bottom of the dustproof cover. The telescopic device is an air cylinder. The dust collection hopper is connected with a dustdischarge pipeline. During the work of the equipment, the dustproof cover can be automatically opened; the airflow smoothness is ensured; during the machine halt of the equipment, the dustproof coveris automatically closed; the dust is prevented from entering the inside of the equipment; the dust removal effect is good; the normal exhaust is not influenced.

Owner:奕响(大连)科技有限公司

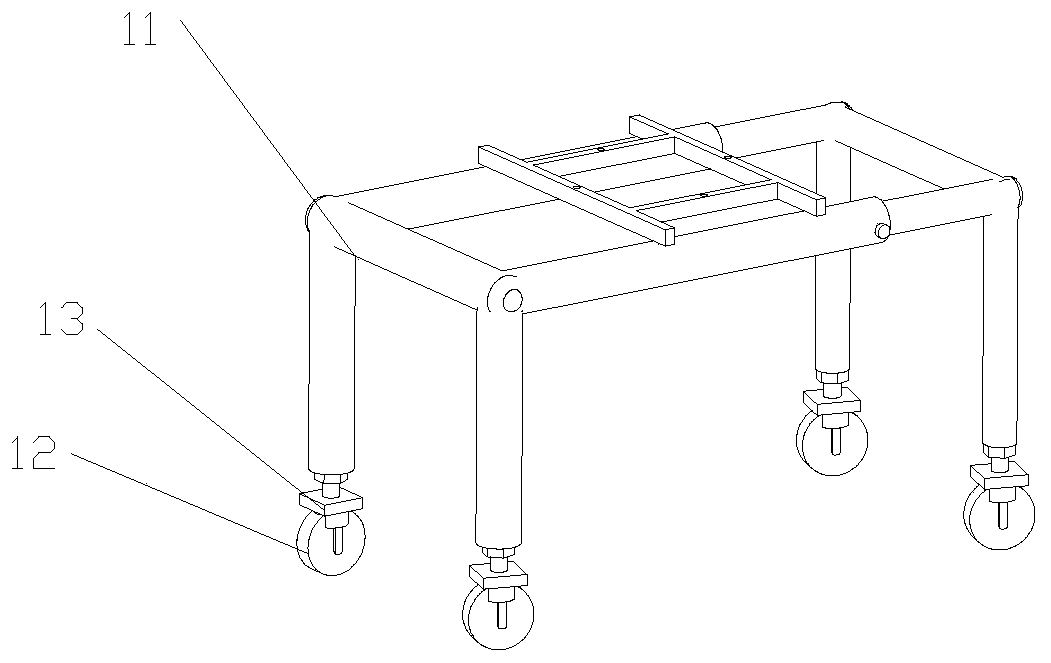

Medical anti-bedsore nursing bed with fresh air system

InactiveCN108042279AImprove comfortUnobstructed airflowNursing bedsAmbulance serviceFresh airEngineering

The invention relates to the technical field of medical instruments, in particular to a medical anti-bedsore nursing bed with a fresh air system. The nursing bed comprises a bed frame, a cavity is formed in the bed frame, and a fresh air chamber is formed in the top surface of the bed frame; a bed board is arranged on the fresh air chamber; and an inverted frustum-shaped battery chamber is arranged in the middle of the bottom surface of the bed frame; a battery pack is arranged in the inverted frustum-shaped battery chamber; an air blower is arranged in the middle of the left side surface of the fresh air chamber, and a heating assembly is arranged on an air outlet of the air blower; an exhaust fan is arranged at an air guide opening in the middle of the right side surface of the fresh airchamber, and a fresh air duct is formed. The fresh air cavity is formed in the lower portion of the nursing bed board, lifting cushion plates are arranged at the ankles, butts and back of the human body, and accordingly direct compression is relieved; a ventilation hole is formed to guarantee smooth air flow. The nursing bed is convenient to use and good in effect, greatly reduces the nursing strength, greatly improves the comfort degree of a patient, and is multipurpose.

