Large steel structure and manufacturing method thereof

A steel structure, large-scale technology, applied in the direction of manufacturing tools, building structures, auxiliary devices, etc., can solve problems such as manufacturing accuracy cannot meet quality requirements, high-strength bolt hole size exceeds the standard, installation quality cannot be guaranteed, etc., to reduce labor intensity of workers , Improve labor efficiency, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

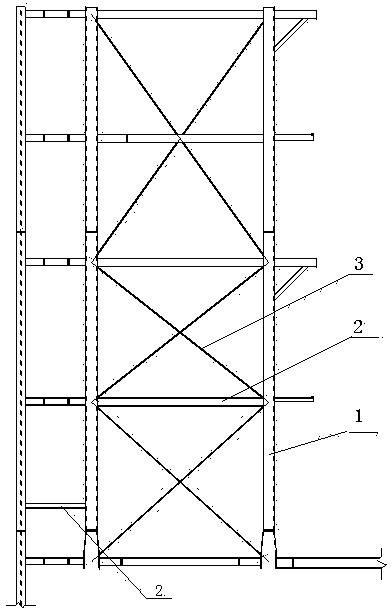

[0039] Embodiment: This embodiment is a urea frame steel structure manufactured by Inner Mongolia Bodashidi 5080 Chemical Fertilizer Project. The main body height is 33.8m, the local height is 59.1m, the plane size is 46.4m×23.5m, six spans and three spans, and the total weight is 1700t.

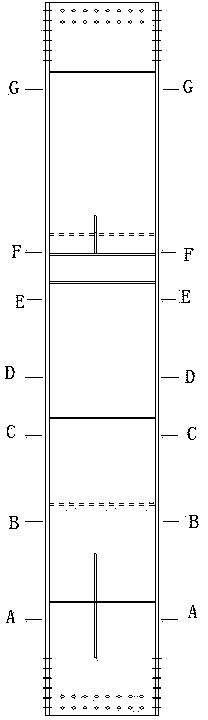

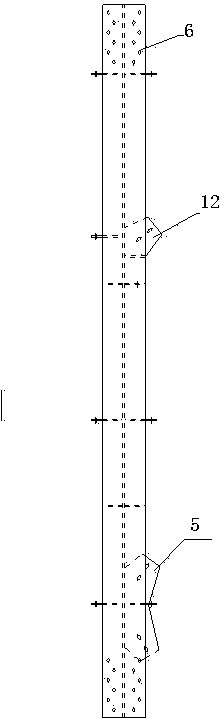

[0040] The column is a box-shaped column, and the specifications of the box-shaped column are 800×650×36×36 (that is, the section length of the box-shaped column is 800, the width is 650, and the thickness of the panel is 36. The following specifications have the same meaning), 800×650×30×30, 650×650×28×28, 500×500×28×28, the beams are 1400×730×30×36, 1400×600×30×36, and the connecting beams are welded with H-shaped steel, and the materials are Q235C and Q345. The length is made in three sections.

[0041] figure 1 As shown, the large-scale steel structure includes columns 1 and beams 2, and the columns 1 are connected by beams 2 and connecting beams.

[0042] The column 1 is a box-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com