Patents

Literature

31results about How to "Realize factory manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

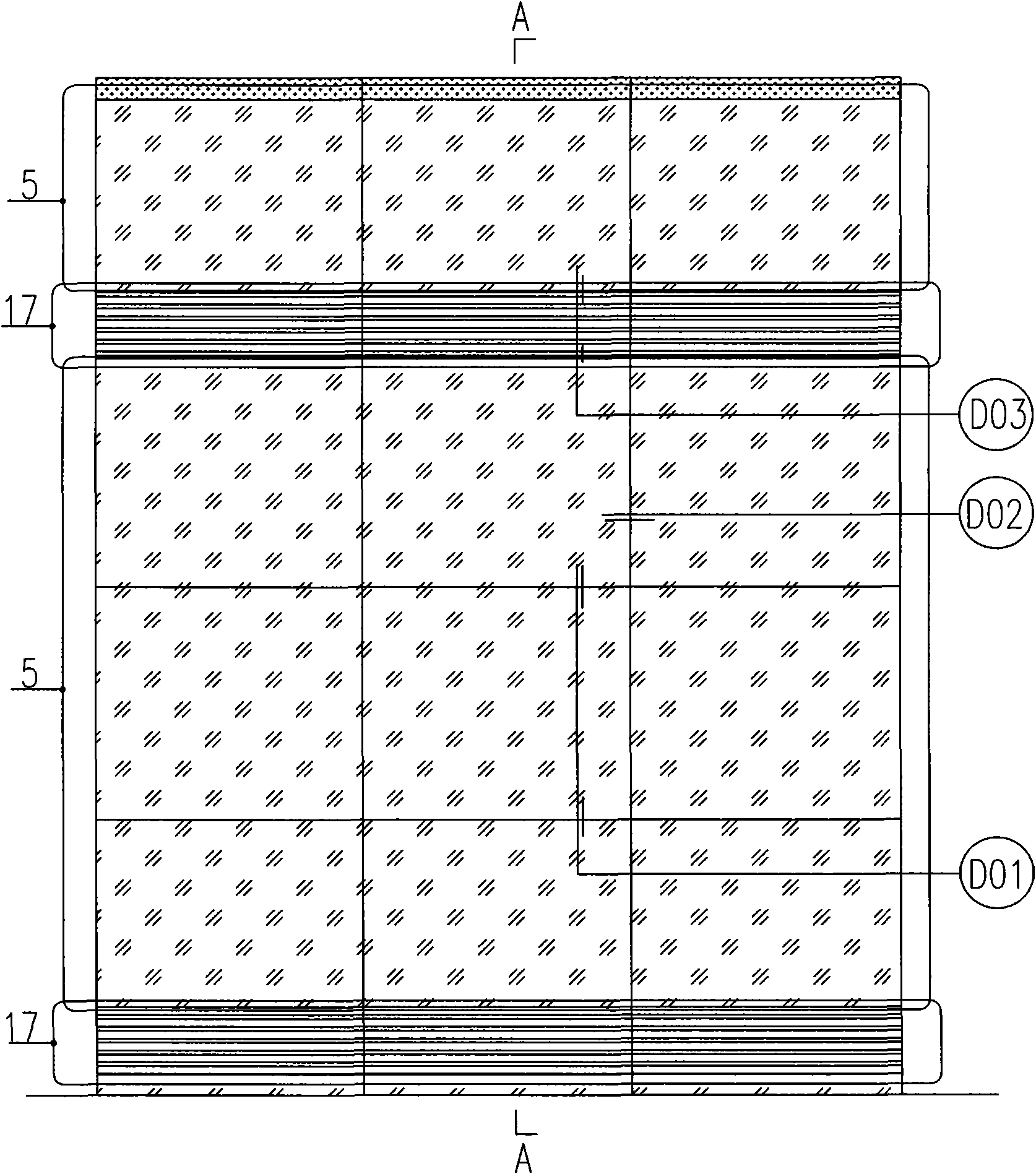

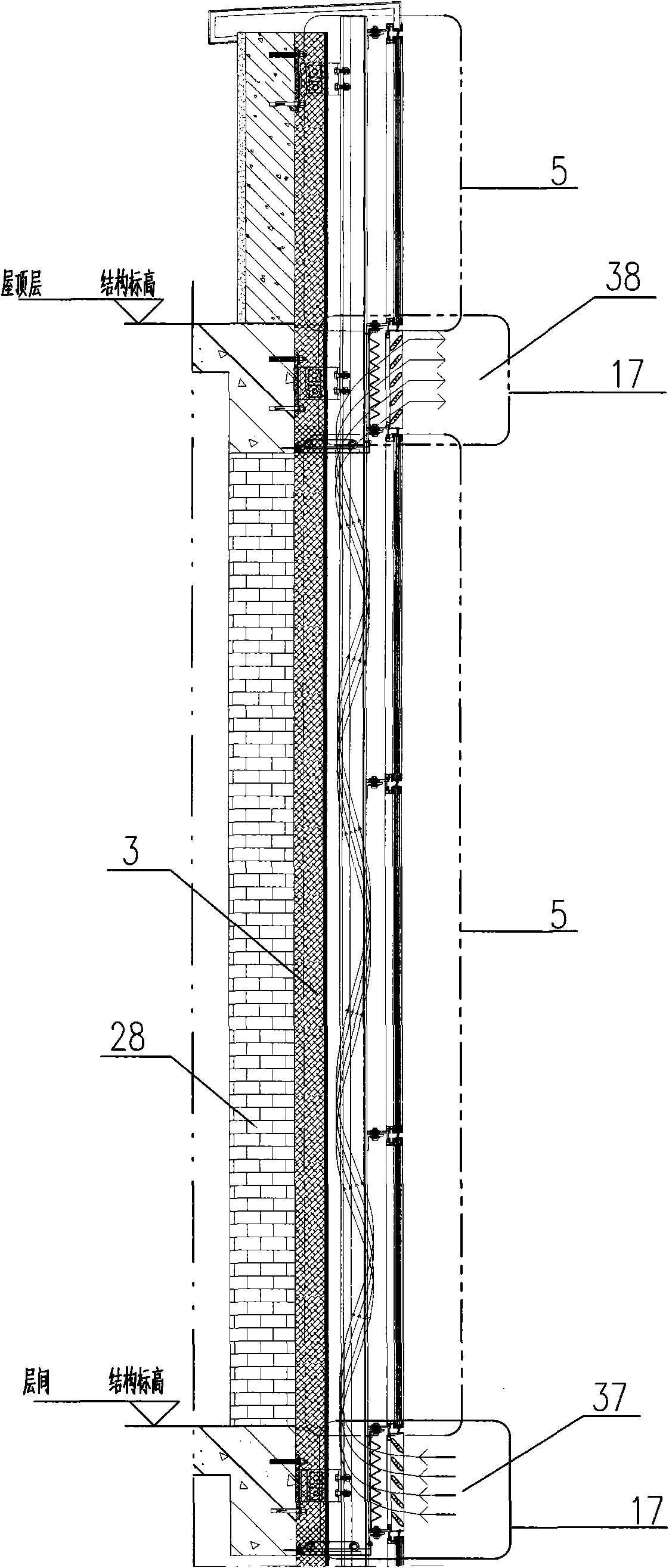

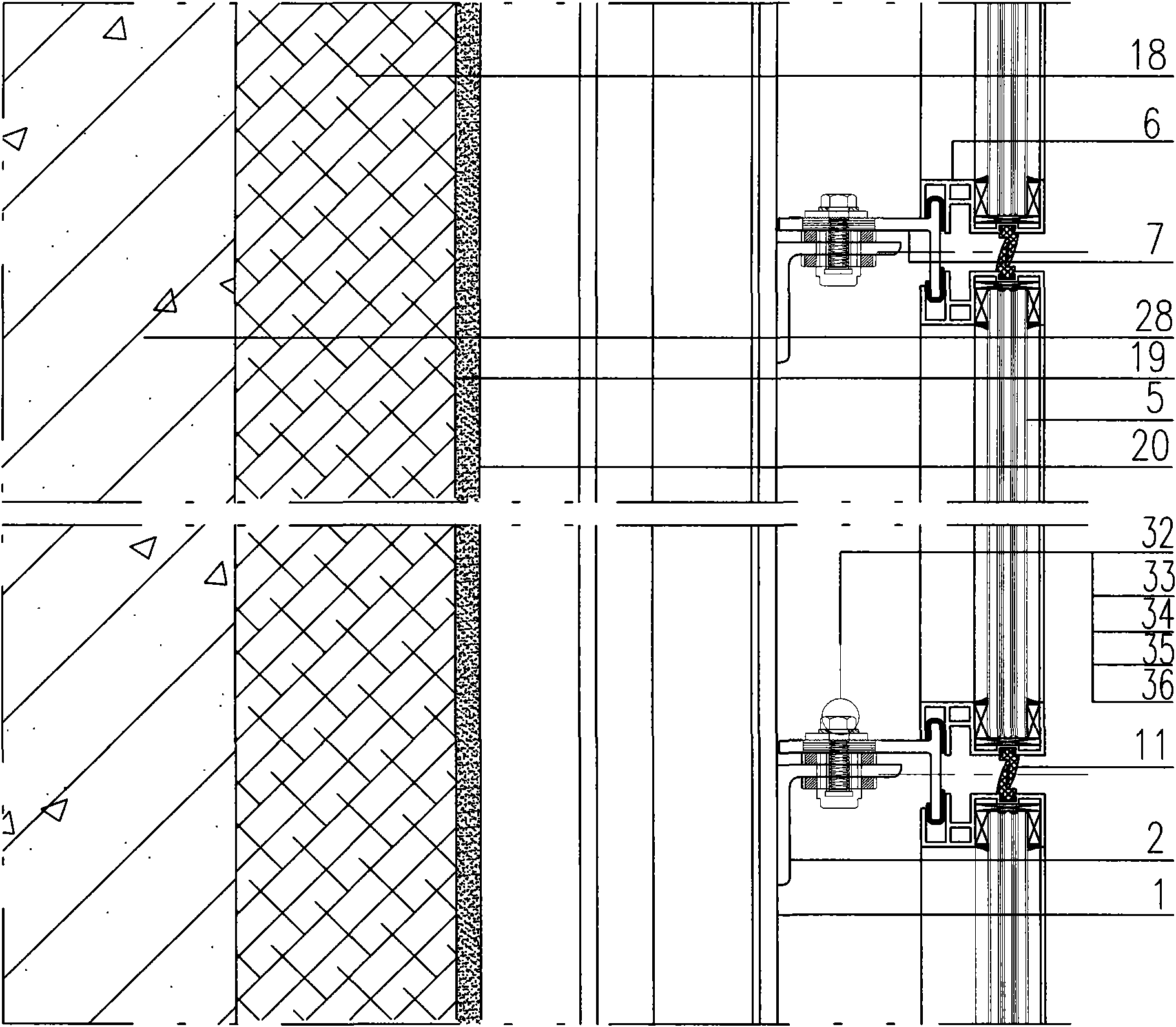

Detachable ventilated photovoltaic curtain wall

InactiveCN102337766AGuaranteed power generation efficiencyProtection temperaturePhotovoltaic supportsWallsBlade plateThermal insulation

The invention relates to a detachable ventilated photovoltaic curtain wall, which comprises a photovoltaic curtain wall body and a photovoltaic matrix control module, wherein the photovoltaic curtain wall body comprises a framework supporting structure, a wall body outer thermal insulation layer and plate blocks; the framework supporting structure comprises a vertical pile, beams, a buried plate, connecting pieces and adjustable bolts; the detachable ventilated photovoltaic curtain wall is characterized in that: the plate blocks comprise ventilated blade plate blocks and photovoltaic plate blocks; the photovoltaic plate blocks comprises a plate block auxiliary frame, a sandwiched glue photovoltaic cell module and a photovoltaic wiring port; the photovoltaic wiring port is connected with a signal transmission port of a photovoltaic controller; a structural air channel which is formed by spaces and in which air flows conveniently is formed between the wall body thermal insulation layer and the plate blocks; and an air outlet and an air inlet are respectively arranged on the upper part and the lower part of the structural air channel. By the invention, the problems of self-heating during power generation of the photovoltaic plate blocks and inconvenience for disassembly, replacement and repair of the photovoltaic plate blocks in the conventional photovoltaic curtain wall are solved, energy is saved, the self-heating of the plate blocks can be eliminated, and the photovoltaic plate blocks are convenient to disassemble, repair and replace.

Owner:沈阳金都铝业装饰工程有限公司

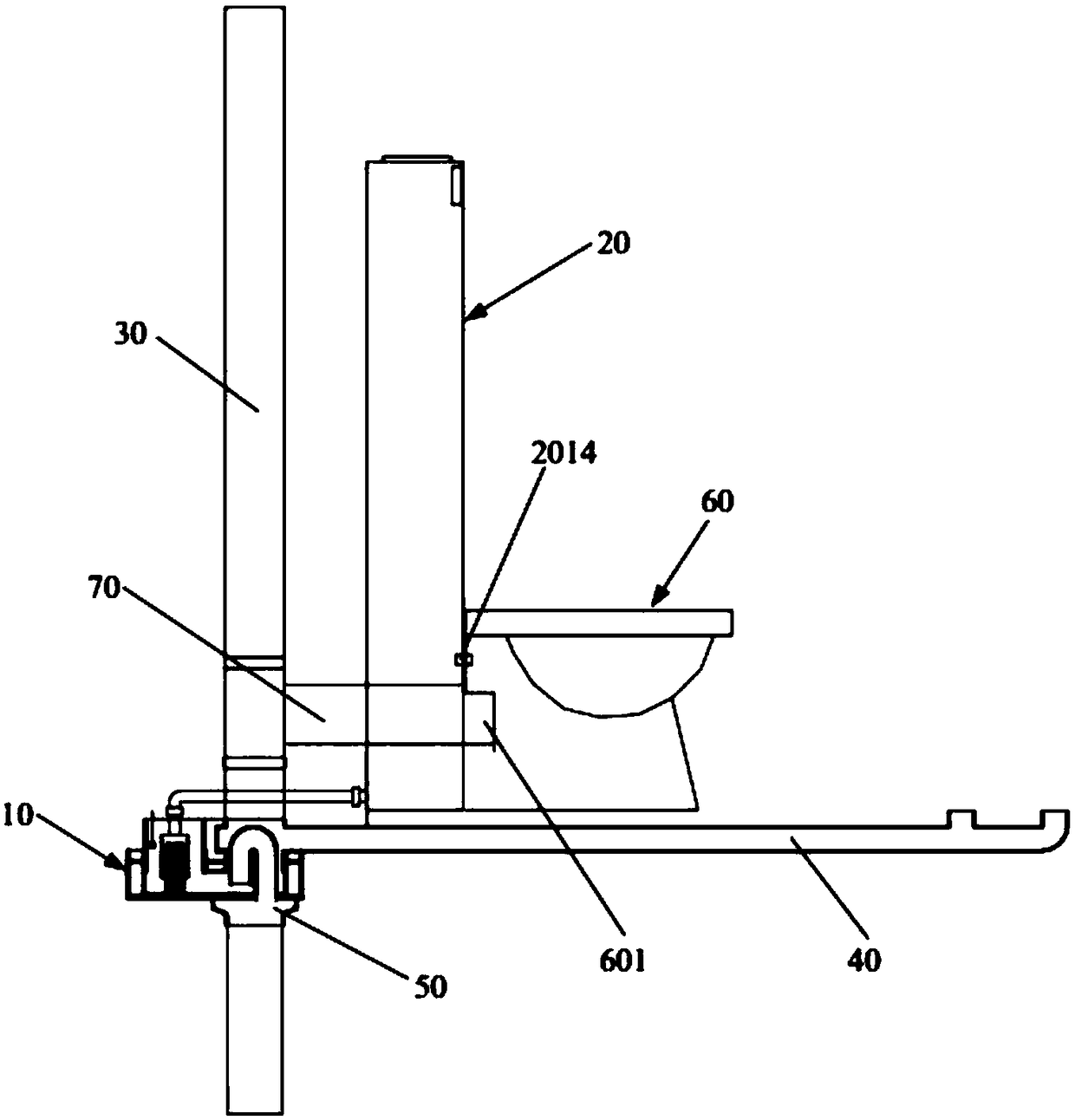

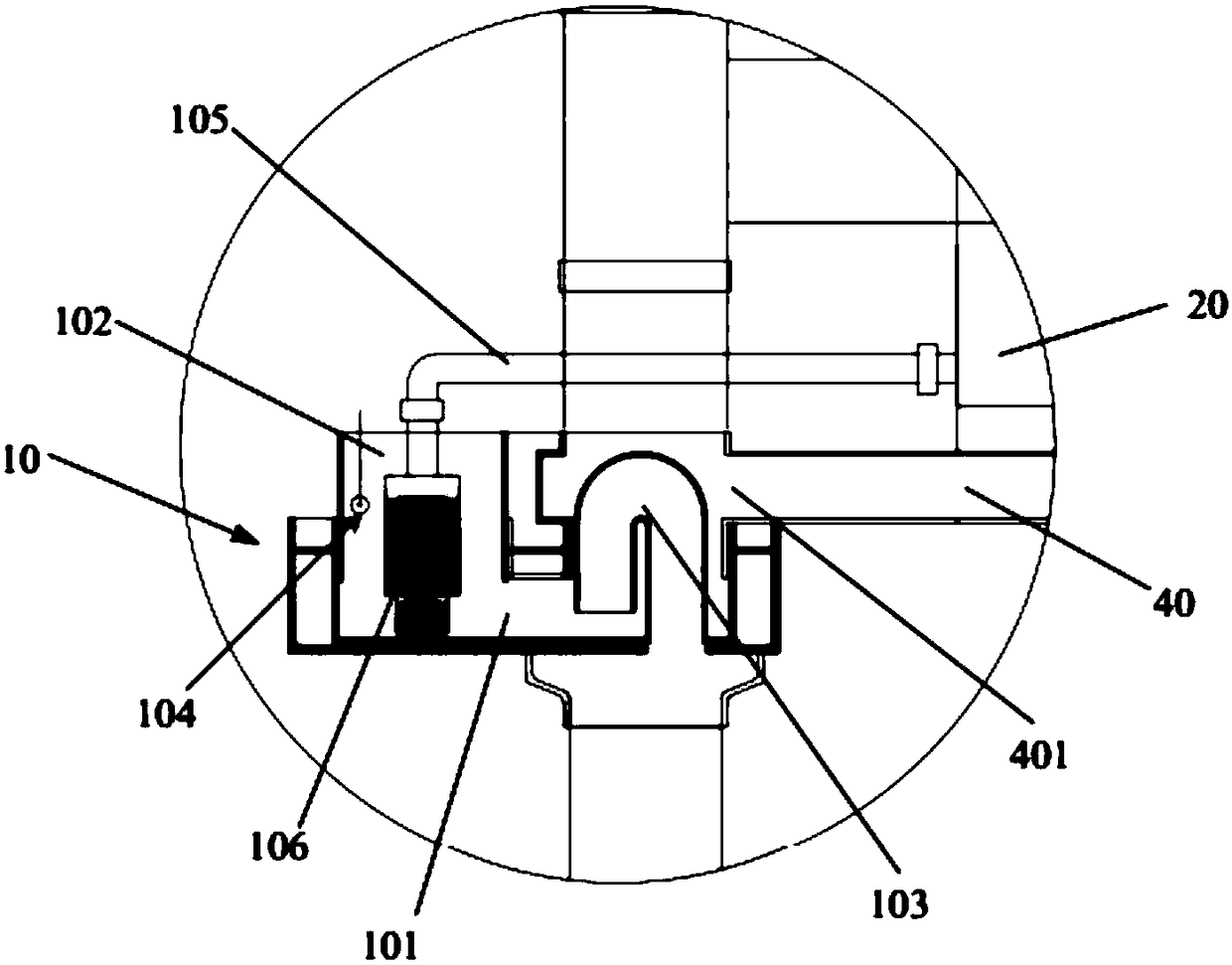

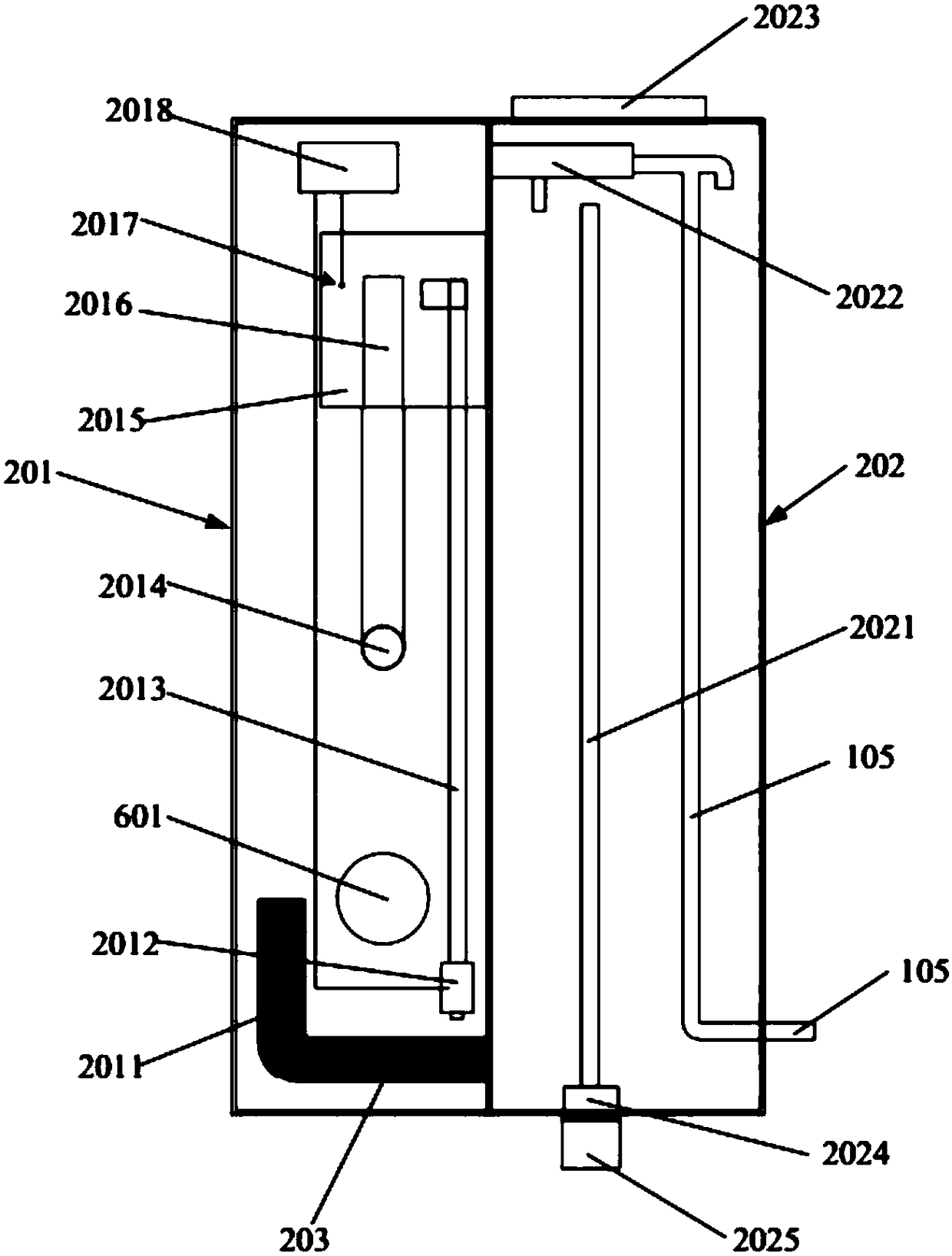

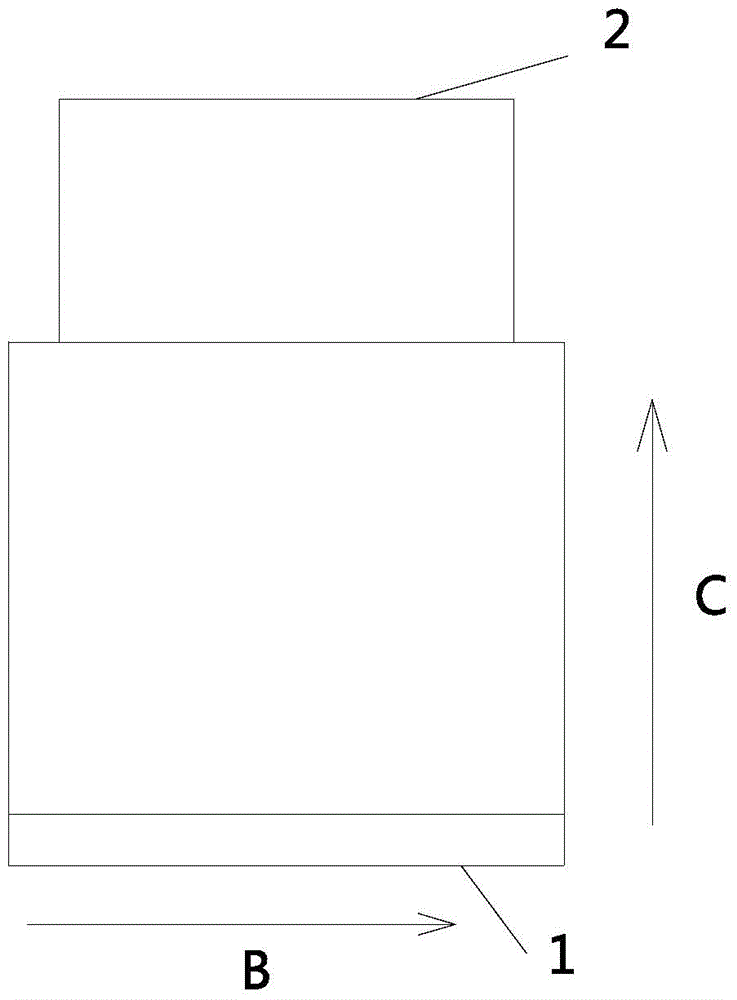

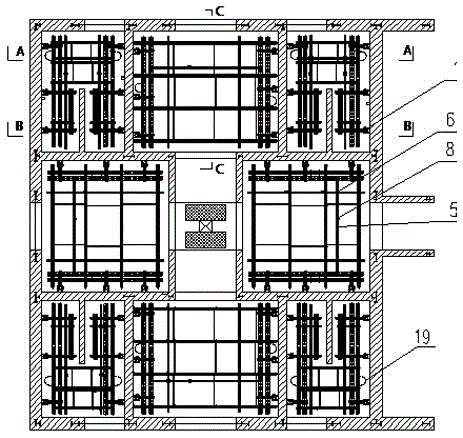

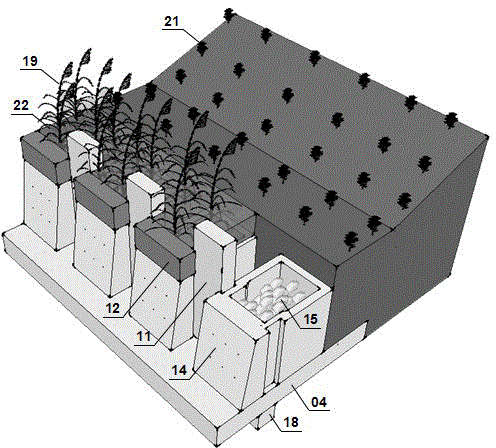

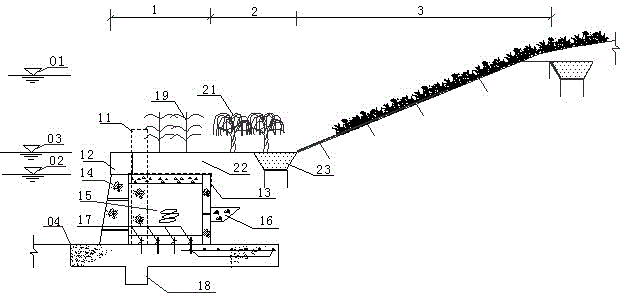

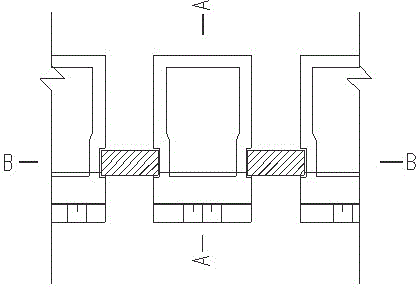

Laterally-vertical reclaimed-water storage, treatment recycling and discharging system for toilet

