Construction methods for building combined buildings

A construction method and combined technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of loss of cement and other building materials, waste of manpower and material resources, air and noise pollution, etc., to solve the problems of environmental and noise pollution, saving installation templates, and strengthening the effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to describe the technical content and structural features of the present invention in detail, further descriptions will be made below in conjunction with the embodiments and accompanying drawings.

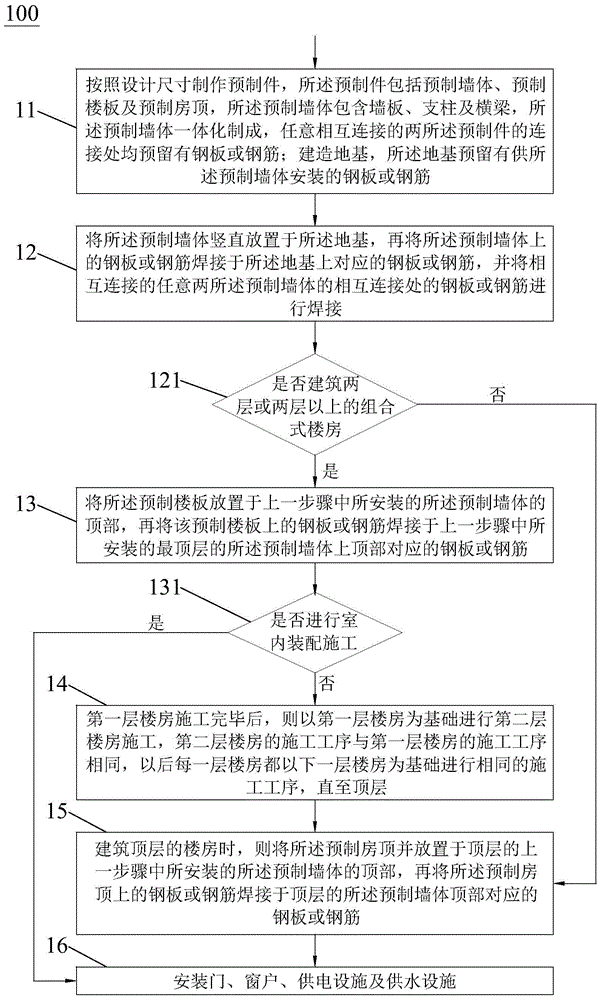

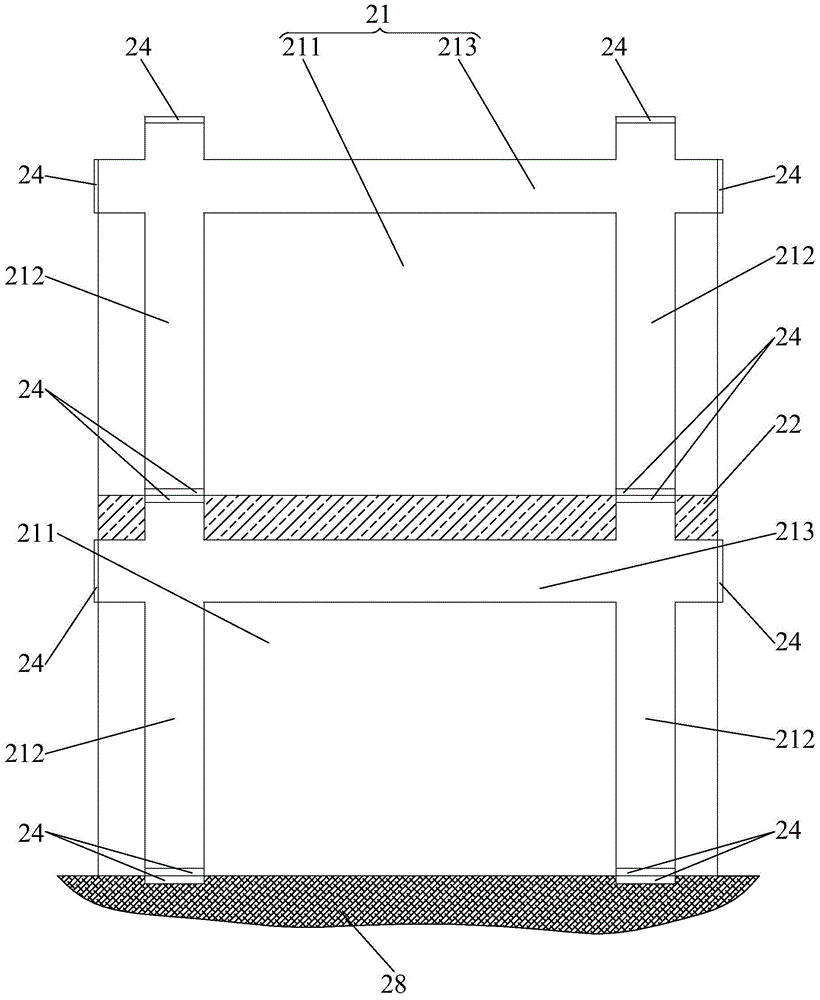

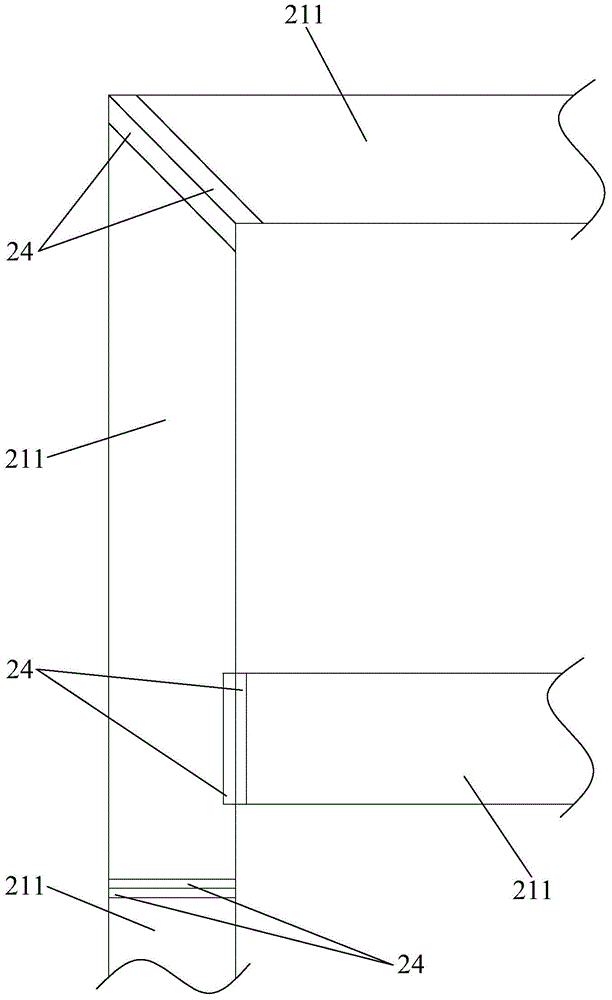

[0031] see figure 1 , The construction method 100 of the combined building of the present invention comprises the following steps: (11) making prefabricated parts (not marked in the figure) according to the design size, the prefabricated parts include prefabricated wall 21, prefabricated floor slab 22 and prefabricated roof 23, prefabricated Body of wall 21 comprises wall panel 211, pillar 212 and crossbeam 213, and prefabricated body of wall 21 is integrally made, and the junction of any two prefabricated parts that are connected with each other is reserved with steel plate 24 or steel bar 25; Construction foundation 28, foundation 28 prefabricated Leave the steel plate 24 or steel bar 25 for prefabricated wall 21 installation; then perform (12) vertically place pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com