Owner:重庆百瑞德生物科技有限公司

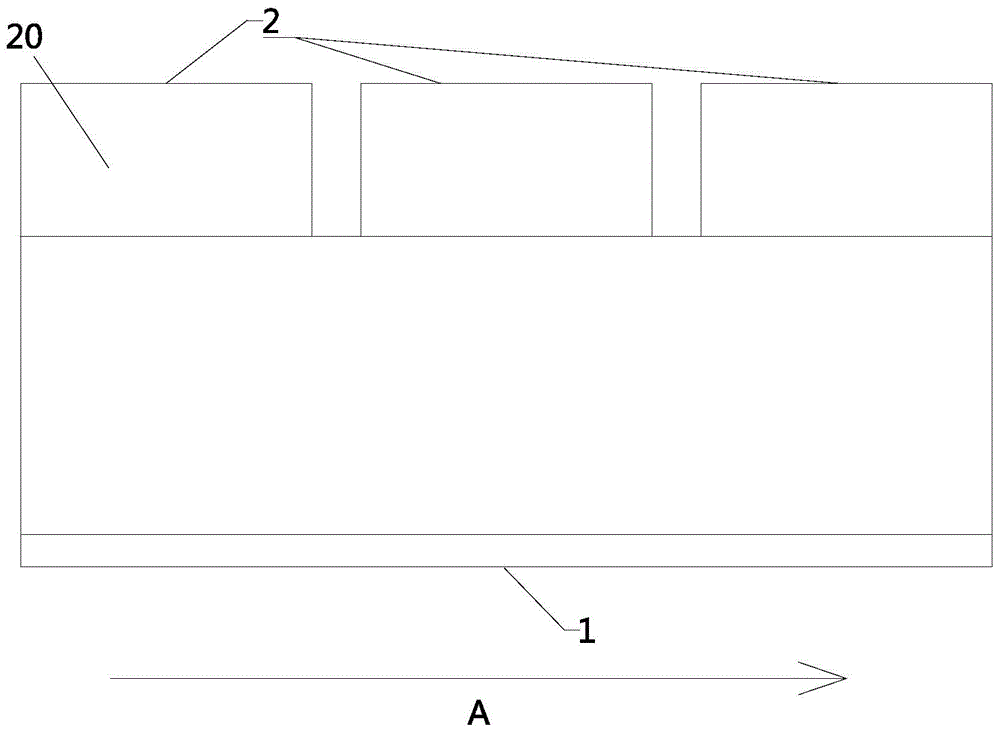

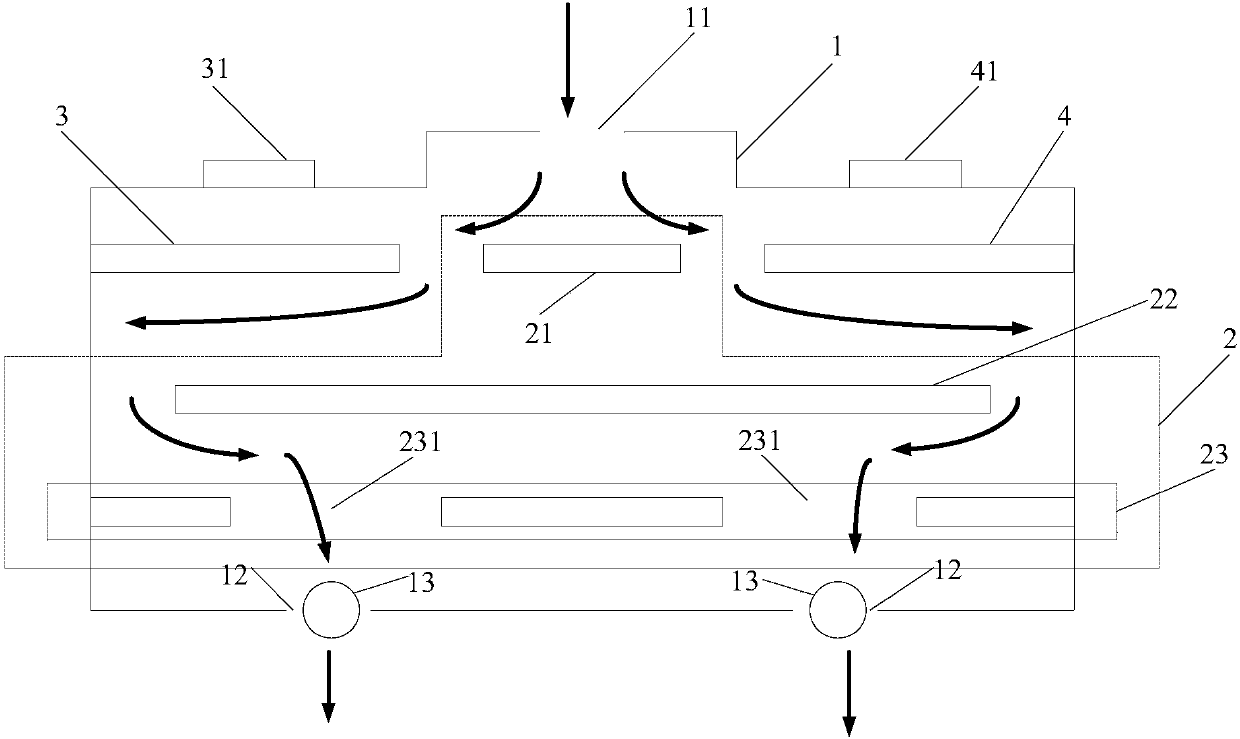

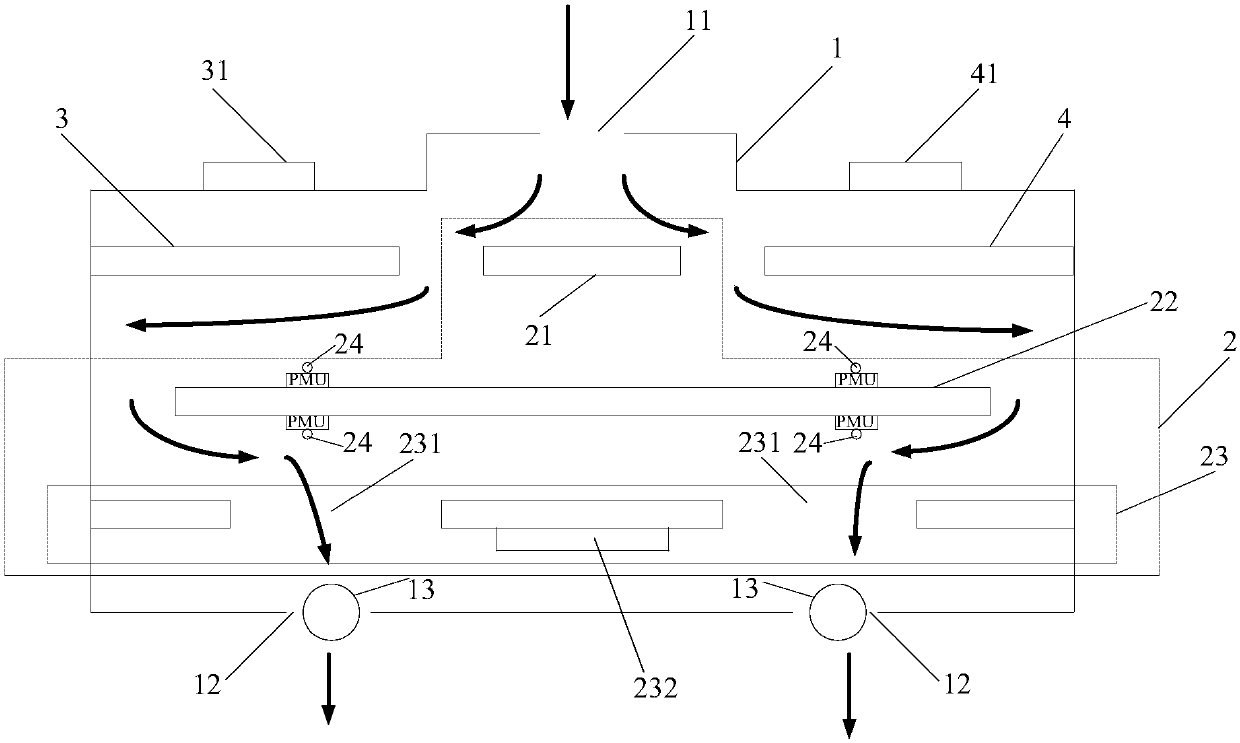

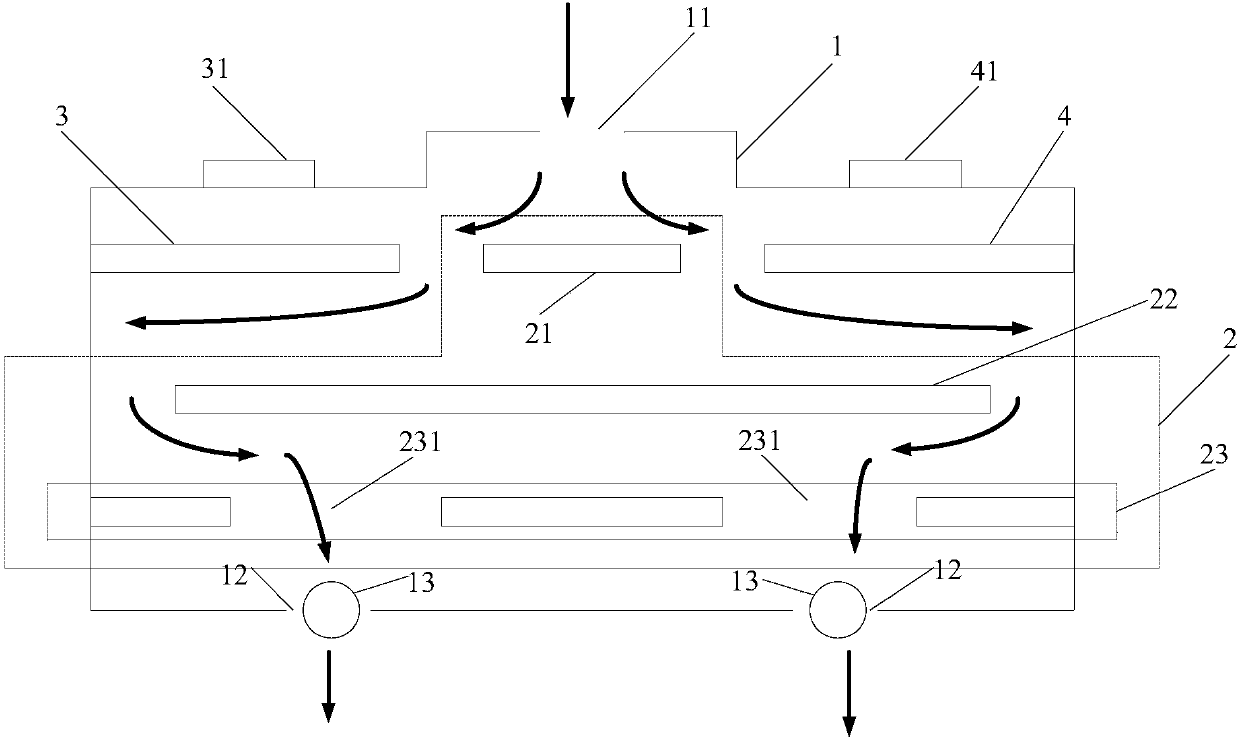

Modularized data center

InactiveCN104951017ARealize factory manufacturingImprove heat exchange efficiencyDigital processing power distributionCold airData center

The invention provides a modularized data center. The modularized data center comprises a lower box body and heat release devices, wherein cabinets and heat absorption devices are arranged in the lower box body, and the heat release devices are arranged outside the lower box body and connected with the heat absorption devices. Each cabinet comprises a cold air inlet and a hot air outlet. Each heat absorption device comprises a hot air inlet and a cold air outlet. The cabinets and the heat absorption devices are arranged side by side. The air entering and leaving direction of the cabinets is parallel to that of the heat absorption devices. The air flow flowing direction of the cabinets is opposite to that of the heat absorption devices. Thus, annular circulating air flow which sequentially passes through the hot air outlets of the cabinets, the hot air inlets of the heat absorption devices, the cold air outlets of the heat absorption devices and the cold air inlets of the cabinets is formed. The cabinets and the heat absorption devices are integrated in the lower box body, the space utilization rate and integrity are high, the modularized data center is suitable for being manufactured in an industrial mode, air flow in the lower box body is smooth, and the heat exchange efficiency is high.

Owner:GUANGDONG HIWAVE TECH

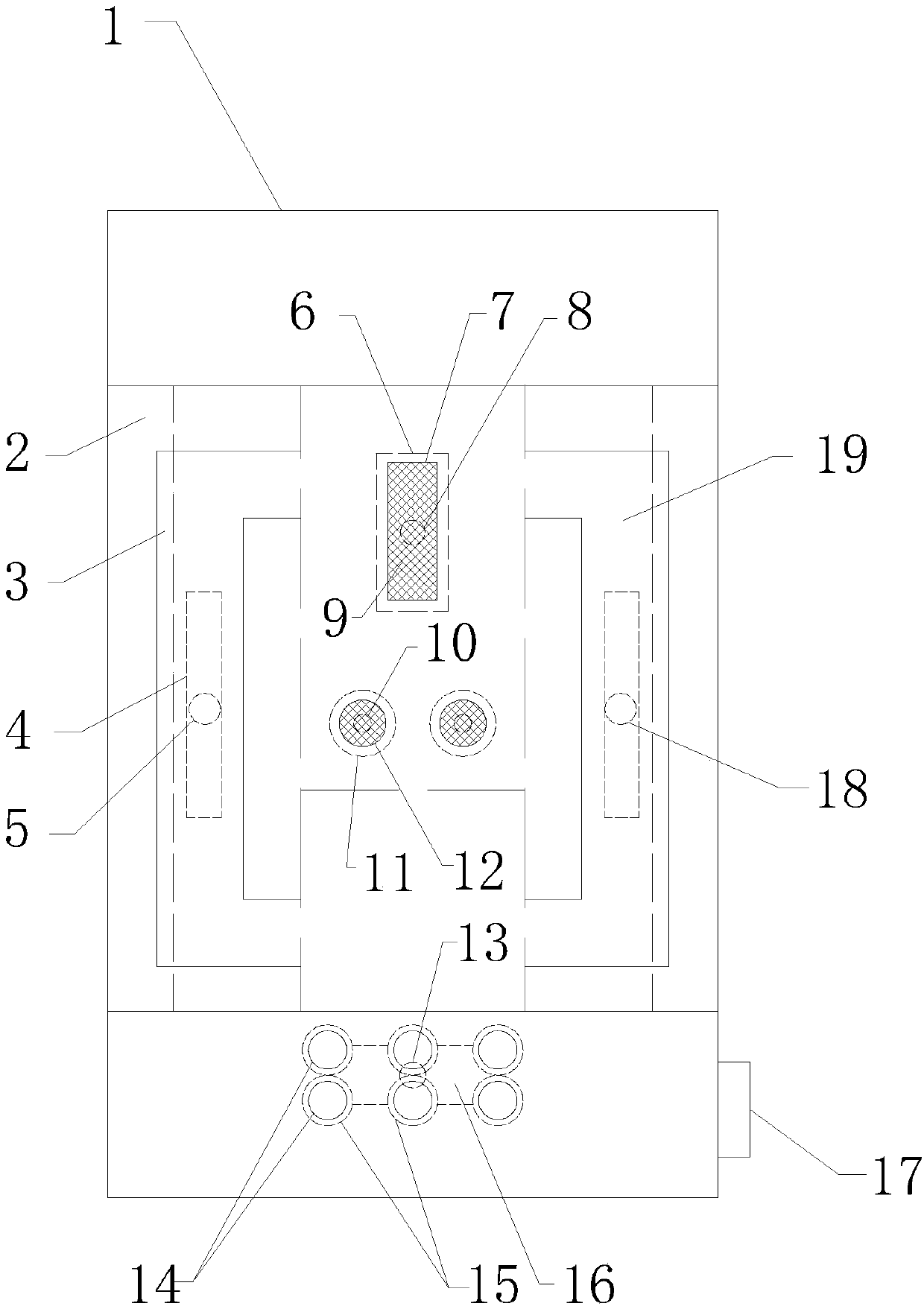

Chip testing system

ActiveCN109975684ARapid coolingUnobstructed airflowElectronic circuit testingCooling/ventilation/heating modificationsElectrical and Electronics engineeringEnvironmental temperature

The invention provides a chip testing system. The chip testing system comprises a heat dissipation cabinet as well as a chip testing device, a first chip interface board and a second chip interface board which are arranged in the heat dissipation cabinet; the chip testing device comprises a main control board, a measuring unit board and a power source board; an air inlet is formed in the top of the cabinet; at least one air outlet and at least one fan are arranged at the bottom of the cabinet; the first chip interface plate, the second chip interface board and the main control board are arranged above the measuring unit board; the power source board is arranged below the measuring unit board; the first chip interface board and the second chip interface board are arranged at two sides of the main control board respectively; gaps are formed between the first chip interface board and the second chip interface board and the main control board; no gaps are left between the first chip interface board and the second chip interface board and the side wall of the heat dissipation cabinet; chip insertion grooves in the first chip interface board and the second chip interface board are arranged outside the cabinet; gaps are formed between two sides of the measuring unit board and the side wall of the cabinet; no gaps exist between the power source board and the side wall of the heat dissipation cabinet; and the power source board comprises at least one through hole. The air circulation performance of the cabinet is good, the environment temperature of the equipment can be controlled,and high-temperature protection can be provided for the equipment.