PendingCN108166564AStop pollutionIncrease profitWater closetsSpecific water treatment objectivesWater sourceReclaimed water

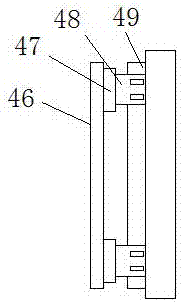

The invention provides a laterally-vertical reclaimed-water storage, treatment recycling and discharging system for a toilet. The system comprises a core module (10), a lifting device, a reclaimed-water storage and treatment recycling system (20), a wastewater draining pipe (40) and a water-draining vertical pipe (30); the core module (10) is provided with a vertical-pipe connecting pipe (50), andthe water-draining vertical pipe (30) is connected with the vertical-pipe connecting pipe (50); wastewater is collected in the core module (10) through the wastewater draining pipe (40); the wastewater in the core module (10) is lifted into the reclaimed-water storage and treatment recycling system (20) through the lifting device; a toilet bowl water inlet (2014) is formed in the reclaimed-waterstorage and treatment recycling system (20), the reclaimed-water storage and treatment recycling system (20) is communicated with a toilet bowl (60) through the toilet bowl water inlet (2014), and thetoilet bowl water inlet (2014) provides a water source for the toilet bowl (60) or a toilet bowl water tank. By means of the laterally-vertical reclaimed-water storage, treatment recycling and discharging system for the toilet, the leaking, smelly and blocking problems existing in toilet water draining are solved, cross pollution of different-degree wastewater is avoided, and mild-wastewater secondary utilization of a single family is achieved.

