Modified type extensible steel-concrete combined precast wall with ribbed profile steel

An improved, prefabricated wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of low resource and energy utilization efficiency, high labor dependence, and many wood applications, and achieve controllable product quality, superior seismic performance, Improve the effectiveness of effective combinations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

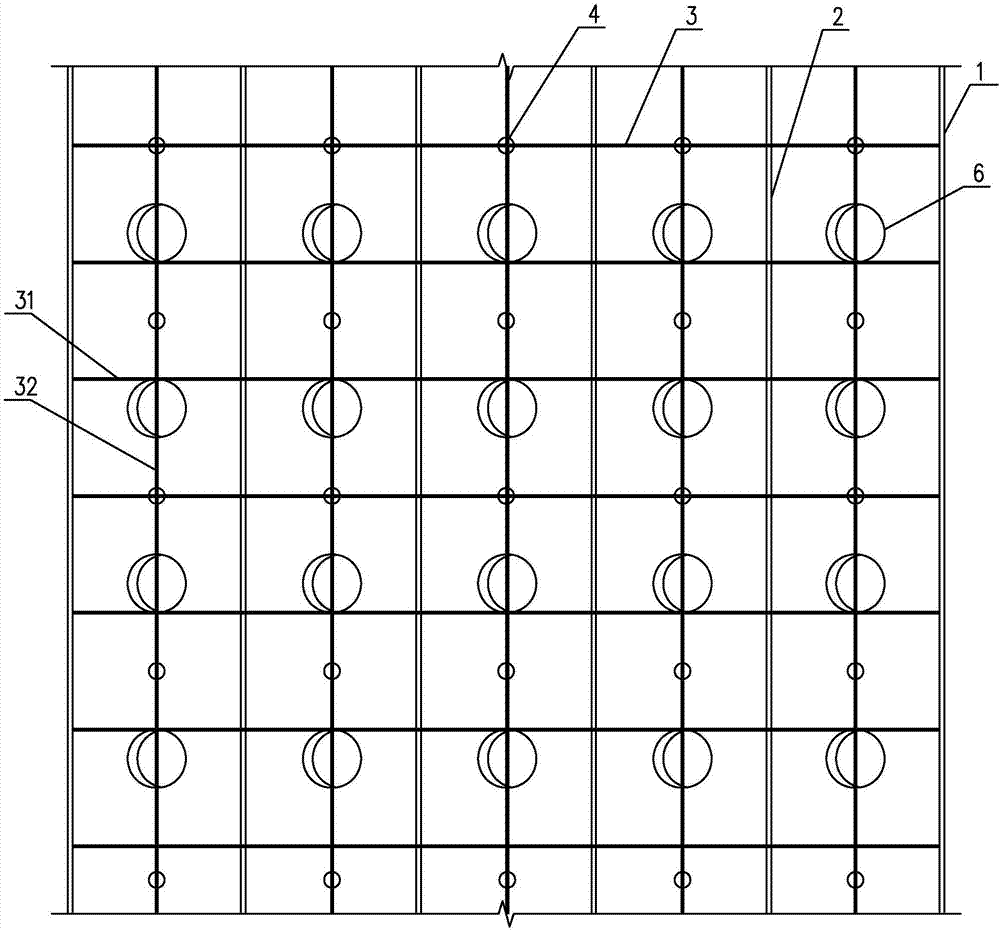

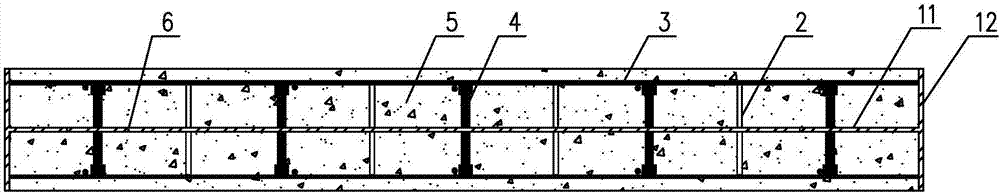

[0030] Please refer to the attached figure 1 to attach figure 2 Shown, the present invention is described in further detail.

[0031] An expandable steel-concrete composite prefabricated wall with section steel and ribs, the main components involved include I-shaped steel 1, stiffening plate 2, steel mesh 3, studs 4, and concrete 5.

[0032] The I-shaped steel 1 can be formed by splicing three steel plates, or a T-shaped steel and one steel plate. The I-shaped steel 1 includes a web 11 and two flange plates 12 on both sides. The wall is symmetrical with the web 11 and is divided into two sides, front and back. Several stiffening plates 2 are arranged on the web 11, and the stiffening plates 2 are parallel to the flange plates 12 and distributed at equal intervals. The height of the stiffener plate 2 is less than half the height of the flange plate 12 .

[0033] Reinforcement mesh 3 is a network composed of several horizontal bars 31 and several longitudinal bars 32 distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com