Building method of assembled low-rise light-steel-structure residence system

A technology of light steel structure and construction method, which is applied in residential construction, building structure, infrastructure engineering, etc., to achieve the effect of simplifying the construction process, good thermal insulation performance, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

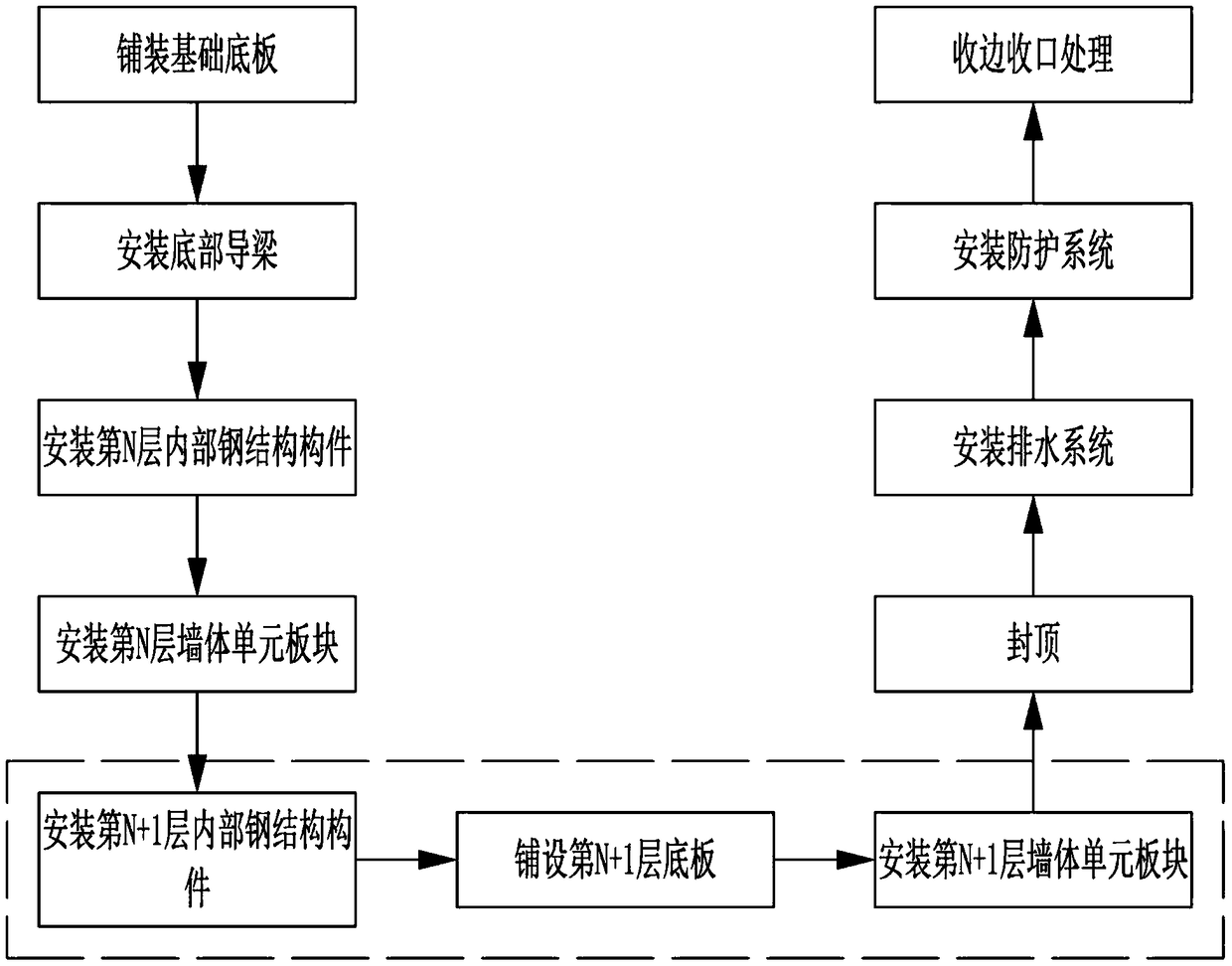

[0052] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0053] Such as figure 1 As shown, a construction method of a prefabricated low-rise light steel structure residential system comprises the following steps:

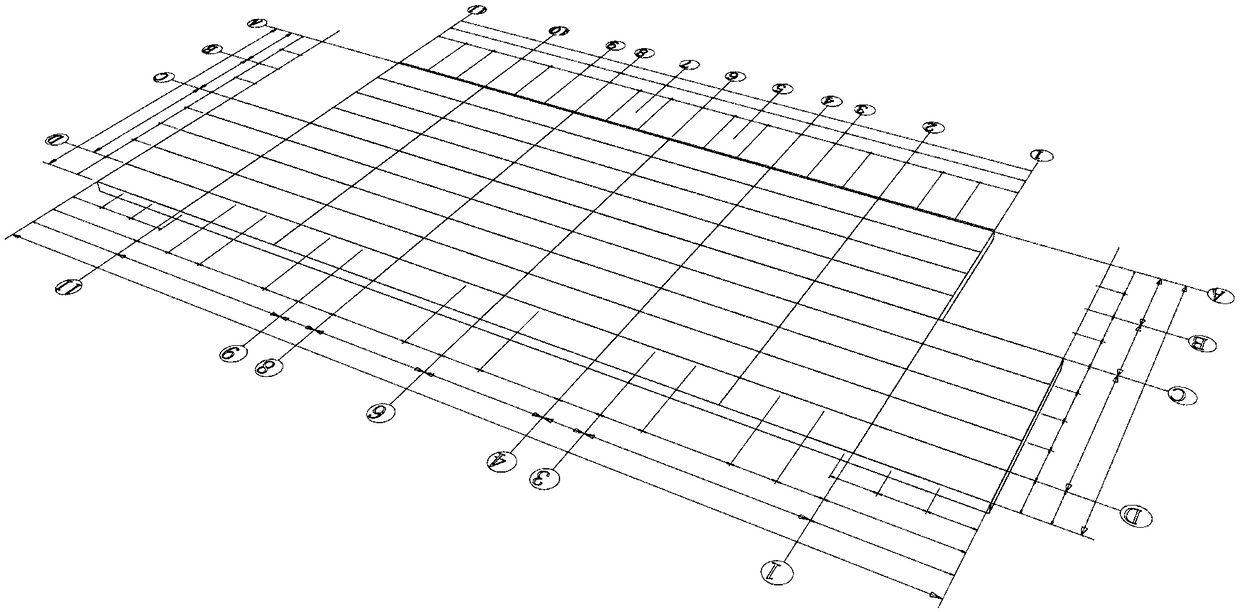

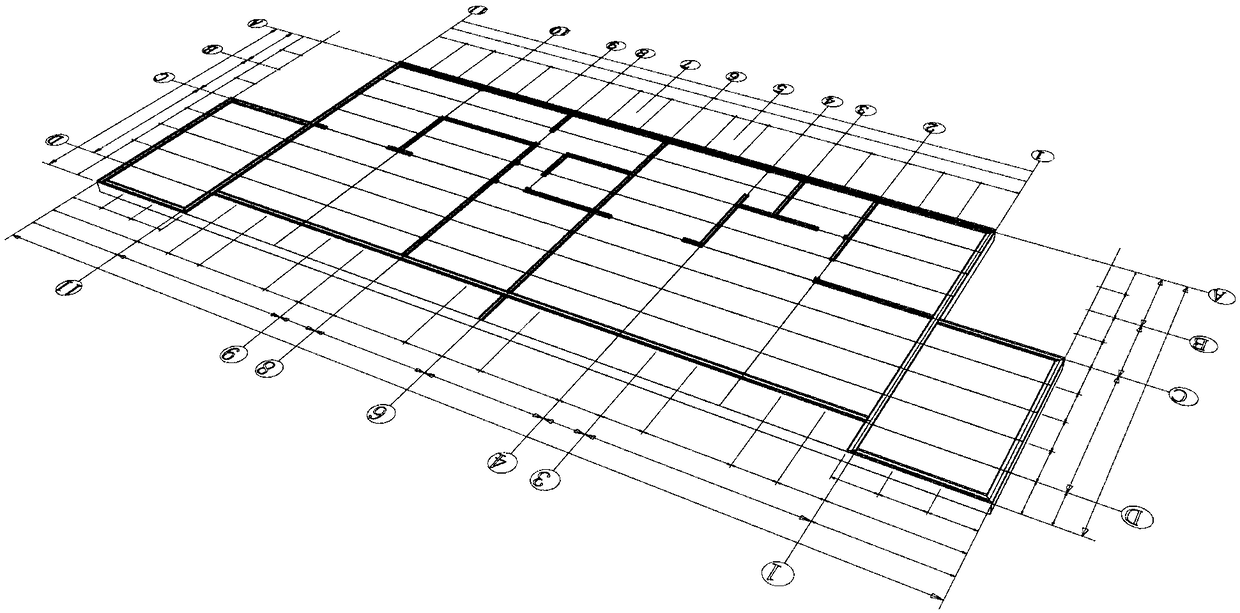

[0054] Such as figure 2As shown, in order to avoid subsidence after the foundation floor is installed, it is necessary to tamp the foundation, or directly drive piles, and directly push the pile body on the stressed layer. The pavement of the foundation floor eliminates the need for foundation leveling in traditional prefabricated houses. In the process, it is only necessary to ensure that the foundation does not sink during use. S1. Pave the foundation floor; directly pave the foundation floor on the foundation, and directly assemble the foundation floor on the compacted foundation or on the pile body, which simplifies the construction process, which improves the construction efficiency, adopts the prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com