Owner:王凤蕊

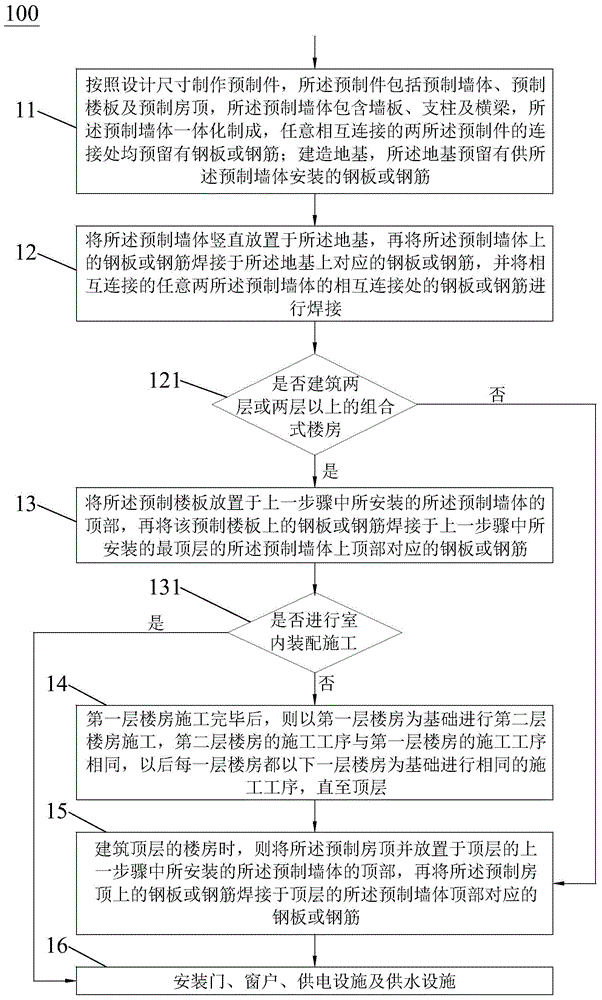

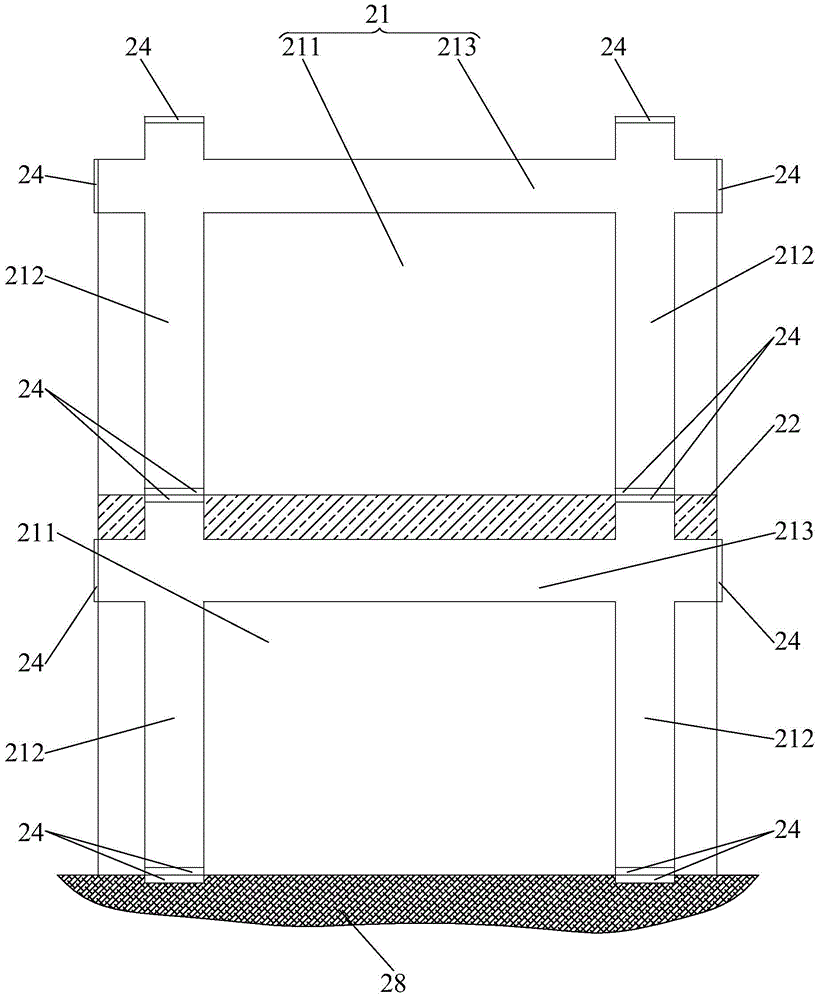

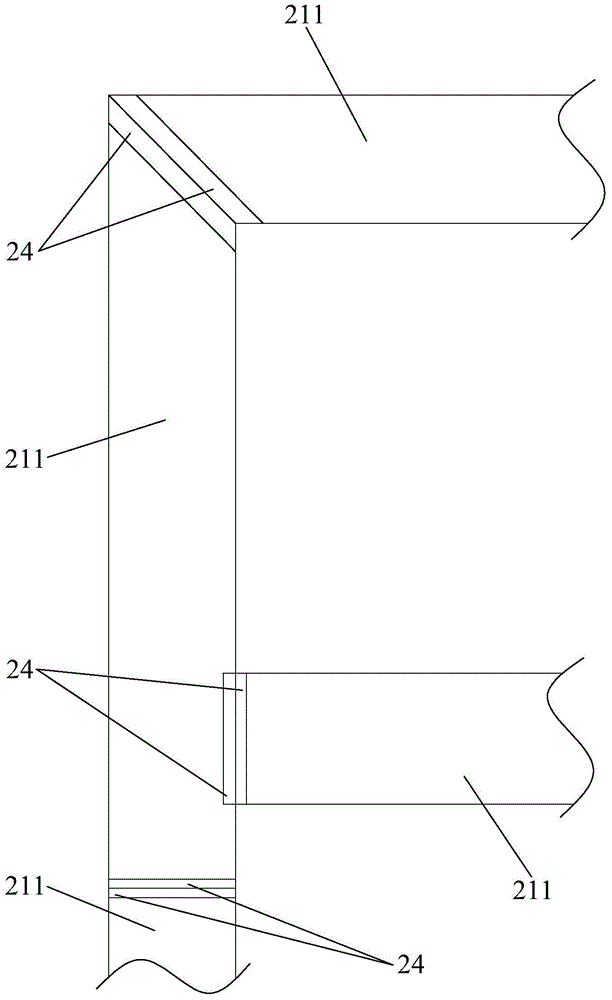

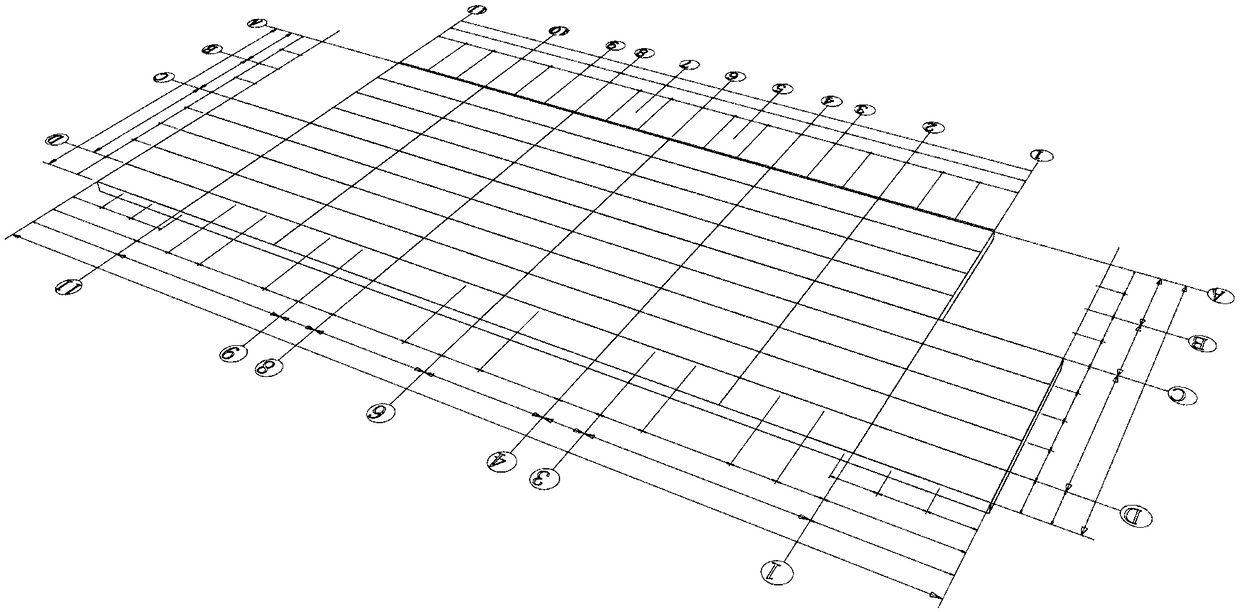

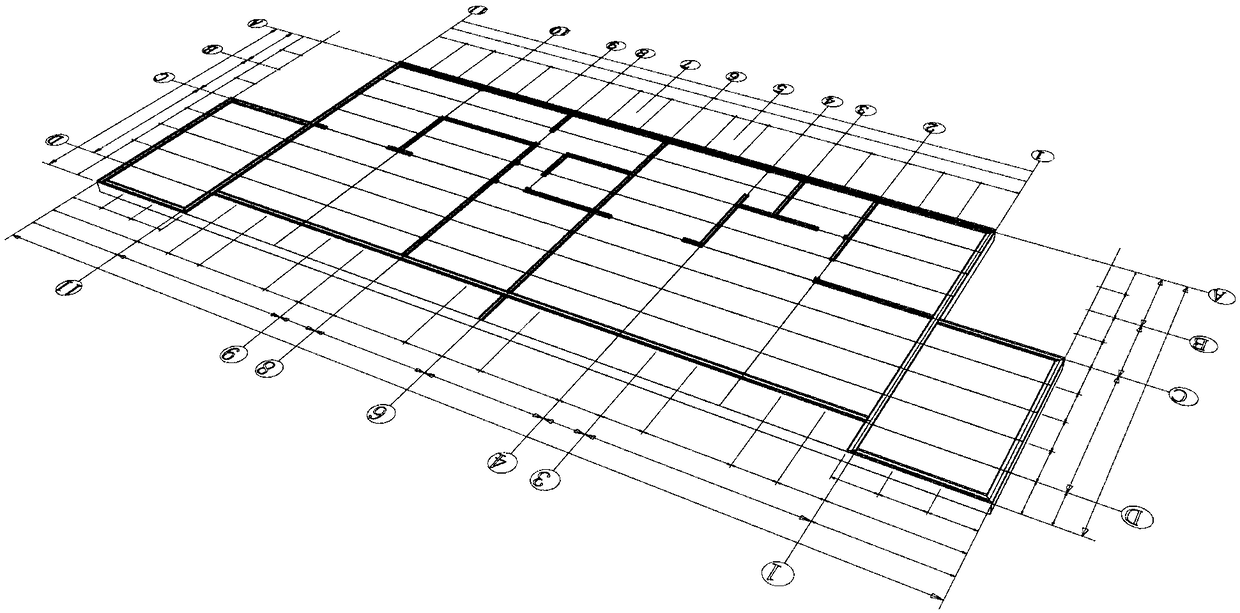

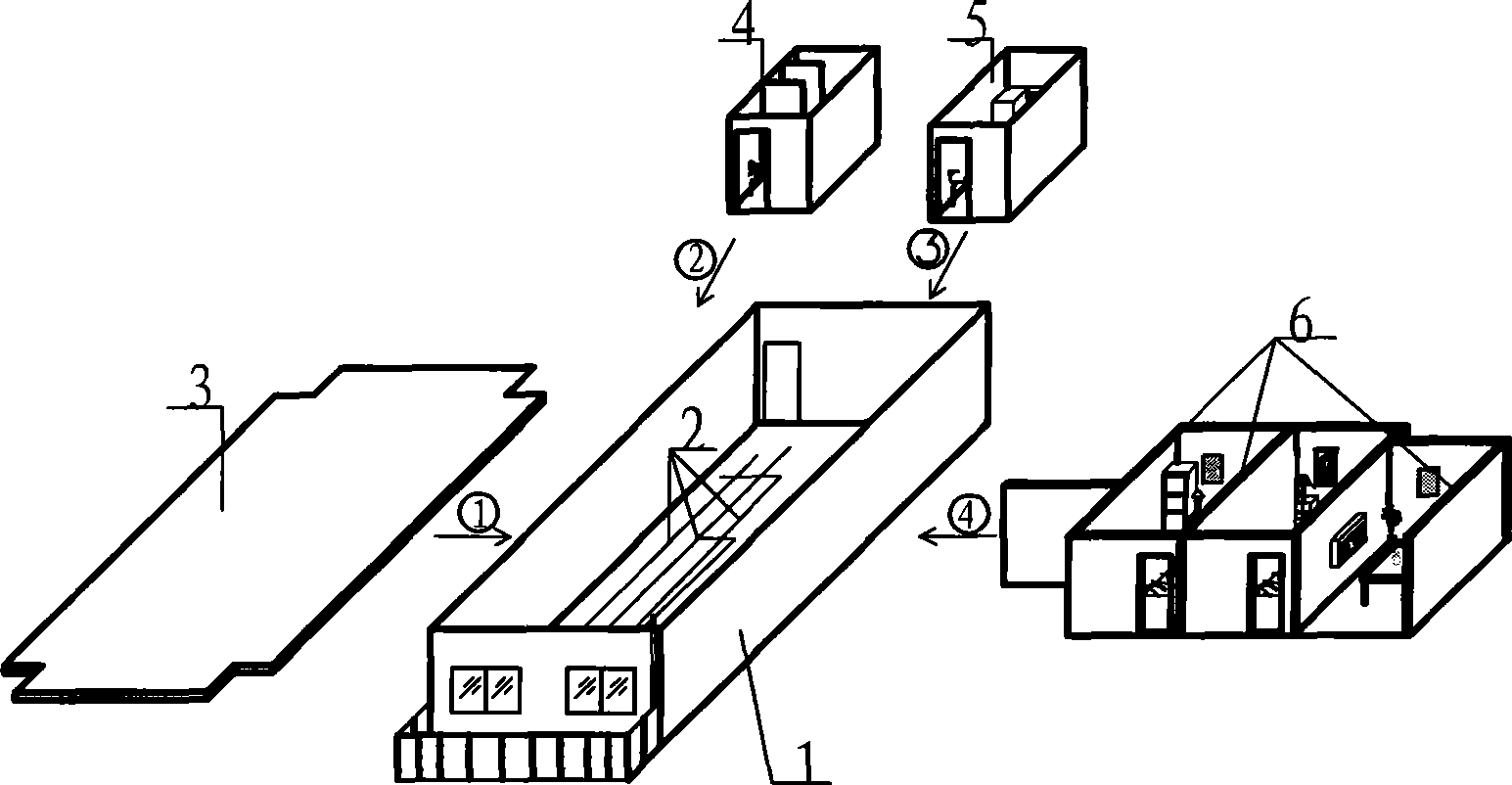

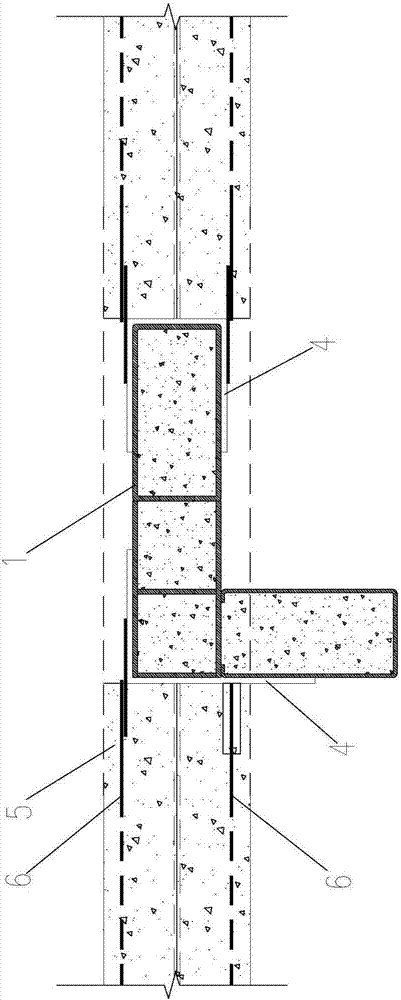

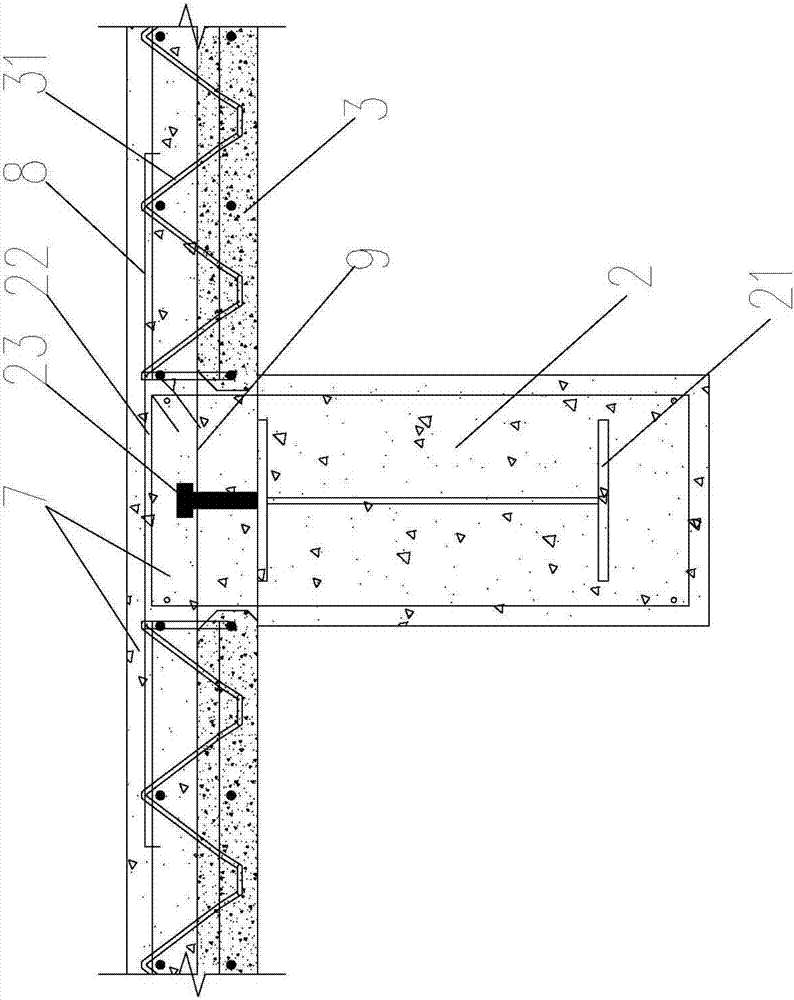

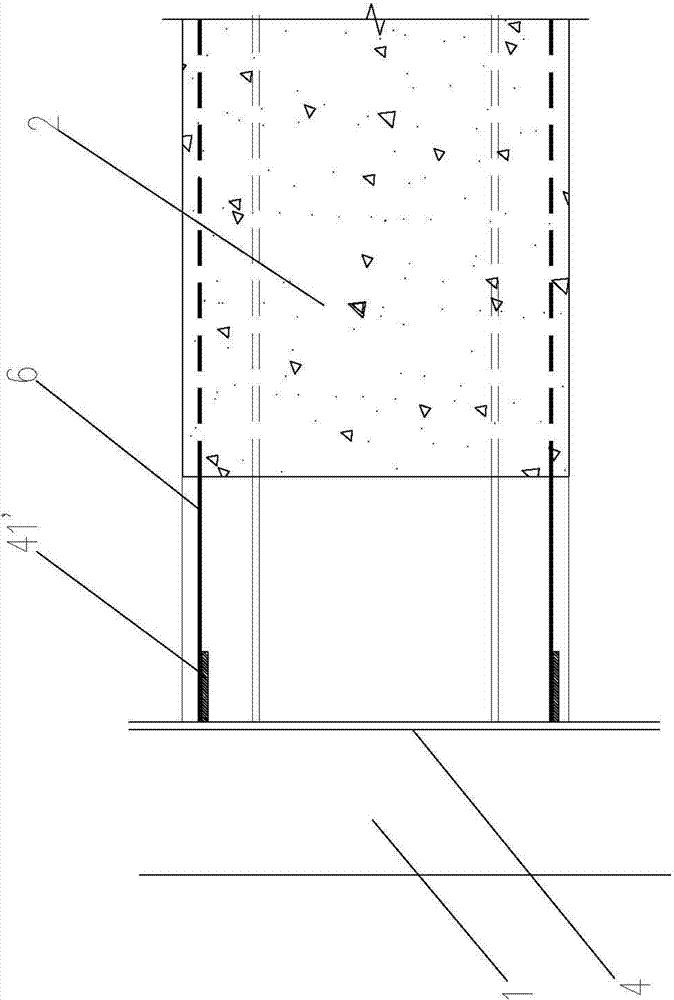

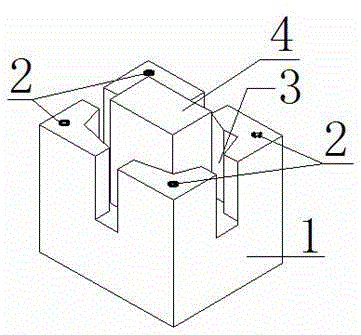

Construction method for building combined type building

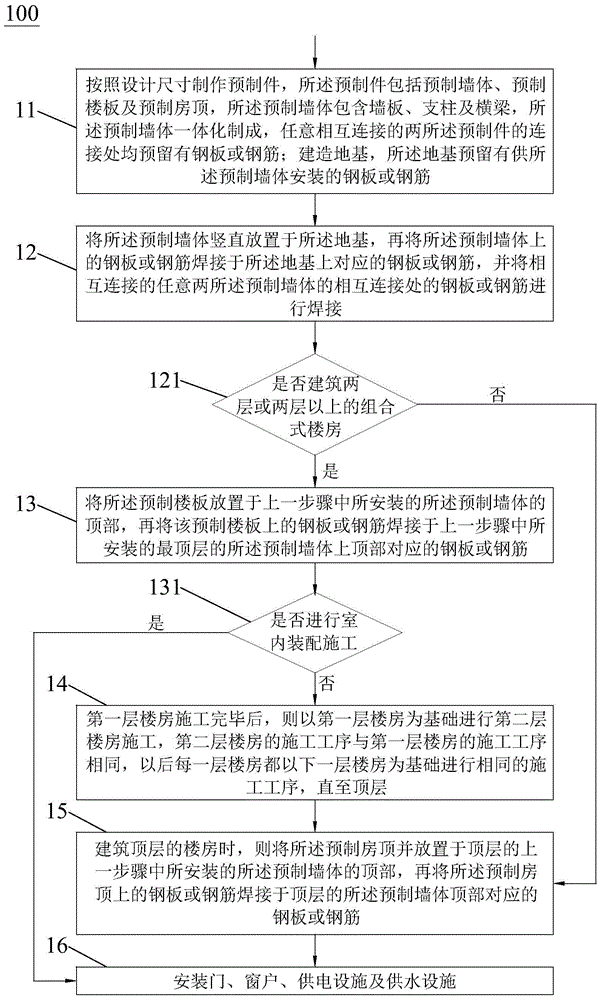

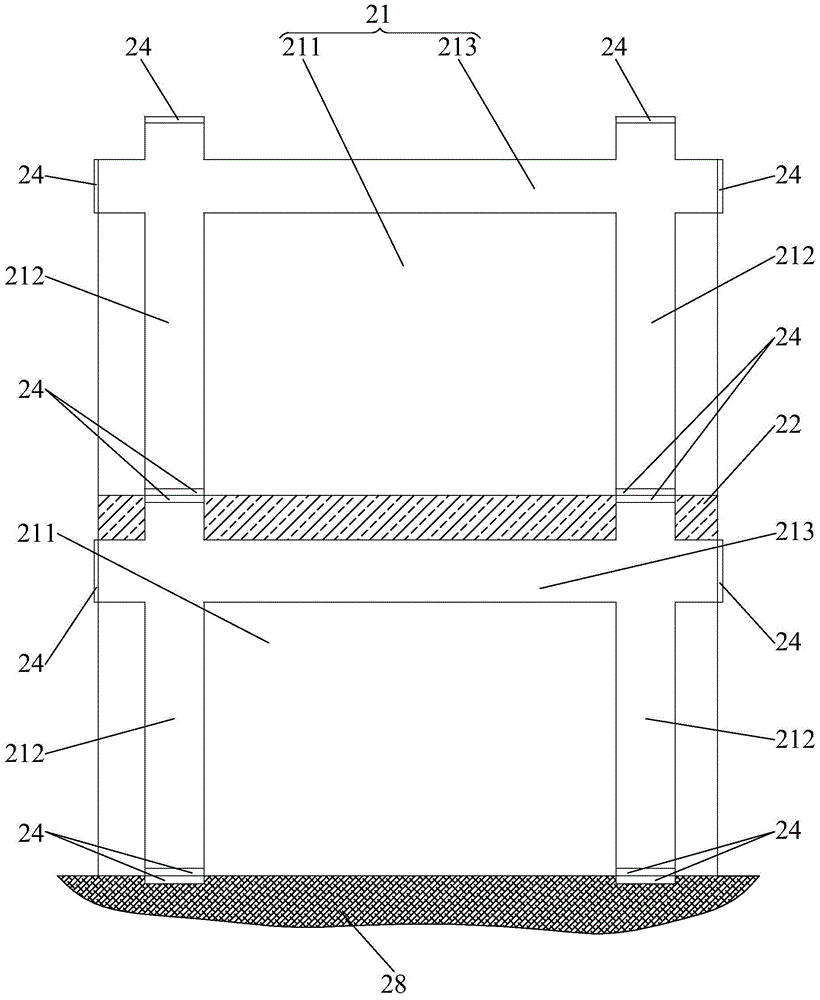

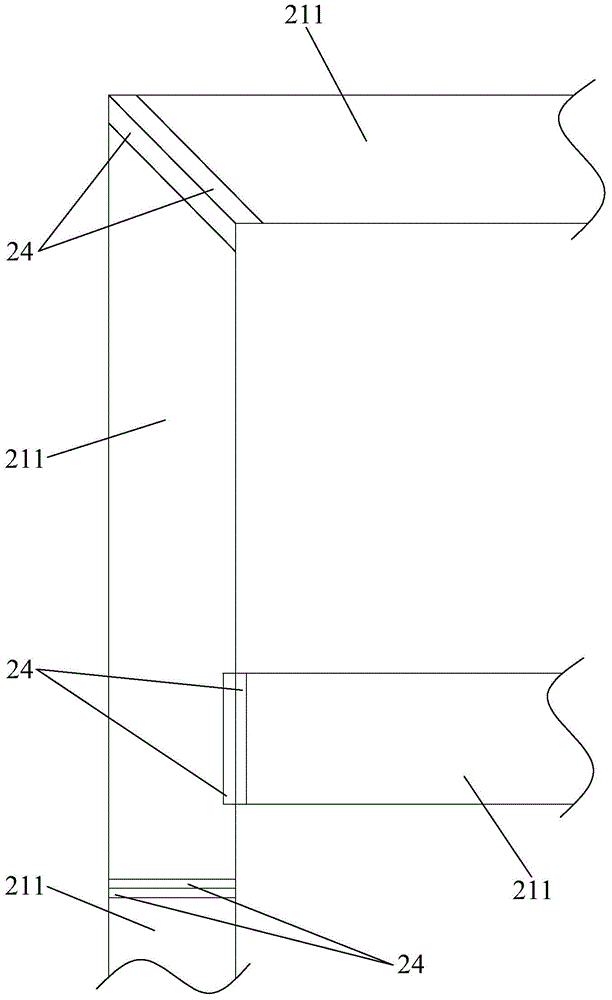

InactiveCN104153576ARealize factory manufacturingImprove stabilityBuilding material handlingFloor slabEngineering

The invention discloses a construction method for building a combined type building. The construction method comprises the following steps that (1) prefabricated members are manufactured according to design dimensions, and a foundation is constructed; (2) steel plates or steel bars on each prefabricated wall are welded to corresponding steel plates or steel bars on the foundation, and steel plates or steel bars at the joint between any two mutually connected prefabricated walls are welded; the step (3) or the step (5) is executed; (3) steel plates or steel bars on the prefabricated floor slabs are welded to the corresponding steel plates or steel bars at the top of the prefabricated walls installed in the previous step, and the step (4) is executed; (4) after construction of the first storey of the building is finished, the same construction procedures are carried out on each storey on the basis of the storey below until the top storey; the step (5) is executed; (5) when the top storey of the building is built, steel plates or steel bars on a prefabricated roof are welded to the corresponding steel plates or steel bars at the top of the prefabricated walls of the top storey. The construction method for building the combined type building has the advantages of being environmentally friendly, shortening the construction period and saving a lot of manpower and material resources.

Owner:袁建华

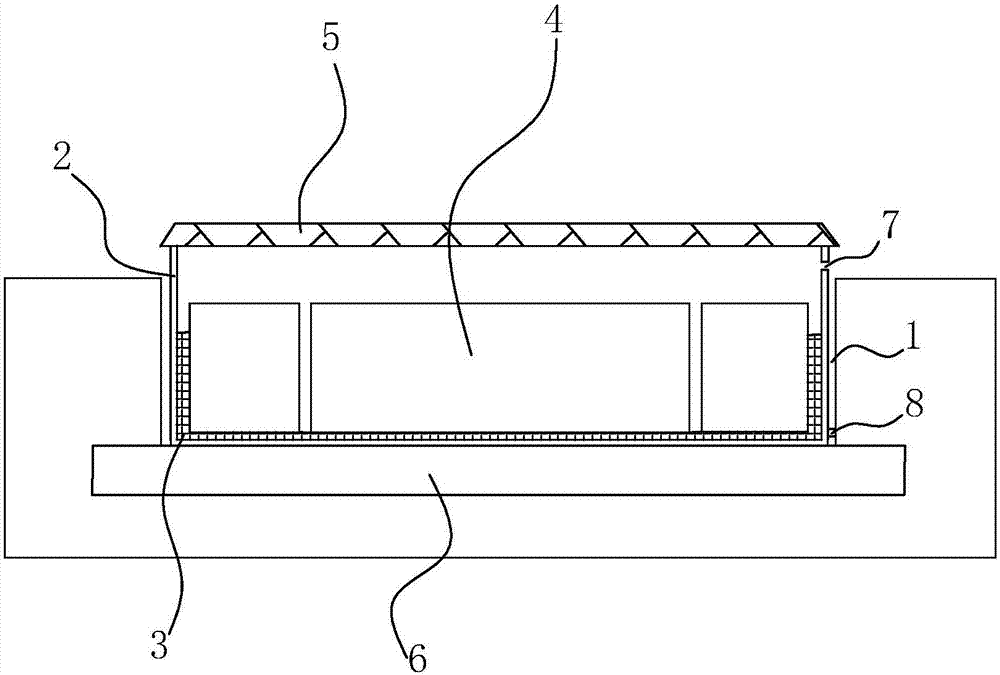

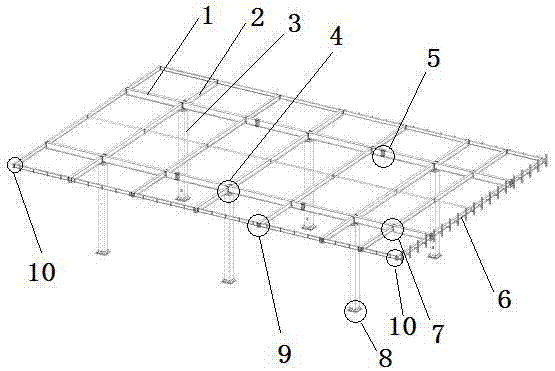

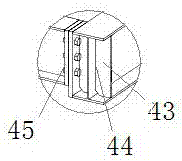

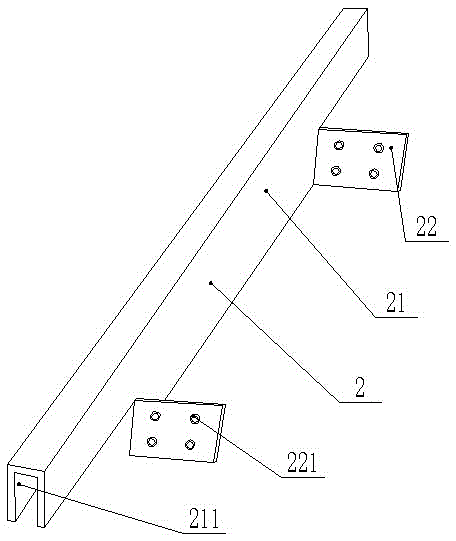

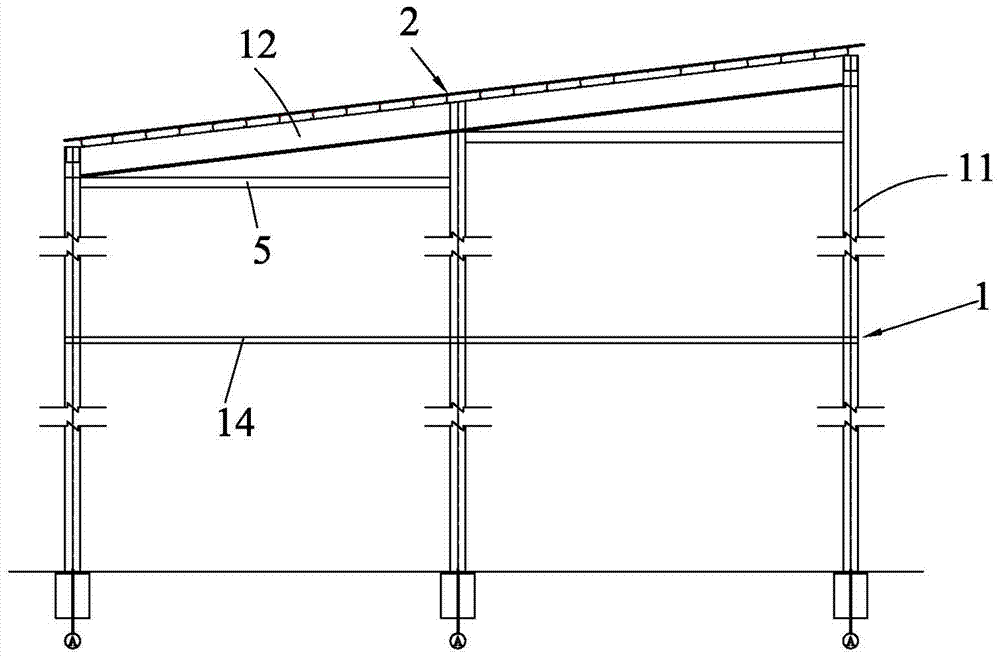

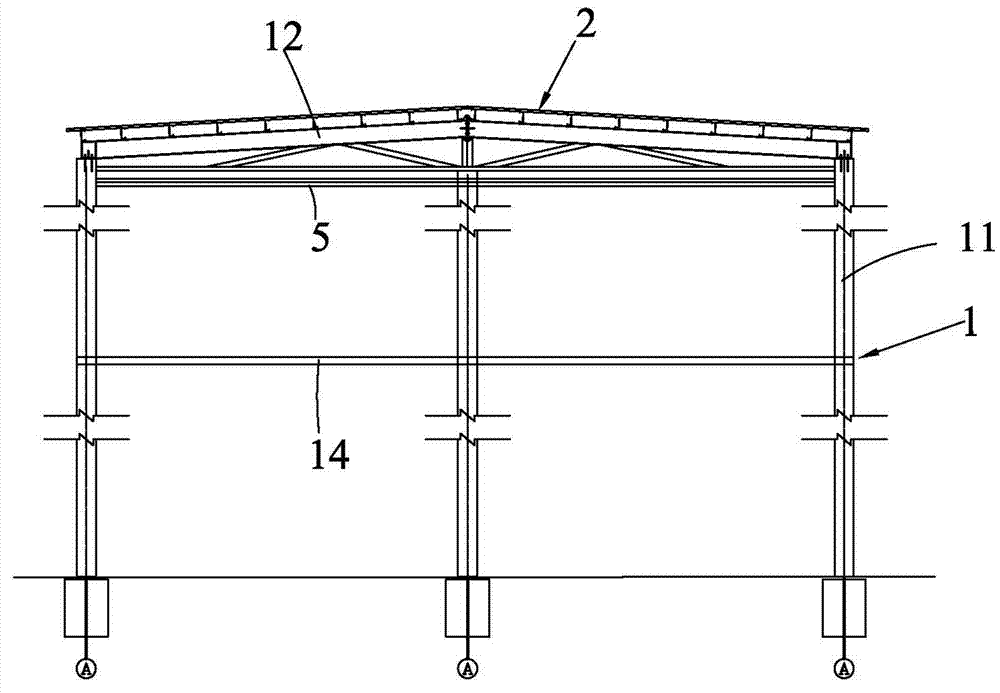

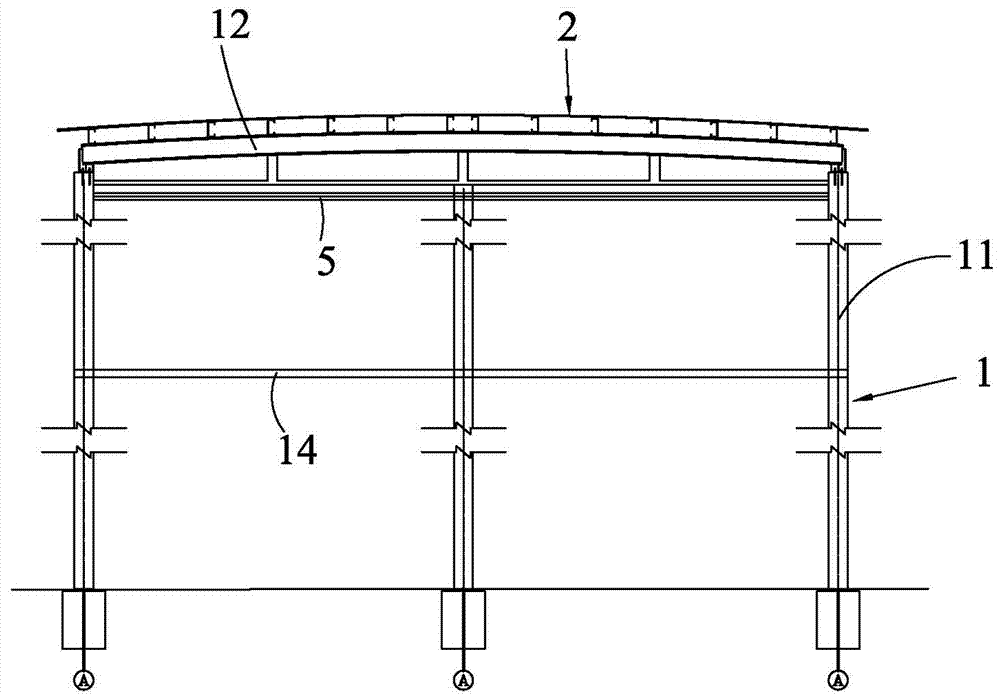

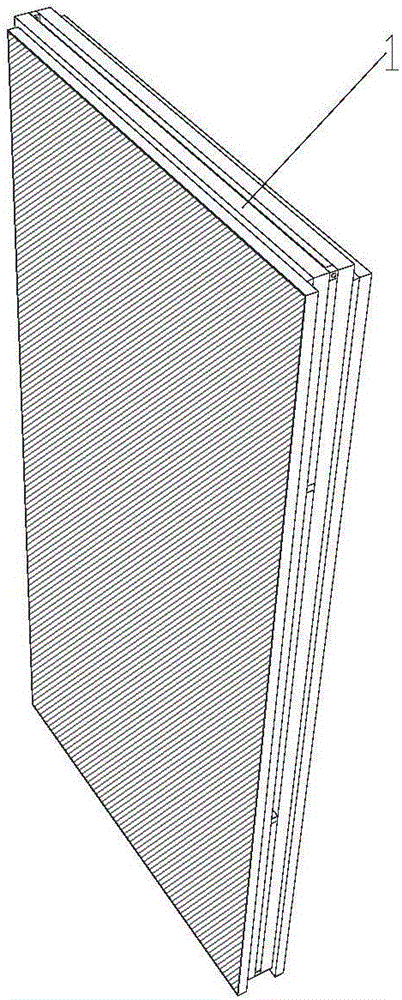

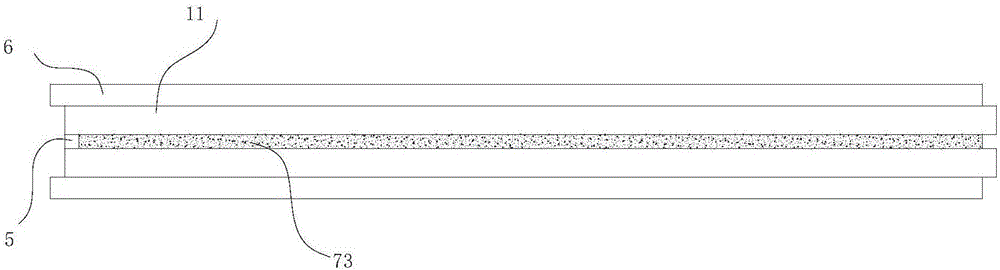

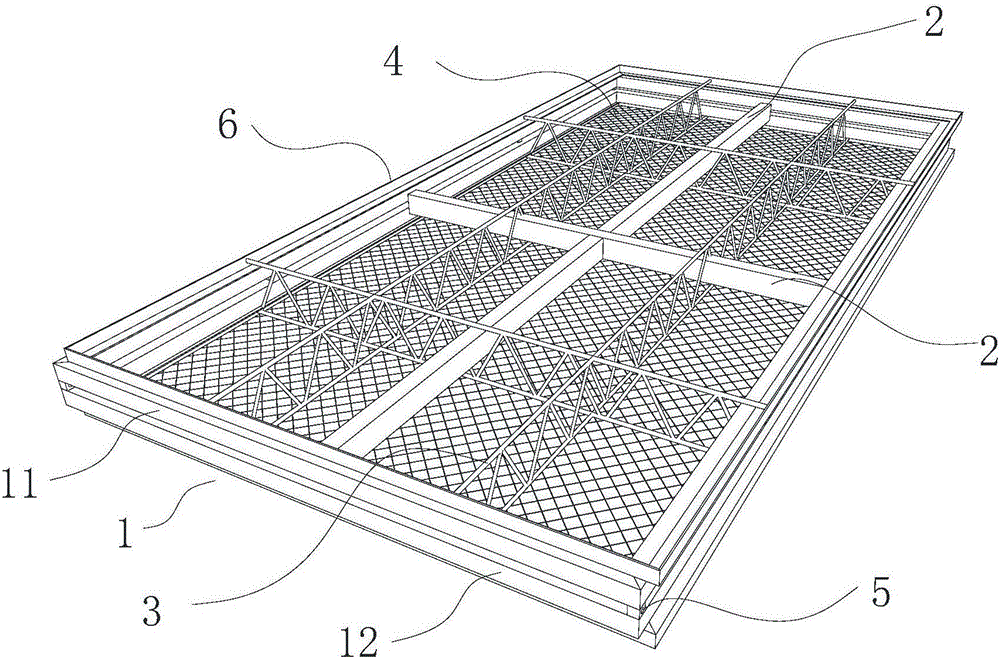

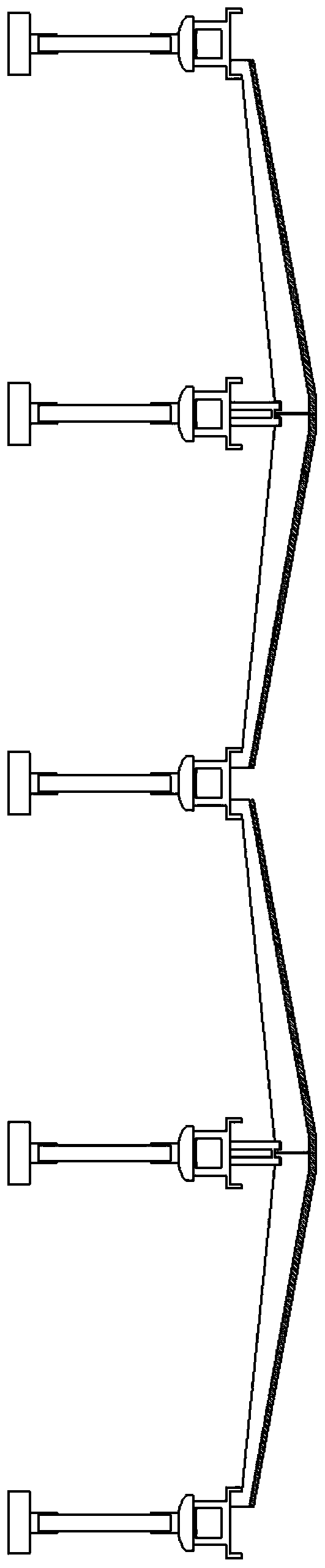

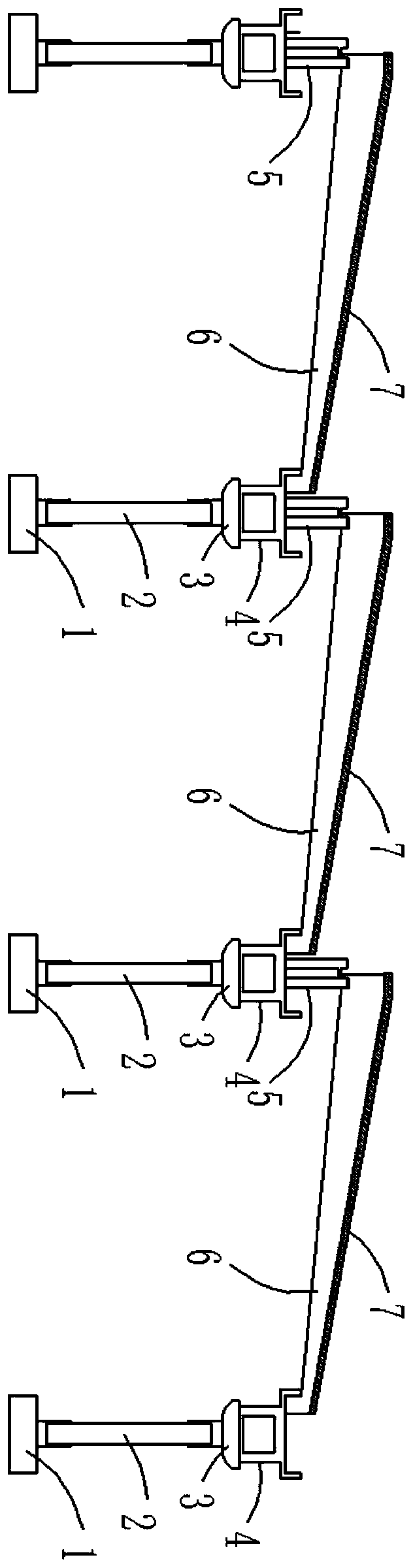

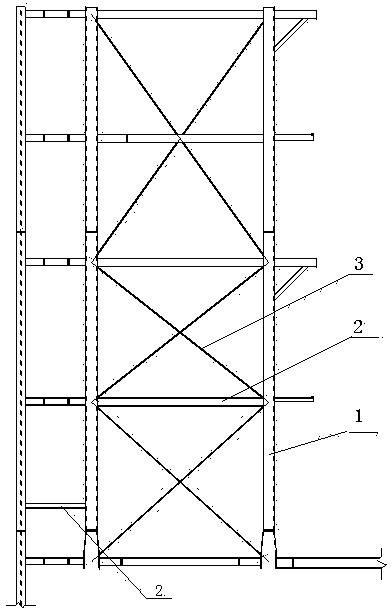

Prefabricated light steel structure factory building and construction method thereof

