Detachable ventilated photovoltaic curtain wall

A ventilated, photovoltaic technology, applied in the direction of photovoltaic modules, photovoltaic power generation, photovoltaic module support structures, etc., can solve the problem of increased self-explosion rate of hollow photovoltaic panels, reduced power generation efficiency of battery packs, and unfavorable disassembly, replacement and maintenance of photovoltaic panels To achieve the effect of ensuring power generation efficiency, facilitating replacement and maintenance, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment and accompanying drawing, concrete technical scheme of the present invention will be further described:

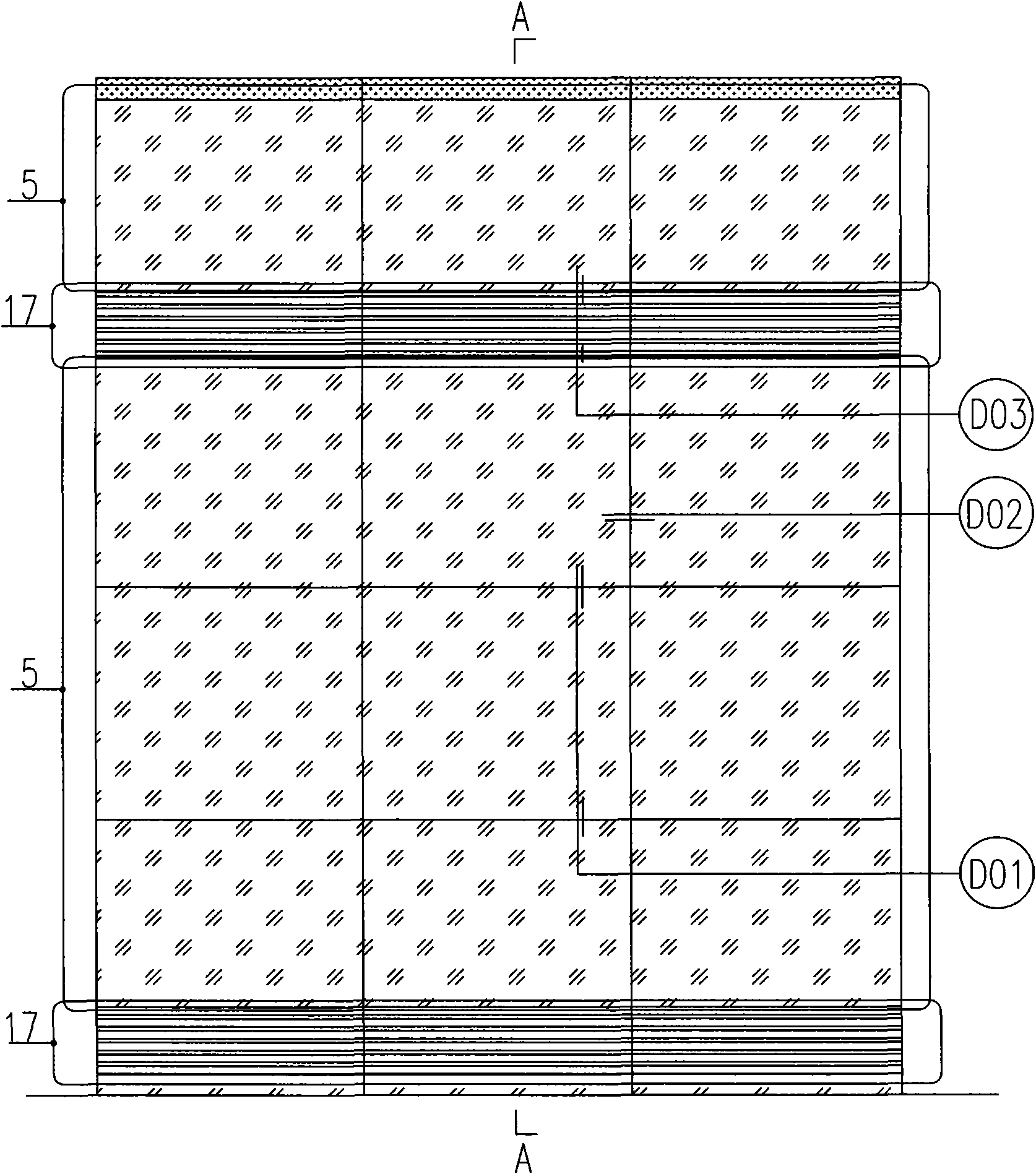

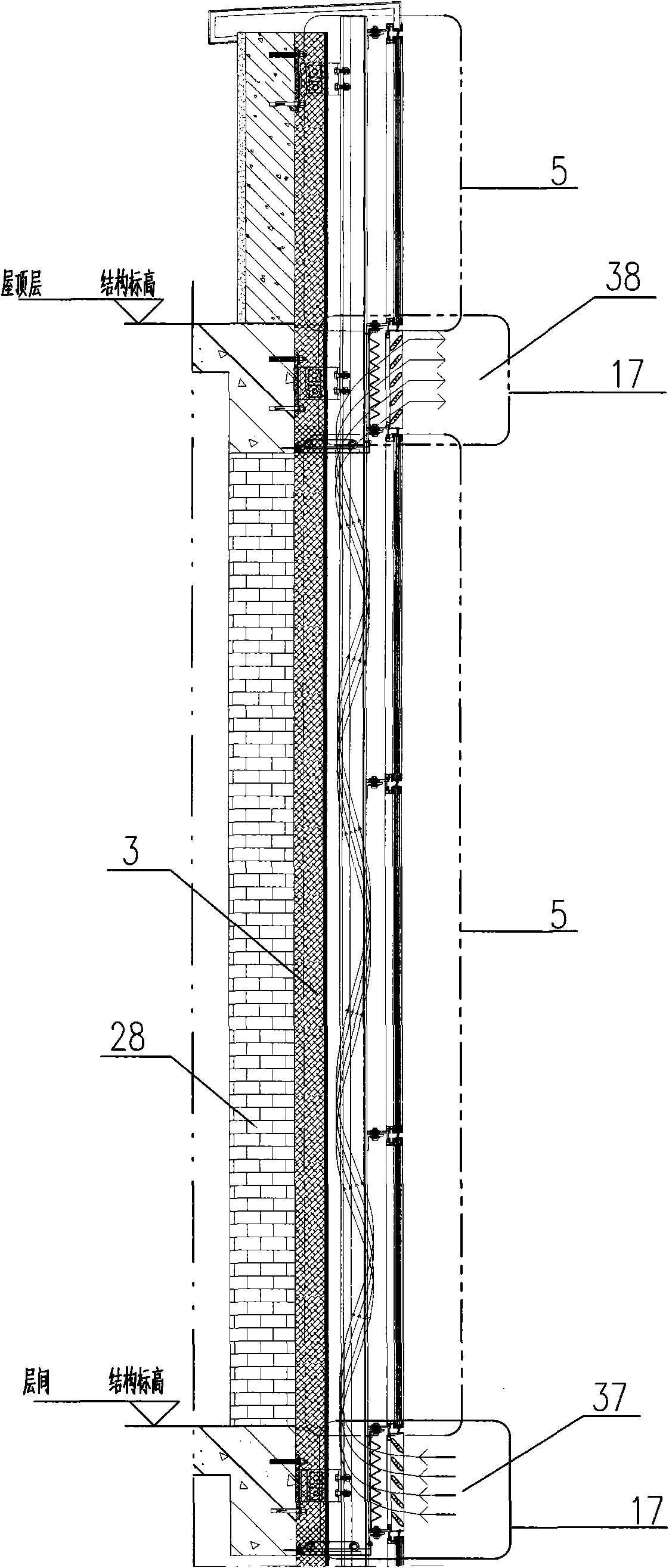

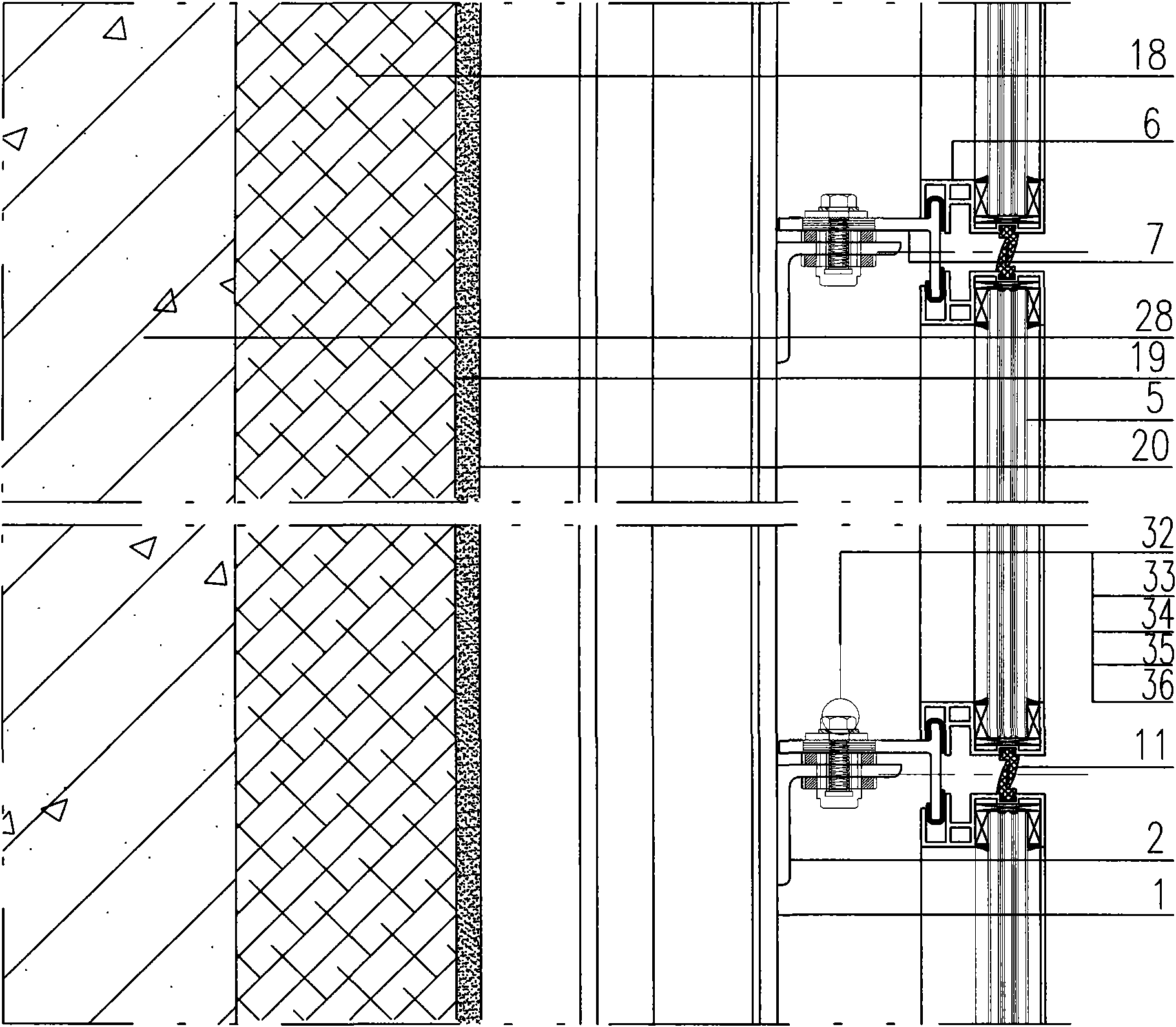

[0031] like Figure 1 to Figure 6 As shown, the partial design diagram of the solar photovoltaic curtain wall and its node diagram include a photovoltaic curtain wall body and a photovoltaic matrix control module. The structure includes columns 1, beams 2, embedded panel connectors and adjusting bolts 4. The above three parts constitute the main load-bearing structure of the photovoltaic curtain wall, and the design must meet the specifications of the curtain wall. The outer wall insulation layer 3 includes insulation material 18, steel mesh 19 and cement layer 20, and the material, density and thickness of the insulation material are selected according to architectural design requirements. A space is left between the outer wall insulation layer 3 and the panels to form a structural air duct, and the panels include ventilation l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com