Owner:GIGADEVICE SEMICON (BEIJING) INC +1

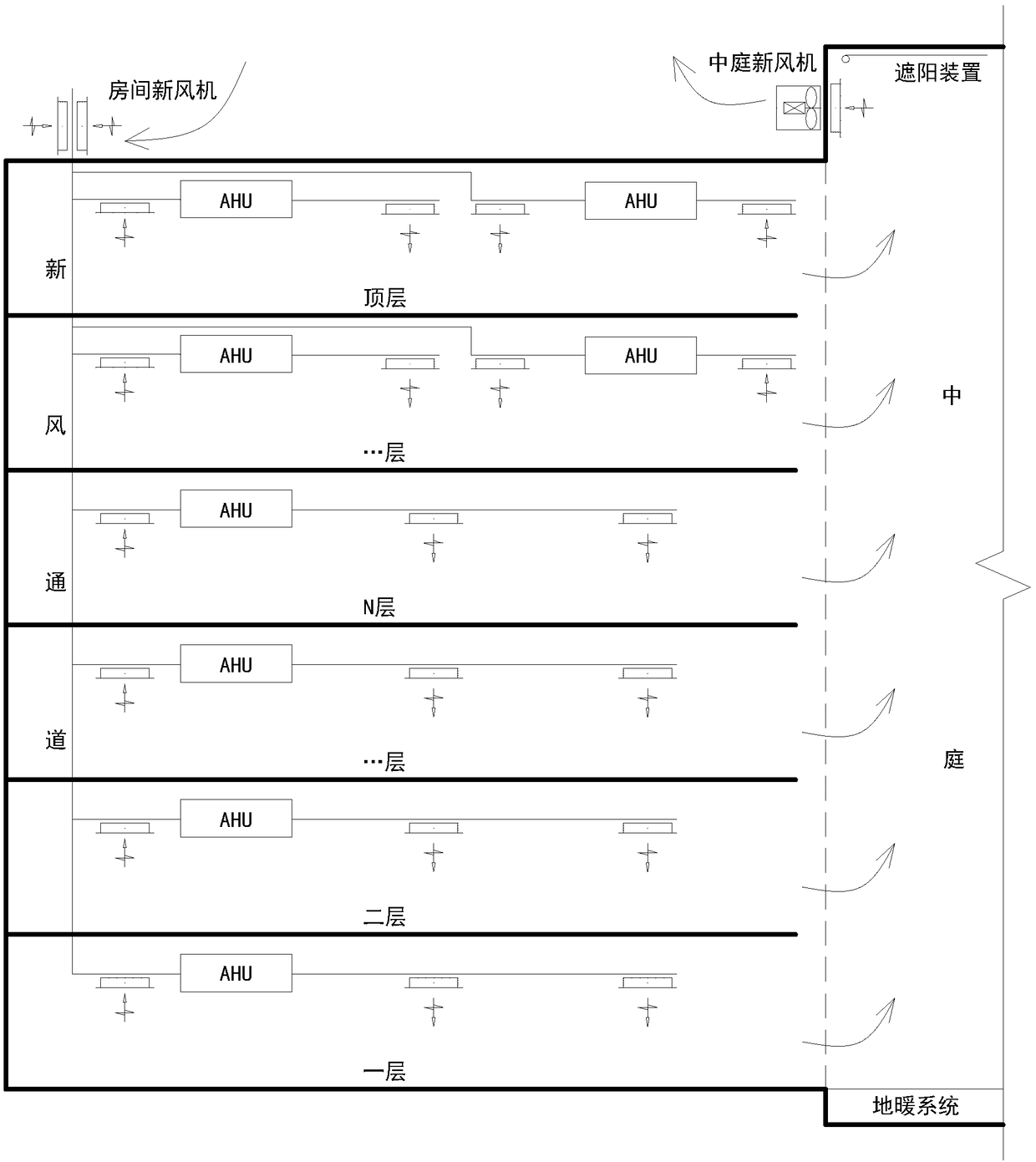

Air conditioning duct system capable of evenly regulating temperature field of building atrium

InactiveCN109140649AReasonable load distributionGuaranteed comfortMechanical apparatusSpace heating and ventilation safety systemsDevice formFresh air

The invention discloses an air conditioning duct system capable of evenly regulating a temperature field of a building atrium. Firstly, rooms and the atrium communicate with the outside, and the roomsand the atrium communicate mutually to form an air flowing channel; and secondly, the rooms or the atrium is provided with a fresh air device forming the air pressure, so that the air pressure difference is formed between the rooms and the atrium. The air conditioning duct system capable of evenly regulating the temperature field of the building atrium is provided for solving the problem that thelarge vertical temperature gradient of the atrium space cannot be solved by an existing air conditioning system. The temperature field of the atrium space can tend to uniform in the vertical direction through the air conditioning duct system.

