Roll compression device for bio-fuels

A compression device and biofuel technology, applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of straw heat energy can not be used, aggravating environmental pollution, small gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

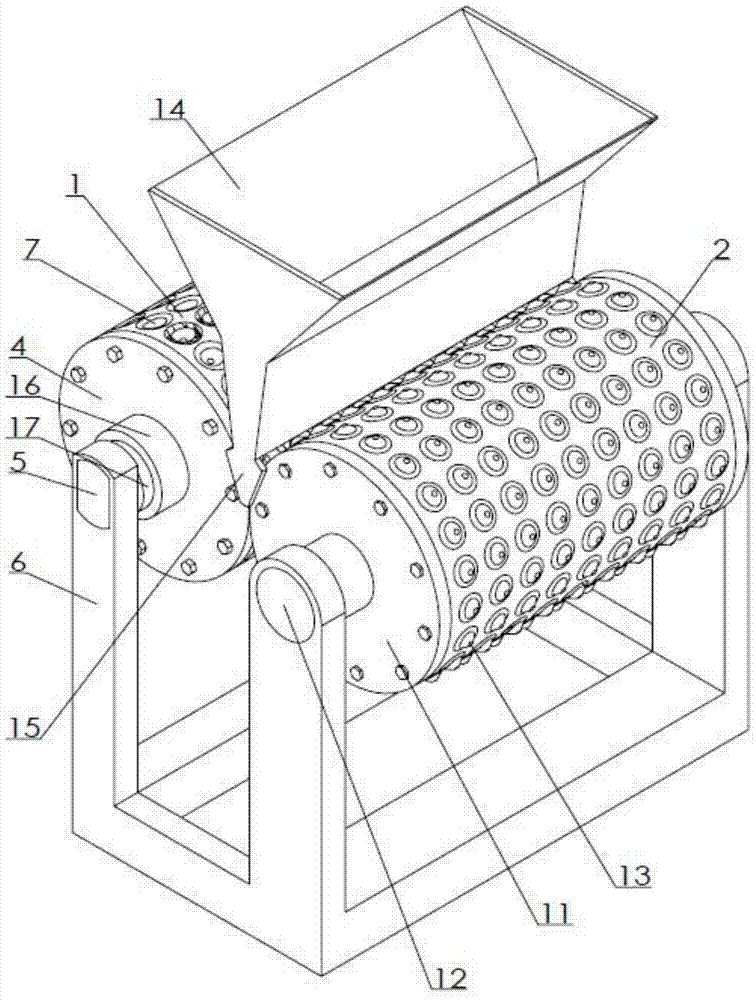

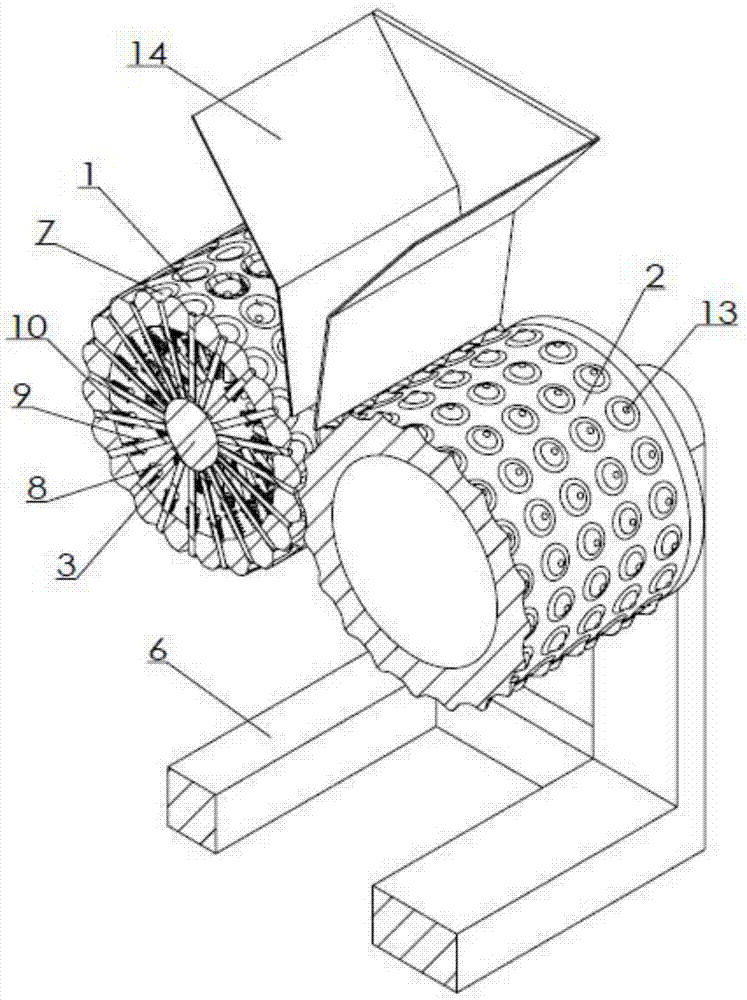

[0011] Examples of the present invention figure 1 , 2 As shown, the biofuel roller compression device is provided with a synchronous main roller 1 and a synchronous roller 2 with opposite rotation directions; the main roller is cylindrical, and a fixed shaft is provided at the axial center, and the middle section of the shaft is aligned with the main roller The position is the camshaft 3 with a downward protruding part, the two ends of the shaft are the optical axis 17 coaxial with the main roller, the optical axis is sleeved with a bushing 16, and the bushing is connected with the main end connected with the end surface of the main roller Plate 4, the optical axis at both ends is connected with positioning shaft 5, the positioning shaft has a flat surface and is fixedly connected with bracket 6, the surface of the main roller is provided with depressions 7 distributed in the circumferential direction, and the bottom of the depression is provided with holes through the side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com