Fabricated prefabricated comprehensive pipe gallery and mounting method

A comprehensive pipe gallery and prefabricated technology, used in protection devices, buildings, artificial islands, etc., can solve the problems of substandard self-waterproofing of concrete, reduce construction efficiency, increase construction procedures, etc., to ensure stability and waterproof reliability. , Improve stability and reliability, and avoid the effect of slowing down construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

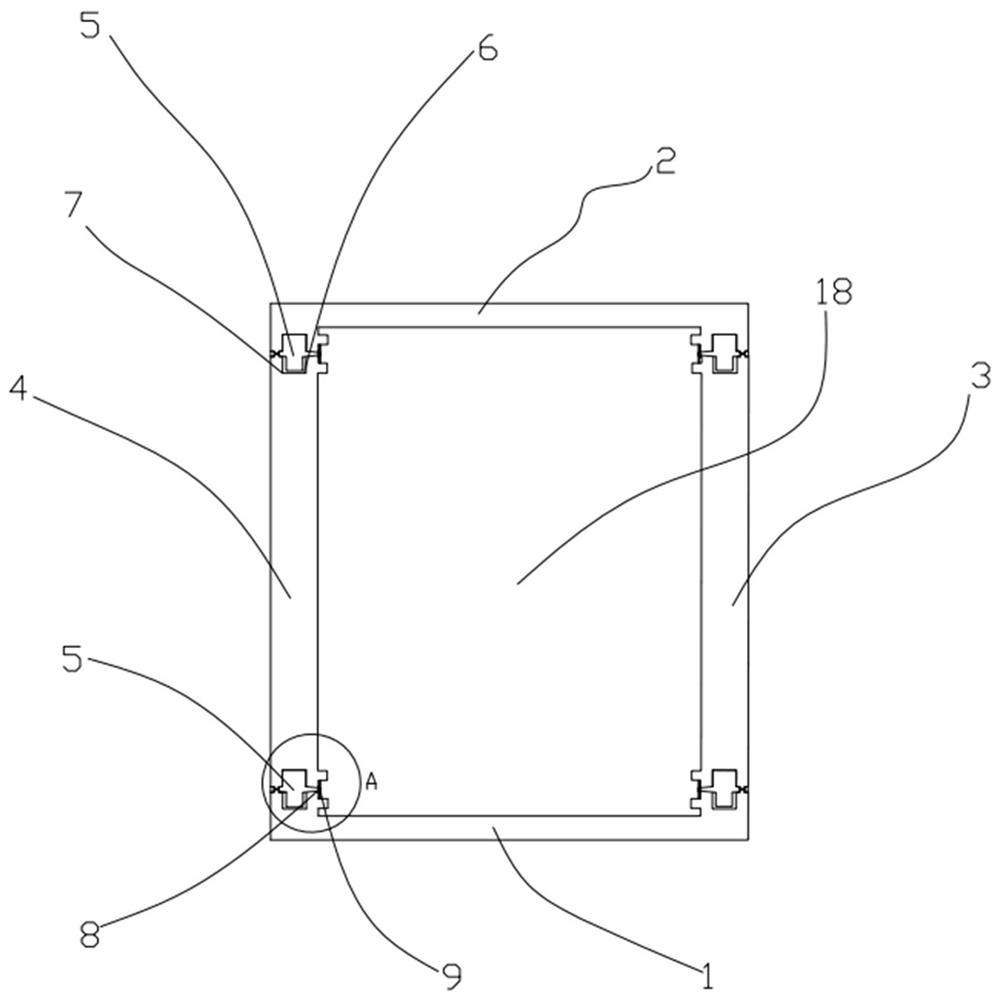

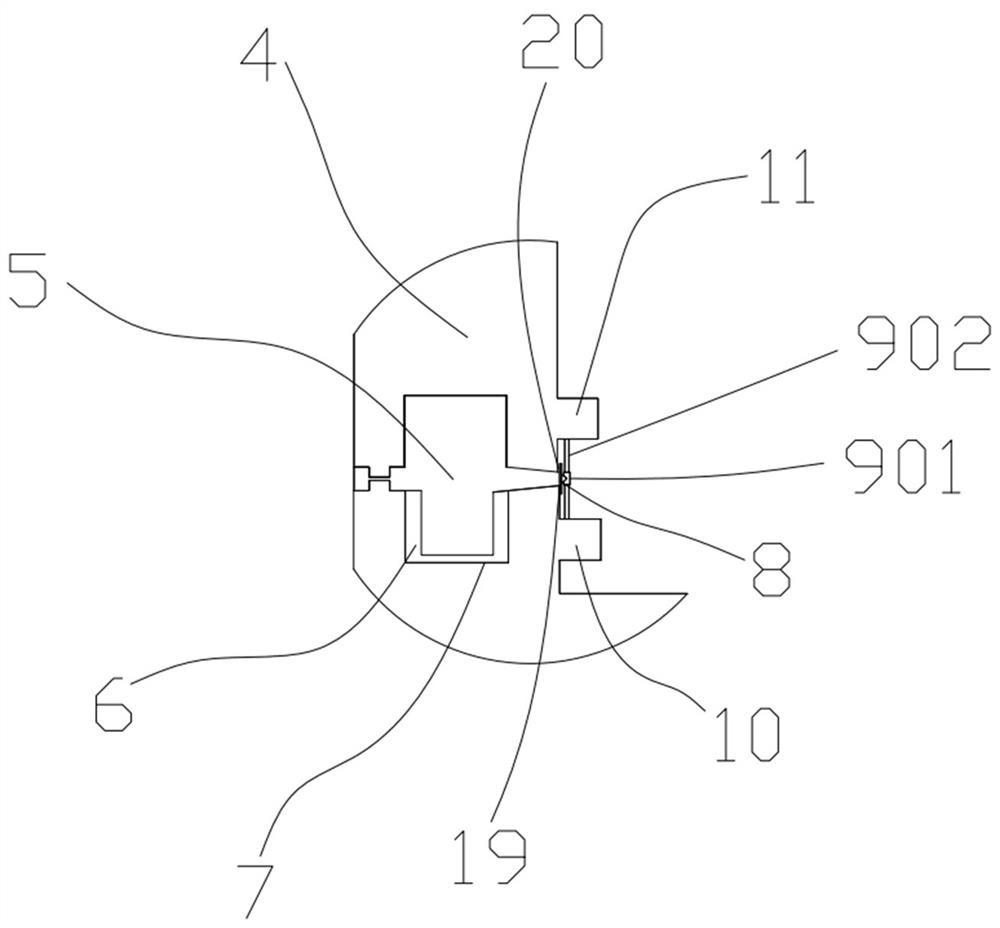

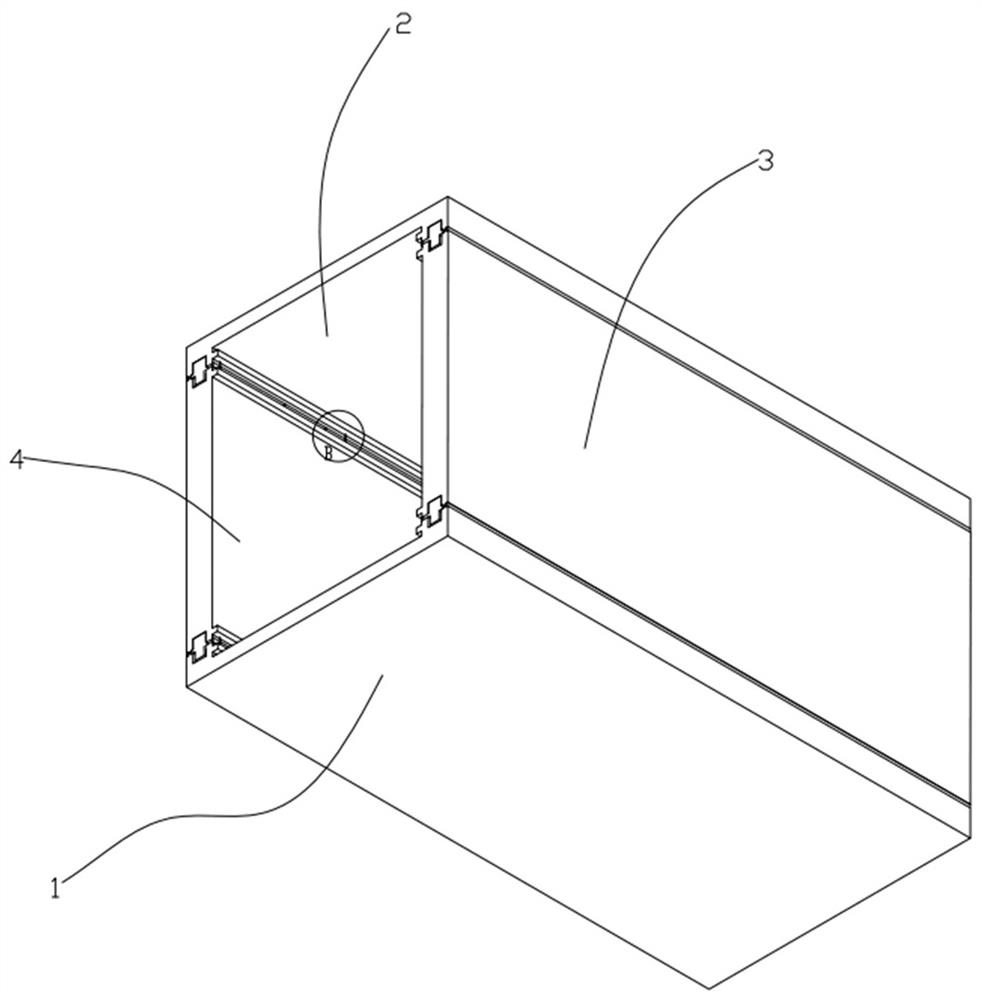

[0059] Example 1, such as Figure 1~12 As shown, the present invention discloses a prefabricated and assembled comprehensive pipe gallery, which is assembled by several prefabricated pipe sections, each prefabricated pipe section includes at least two