Owner:SICHUAN LIJIU INTPROP SERVICE CO LTD

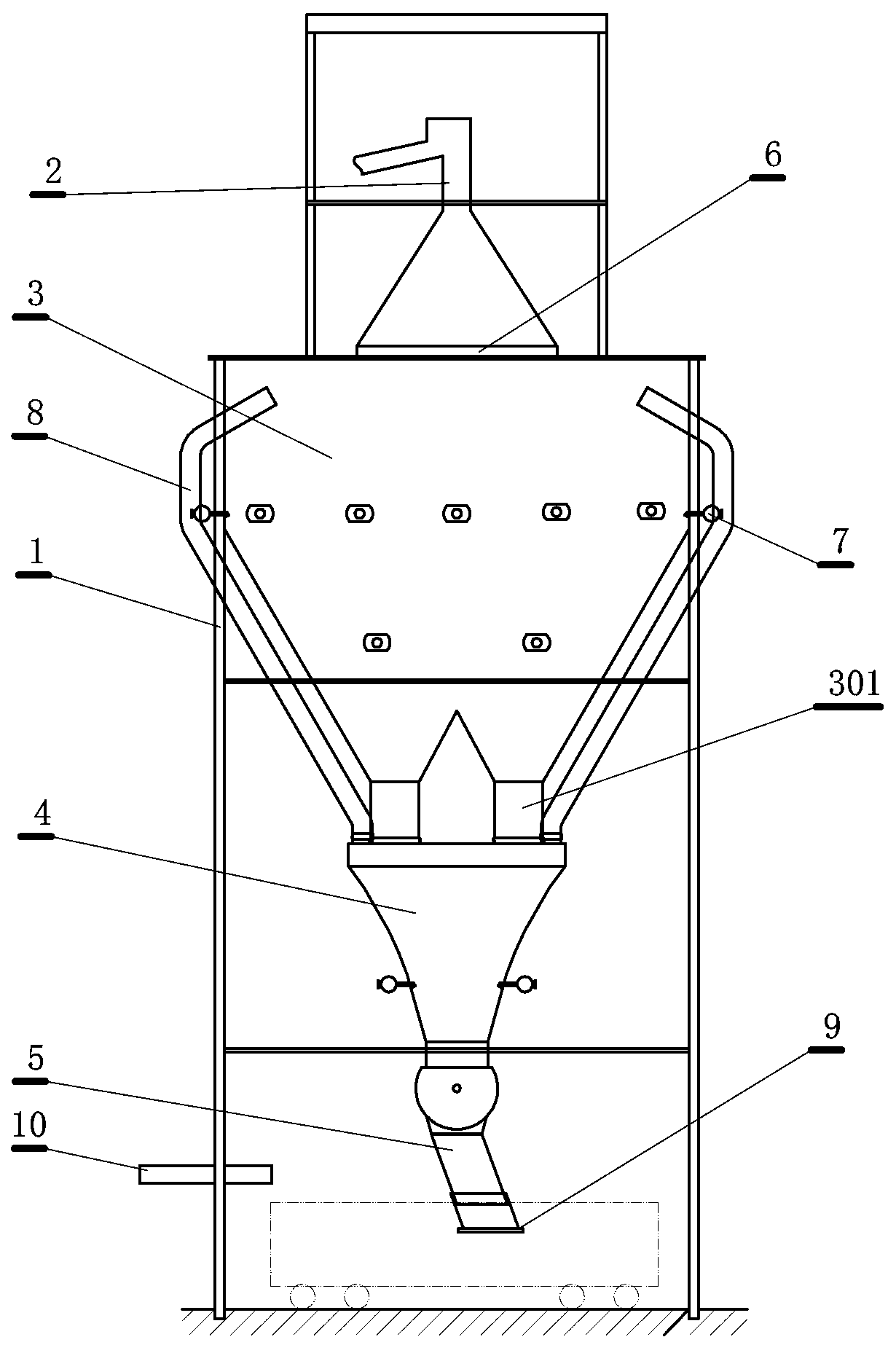

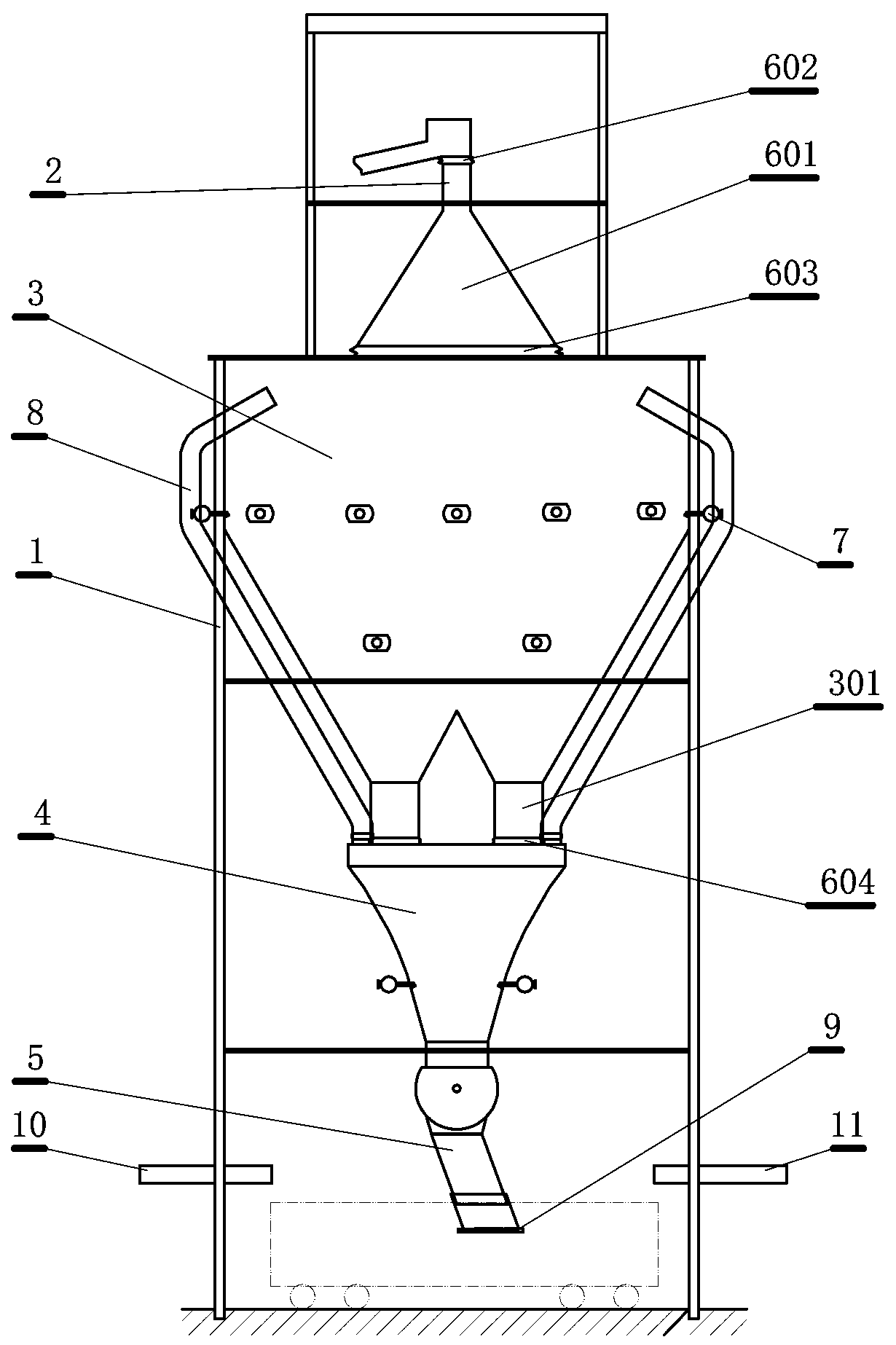

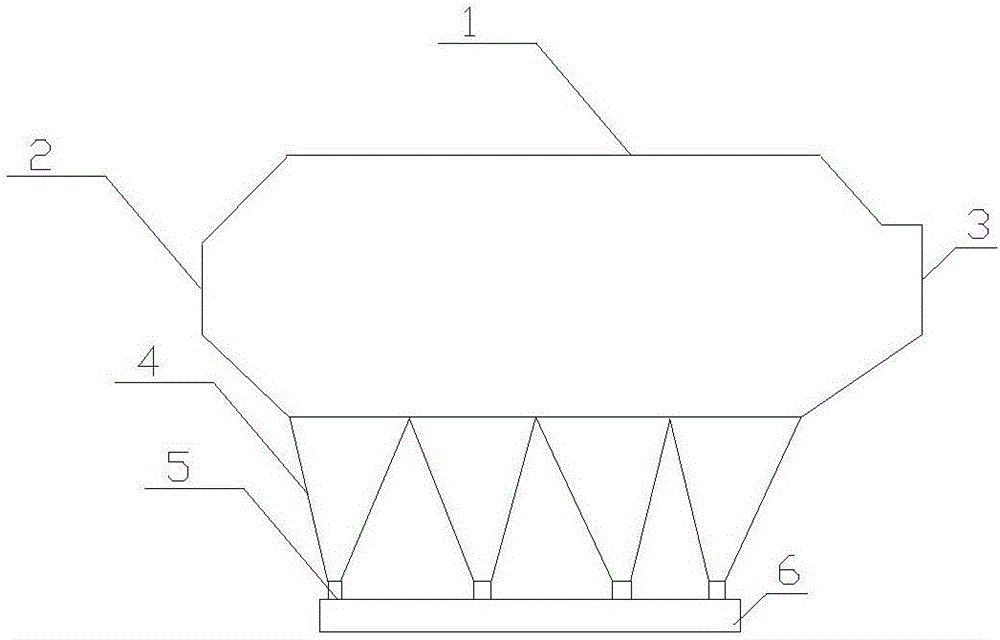

Coal-fired power plant fly ash rapid quantitative loading station and method

The invention relates to a coal-fired power plant fly ash rapid quantitative loading station and method. Sealing facilities are arranged between a conveyor belt machine head, a buffer bin, a quantitative bin and a swing chute, the buffer bin is provided with at least four discharge ports, the weighing bin body of a weighing bin is a hyperbolic liner polyurethane lining plate which is bent inwards,at least one layer of air cannons are uniformly distributed on the periphery bin wall of the buffer bin and the periphery bin wall of the quantitative bin respectively, nozzles of all the air cannonsare arranged downwards along the bin walls, one end of a vent pipe is arranged at the top of the quantitative bin, and the other end of the vent pipe is arranged in the position, close to the top, ofthe buffer bin. The buffer bin provided by the invention is provided with a plurality of material outlets, the quantitative bin adopts a hyperbolic bin wall, the bin wall is quite steep, so that rapid agglomeration of fly ash is avoided, the fly ash flows downwards easily, and meanwhile, the air cannons are arranged to promote the flow of the fly ash and effectively avoid agglomeration. Meanwhile, sealing is carried out between each cabin in the whole loading process to prevent leakage of the fly ash.

