Construction method of cold box interior installation equipment

A technology for installing equipment and a construction method, applied in the field of manufacturing, can solve the problems such as the inside of the outer cylinder, the outer cylinder and the equipment are prone to quality problems, and the difficulty of making up for quality defects, so as to achieve convenient repair and operation, realize factory-like manufacturing, and save height. effect on space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific examples.

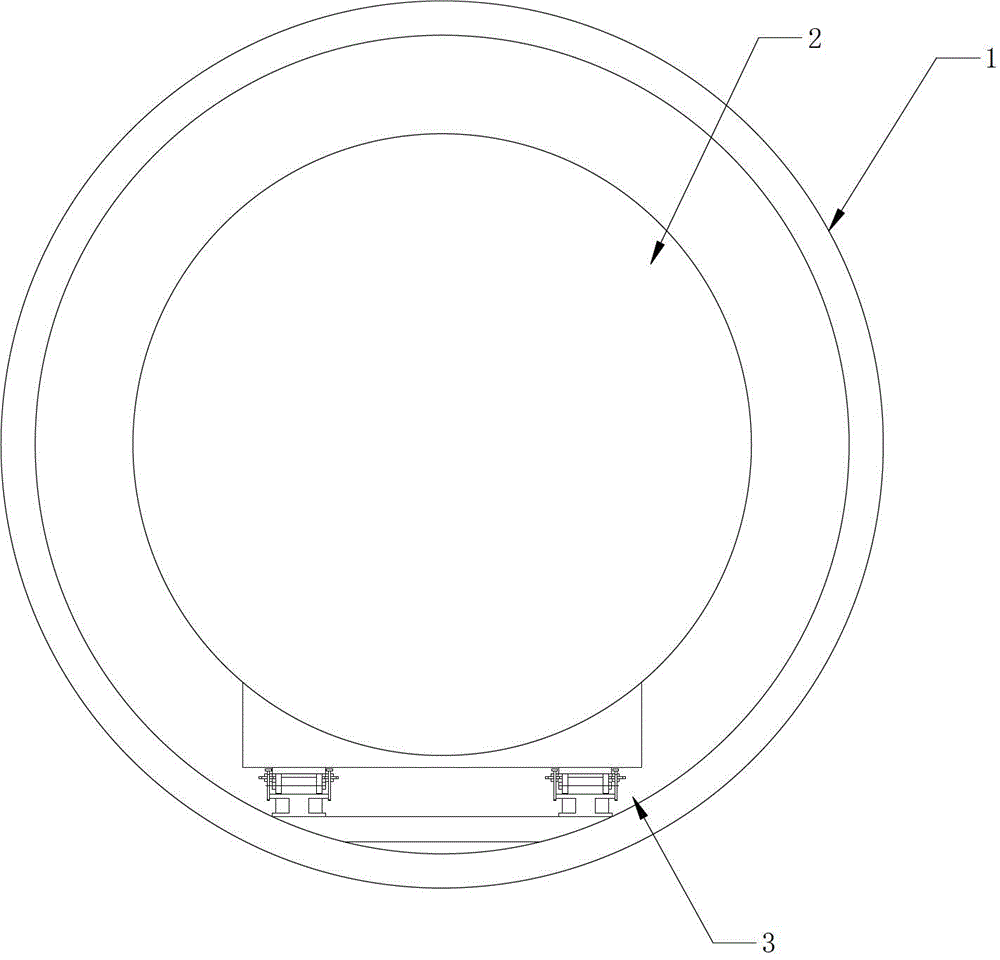

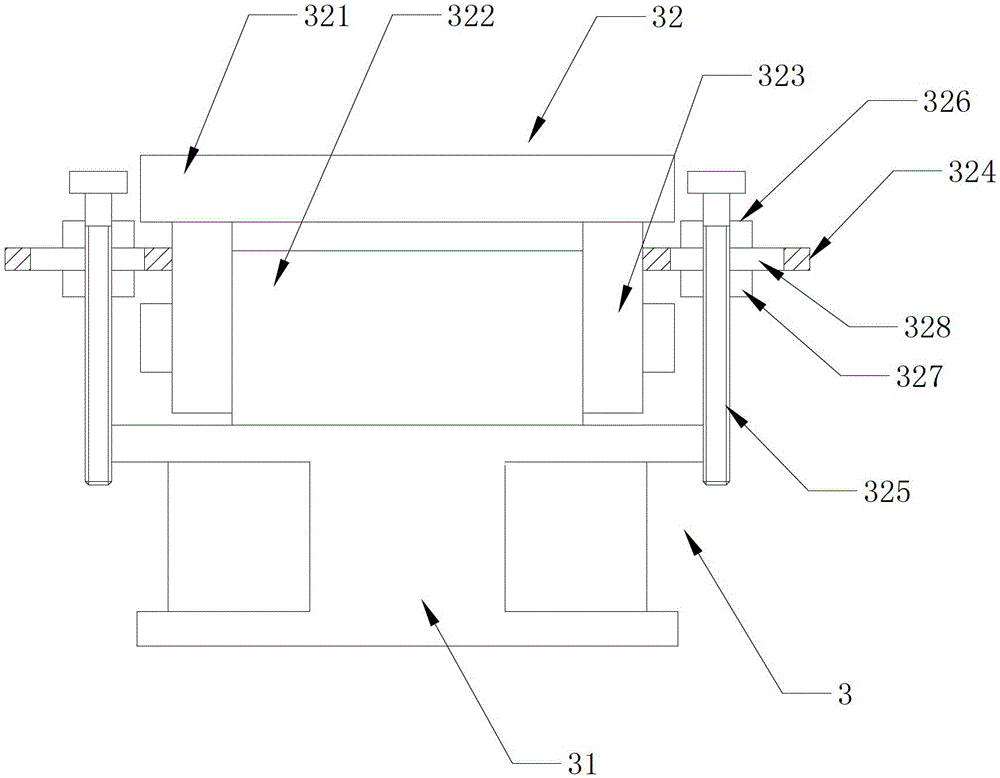

[0023] Such as figure 1 , 2 As shown, a construction method for installing equipment inside a cold box, including

[0024] A. The equipment 2 and the outer cylinder 1 of the cold box are welded and formed in advance; because the height of the equipment 2 and the outer cylinder 1 is high and the inner diameter is large, the method of segmental welding is adopted, that is, the equipment 2 and the outer cylinder 1 are made of several It is only welded at this time without considering the positional relationship and installation relationship between the inner and outer cylinders 1, as long as the welding quality of the equipment 2 and the ring sections of the outer cylinder 1 and the formed outer cylinder 1 and Whether the equipment 2 meets the respective size requirements; at this time, if the welding quality of the equipment 2 or the outer cylinder 1 is found, it can be repaired...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com