ActiveCN109854010AGuaranteed ventilation effectImprove aestheticsBuilding material handlingIndustrial buildingsAutomationSurface plate

The invention discloses a prefabricated light steel structure factory building and a construction method thereof. The prefabricated light steel structure factory building comprises foundation bases, supporting row columns, supporting T-shaped columns, supporting cross beams, drop supporting members, building frames and skin assemblies. The construction method comprises the steps of assembling thesupporting row columns, assembling supporting foundation columns, raising the beams, manufacturing a roof and manufacturing wall panels. According to the prefabricated light steel structure factory building and the construction method thereof, the structure is simple, and the prefabricated light steel structure factory building and the construction method thereof have the advantages that the weight is light, the steel consumption per unit area is small, industrial manufacture can be realized, and the degree of automation is higher.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

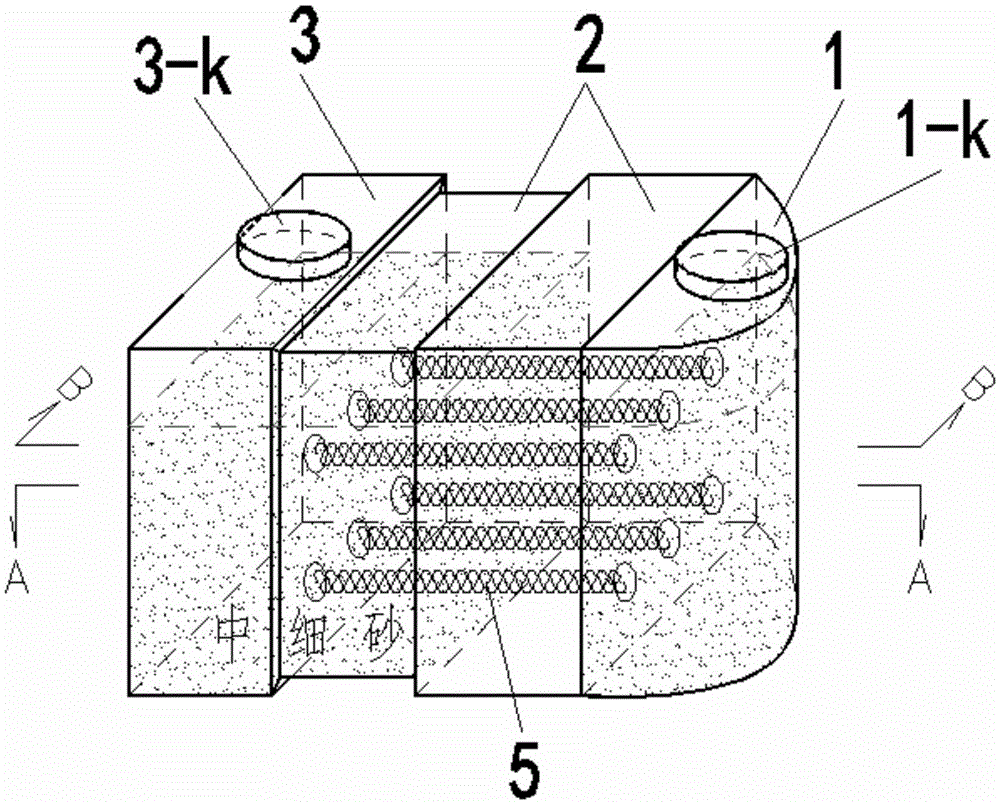

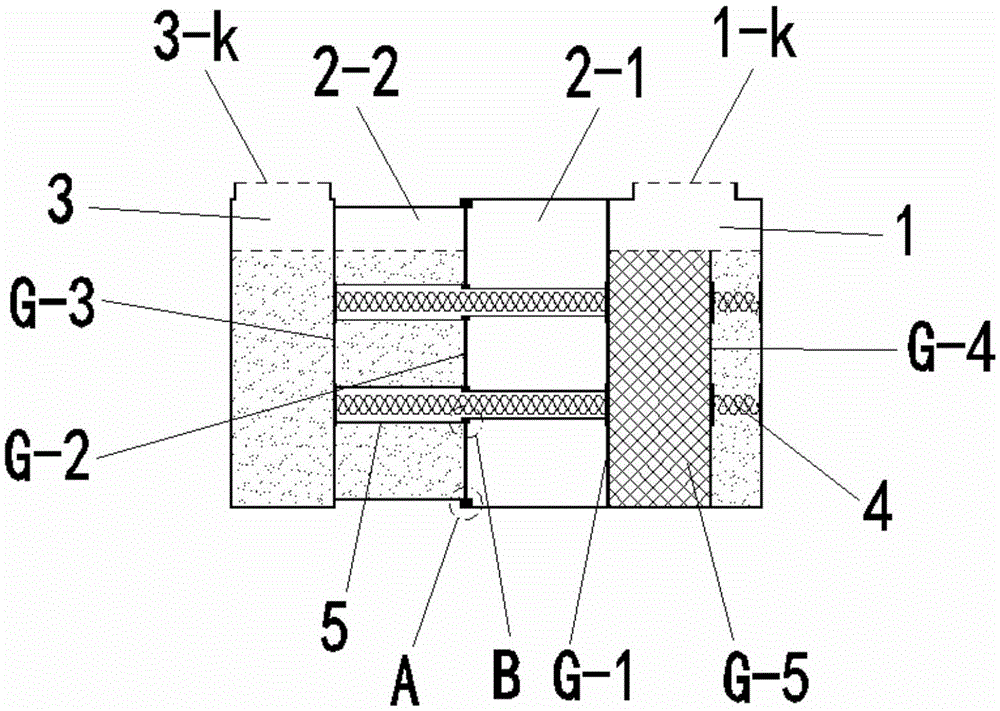

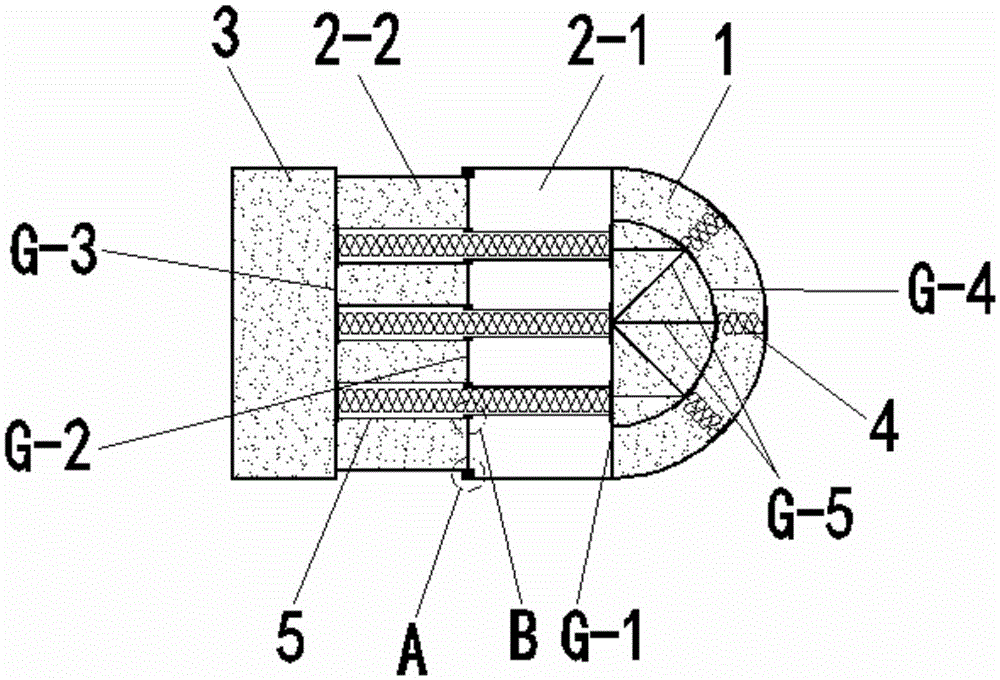

Buffering energy dissipation anti-collision barrel used for road

ActiveCN105672174ARealize factory manufacturingStructural innovationRoadway safety arrangementsElastomerEngineering

The invention provides a buffering energy dissipation anti-collision barrel used for a road and belongs to the field of road traffic safety facilities. The anti-collision barrel comprises a barrel body and barrel pressing sand. The barrel body is an integrated barrel body composed of a semicircular barrel head, a rectangular barrel tail and a sleeve type telescopic rectangular barrel body connected between the barrel head and the barrel tail through a front partition plate and a back partition plate. The barrel head is provided with energy dissipation elastomers and a supporting partition plate. A middle partition plate is arranged between a front barrel body and a back barrel body of the sleeve type telescopic rectangular barrel body. Elastic telescopic energy dissipation devices are positioned to penetrate through the middle partition plate and are connected between the front partition plate and the back partition plate of the telescopic rectangular barrel body. When the barrel body is subjected to exogenic action, the sleeve type telescopic rectangular barrel body compresses the elastomers of the elastic telescopic energy dissipation devices to be contracted through the elastic telescopic energy dissipation devices arranged inside the sleeve type telescopic rectangular barrel body, is backwards compressed along with the elastomers and gradually sleeved outside the back barrel body, so that the buffering impact force is absorbed, the loss caused by impact accidents is reduced, and after the impact force disappears, the barrel body gradually returns to the original state under the action of the elastic telescopic energy dissipation devices.

Owner:WUHAN MUNICIPAL ENG DESIGN & RES INST

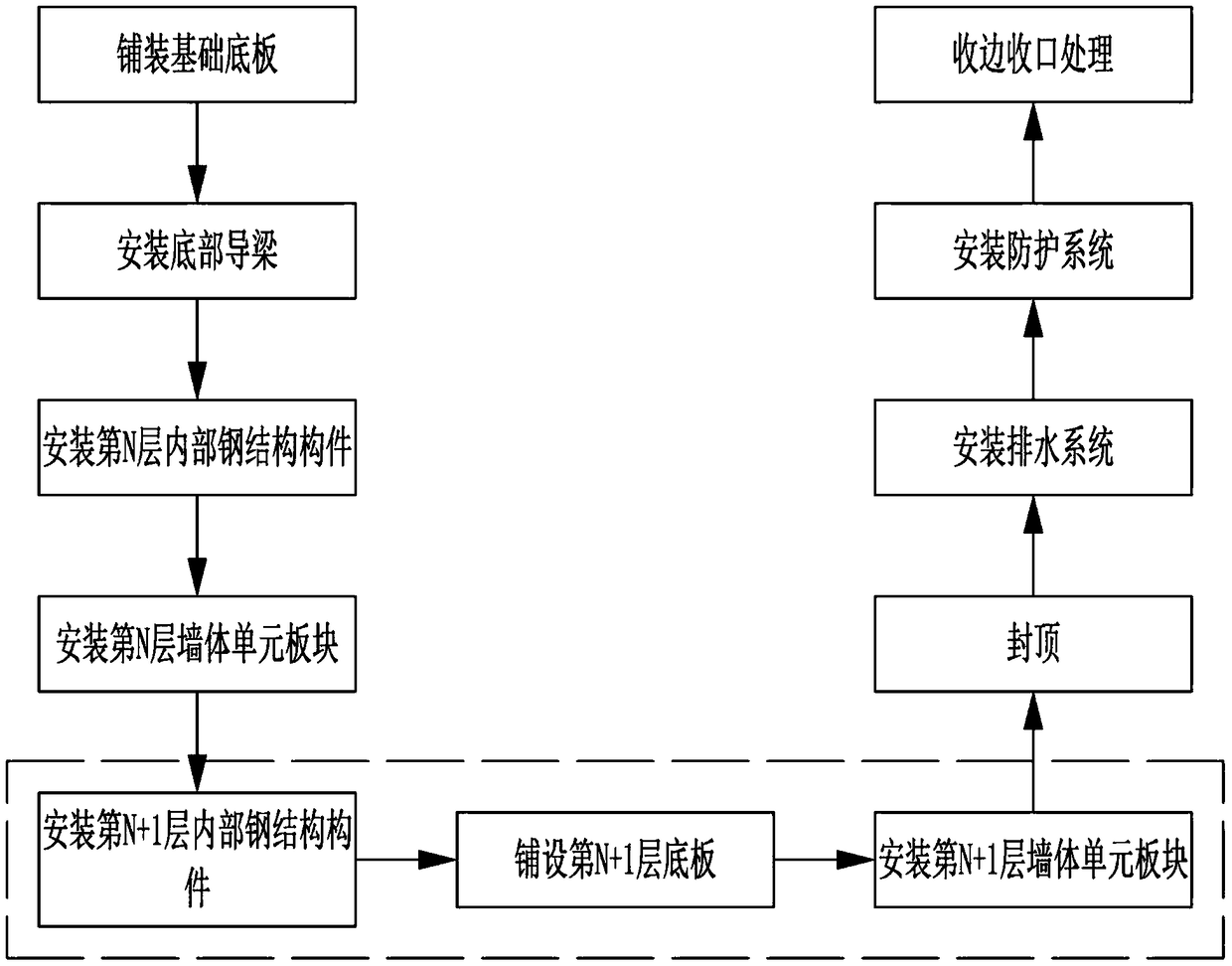

Building method of assembled low-rise light-steel-structure residence system

InactiveCN108729692ASimplify the construction processImprove construction efficiencyFoundation engineeringBuilding constructionsResidenceEngineering

The invention provides a building method of an assembled low-rise light-steel-structure residence system. The method is characterized by including the steps of S1, laying a foundation slab; S2, mounting the first layer of bottom nose girder on the foundation slab; S3, mounting the Nth layer of internal steel structure component; S4, mounting the Nth layer of outer wall unit plate and inner wall unit plate; S5, mounting the (N+1)th layer of internal steel structure component; S6, laying the (N+1)th layer of bottom plate, and sealing; S7, mounting the (N+1)th layer of outer wall unit plate and inner wall unit plate; S8, roofing. The method has the advantages that the later outer wall decoration problem of the outer protecting wall of a traditional low-rise light-steel-structure residence issolved, various parts are completely assembled in a factory, workers only need to perform on-site hoisting and splicing, assembling rate can reach above 95%, and the construction speed of the assembled low-rise light-steel-structure residence is increased greatly.

Owner:山东津单幕墙有限公司

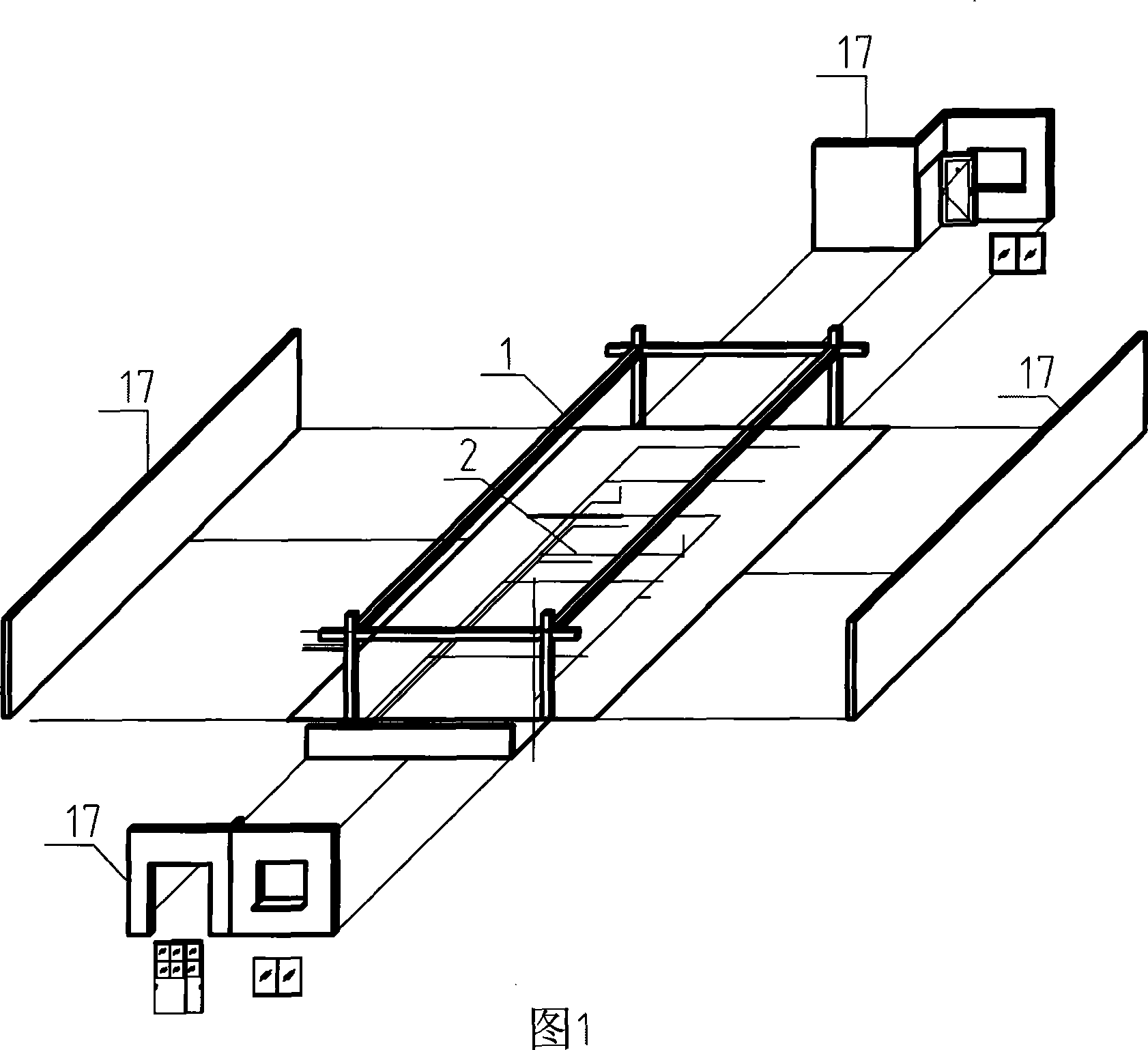

Long-life variable residence and construction method therefor

InactiveCN101446139AStrong durabilityExtended service lifeBuilding constructionsDwelling buildingResidenceLine tubing

The invention discloses a long-life variable residence, which includes a large space structure, wherein, the large space structure fully adopts variable space inside thereof; and the variable space is designed and constructed by a user. The invention also discloses a construction method for the long-life variable residence, which comprises the following steps: 1) the construction of the large space structure is conducted by a construction unit; and 2) design and construction for the variable space by the user include the design of house types and concrete layout; each pipeline is arranged comprehensively and connected with standpipes among public equipments; a movable overhead floor is installed; the functional separation is achieved through inner movable partition boards according to the design house types; an integral kitchen and an integral washroom are installed, so as to achieve the connection among the integral kitchen, the integral washroom and each pipeline indoors. The large space structure in the invention fully adopts variable space inside thereof, the movable overhead floor layer has the detachable performance, and the pipeline capable of being freely mounted is arranged between the movable overhead floor layer and a lower floorboard, thereby breaking through limitation of difficult reconstruction for the house types of traditional residence.