Owner:TIANDI SCI & TECH CO LTD +1

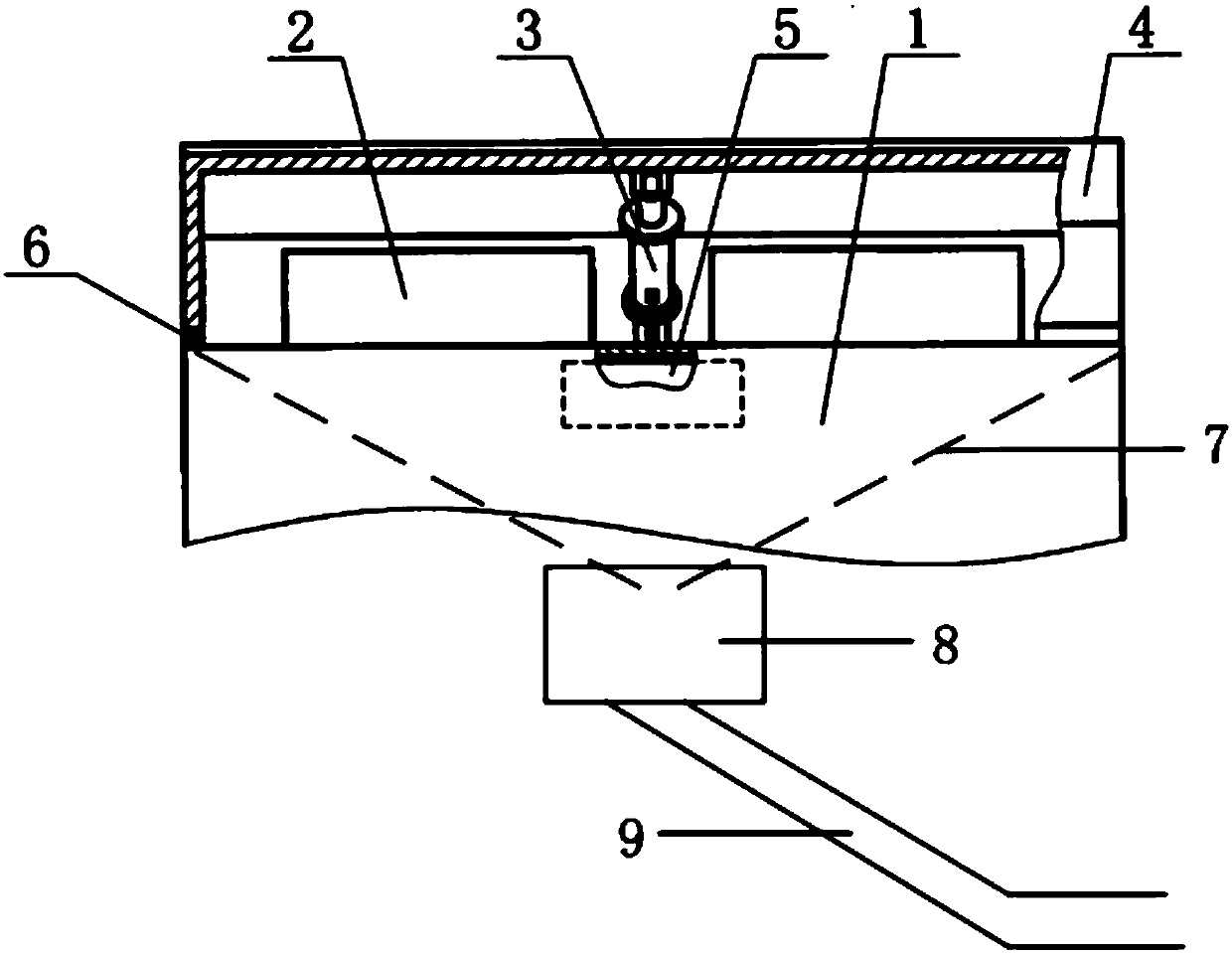

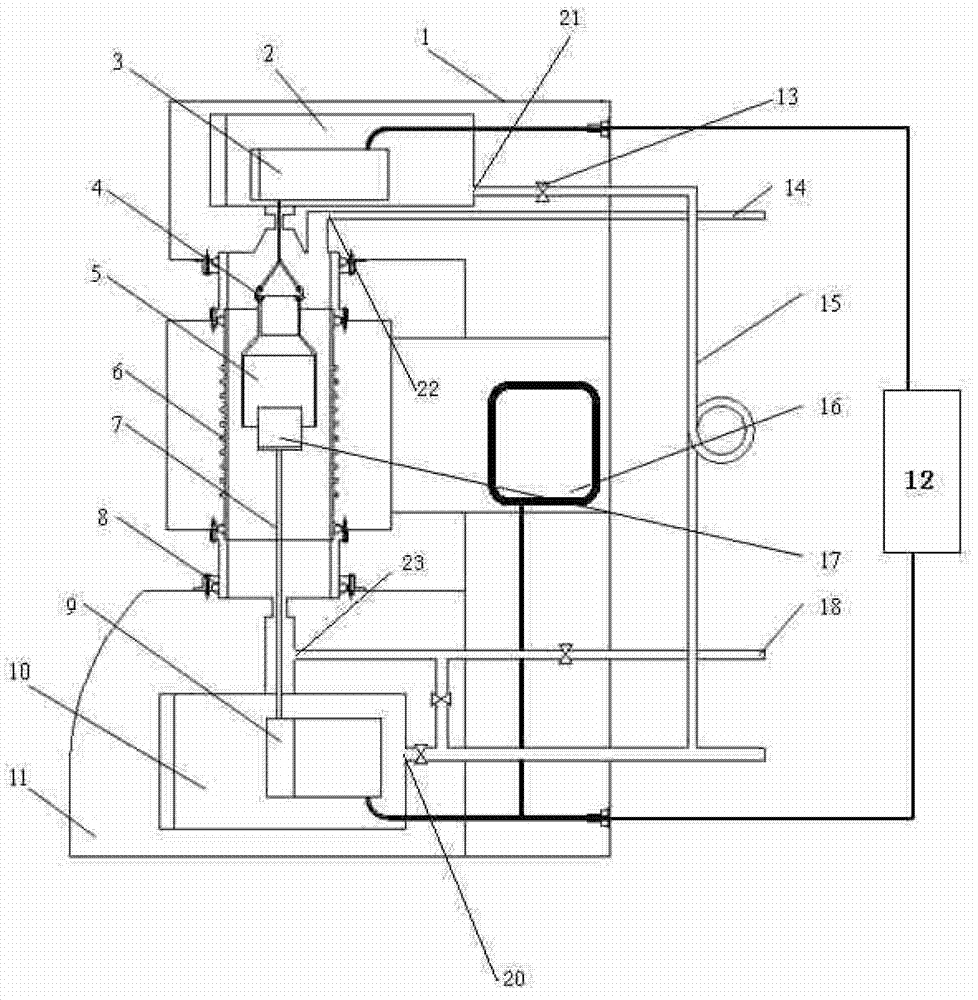

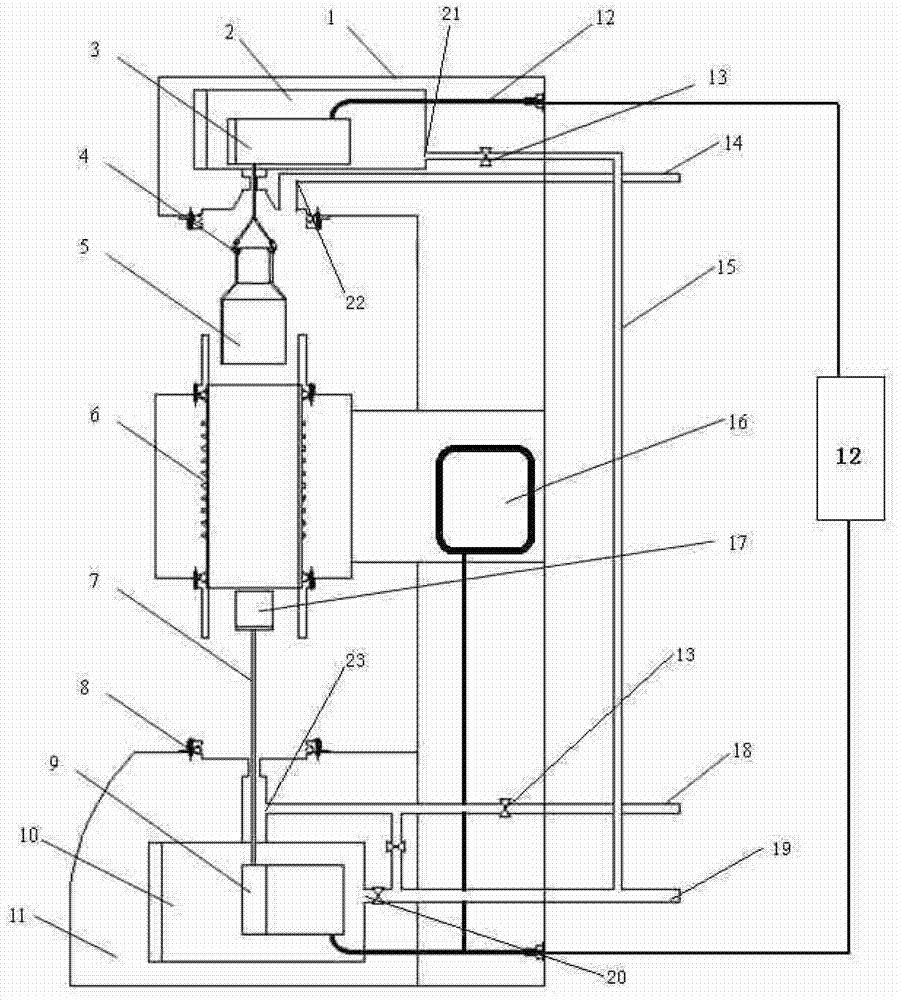

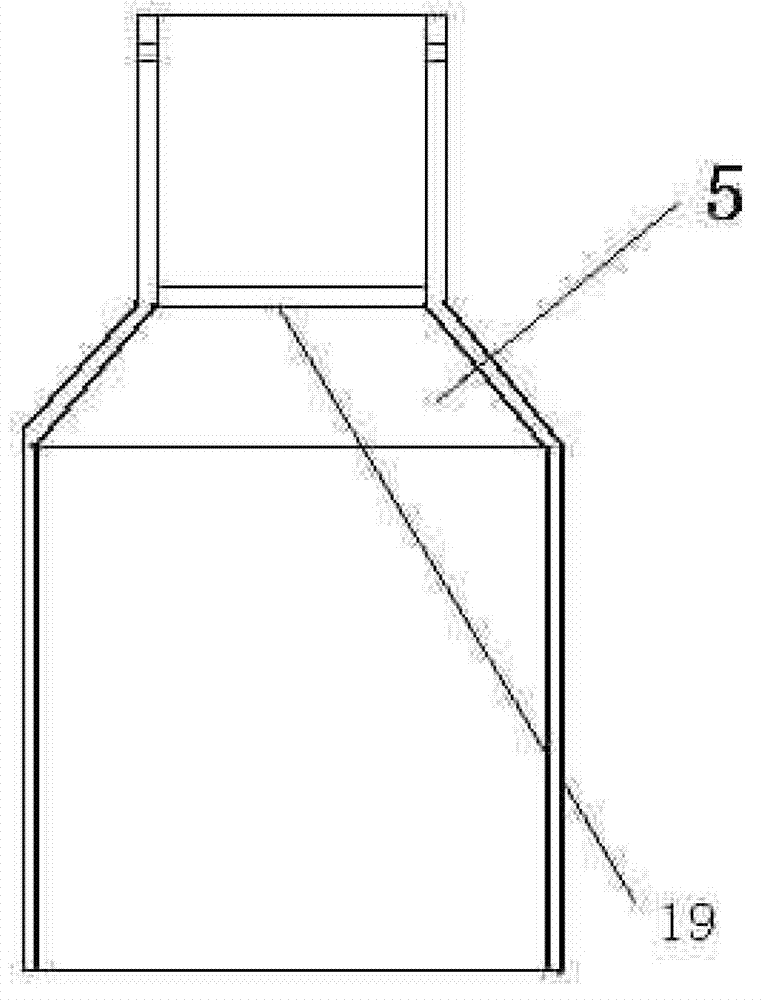

Thermogravimetric apparatus for measuring volatile and easily condensed products in reaction process

InactiveCN102901687AUnobstructed airflowComprehensive dataMaterial weighingData processing systemCrucible

The invention provides a thermogravimetric apparatus for measuring volatile and easily condensed products in products. The apparatus comprises a balance (1), a collecting cup (2), a heating furnace (3), an elevating device (4), a data processing system (5) and a gas circuit system (6), wherein the balance is used for measuring mass variation and comprises an upper end micro balance and a lower end micro balance; the lower end of the upper end micro balance is connected with a volatile matter condensing and collecting cup by a hanging hook and used for measuring the mass variation of the volatile and easily condensed products generated in the reaction; the lower end micro balance is connected with a crucible for placing samples through a reactant supporting rod and is used for measuring mass variation of the reactant; and the collecting cup completely covers the crucible for filling the reactant and has an effect of preventing volatile matters generated in the reaction from being condensed on a furnace tube. Through the adoption of the thermogravimetric apparatus provided by the invention, a difficult problem that the traditional thermogravimetric equipment cannot measure the samples of the volatile and easily condensed products generated in the reaction process; moreover, the mass variations of the samples and the volatile matters can be simultaneously measured, so that the thermogravimetric equipment obtains wider applicability.

Owner:UNIV OF SCI & TECH BEIJING

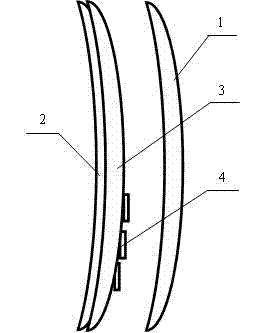

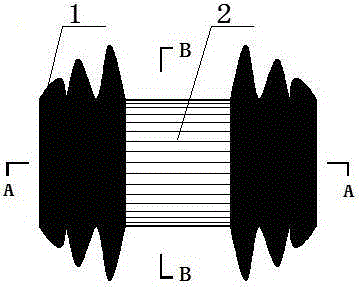

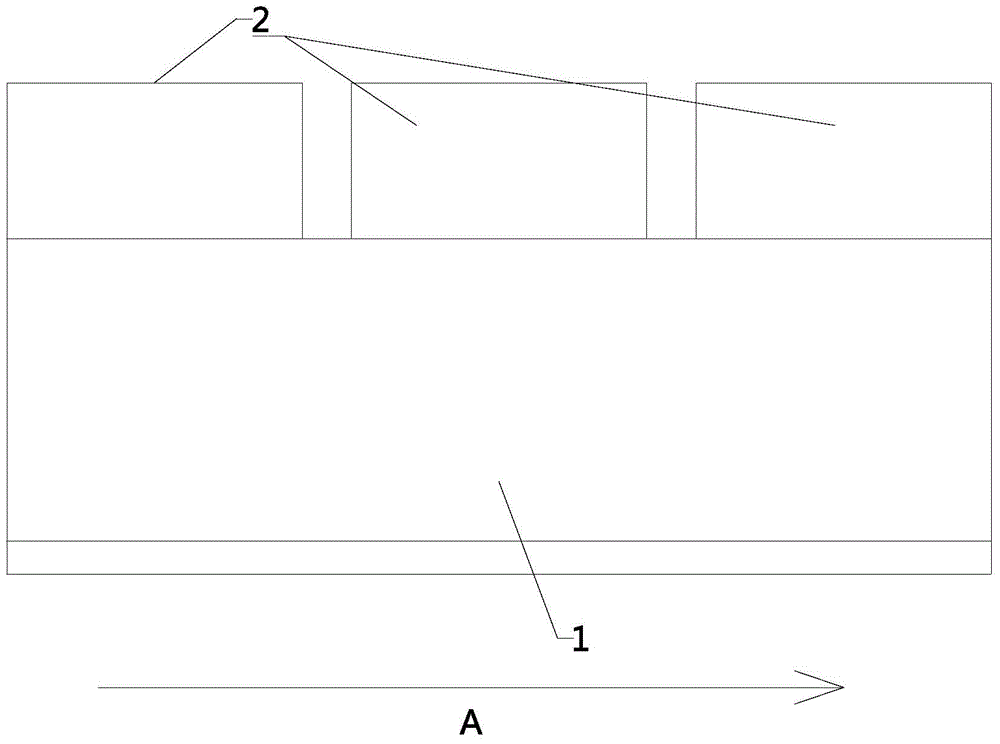

Biofuel curved piece type pressing device

The invention discloses a biofuel curved piece type pressing device. The biofuel curved piece type pressing device is characterized by comprising a main roller and a synchronous roller; the main roller is cylindrical; the two end surfaces of the main roller are fixedly connected with main end plates; the two main end plates are connected with main transmission rollers coaxially connected to a bracket with the main roller; peripheral main wave peaks and peripheral main wave troughs are axially spaced on the surface of the main roller; the synchronous roller is cylindrical, has the same length with the main roller, and is parallel to the axis of the main roller; the two ends of the synchronous roller are fixedly connected with synchronous end plates; the synchronous end plates are fixedly connected with synchronous transmission shafts coaxial with the synchronous roller; the synchronous transmission shafts and the main transmission rollers are connected through synchronous gears, and are opposite in rotating direction; and peripheral synchronous wave peaks and peripheral synchronous wave troughs are axially spaced on the surface of the synchronous roller. Particles obtained by pressing and smashing are accumulated to obtain big gaps, are filled in a boiler to realize smoothness of air currents, and are vigorously burnt; and burnt thin dust can retain the gaps to the greatest extent to accelerate combustion.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

