High and low web member truss girders based on fabricated type cold-formed thin-wall section steel

A technology of cold-formed thin-walled steel and truss beams, which is applied in the direction of buildings and building structures, can solve problems such as unfavorable room use function, increase of lower wall frame columns, affecting living comfort, etc., and achieves a clear force transmission path, The effect of improving construction quality and improving living comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

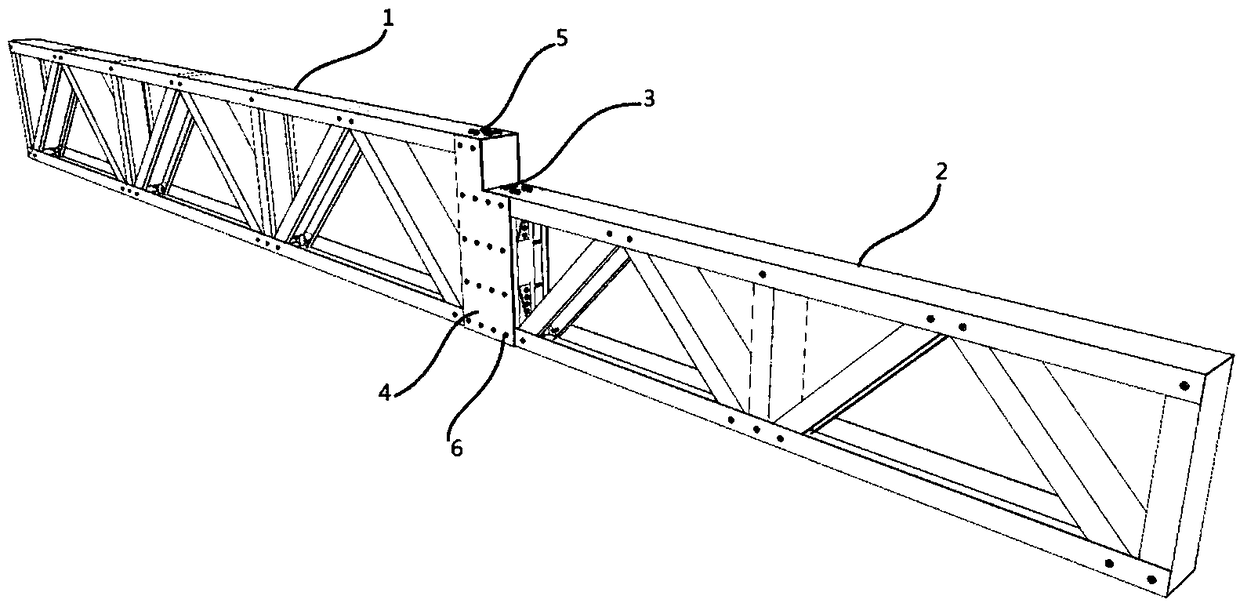

[0041] like figure 1 As shown, a high and low web truss beam according to an embodiment of the present invention includes a high web truss beam 1, a low web truss beam 2, an L-shaped connector group 3, a steel strip 4, a hexagonal bolt 5, and a self-tapping screw 6. Among them, the high-web truss beam 1 and the low-web truss beam 2 are butt-connected through the connector group 3, the steel strip 4, the hexagonal bolt 5 and the self-tapping screw 6.