Owner:JINAN CITY HOUSING INDUSTRIALIZATION DEV CENT

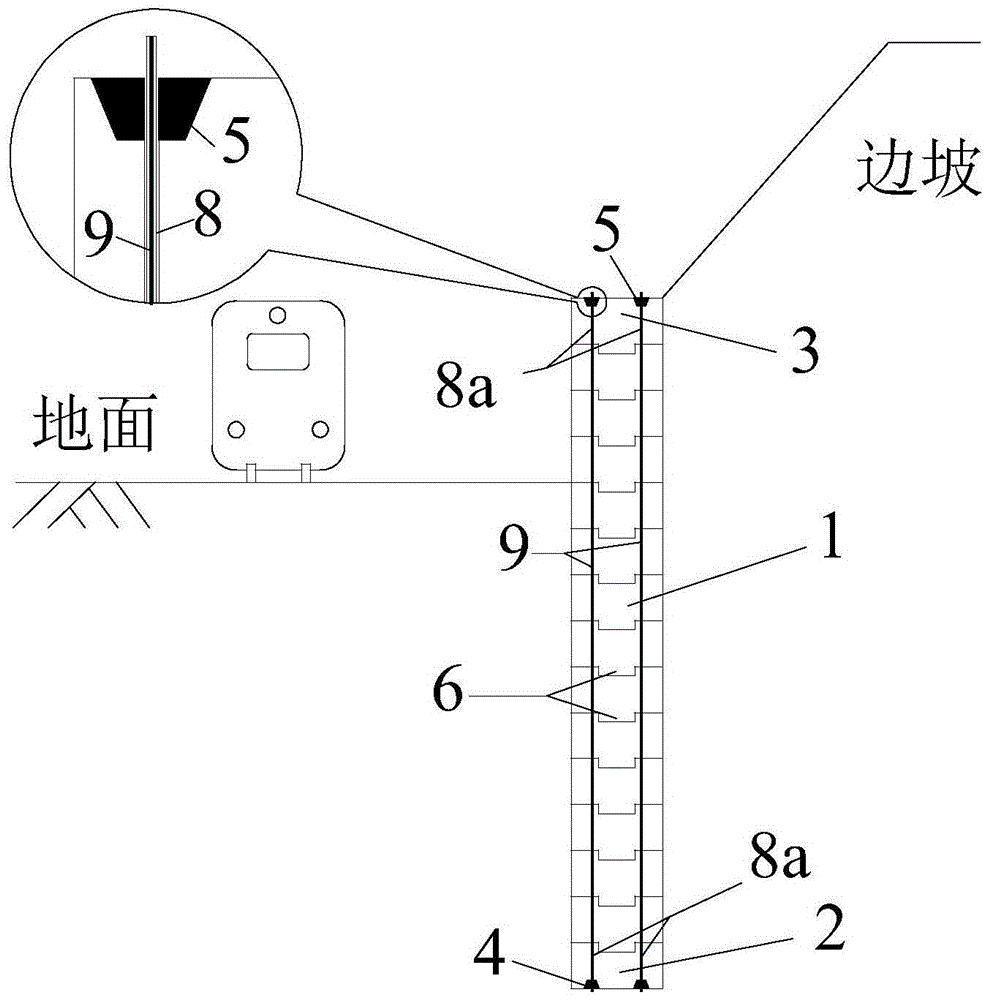

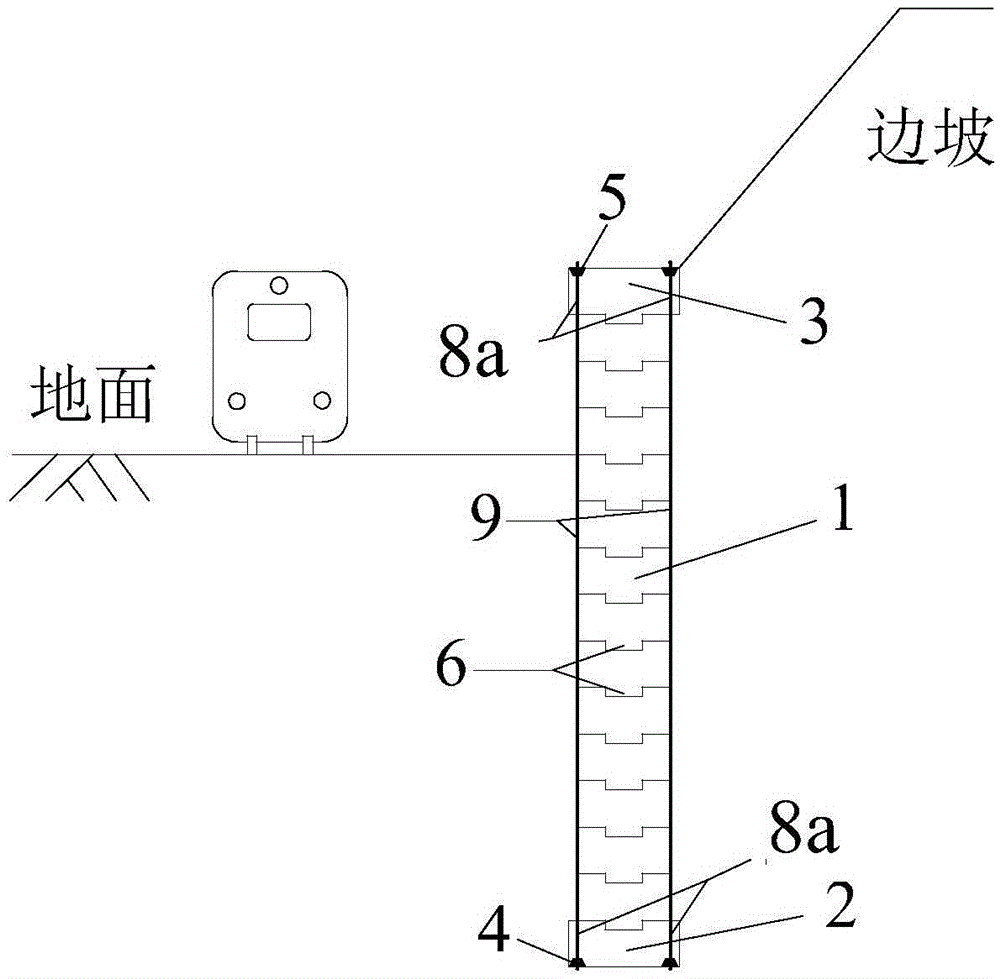

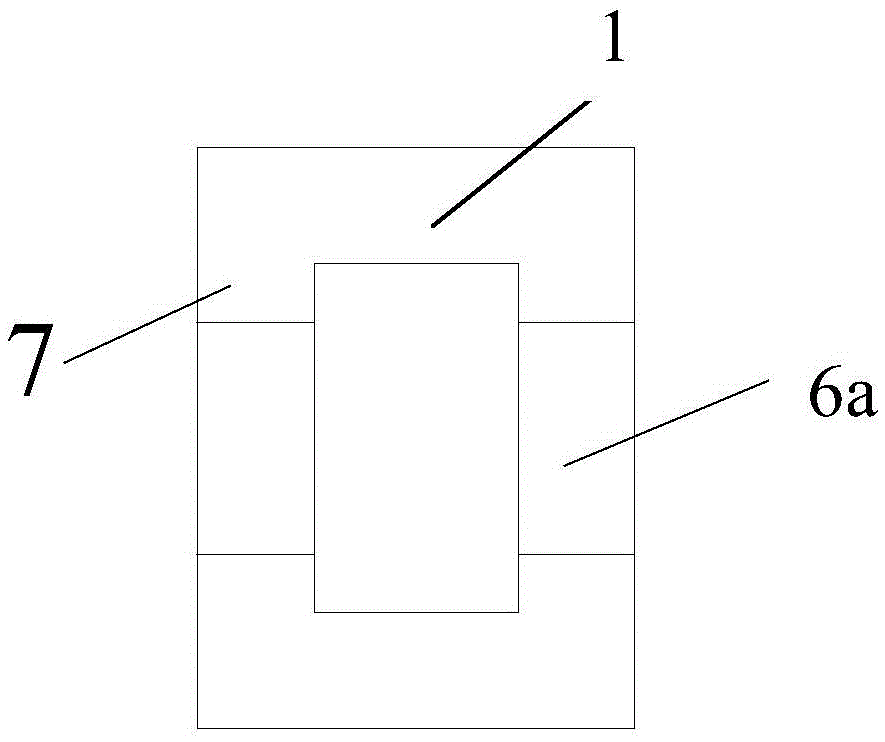

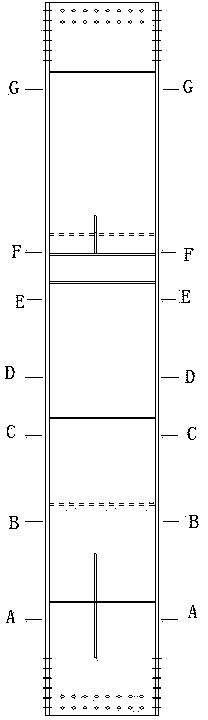

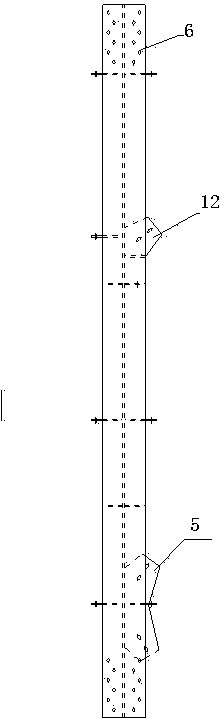

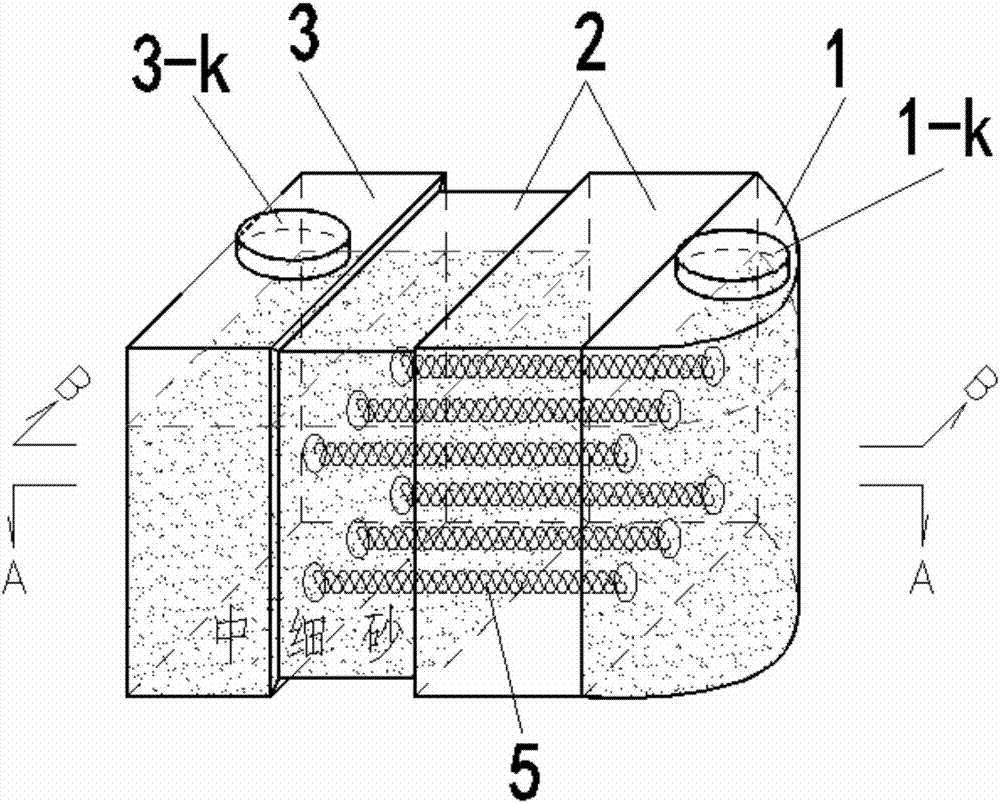

Prefabricated assembling type externally pre-stressed anchoring anti-slide pile

InactiveCN105544528AQuality assuranceTake advantage of stress resistanceBulkheads/pilesPre stressPre stressing

The invention discloses a prefabricated assembling type externally pre-stressed anchoring anti-slide pile. A pile body of the anchoring anti-slide pile comprises a pile head section, a pile shaft and a pile tip section which are connected in sequence. The pile shaft is formed by connecting a plurality of pile shaft sections of the same structure from top to bottom in sequence. The cross section of each pile shaft section is in an ''I'' shape or hollow rectangular shape. A groove is formed in the top surface of each pile shaft section, and a protruding block is arranged on the bottom surface of each pile shaft section. In two adjacent pile shaft sections, the protruding block of the pile shaft section on the upper portion is embedded in the groove of the pile shaft section on the lower portion. Protruding blocks adaptive to the grooves of the pile shaft sections are arranged on the bottom surface of the pile head section. Grooves adaptive to the protruding blocks of the pile shaft sections are formed in the top surface of the pile tip section. The pile head section and the pile tip section are of an entity structure. The pile head section, the pile shaft and the pile tip section are anchored together through pre-stressed tendons arranged outside the pile shaft. According to the prefabricated assembling type externally pre-stressed anchoring anti-slide pile, factory-like manufacturing is achieved, the anchoring anti-slide pile has the characteristics of modularization, standardization and mass manufacturing, construction difficulties are reduced, and constructing is fast and efficient.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Optical cable and electric cable laying method applicable to intelligent substation

InactiveCN107317266AShallow trenching depthReduce excavationApparatus for laying cablesEngineeringMaintainability

The invention discloses an optical cable and a cable laying method applied to an intelligent substation, aiming to solve the problems of inflexible structure and poor maintainability during traditional cable laying. The key points of the technical solution are step a, ground ditching; step b, outer Laying of tank boxes; step c, laying of supporting bridges; step d, laying of inner tank boxes; step e, laying power cables, control cables and optical cables in three groups of inner tank boxes; step f, inner layer tank boxes at branches Laying; step g, the tank box is closed. The optical cable and cable laying method applied to the intelligent substation of the present invention have more flexible installation structure and strong maintainability.

Owner:JIAXING HENGCHUANG ELECTRIC POWER DESIGN & RES INST CO LTD +1

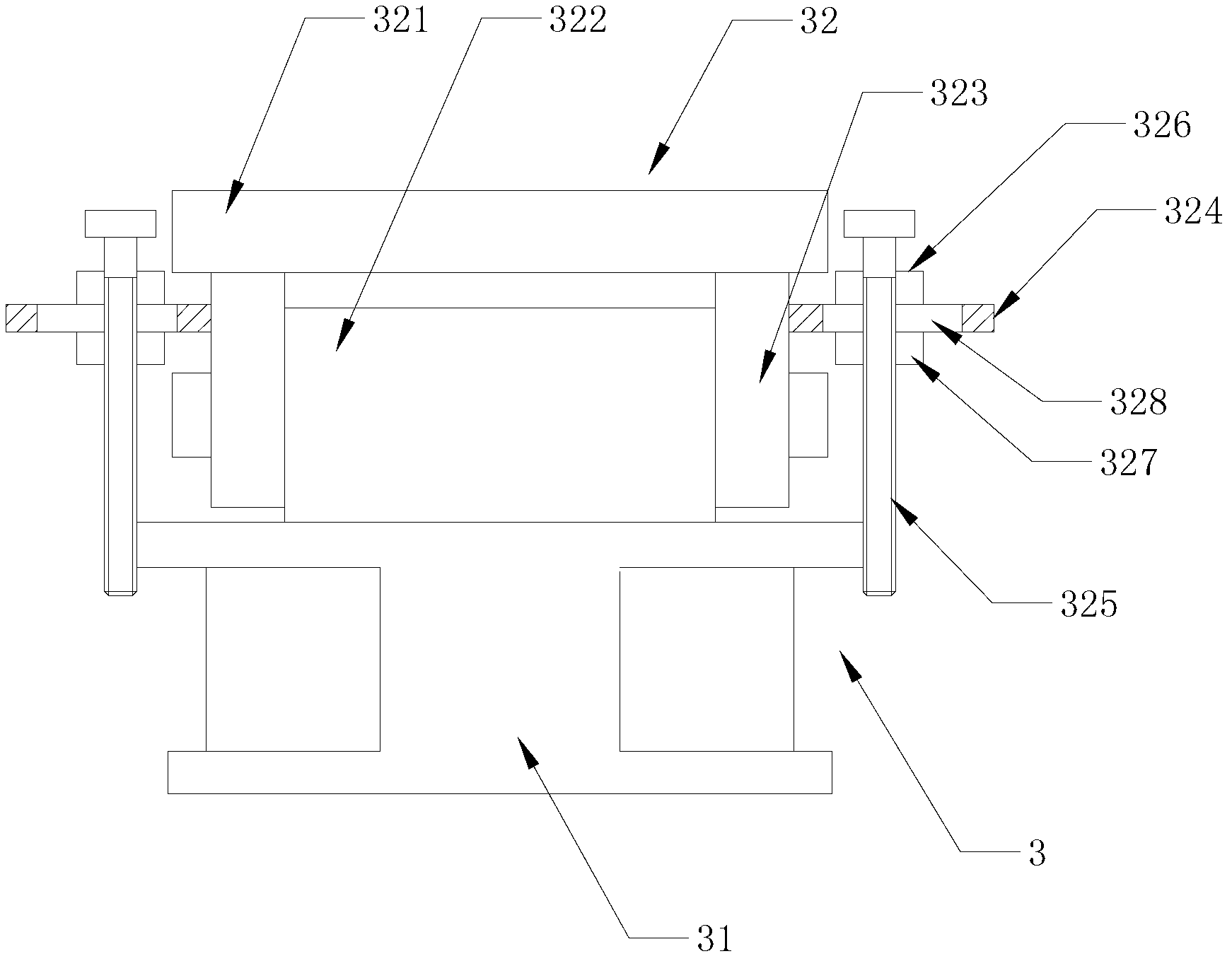

Construction method of cold box interior installation equipment

ActiveCN103212951ARealize factory manufacturingGuarantee welding qualityArchitectural engineeringRefrigerated temperature

The invention discloses a construction method of cold box interior installation equipment. The construction method of the cold box interior installation equipment comprises the following steps: A, equipment and an outer cylinder of a cold box are formed in a welding mode in advance; B, the outer cylinder is horizontally arranged, a set of conveying tracks are horizontally fixed on the inner wall of the outer cylinder, and the conveying tracks are arranged at the bottom of the inner wall of the outer cylinder; C, a horizontal conveying cart is placed on the conveying track, so that the horizontal conveying cart is guaranteed to move smoothly; D, equipment is horizontally hoisted, a random end of the equipment is placed on the horizontal conveying cart by entering from one end of the outer cylinder; E, the equipment is dragged from the other end of the outer cylinder, and the equipment can be conveyed to a preset position on the horizontal conveying cart; F, connecting supports are installed between the inner wall of the equipment and the outer wall of the equipment one by one till the equipment and the outer cylinder are fixed and guaranteed to be concentric; and F, the conveying track and the horizontal conveying cart are taken out. The construction method of the cold box interior installation equipment has the advantages that not only forming quality of an inner cylinder and the outer cylinder is guaranteed, large-scale refrigerators can be manufactured in a factorization mode, and personnel safety and equipment safety in the construction process are guaranteed.

Owner:江苏利柏特股份有限公司

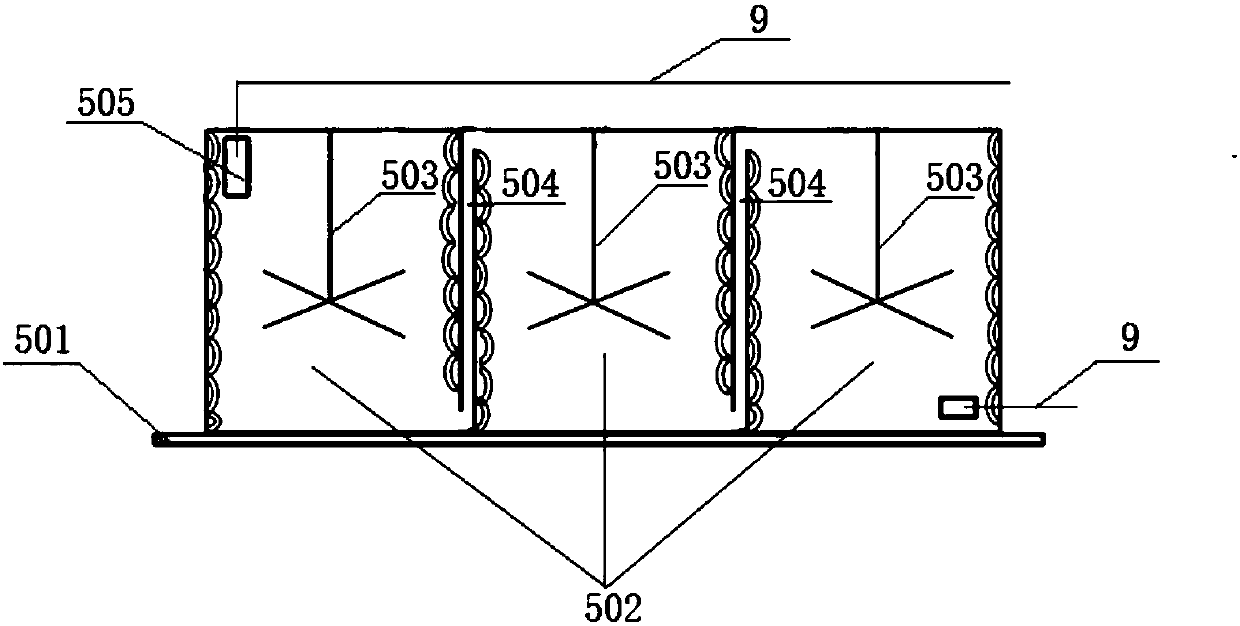

Modularized data center

InactiveCN104951017ARealize factory manufacturingImprove heat exchange efficiencyDigital processing power distributionCold airData center

The invention provides a modularized data center. The modularized data center comprises a lower box body and heat release devices, wherein cabinets and heat absorption devices are arranged in the lower box body, and the heat release devices are arranged outside the lower box body and connected with the heat absorption devices. Each cabinet comprises a cold air inlet and a hot air outlet. Each heat absorption device comprises a hot air inlet and a cold air outlet. The cabinets and the heat absorption devices are arranged side by side. The air entering and leaving direction of the cabinets is parallel to that of the heat absorption devices. The air flow flowing direction of the cabinets is opposite to that of the heat absorption devices. Thus, annular circulating air flow which sequentially passes through the hot air outlets of the cabinets, the hot air inlets of the heat absorption devices, the cold air outlets of the heat absorption devices and the cold air inlets of the cabinets is formed. The cabinets and the heat absorption devices are integrated in the lower box body, the space utilization rate and integrity are high, the modularized data center is suitable for being manufactured in an industrial mode, air flow in the lower box body is smooth, and the heat exchange efficiency is high.

Owner:GUANGDONG HIWAVE TECH

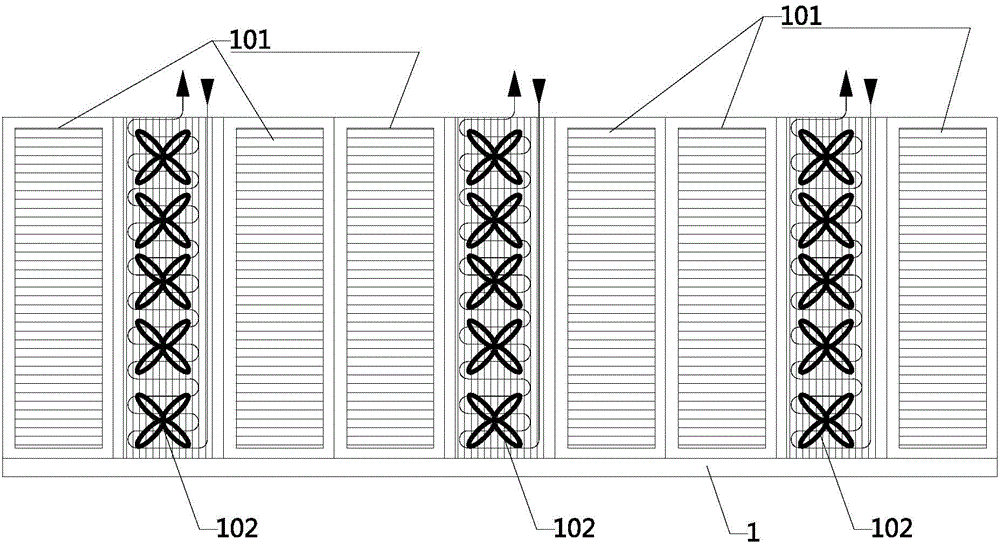

Method for realizing online centralized intelligent injection control of sewage treatment reagents

InactiveCN110422918AAvoid pollutionRealize regular fixed-point dischargeWater treatment parameter controlTransportation and packagingAutomatic controlMarine engineering

The invention provides a method for realizing online centralized intelligent injection control of sewage treatment reagents. According to the invention, a set of centralized injection control devicesis utilized; a plurality of sewage treatment reagents are designed to be centralized in a skid-mounted spill base and to be centralizedly placed on a foundation platform on site, so an occupied floorarea is greatly reduced and maintenance and management are more centralized and convenient. In particular, the method can realize both on-site and remote automatic online centralized intelligent injection control of a variety of sewage treatment reagents in the skid-mounted spill base, so the automation degree of the sewage treatment reagents is increased, and centralized control and storage of data such as running time, real-time flow, operating temperature, operating pressure, accumulated operating data and equipment outage states can be realized through intelligent control program and hardware in a control box. The method is very suitable for realizing remote online monitoring. A skid-mounted modularized integral structure enables factory manufacturing and long-distance transportation to be realized and also facilitates on-site installation and debugging.

Owner:LUOYANG LVCHAO ENVIRONMENTAL PROTECTION TECH

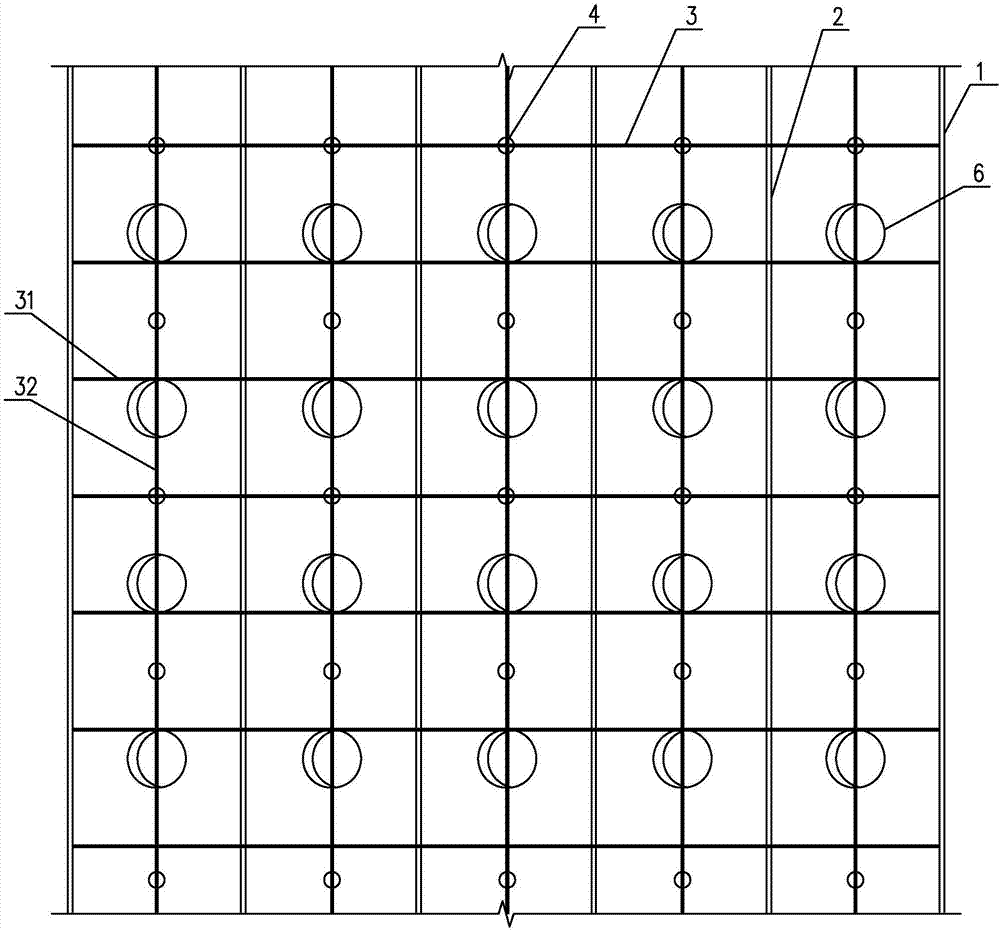

Assembly type residential steel structure system

InactiveCN107090938AAchieve standardized designRealize factory manufacturingConstruction materialFloorsFloor slabSteel bar

The invention relates to an assembly type residential steel structure system. The system comprises steel plate shear walls, superimposed steel composite beams and superimposed floor stabs; stiffened plates are welded to the steel plate sheer walls; the end portions of the superimposed steel composite beams are connected with the steel plate shear walls; an out-wrapped concrete layer is wrapped on the outer surface of each superimposed steel composite beam, and stressed steel bars are laid in the out-wrapped concrete layer; the stressed bars are connected to the stiffened plates; the superimposed floor stabs are connected to the superimposed steel composite beams. The fabricated steel structural system of the house has the advantages of high industrialization and modularization, controllable quality and short investment payback period and can be applied and popularized in the field of architecture structures.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