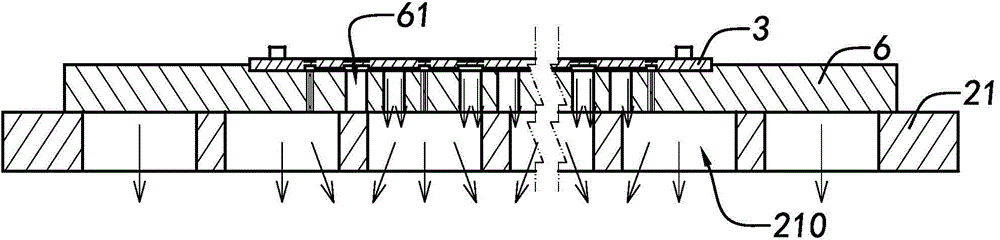

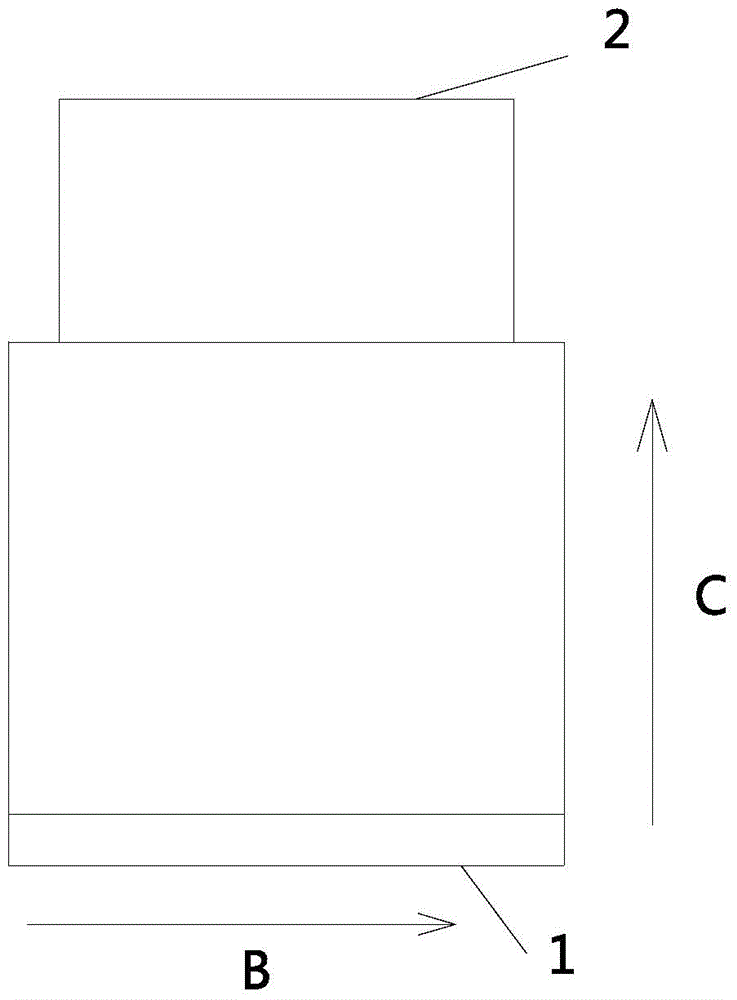

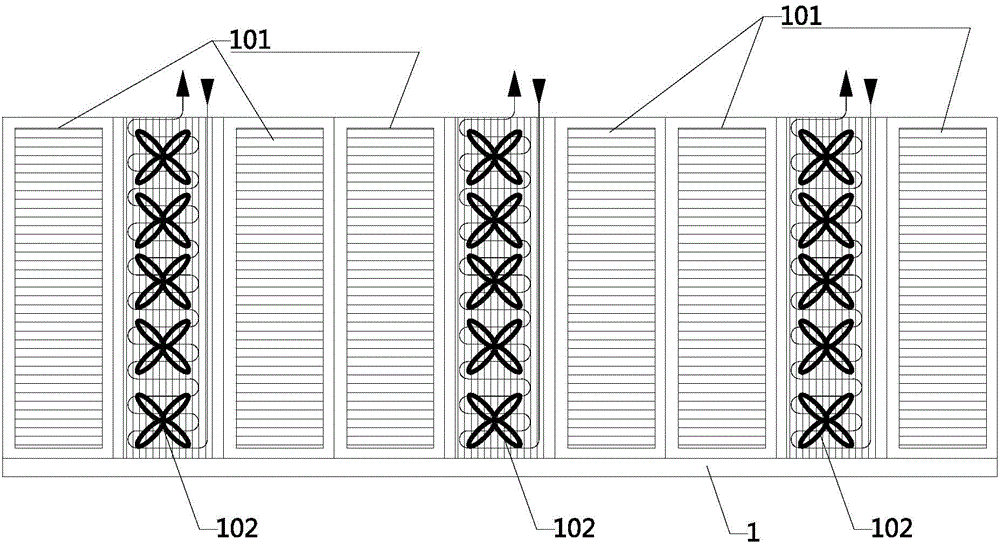

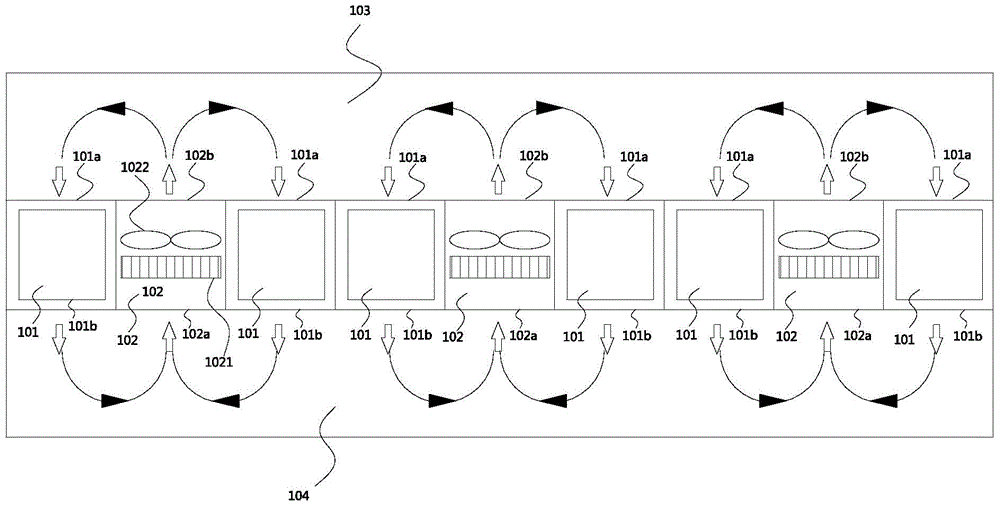

Module box for modular data center

InactiveCN104883860AImprove heat exchange efficiencyPromote circulationCooling/ventilation/heating modificationsCold airData center

The invention provides a module box for a modular data center, comprising a shell (1), and cabinets (101) and heat absorption devices (102) arranged inside the shell (1). Each cabinet (101) has a cold air inlet (101a) and a hot air outlet (101b). Each heat absorption device (102) has a hot air inlet (102a) and a cold air outlet (102b). The cabinets (101) and the heat absorption devices (102) are arranged side by side, the air inlet and outlet direction of the cabinets (101) is parallel to the air inlet and outlet direction of the heat absorption devices (102), and the airflow direction of the cabinets (101) is opposite to the air flow direction of the heat absorption devices (102), so that annular circulating airflow sequentially passing the hot air outlets (101b) of the cabinets (101), the hot air inlets (102a) of the heat absorption devices (102), the cold air outlets (102b) of the heat absorption devices (102) and the cold air inlets (101a) of the cabinets (101) is formed. The airflow inside the module box is smooth, and the heat exchange efficiency is high.

Owner:GUANGDONG HIWAVE TECH

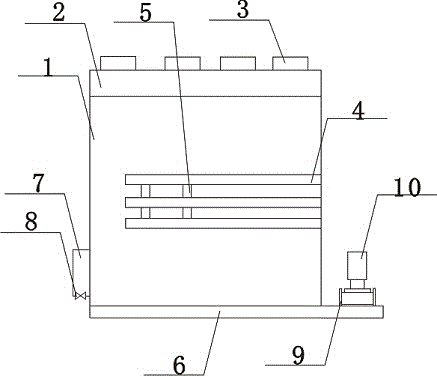

Novel electric dust remover

InactiveCN106238208AUnobstructed airflowNo dust accumulationElectrostatic separation detailsAirflowEngineering

The invention provides a novel electric dust remover and relates to the field of environmental protection equipment. The novel electric dust remover comprises a dust remover shell body. One end of the dust remover shell body is provided with an air inlet, and the other end of the dust remover shell body is provided with an air outlet. The lower end of the dust remover shell body is further provided with at least two dust storage hoppers. The air outlet of the dust remover shell body is further provided with a filter screen. The filter screen is further arranged at the air outlet of the dust remover shell body, thus, smooth airflow can be ensured, and the dust deposition phenomenon is avoided. The novel electric dust remover is low in improvement cost and can be widely applied to the technical field of environmental protection equipment.

Owner:扬州天泓科技实业有限公司

Cooling spray tower

InactiveCN105043128AImprove stabilityImprove pre-cooling effectTrickle coolersCooling towerAtmospheric air

The invention discloses a cooling spray tower. The cooling spray tower comprises a cooling tower body. An air inlet device is arranged at the position, close to the top, of the cooling tower body and is fixed to the cooling tower body. The upper surface of the air inlet device is connected with more than one air inlet pipe. The air inlet pipes are evenly arranged on the air inlet device. The air inlet pipes are detachably connected with the air inlet device. Pre-cooling layers are arranged in the cooling tower body. One end of each pre-cooling layer is fixed to the inner wall of the cooling tower body. Shifting pieces are connected to the pre-cooling layers. The shifting pieces are connected with the pre-cooling layers in a sliding manner. A water collection tank is arranged at the bottom of the cooling tower body. The cooling tower body and the water collection tank are communicated and connected. By means of the cooling spray tower, the stability of air flow entering the tower can be better improved; the influences of the wind force of the atmosphere on the cooling tower can be effectively avoided; the air inlet resistance is small; the air flow is smooth; the cooling efficiency is greatly improved; pre-cooling can be conveniently conducted; the pre-cooling effect is quite good; and therefore the cooling efficiency is greatly improved, and energy is effectively saved to a certain extent.

