High-strength thermal insulation composite wall, manufacturing method thereof and house

A thermal insulation composite, high-strength technology, applied in thermal insulation, walls, manufacturing tools, etc., can solve problems such as ugliness, environmental impact, labor and material resources, and achieve the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

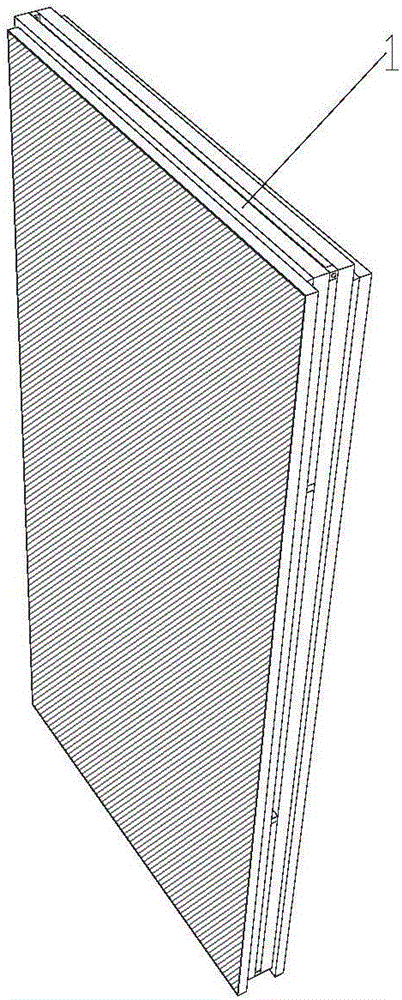

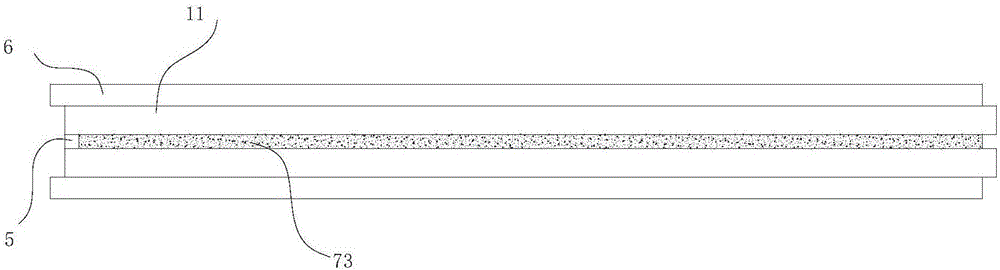

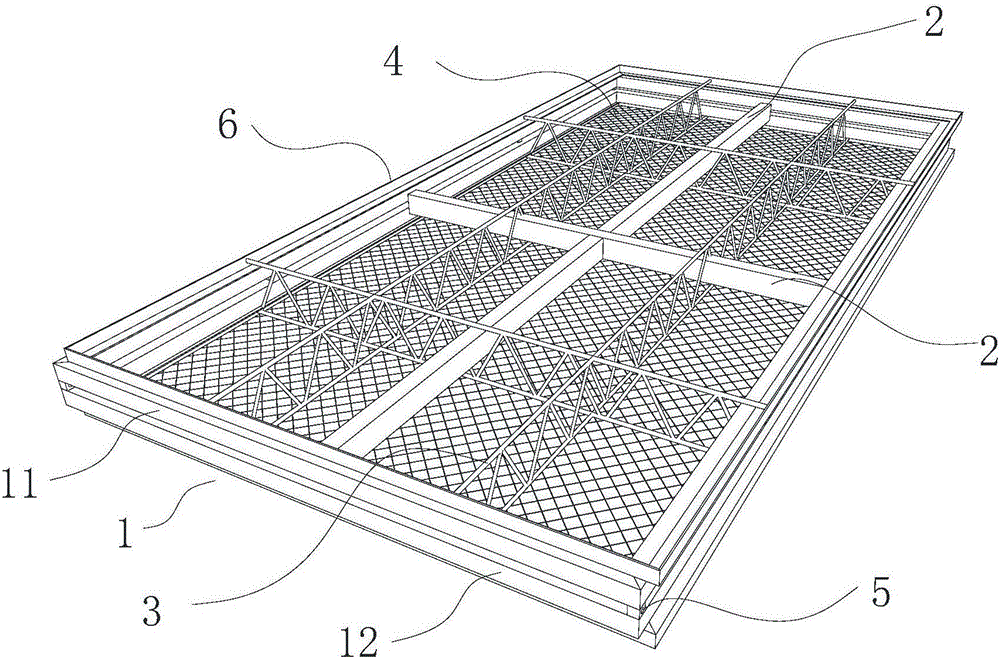

[0040] figure 1 It is a schematic diagram of the structure of the high-strength thermal insulation composite wall in Example 1 of the present invention. figure 2 yes figure 1 Top view of medium and high strength thermal insulation composite wall. combine figure 1 with figure 2 It can be seen that this embodiment discloses a high-strength thermal insulation composite wall, including a wall frame 1 and a composite wall panel.

[0041] Wherein the wall body frame 1 is a metal structure, and a steel structure with sufficient strength is preferred in this embodiment.

[0042] The metal structure can be used to realize custom size or regular size production, so as to realize modularization and factory production. During the production process, the steel size and the support method of the steel structure can be selected according to the load-bearing requirements of the wall, which can ensure that the steel frame will not be deformed and meet the overall load-bearing degree of ...

Embodiment 2

[0056] The preparation method of the high-strength thermal insulation composite wall of the present invention comprises the following steps:

[0057] Step a: Prepare the bottom surface mold, and then make a point-linked wall frame, including the main body of the first frame and the second frame, and the connection between the internal support square steel and cross steel structure and the first frame and the second frame;

[0058] Then the lower wall is first welded with protective steel mesh to the surface of the cross-bar structure.

[0059] Step b: Preparation of high-strength cement: Prepare cement according to design requirements; including cement composition and color, etc.

[0060] Step c: the layers of the wall are poured from inside to outside or from outside to inside;

[0061] This embodiment adopts pouring from the outside to the inside. Firstly, high-strength concrete with different tones is poured into the predetermined bottom surface mold, and the barbed wire i...

Embodiment 3

[0065] A house using the high-strength thermal insulation composite wall in Embodiment 1. Other parts of the house can be made by using the existing technology, and preferably adopt a modular, decoration-free structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com