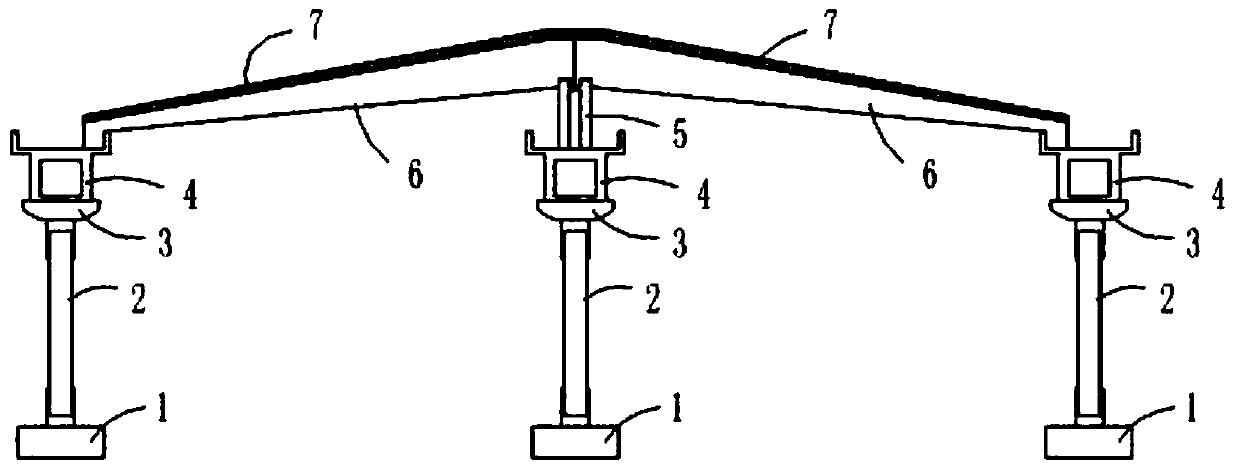

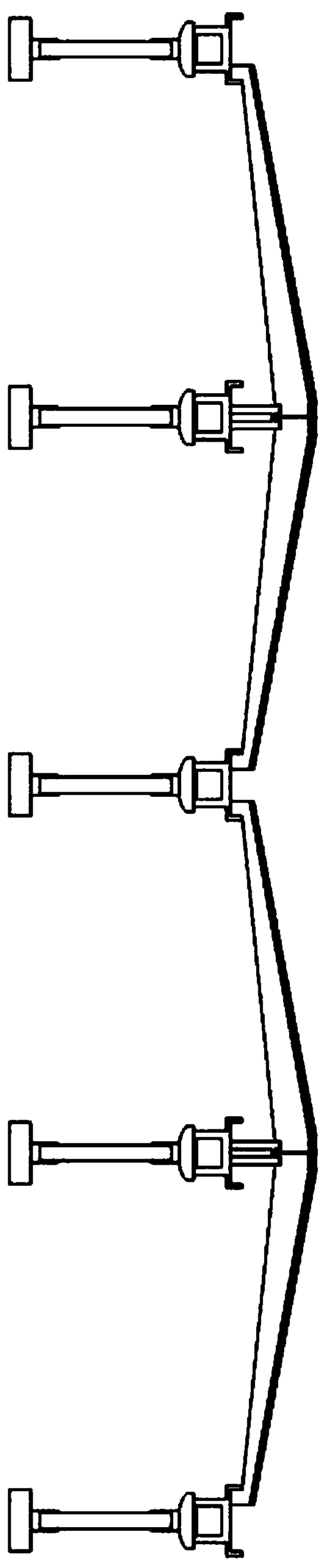

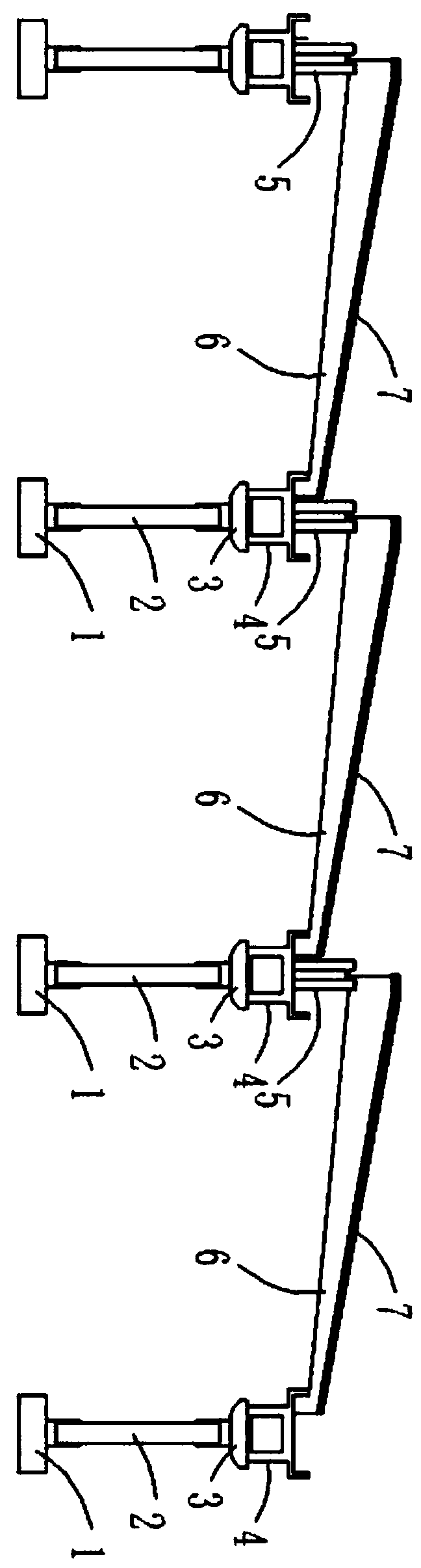

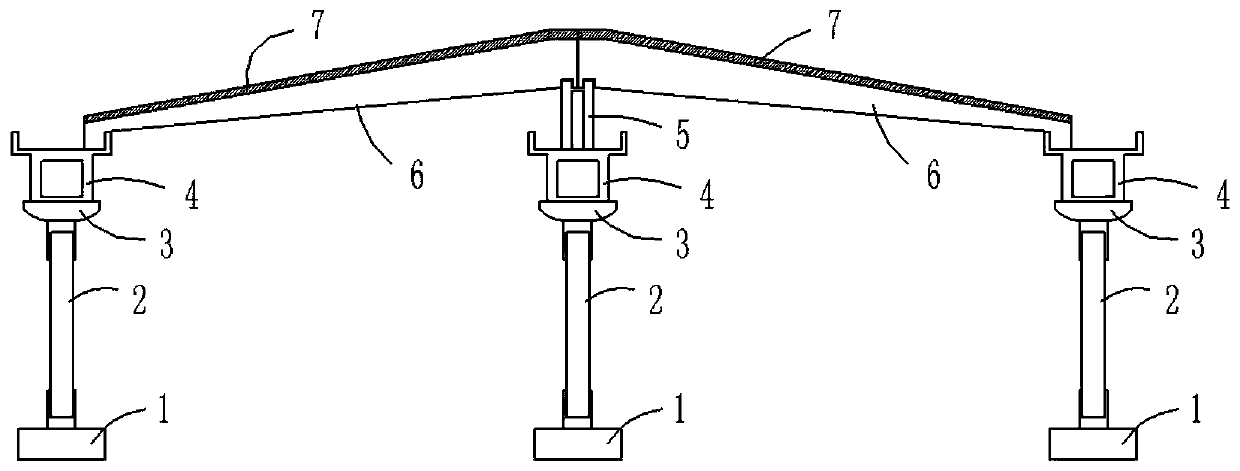

A gas station light steel structure canopy

ActiveCN105442873BRealize on-site installationRealize factory manufacturingSpecial buildingSmall buildingsCorniceAwning

The invention discloses a lightweight steel structure awning of a gas station. The lightweight steel structure awning comprises stand columns, and main beams and auxiliary beams which are arranged at the top ends of the stand columns. A top plate is arranged at the tops of the main beams and the auxiliary beams. The main beams and the auxiliary beams are connected through column-beam joints, beam-beam joints, beam-beam connecting joints, cantilever beam joints and corner-beam joints. A pressing plate and an installation support are arranged on the tops of the main beams or the auxiliary beams. The installation support fixes the top plate. A lamp box frame is arranged at cornices. A gutter bracket and a gutter are arranged at the cornice at the lowest end of the top of the awning. A down pipe is connected to the bottom of the gutter. According to the technical scheme, connection between the main beams and connection between the main beams and the auxiliary beams are achieved through the uniquely-designed connection joints, welding is not needed in the construction process, meanwhile, the top plate, the lamp box frame and the like are also connected and fixed through bolts, and installation is achieved without welding; due to the arrangement, the construction difficulty is lowered, the construction period is shortened, and therefore the stability and safety of the lightweight steel structure awning are higher.

Owner:SHANDONG SHENGFA IND & TRADE CO LTD

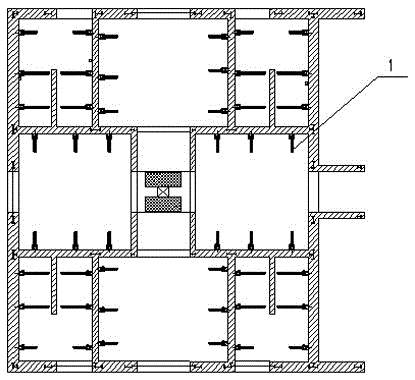

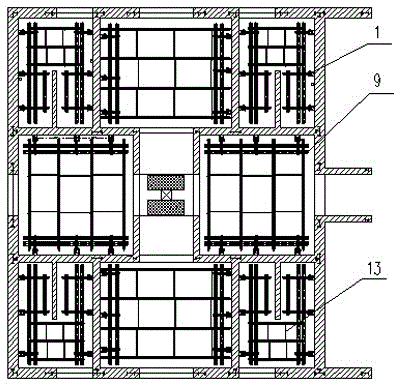

Construction methods for building combined buildings

InactiveCN104153576BRealize factory manufacturingImprove stabilityBuilding material handlingMaterial resourcesRebar

The invention discloses a construction method for a combined building, which comprises the following steps: (1) making prefabricated parts according to the designed size and constructing the foundation; (2) welding the steel plates or steel bars on the prefabricated walls to the corresponding steel plates or bars on the foundation Steel bars, and weld the steel plates or steel bars at the joints of any two prefabricated walls that are connected to each other; then perform step (3) or step (5); (3) weld the steel plates or steel bars on the prefabricated floor to the upper The steel plate or steel bar corresponding to the top of the prefabricated wall installed in the first step; then perform step (4); (4) after the construction of the first floor of the building is completed, each floor of the building is based on the next floor of the building to carry out the same construction process , until the top floor; then perform step (5); (5) when building a building on the top floor, the steel plates or reinforcing bars on the prefabricated roof are welded to the corresponding steel plates or reinforcing bars on the top of the prefabricated wall body on the top floor. It has the advantages of environmental protection, shortening the construction period and saving a lot of manpower and material resources.

Owner:袁建华

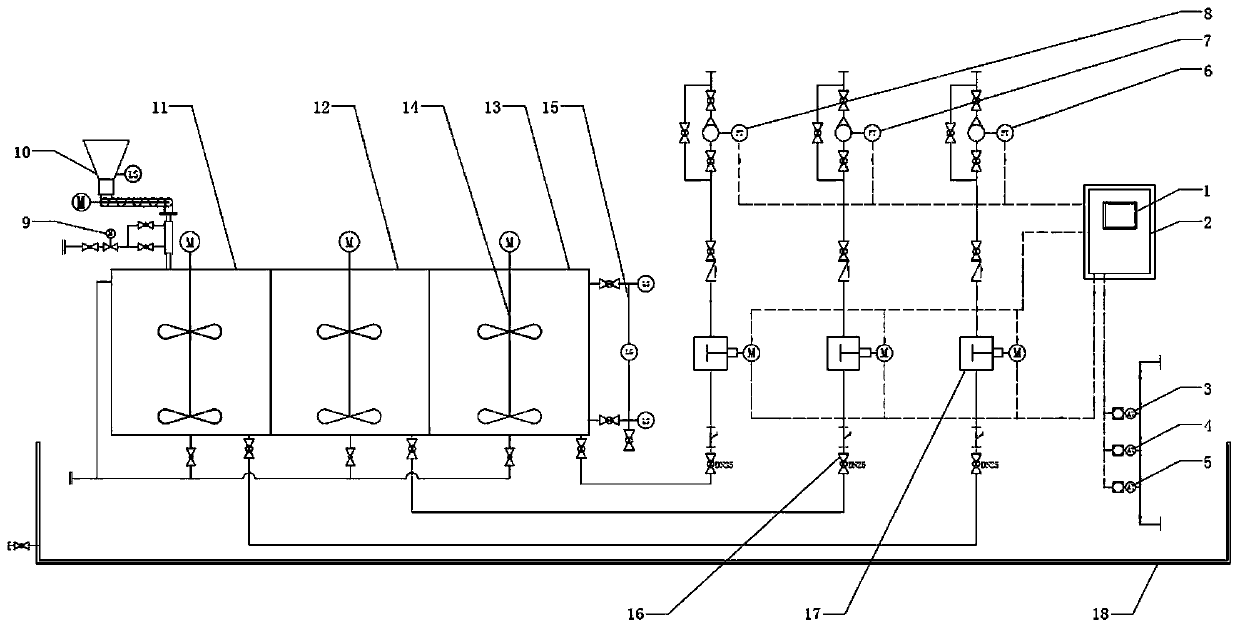

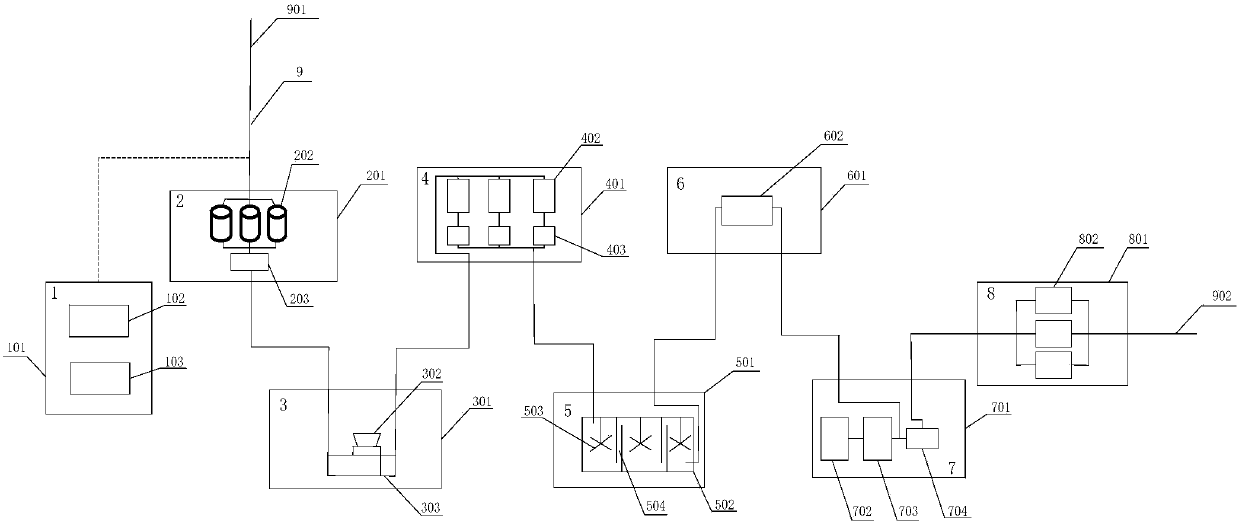

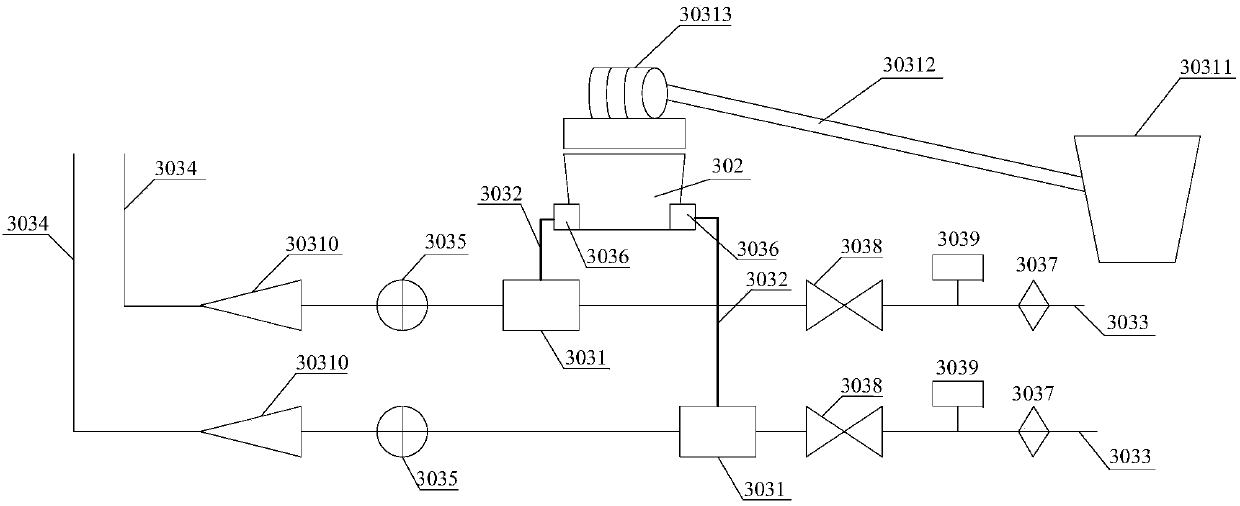

Skid-mounted modularized polymer-surfactant binary drive injection allocation device applicable to complex fault block oil field

The invention discloses a skid-mounted modularized polymer-surfactant binary drive injection allocation device applicable to a complex fault block oil field and belongs to the technical field of tertiary oil recovery. According to the skid-mounted modularized polymer-surfactant binary drive injection allocation device applicable to the complex fault block oil field, a moveable produced water deeptreatment module, a moveable polymer dry powder dispersion module, a moveable auxiliary agent addition module, a moveable polymer mother liquid on-line aging module, a moveable feeding module, a moveable surfactant storage dilution and addition module and a moveable injection module are sequentially arranged at the liquid inlet end and the liquid outlet end of a first pipeline, a moveable power supply and distribution and automation control module is arranged at the liquid inlet end of the first pipeline, then power support and automatic control are provided for the modules, a standardized andmodularized polymer injection binary drive injection allocation device is established, industrial manufacturing and production can be achieved, the station construction period of a polymer injectionbinary drive injection allocation station is shortened, and convenience is brought to on-site management and repeated multi-time use.

Owner:PETROCHINA CO LTD

Can be assembled with environmentally friendly exterior walls

ActiveCN104005496BSolve the requirements of heat preservation, fire prevention, sound insulation and heat preservationThe requirements of heat preservation, fire prevention, sound insulation and heat preservation are realizedWallsFire protectionStructural engineering

