Steel box girder bridge deck slab structure and paving method

A technology for steel box girders and bridge decks, applied in bridges, bridge parts, bridge construction, etc., can solve problems that affect construction efficiency, affect the construction quality of bridge deck concrete cushions, and damage studs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

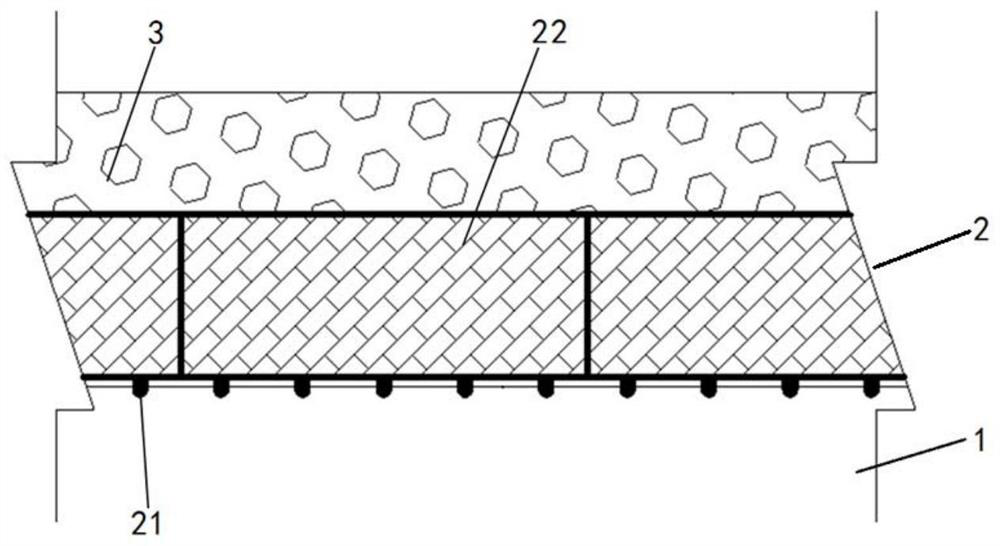

[0044] A steel box girder bridge deck structure, such as figure 1 As shown, it includes steel box girder 1, concrete module cushion 2 and asphalt layer 3 arranged in sequence from bottom to top. On the top plate of box girder 1.

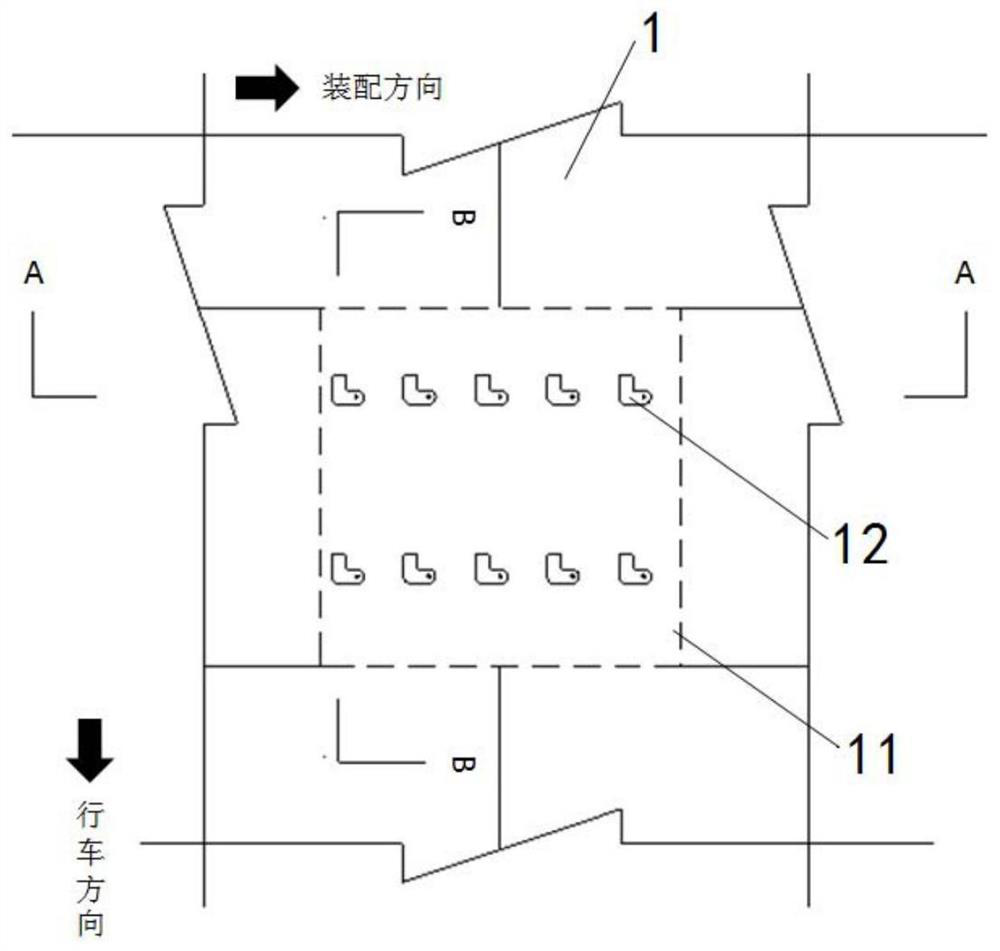

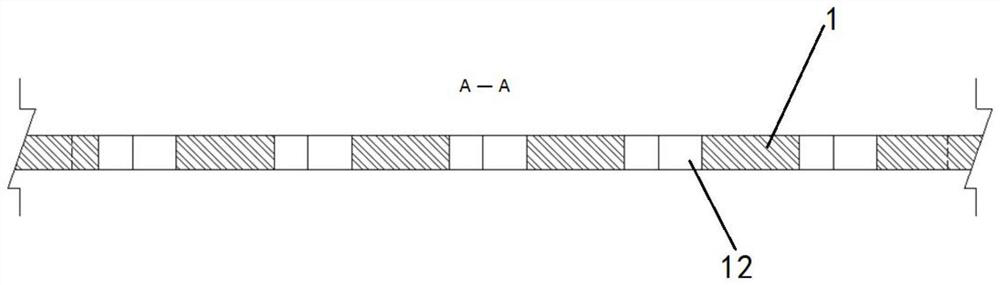

[0045] Specifically, such as Figure 2-6 As shown, a rectangular assembly area 11 is provided on the top plate of the steel box girder 1. The shape and size of the assembly area 11 match the concrete module 22. Two rows of assembly holes 12 are arranged in parallel in the assembly area 11, and the assembly holes 12 are horizontal The direction section is L-shaped, one side is parallel to the transverse section of the bridge deck, that is, the assembly direction, and the other side is parallel to the longitudinal section of the bridge deck, that is, the driving direction, and the end of the side parallel to the assembly direction is hemispherical, which can make the fixed The bolt and the assembly hole better form a hoop effect.

[0046] like Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com