pipe gallery plates, and the edges of the pipe gallery plates are opposed and surrounded by a The tubular structure of the chamber 18 forms a connecting chamber 7 at the joint of the two pipe corridors, and a connecting piece 5 is arranged in the connecting chamber 7, and the connecting piece 5 is an elastomer waterproof seal. The pouring space 6 is formed under the connecting piece 5 provided in the 7, and the pouring space 6 communicates with the accommodating chamber 18 through the pouring port 19, and the sealing and waterproof connecting piece is cast in the pouring space 6, and the casting The material of the sealed and waterproof connector is prepared by mixing two kinds of waterproof and sealing resin materials. The water...

Embodiment 2

[0117] Example 2, such as Figure 1~17 As mentioned above, the present invention also discloses another prefabricated integrated pipe gallery, which is assembled from several prefabricated pipe sections, each prefabricated pipe section includes a bottom plate 1, a top plate 2, a first side plate 3, and a second side plate 4 , connecting cavities 7 are formed at the joints of the bottom plate 1, the top plate 2, the first side plate 3, and the second side plate 4, and a connecting cavity 7 is provided in each of the connecting cavities 7. 5 and the blocking device, a downwardly bent outer vertical plate is provided on the outside of the connection cavity 7 structure formed on the top plate 2, and an upwardly bent external vertical plate is provided on the outside of the connection cavity 7 structure on the bottom plate 1. The outer vertical plate, the inner side of the outer vertical plate is close to the first side plate 3 or the second side plate 4, and a telescopic structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com