Owner:ASIA PACIFIC GREEN ARCHITECTURE BEIJING TECH GRP CO LTD

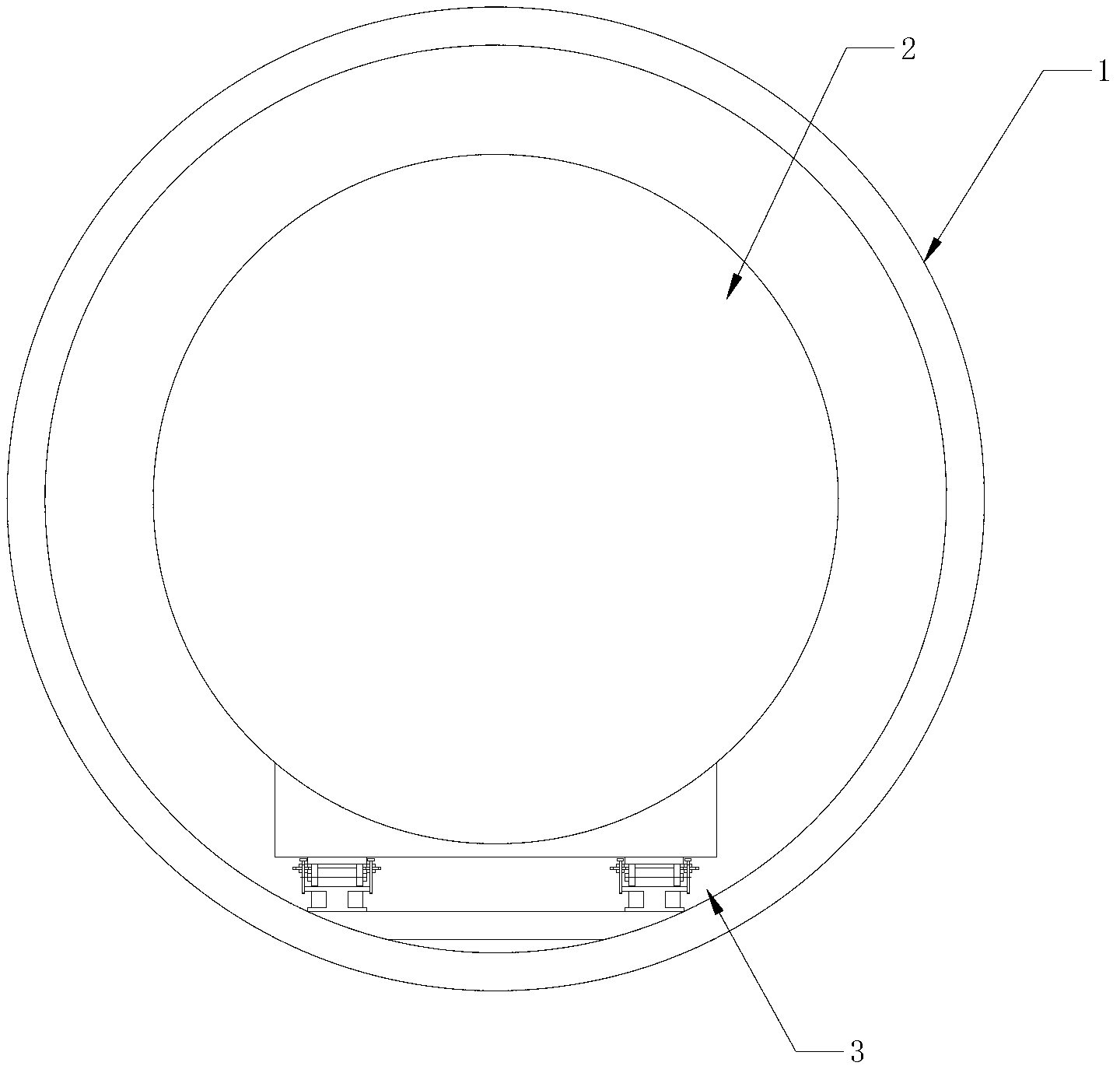

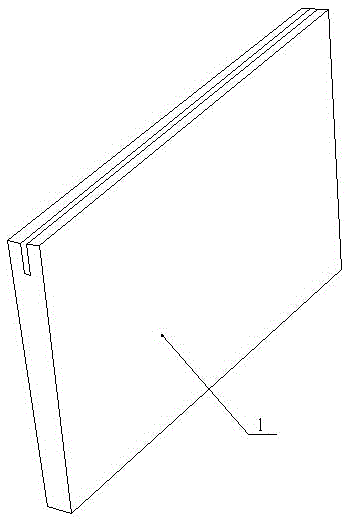

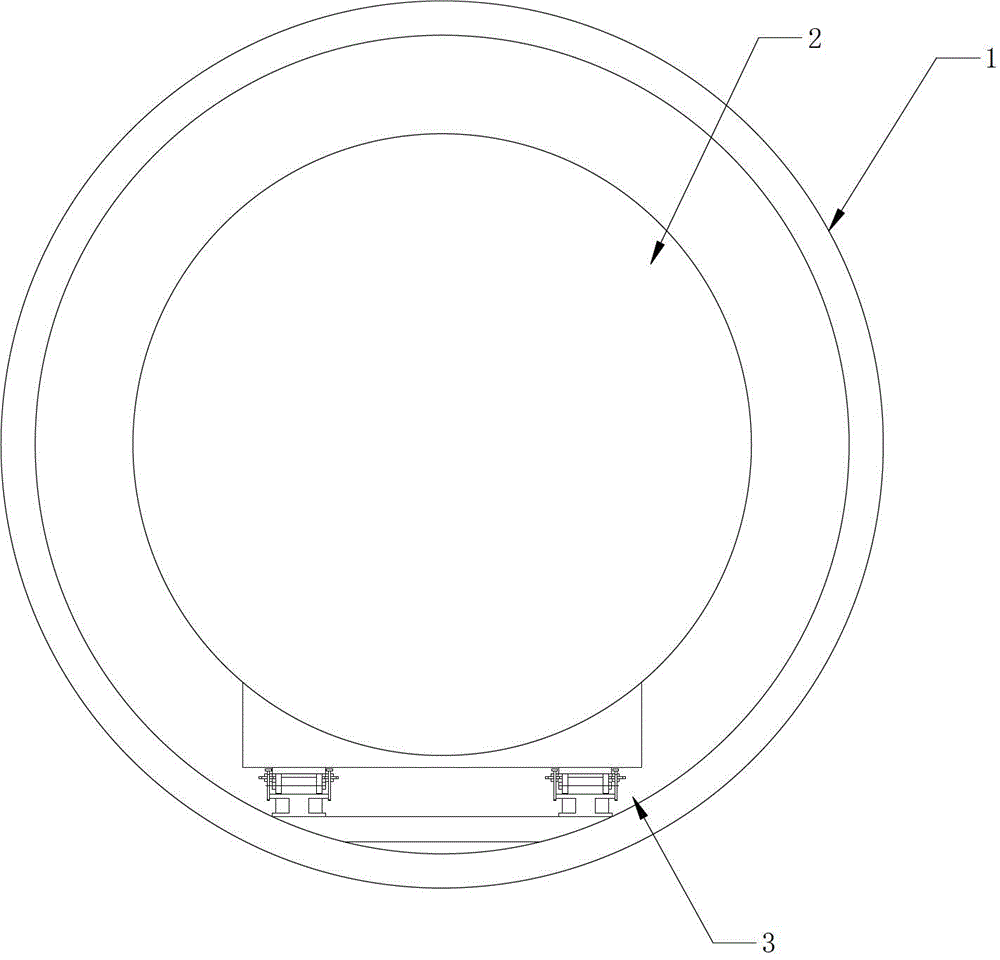

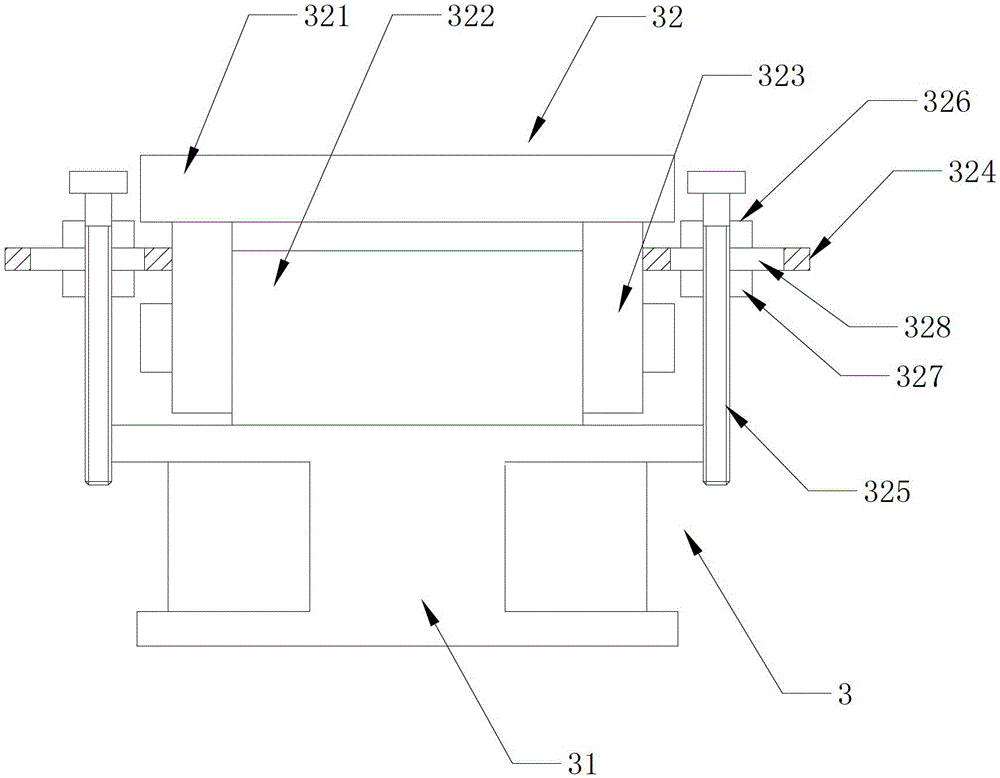

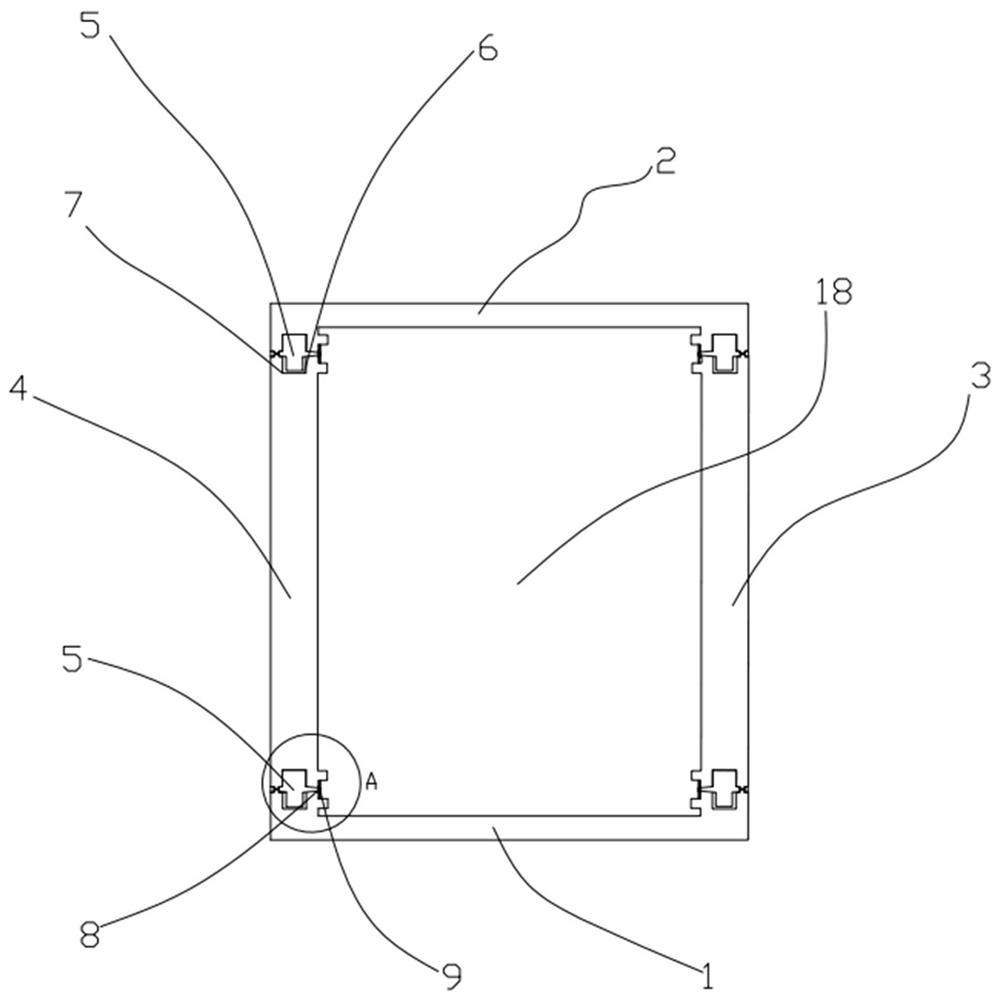

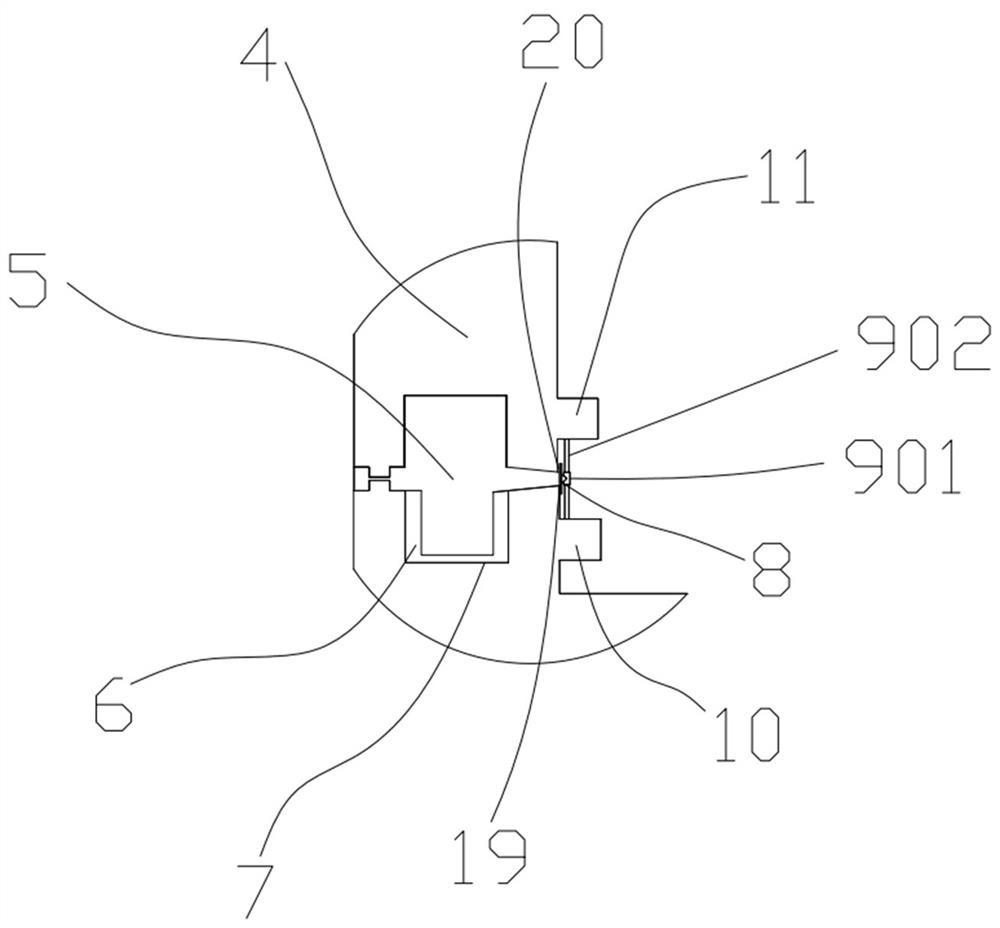

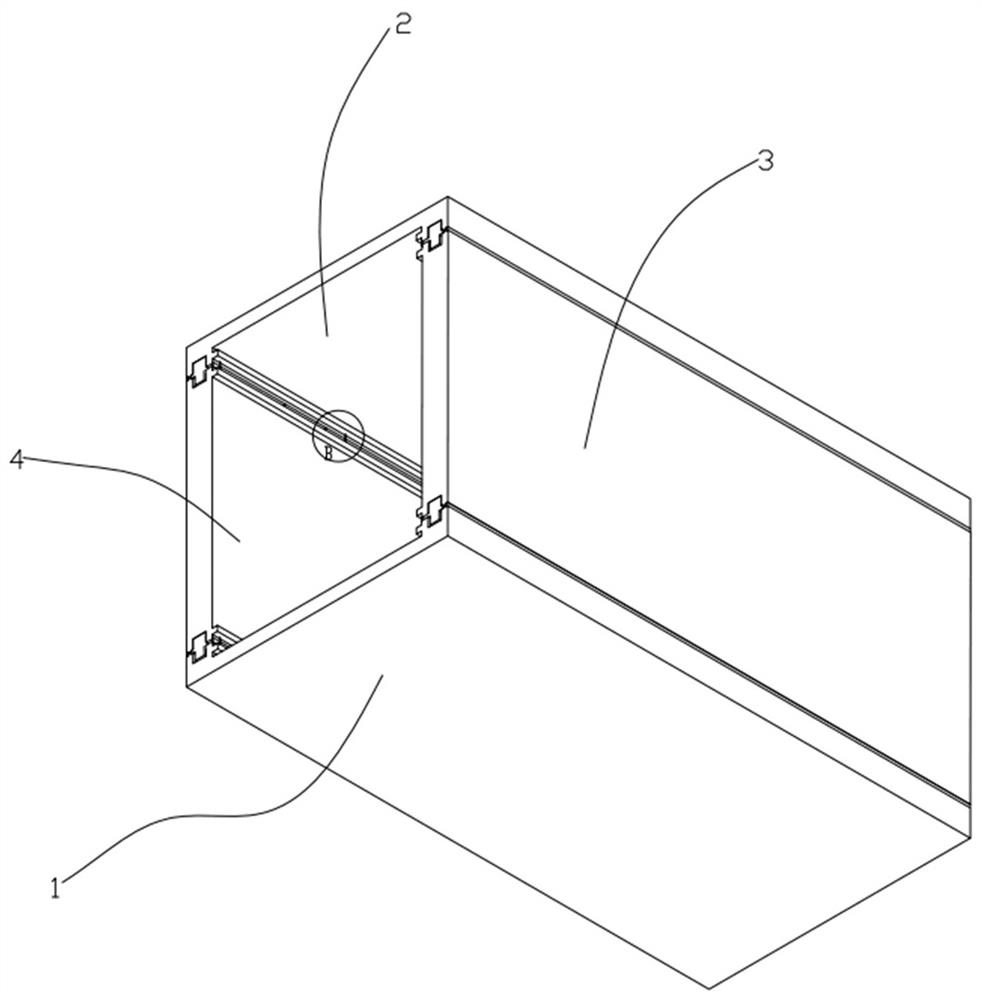

Modular photovoltaic power generation building

InactiveCN102561723BRealize factory manufacturingAchieve integrationPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringPhotovoltaic power generation

The invention discloses a modular photovoltaic power generation building, which aims to be easy in control of quality and high in efficiency, and is economical and environment-friendly. The modular photovoltaic power generation building comprises a building framework and a plurality of photovoltaic power generation modules, modular light steel components are detachably assembled to form the building framework, the photovoltaic power generation modules are modularly and detachably assembled on the outer surface of the building framework, and the light steel components comprise upright columns, house top beams and wall beams, wherein the house top beams are connected with the upright columns, and the wall beams are connected with the upright columns. The invention can be used for various buildings.

Owner:深圳市新天光电科技有限公司

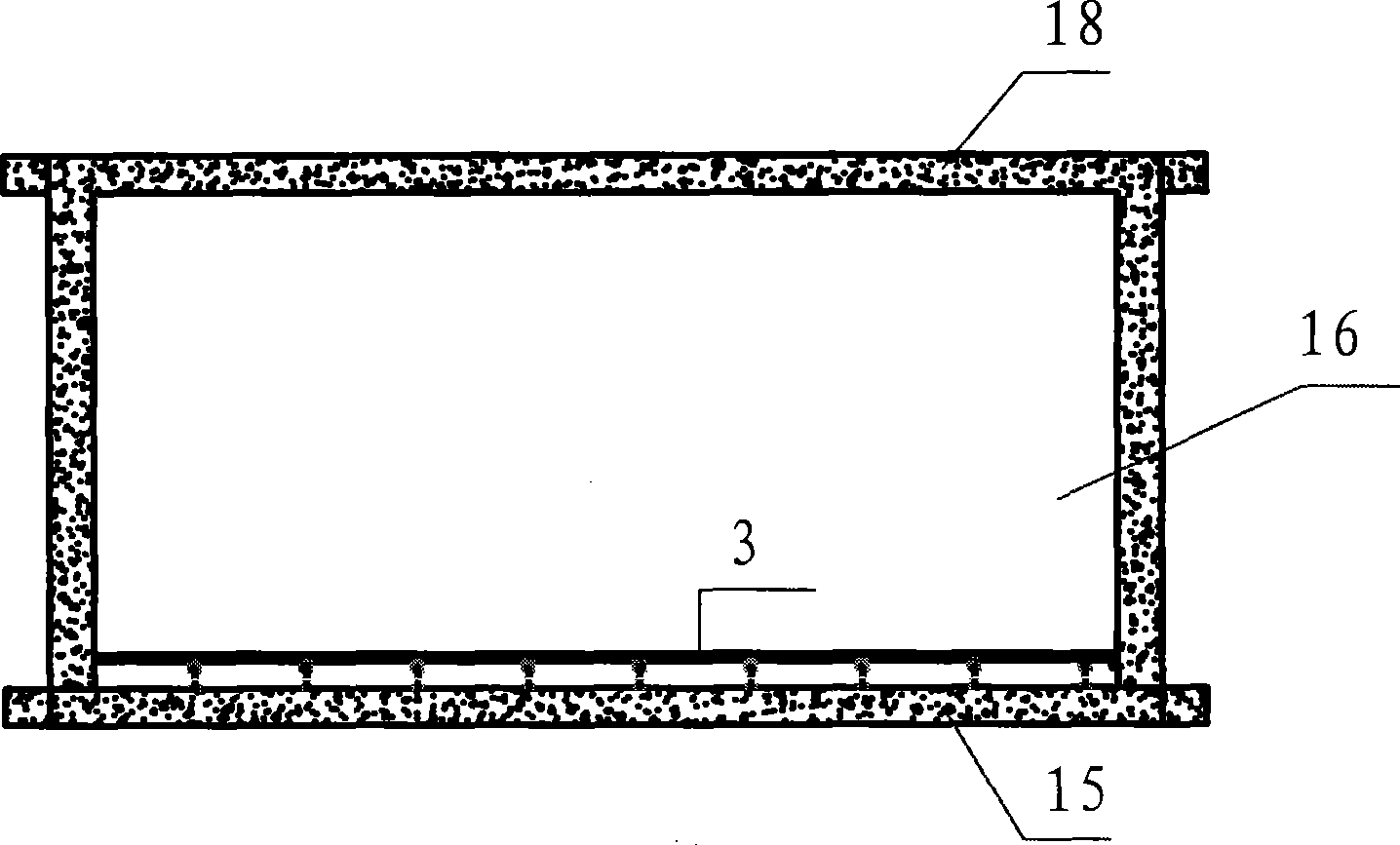

High-strength thermal insulation composite wall, manufacturing method thereof and house

InactiveCN106639048AReduce heatStrong enoughWallsFeeding arrangmentsThermal insulationHigh intensity

The invention provides a high-strength thermal insulation composite wall, a manufacturing method thereof and a house adopting the high-strength thermal insulation composite wall. The high-strength thermal insulation composite wall comprises a wall frame and a composite wall board. The wall frame is a metal framework and comprises a first frame body close to the inside of the wall and a second frame body close to the outside of the wall from outside to inside. A gap is formed between the first frame body and the second frame body. The first frame body and the second frame body are separated by a certain distance and hinged in a dot mode. The high-strength thermal insulation composite wall with inner and outer veneers adopts the metal wall frame, the high-strength load-bearing of the wall can be achieved, the wall frame is formed by assembling the two parts which are separated in a dot hinged mode, broken bridge isolation is achieved, a heat conduction source of an external steel structure can be effectively isolated, and internal wall heat can be reduced.

Owner:丽水山居乡创建筑规划设计有限公司

Construction method of cold box interior installation equipment

ActiveCN103212951BRealize factory manufacturingGuarantee welding qualityArchitectural engineeringRefrigerated temperature

The invention discloses a construction method of cold box interior installation equipment. The construction method of the cold box interior installation equipment comprises the following steps: A, equipment and an outer cylinder of a cold box are formed in a welding mode in advance; B, the outer cylinder is horizontally arranged, a set of conveying tracks are horizontally fixed on the inner wall of the outer cylinder, and the conveying tracks are arranged at the bottom of the inner wall of the outer cylinder; C, a horizontal conveying cart is placed on the conveying track, so that the horizontal conveying cart is guaranteed to move smoothly; D, equipment is horizontally hoisted, a random end of the equipment is placed on the horizontal conveying cart by entering from one end of the outer cylinder; E, the equipment is dragged from the other end of the outer cylinder, and the equipment can be conveyed to a preset position on the horizontal conveying cart; F, connecting supports are installed between the inner wall of the equipment and the outer wall of the equipment one by one till the equipment and the outer cylinder are fixed and guaranteed to be concentric; and F, the conveying track and the horizontal conveying cart are taken out. The construction method of the cold box interior installation equipment has the advantages that not only forming quality of an inner cylinder and the outer cylinder is guaranteed, large-scale refrigerators can be manufactured in a factorization mode, and personnel safety and equipment safety in the construction process are guaranteed.

Owner:江苏利柏特股份有限公司

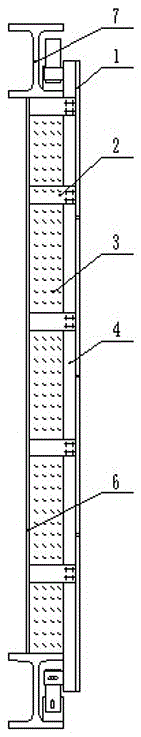

An integrated system for inner rigid protection and hoisting of the core tube of a super high-rise building

ActiveCN104291222BImprove liftingEnsure safetyTrolley cranesBuilding material handlingElectric machineryHigh rise

The invention discloses a rigid protection and crane integration system inside a super high-rise building core tube. The rigid protection and hoist integration system comprises an attachment device, an electric lifting device, an intelligent control system, a frame machine placement device, a safety anti-falling device, a truss platform, a bottom platform, a track beam, a travelling motor, a travelling sliding rail and a hoist crane, wherein a crane system drives the whole system to be lifted under the transmission of the electric lifting device, and the intelligent control system controls the operation of the whole system. The system can remarkably improve the hoisting and mounting efficiency of steel members and materials inside the super high-rise building core tube, ensures the safety of constructors, the components and the devices in the super high-rise building core tube, and can realize factory-like manufacturing and intelligent control.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

A prefabricated light steel structure factory building and its construction method

ActiveCN109854010BImprove aestheticsEasy to transportBuilding material handlingIndustrial buildingsConstruction engineeringArchitectural engineering

The invention discloses a prefabricated light steel structure factory building and a construction method thereof. The prefabricated light steel structure factory building comprises foundation bases, supporting row columns, supporting T-shaped columns, supporting cross beams, drop supporting members, building frames and skin assemblies. The construction method comprises the steps of assembling thesupporting row columns, assembling supporting foundation columns, raising the beams, manufacturing a roof and manufacturing wall panels. According to the prefabricated light steel structure factory building and the construction method thereof, the structure is simple, and the prefabricated light steel structure factory building and the construction method thereof have the advantages that the weight is light, the steel consumption per unit area is small, industrial manufacture can be realized, and the degree of automation is higher.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Large steel structure and manufacturing method thereof

ActiveCN103184766BReliable quality assuranceReduce labor intensityWelding/cutting auxillary devicesBuilding constructionsLower faceIndustrial engineering

Owner:CHINA CHEM ENG SECOND CONSTR +1

A buffer energy dissipation anti-collision barrel for roads

ActiveCN105672174BRealize factory manufacturingStructural innovationRoadway safety arrangementsElastomerEngineering

The invention provides a buffering energy dissipation anti-collision barrel used for a road and belongs to the field of road traffic safety facilities. The anti-collision barrel comprises a barrel body and barrel pressing sand. The barrel body is an integrated barrel body composed of a semicircular barrel head, a rectangular barrel tail and a sleeve type telescopic rectangular barrel body connected between the barrel head and the barrel tail through a front partition plate and a back partition plate. The barrel head is provided with energy dissipation elastomers and a supporting partition plate. A middle partition plate is arranged between a front barrel body and a back barrel body of the sleeve type telescopic rectangular barrel body. Elastic telescopic energy dissipation devices are positioned to penetrate through the middle partition plate and are connected between the front partition plate and the back partition plate of the telescopic rectangular barrel body. When the barrel body is subjected to exogenic action, the sleeve type telescopic rectangular barrel body compresses the elastomers of the elastic telescopic energy dissipation devices to be contracted through the elastic telescopic energy dissipation devices arranged inside the sleeve type telescopic rectangular barrel body, is backwards compressed along with the elastomers and gradually sleeved outside the back barrel body, so that the buffering impact force is absorbed, the loss caused by impact accidents is reduced, and after the impact force disappears, the barrel body gradually returns to the original state under the action of the elastic telescopic energy dissipation devices.

Owner:WUHAN MUNICIPAL ENG DESIGN & RES INST

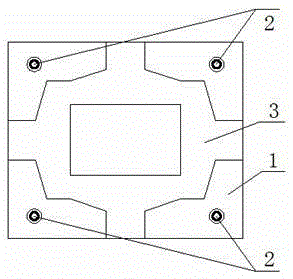

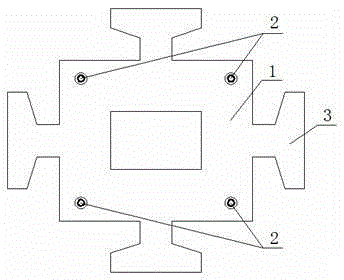

Connection method of prefabricated reinforced concrete block assembled bridge piers

ActiveCN104088230BConstantly expanding connection areaThe connection method is firm and reliableBridge structural detailsBridge erection/assemblyReinforced concreteAbutment

The invention discloses a method for connecting assembly type bridge pier abutments through prefabricated reinforced concrete blocks. The method comprises the steps that a plurality of first reinforced concrete blocks are poured, wherein each first reinforced concrete block is of a cuboid shape as a whole, the top end of each first reinforced concrete block is provided with a T-shaped groove, and a first through hole is formed in each first reinforced concrete block; a plurality of second reinforced concrete blocks are poured, wherein each second reinforced concrete block is of a cuboid shape as a whole, the four sides of each second reinforced concrete block are provided with T-shaped convex bodies with the height the same as that of the planes of the top ends of the block bodies, and the T-shaped convex bodies are matched with inverted-T-shaped grooves formed in the first reinforced concrete blocks; the second reinforced concrete blocks are provided with second through holes, the first reinforced concrete blocks of the upper layer are matched with the first reinforced concrete blocks of the lower layer, the second reinforced concrete blocks of the upper layer are matched with the second reinforced concrete blocks of the lower layer, and the reinforced concrete blocks of each layer are connected through steel bars. The method can effectively ensure that a plurality of layers of the pier abutments are reliably connected, and on-site fast assembling of the pier abutments can be achieved.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