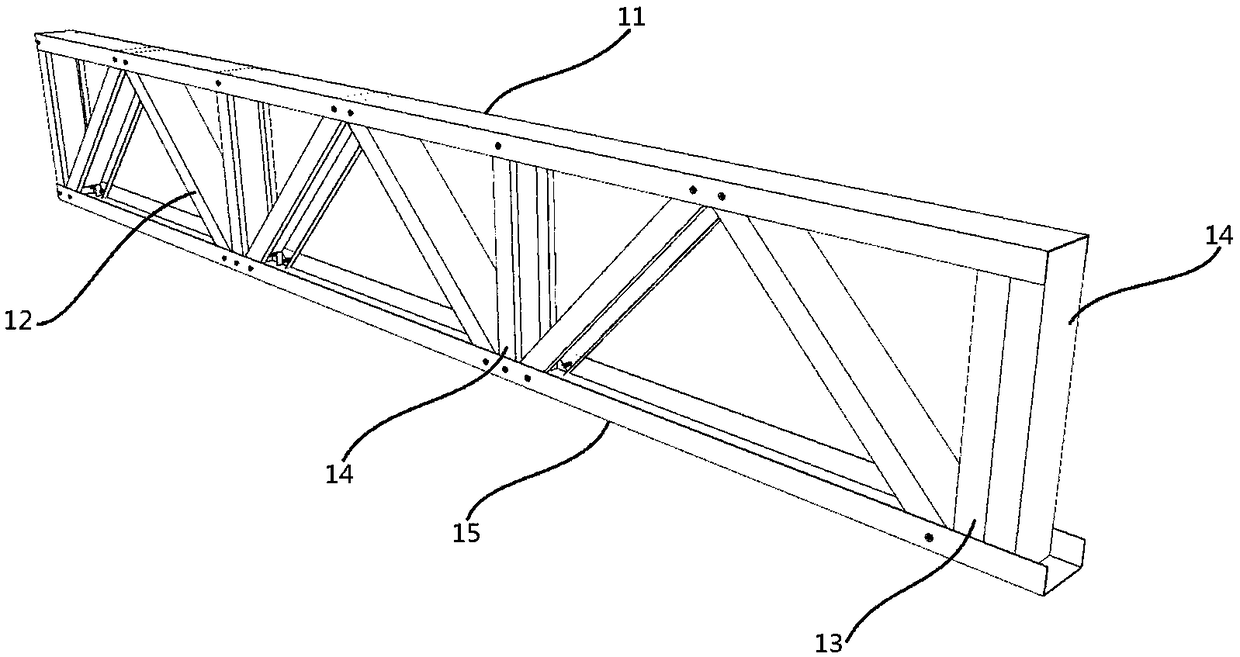

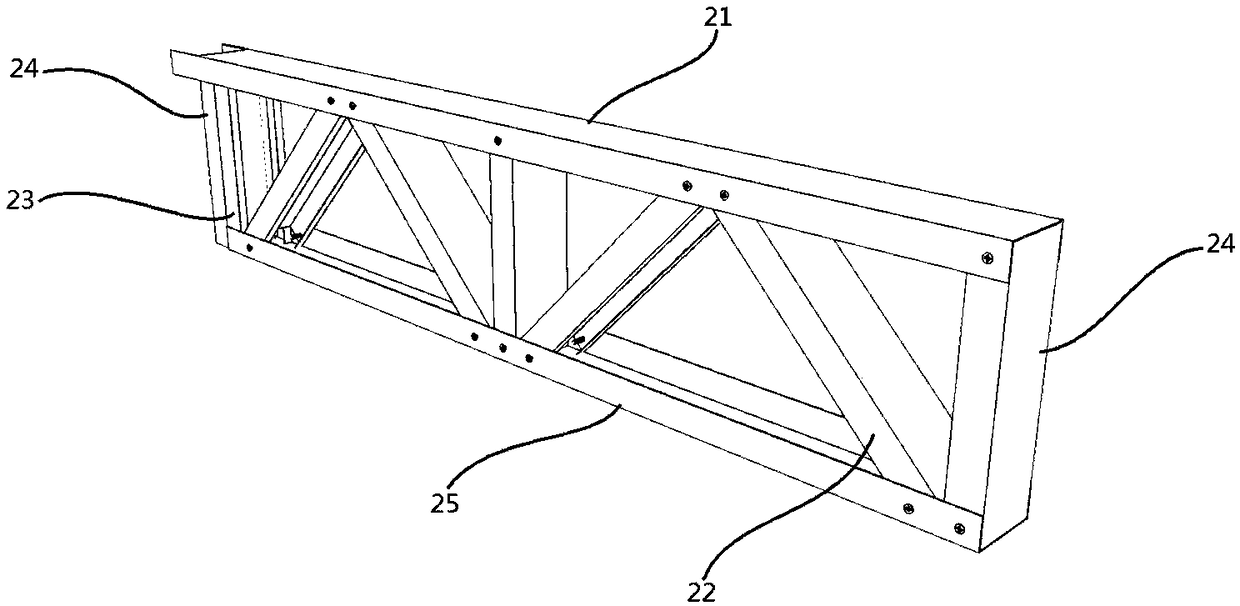

[0042] like figure 2 , Figure 4 As shown, the high-web bar truss beam 1 includes a first U-shaped steel upper chord 11, a first C-shaped steel oblique web bar 12, a first C-shaped steel straight web bar-13, a C-shaped steel second straight web bar-14, a first A U-shaped steel bottom chord 15. Fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com