Owner:CHENGDU JIAMEIJIA SCI & TECH

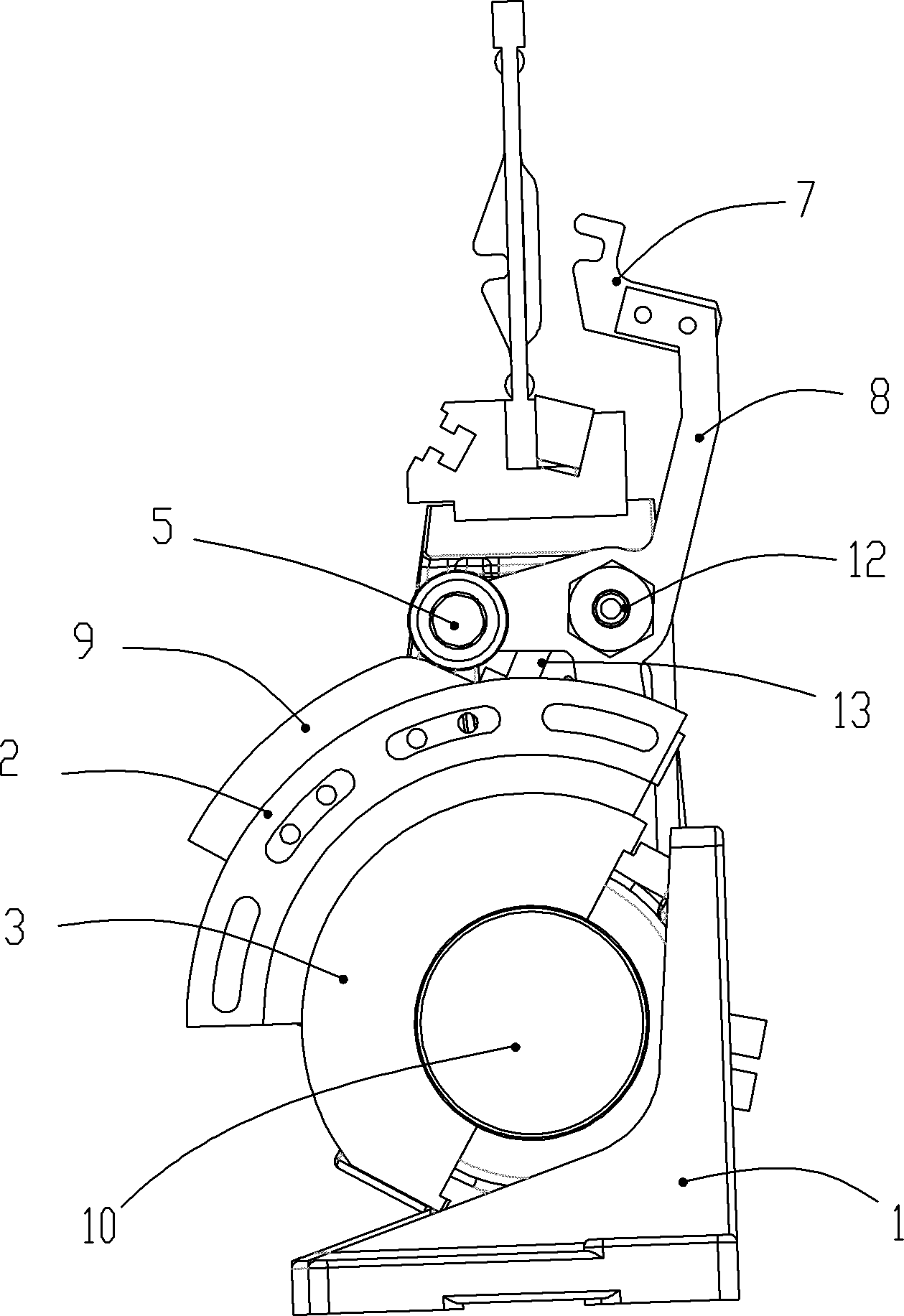

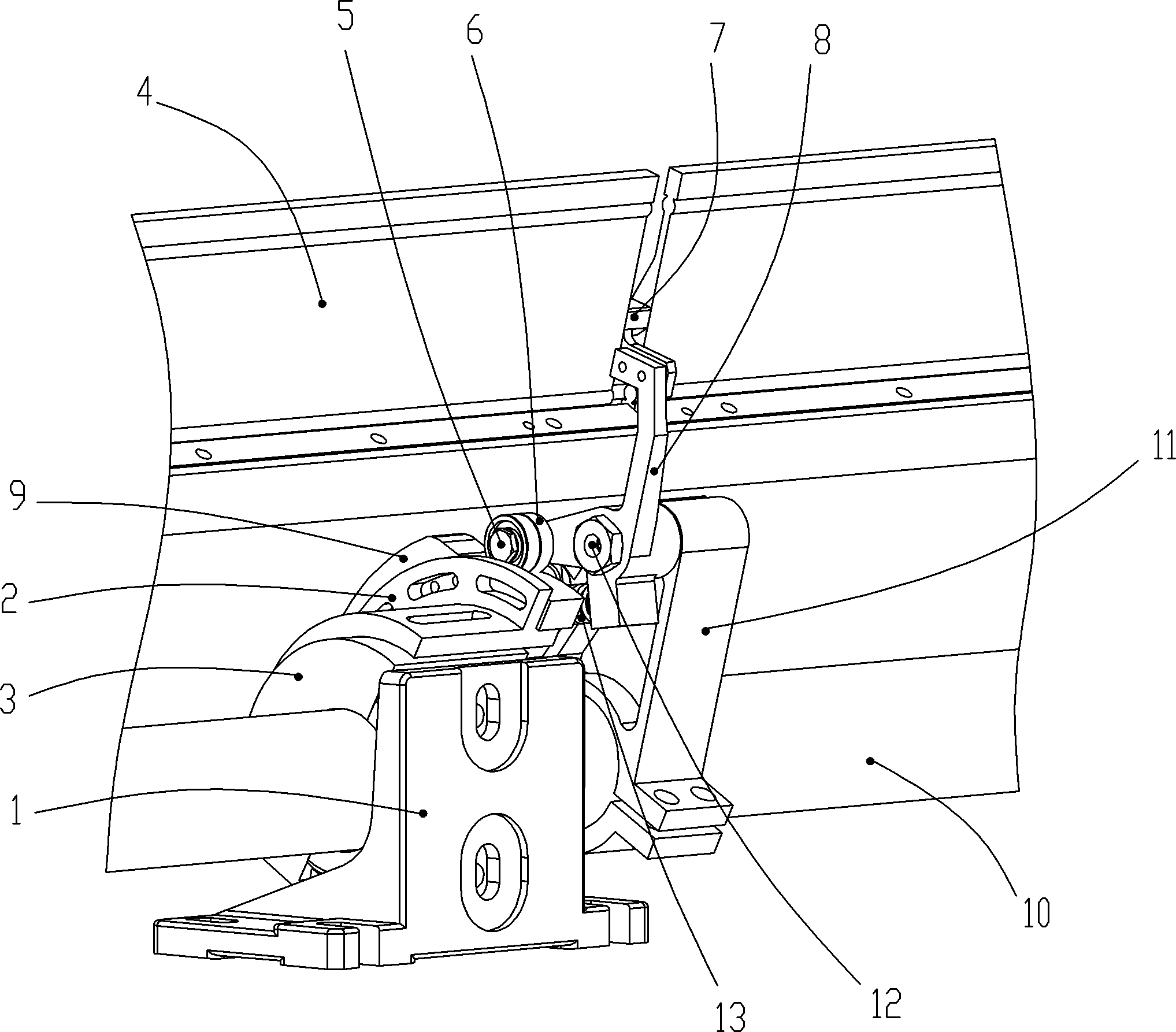

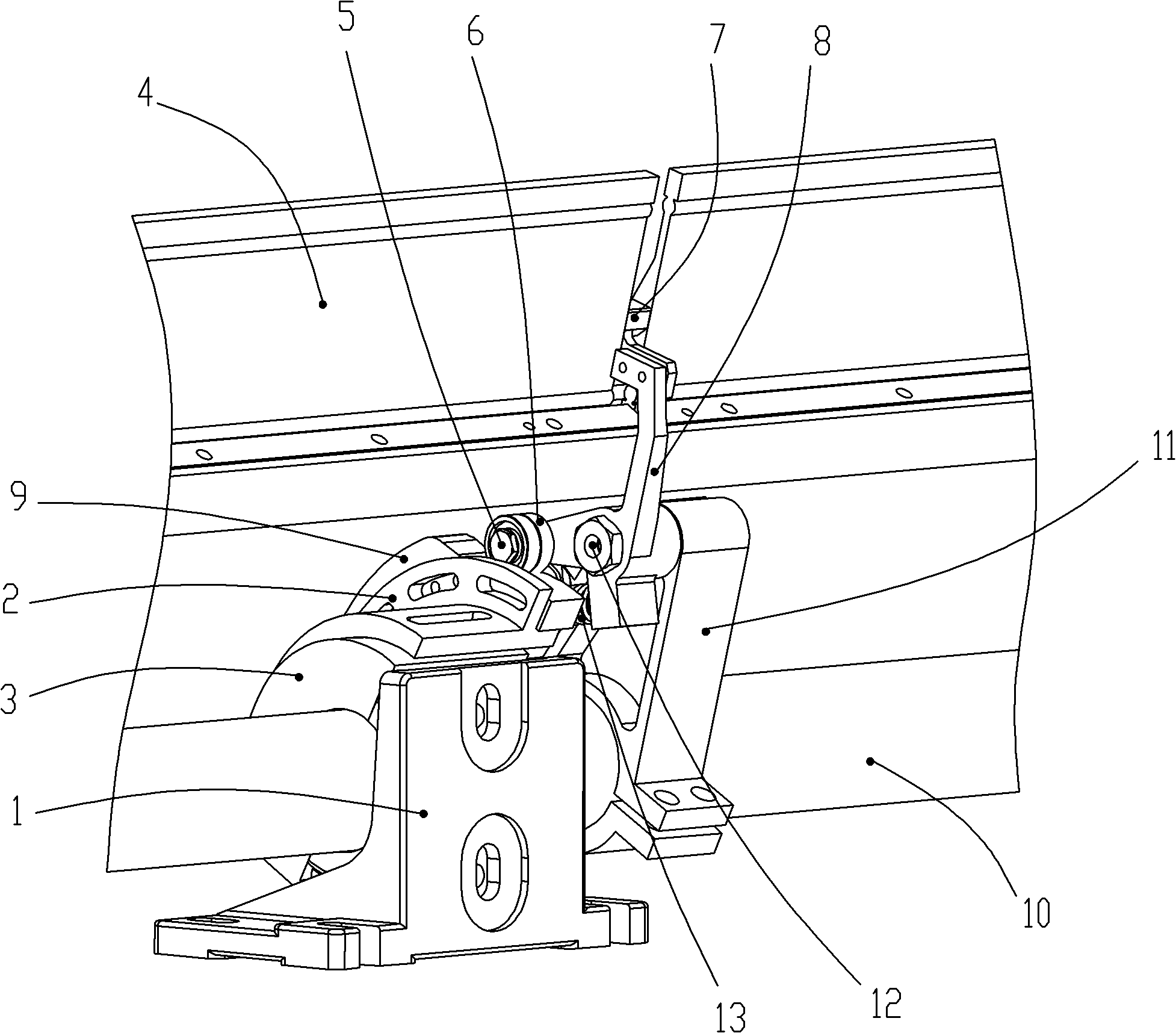

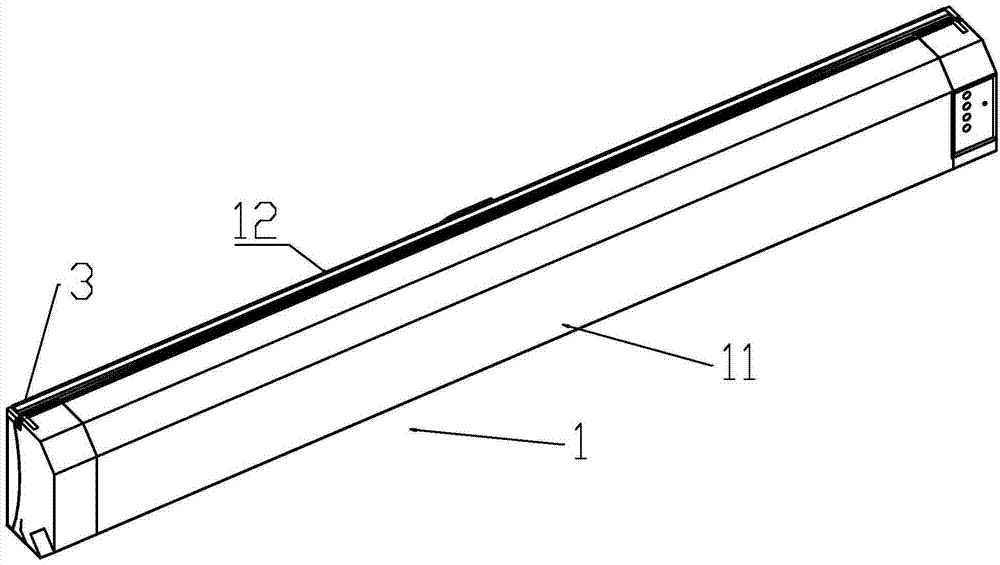

Reed opening and weft inserting auxiliary mechanism for air jet loom

The invention discloses a reed opening and weft inserting auxiliary mechanism for an air jet loom. The reed opening and weft inserting auxiliary mechanism is characterized by comprising a bearing seat assembly, a cam, a swing arm and an auxiliary reed groove, wherein the bearing seat assembly is fixedly arranged on a rack of the air jet loom and is hollowly sleeved on a beating-up shaft of the air jet loom; the bearing seat assembly is provided with a cam supporting block and the cam is connected with the cam supporting block through a cam connecting block; the swing arm is fixed on the beating-up shaft through a swing arm bracket; one end of the swing arm is provided with an idler wheel and the idler wheel is matched with the cam; and the other end of the swing arm is connected with the auxiliary reed groove. With the adoption of the air jet loom disclosed by the invention, a through air channel is formed by the whole reed groove in a weft insertion processing period so as to guarantee smooth air flow and ensure the weft insertion to be smoother, so that the operation of the loom is more stable and reliable. Furthermore, the reed opening and weft inserting auxiliary mechanism has the advantages of compact structure, convenience for adjustment and the like.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