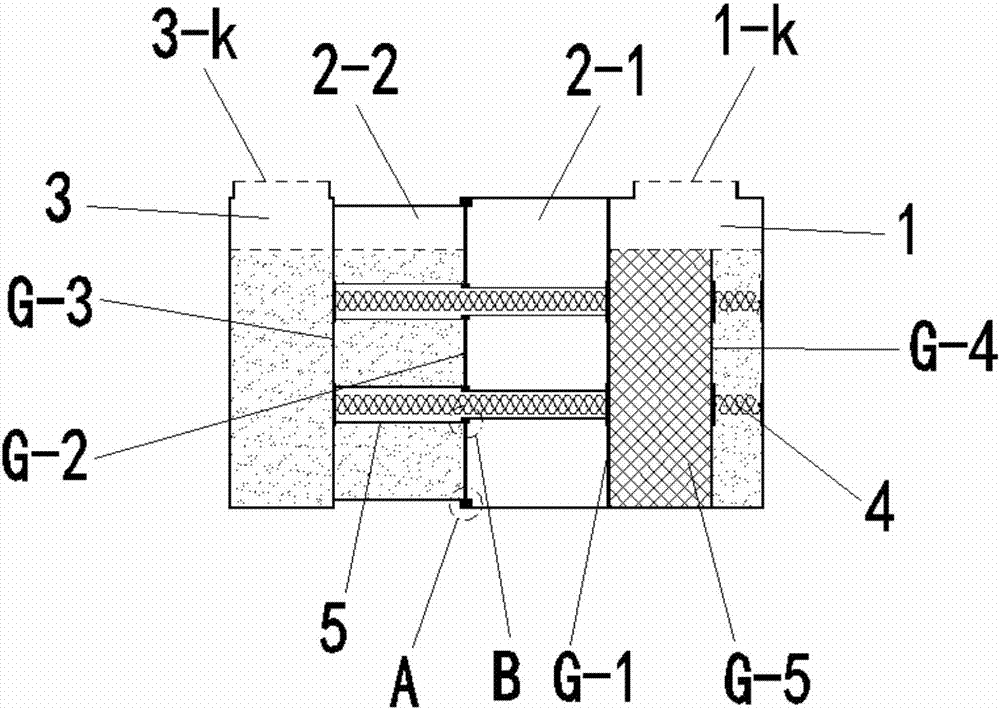

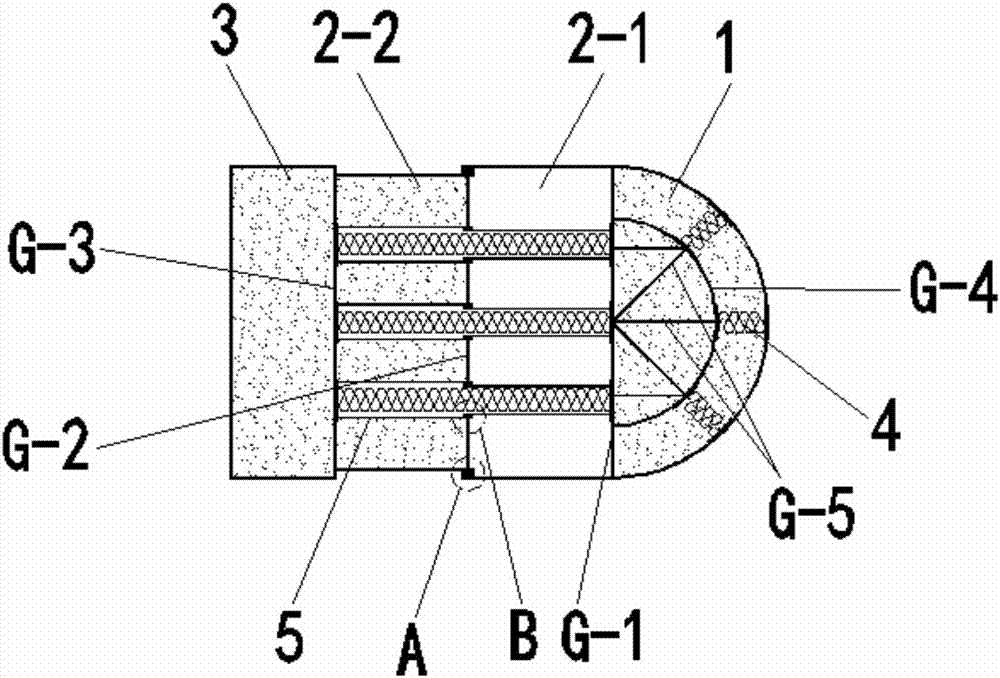

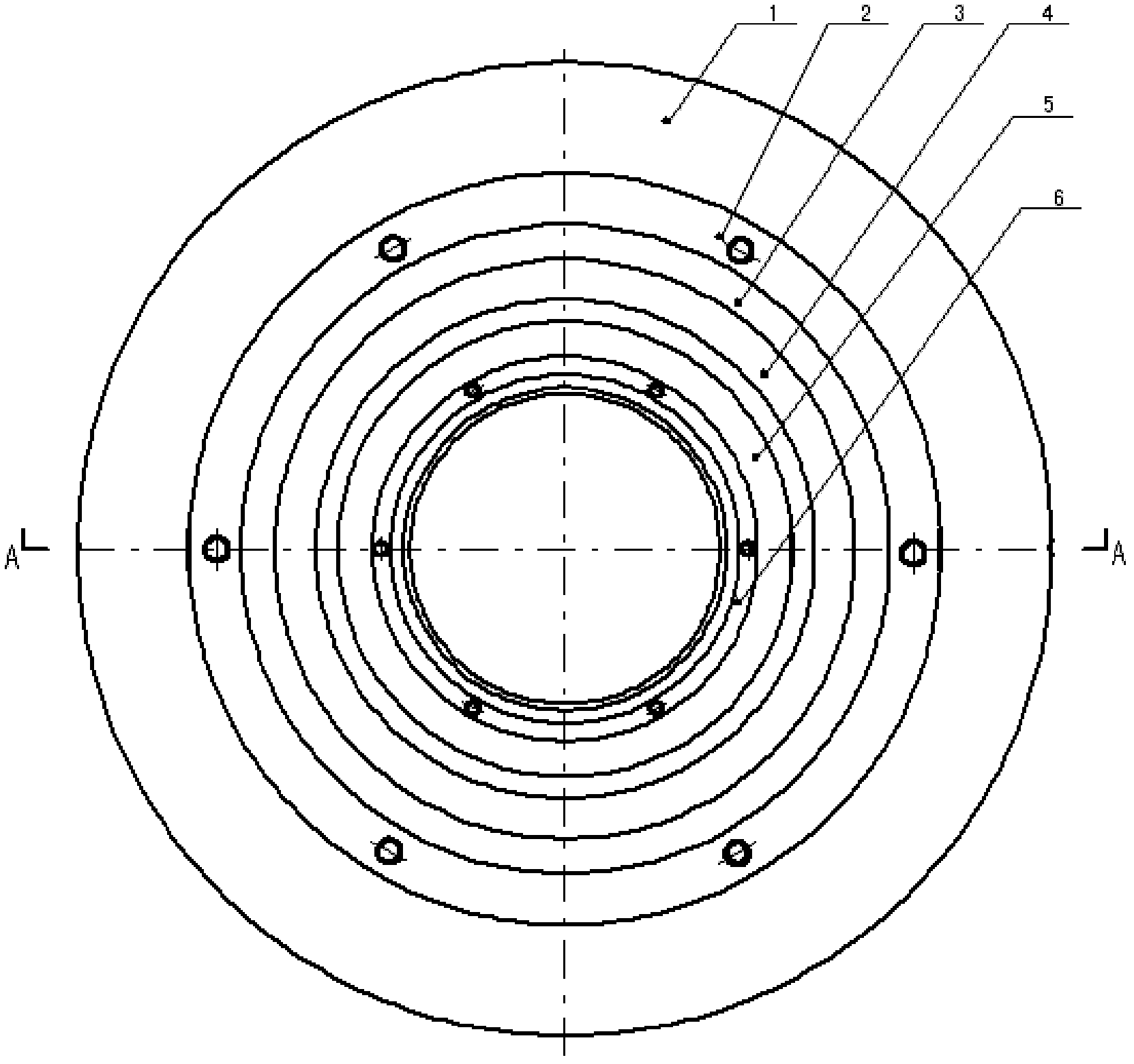

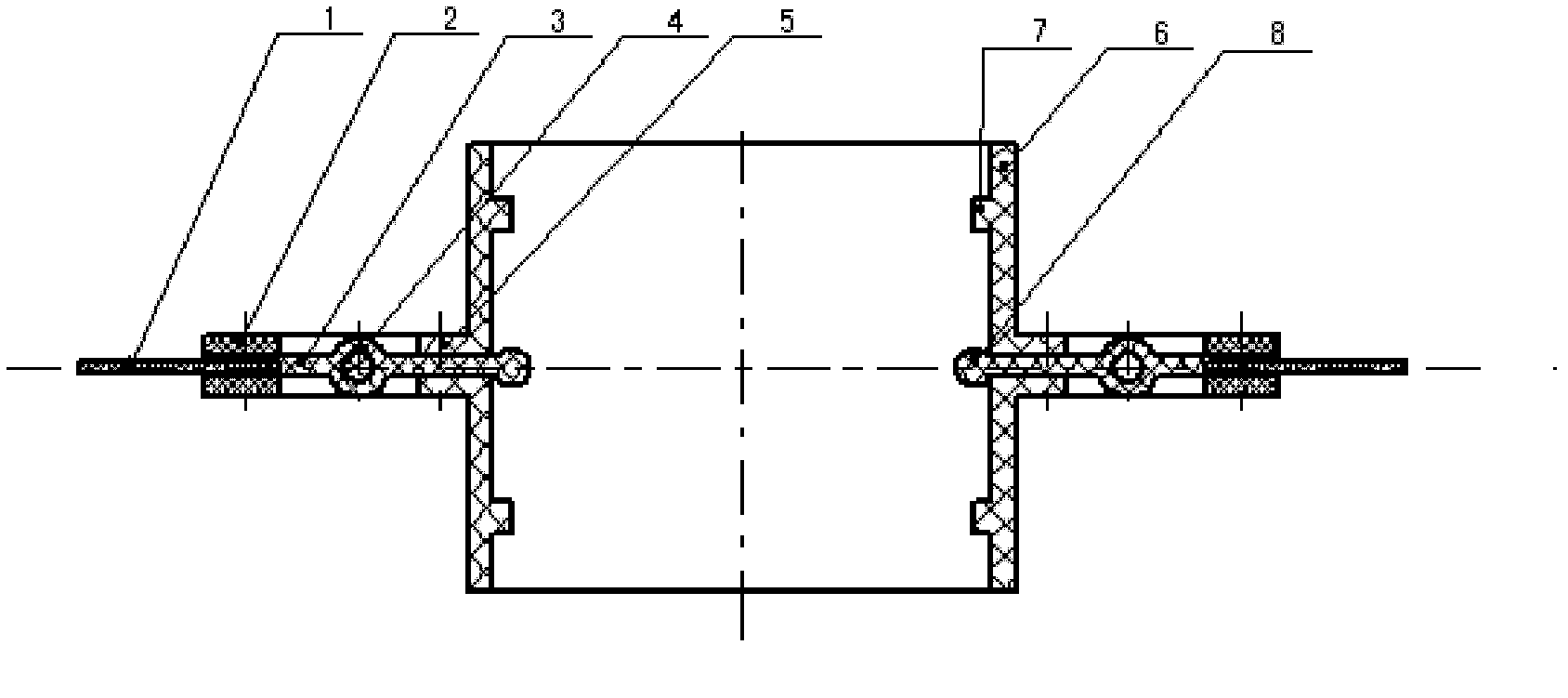

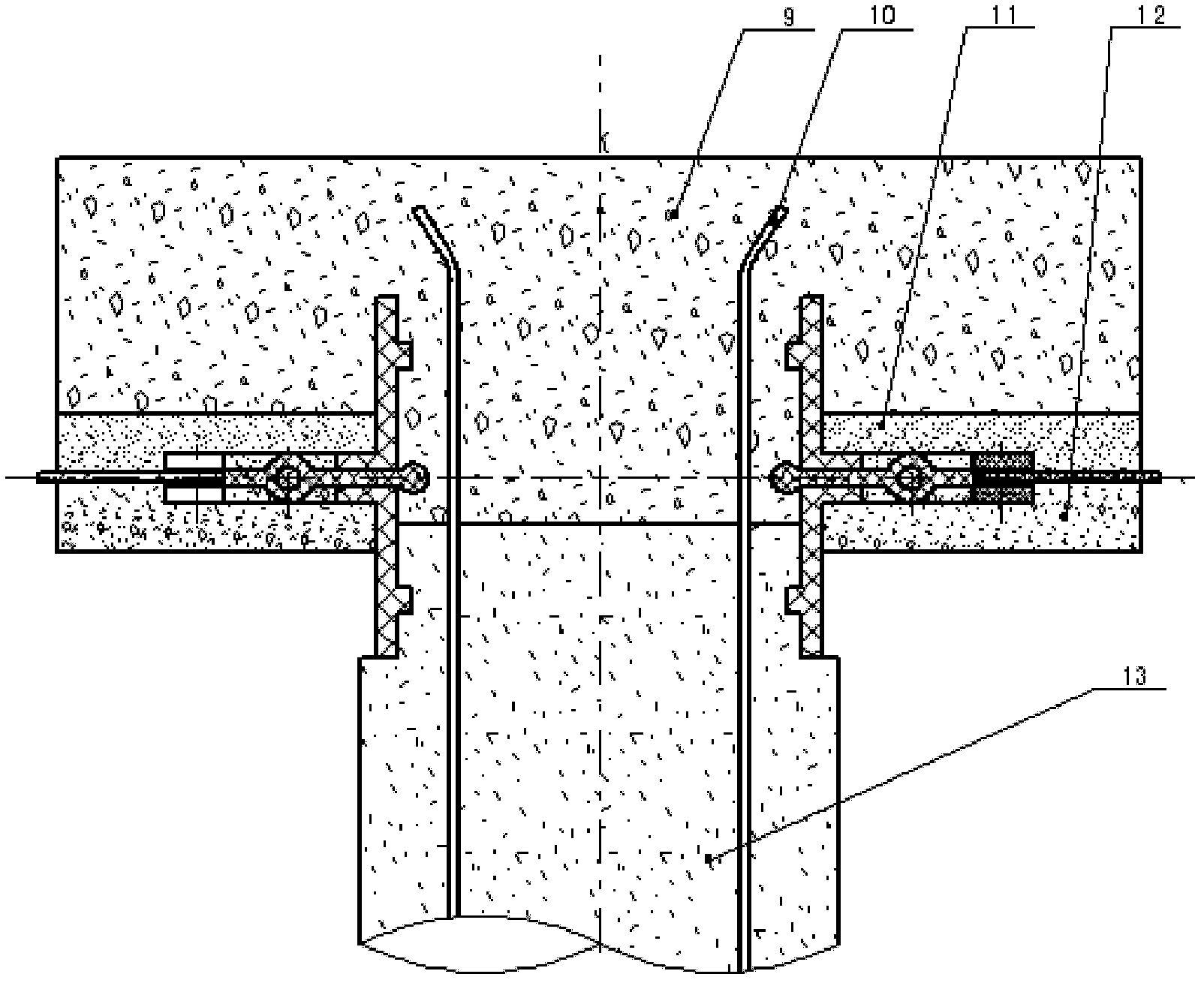

Waterproof sealing device for pile head of cast-in-place pile

InactiveCN102296638BSolve the problem of water seepageSolve the problem of waterproof failureArtificial islandsProtective foundationRubber ringEngineering

The invention relates to a waterproof sealing device for a pile head of a cast-in-place pile, which comprises an upper sealing shaft sleeve and a lower sealing shaft sleeve, a sizing waterproof rubber ring, a horizontal sealing pressure ring and a waterproof roll, wherein the two sealing shaft sleeves have the same shaft and the same diameter, the sizing waterproof rubber ring is arranged betweenthe sealing shaft sleeves in the radial direction, a circle of bulges are made on the sizing waterproof rubber ring in the sealing shaft sleeves; and the connecting part of the sizing waterproof rubber ring and the waterproof roll is pressed and fixedly arranged by adopting the horizontal sealing pressure ring, and the sealing shaft sleeves, the horizontal sealing pressure ring, the waterproof roll and the sizing waterproof rubber ring are connected to form a waterproof whole. The waterproof sealing device has the advantages of simple structure, scientific and reasonable design, reliability in sealing, compact connection of a pile platform and a pile foundation, convenience and rapidness in installation, forms a sealing system around the pile head, effectively solves the problem of water seepage of the pile head, is an optimal waterproof sealing device of the traditional pile head, and has a wide application range.

Owner:天津市瑞固建材有限公司

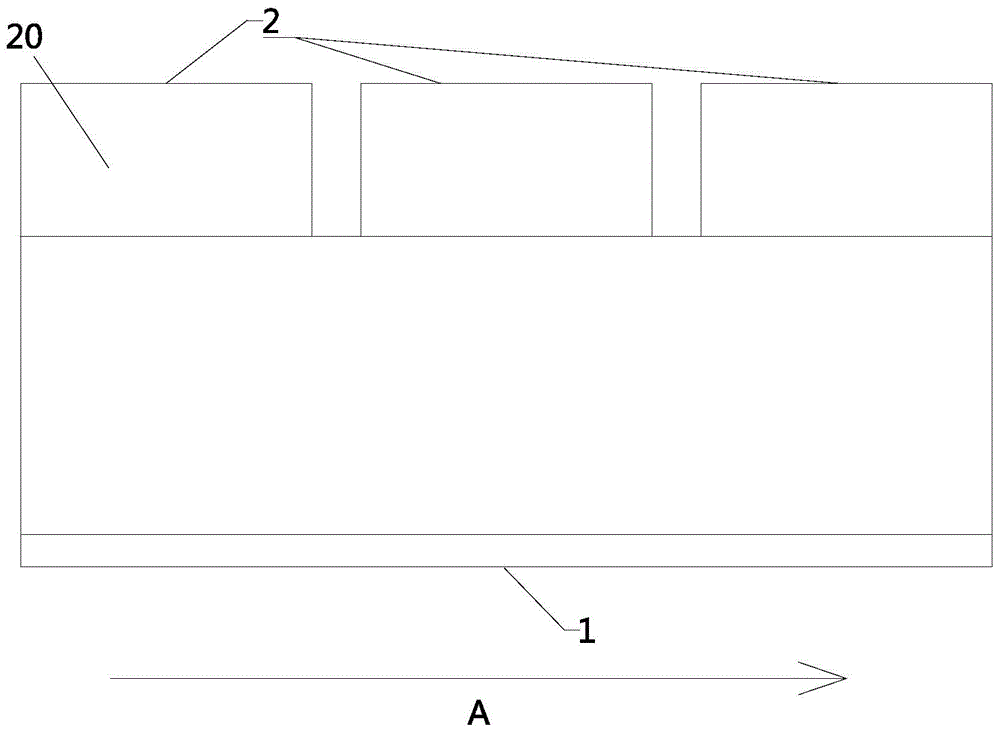

Fabricated prefabricated comprehensive pipe gallery and mounting method

ActiveCN112554232AImprove stabilityImprove reliabilityArtificial islandsProtective foundationClassical mechanicsEngineering

The invention provides a fabricated prefabricated comprehensive pipe gallery and a mounting method. The fabricated prefabricated comprehensive pipe gallery is formed by assembling a plurality of prefabricated pipe joints; each prefabricated pipe joint comprises a bottom plate, a top plate, a first side plate and a second side plate; connecting cavities are formed in the connecting positions of every two of the bottom plates, the top plates, the first side plates and the second side plates; a connecting part and a plugging device are arranged in each connecting cavity; an outer vertical plate which is bent downwards is arranged at the outer side, forming a connecting cavity structure, of the top plate, and an outer vertical plate which is bent upwards is arranged at the outer side, forminga connecting cavity structure, of the bottom plate; an expansion joint is formed between the outer vertical plate on the top plate and the outer vertical plate on the bottom plate; and the expansion joint is in water-stop sealing connection. According to the fabricated prefabricated comprehensive pipe gallery and the mounting method, the structure is reasonable, assembly is convenient and fast, connection is stable, waterproof and reliable, the applicability is extremely high, the steps of the construction method are simple, and the operability is extremely high.

Owner:SHANXI INSTALLATION GRP CO LTD

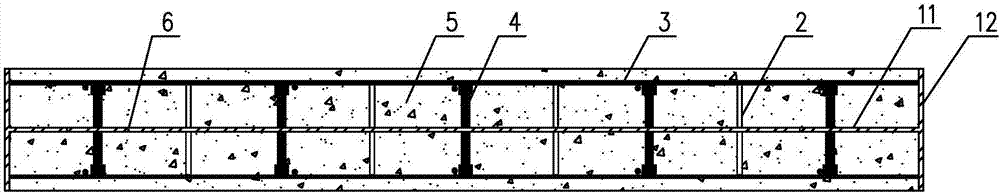

Modified type extensible steel-concrete combined precast wall with ribbed profile steel

InactiveCN107060138AAchieve standardized designRealize factory manufacturingWallsSocial benefitsMesh reinforcement

The invention mainly discloses a modified type extensible steel-concrete combined precast wall with ribbed profile steel. The modified type extensible steel-concrete combined precast wall comprises I-shaped steel, stiffening plates, steel mesh reinforcements and concrete; the I-shaped steel comprises a web and flange plates on two sides, the stiffening plates are arranged on the web in a distributed mode and parallel to the flange plates, the height of each stiffening plate is smaller than half of the height of each flange plate, the steel mesh reinforcements cover the surfaces of the stiffening plates, and the concrete is poured between the flange plates of the I-shaped steel. According to the modified type extensible steel-concrete combined precast wall, the material performance advantages that the steel is light in weight and high in strength and the concrete is great in rigidity are brought into play, the materials are saved better, the environmental pollution is reduced, the living condition is improved, and the social benefits are increased.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

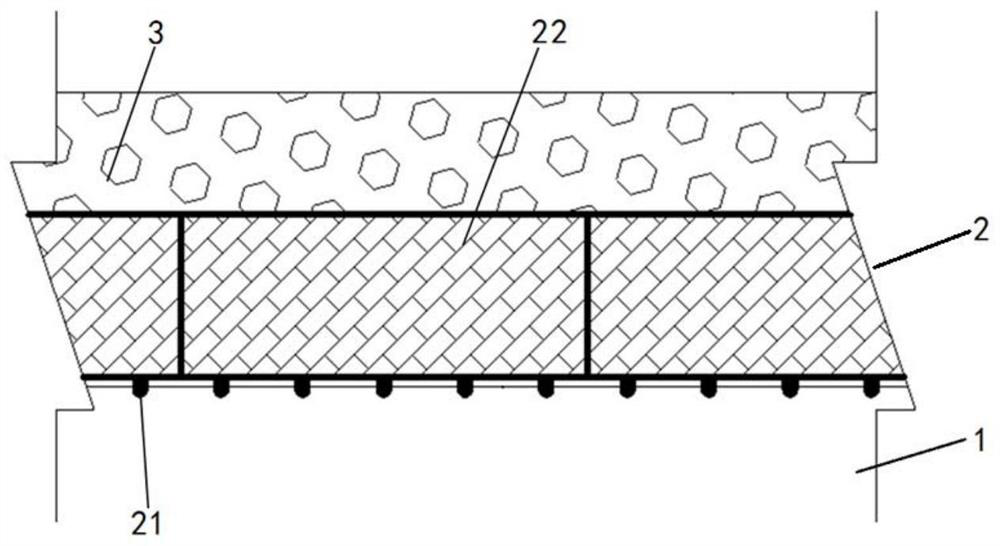

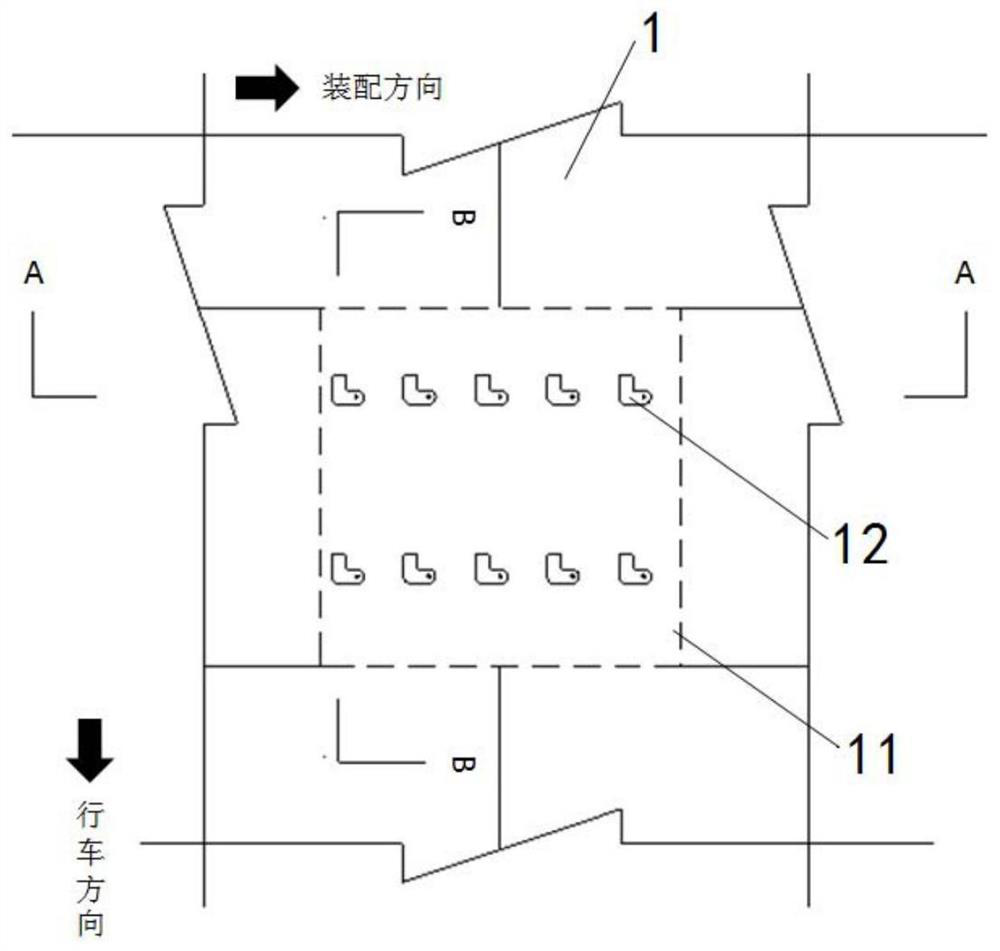

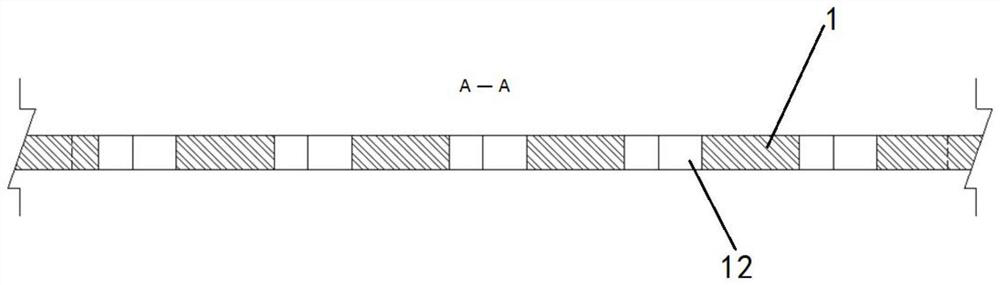

Steel box girder bridge deck slab structure and paving method

PendingCN112853978AQuick removalImprove pavement qualityBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention relates to a steel box girder bridge deck slab structure and a paving method. The steel box girder bridge deck slab structure comprises a steel box girder (1), a concrete module cushion layer (2) and an asphalt layer (3) which are sequentially arranged from bottom to top, wherein the concrete module cushion layer (2) is clamped on the steel box girder (1). Compared with the prior art, the steel box girder bridge deck slab structure can ensure road quality of the steel box girder bridge and can also improve the maintainability of the road.

Owner:上海瑞史坦环保科技有限公司

Combined ecological revetment structure of box body and plug board

InactiveCN103821107BReduce reflectionEasy plantingCoastlines protectionHorticultureShip wavesEcological environment

The invention discloses an ecological bank protection structure combining boxes and insertion plates. A first-level hard protection bank, a bank protection platform and a second-level flexible protection bank are sequentially arranged from bottom to top. The first-level hard protection band is of a structure combining the prefabricated water-pervious steel bar concrete boxes and the insertion plates, each box is almost a square hollow box, the insertion plates are square, every two adjacent boxes are connected through the insertion plates, each insertion plate is fixed in clamping grooves in the middle of the outer walls on the two sides of the corresponding box, the crest level of each box is 0.4 m-0.6 m lower than a normal water level, the insertion plates are 0.8 m-1.2 m higher than the corresponding box and are 0.4 m-0.6 m away from the water facing vertical face of the corresponding box, a grid-type wave eliminating structure is formed on each water facing vertical face, and an open-type plate wave-resisting structure is formed on the upper portion of each structure. The tops of the boxes are covered with soil so that reeds and other protection plants can be planted, and concrete is poured on a bywater side of each box for blocking soil. Ship waves can be effectively reduced, the variety of off-shore water currents is improved, materials are saved, project manufacturing cost is reduced, and ecological benefits and economic benefits are both obtained.

Owner:SOUTHEAST UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com