Exhaust device for decorating machine

The invention relates to an exhaust device for a decorating machine. The exhaust device comprises a cover covering a drying component of the decorating machine, clearances allowing a printing sheet to penetrate are formed in the upper portion and the lower portion of the cover, and a draft fan for pumping out ink smoke, heat and steam is connected with the cover. The exhaust device of the structure comprises the cover covering the drying component of the decorating machine, the cover is connected with the draft fan for pumping out the ink smoke, the heat is prevented from being dissipated into a room, drying quality is improved, the situation that the heat is dissipated into the room, consequently, indoor temperature is too high, high-power cooling equipment has to be mounted, and electric energy is wasted is avoided, the effect of saving energy is achieved, and production cost is saved. Ink gas generated in the drying process and other gas harmful to the human body are pumped out by the draft fan, and exhausted outdoors, work environment is improved, the bodies of production personnel are prevented from being injured, and the function of environmental protection is achieved. The steam generated in the drying process is pumped away, humidity in the cover is reduced, and the drying effect is better.

Owner:王卫霞

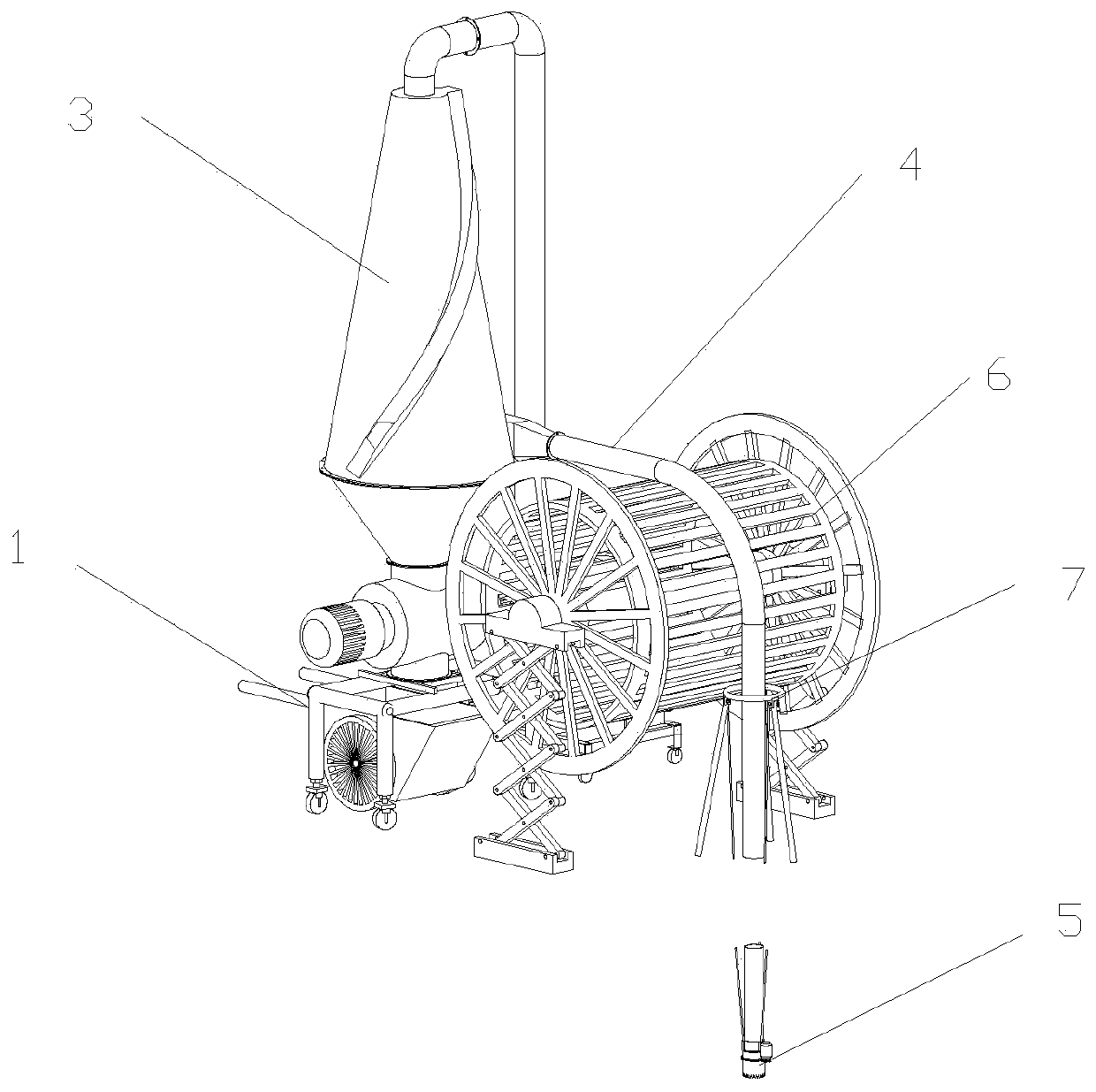

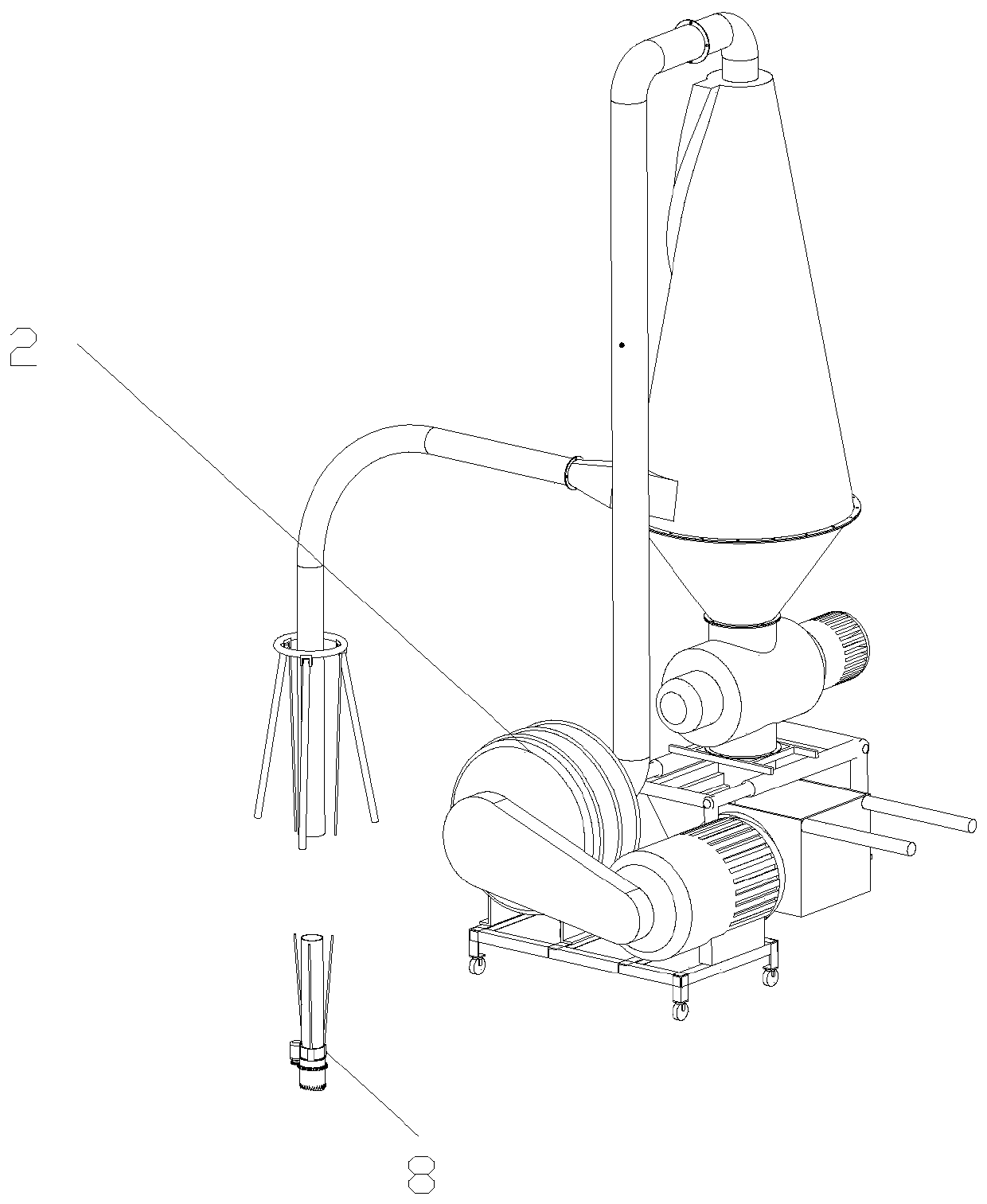

Intelligent pile hole inner muck suction machine and pile hole muck automatic suction method

PendingCN110820746ASolve cleaning difficultiesSimple suction principleBulkheads/pilesCell controllerMechanical engineering

The invention belongs to the technical field of engineering machinery, and particularly relates to an intelligent pile hole inner muck suction machine and a pile hole muck automatic suction method. The intelligent pile hole inner muck suction machine comprises a chassis, a fan, a suction separation device, a suction pipe, a suction unit, a controller, a master control platform and an imaging mechanism; the suction unit is arranged at the tail end of the suction pipe, the suction separation device is arranged above the chassis, the imaging mechanism is arranged at the tail end of the suction pipe, the suction unit and the imaging mechanism are electrically connected with the controller, and the controller and the imaging mechanism are electrically connected with the master control platformor are in wireless communication with the master control platform; According to the muck suction machine, the problem that mucks in the bottom of pile holes are difficult to clean is solved, the large-block mucks are subjected to rotary cutting, scattering and separation by using the suction unit, and the scattered mucks are sucked into the suction separation device to complete gas and dust separation as the airflow enters the suction separation device through the negative pressure suction principle.

Owner:甘肃中建市政工程勘察设计研究院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com