A gas station light steel structure canopy

A light steel structure and gas station technology, applied in special buildings, small buildings, building types, etc., can solve the problems of short service life, inconvenient maintenance, long construction period, etc. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with embodiment, further illustrate the present invention.

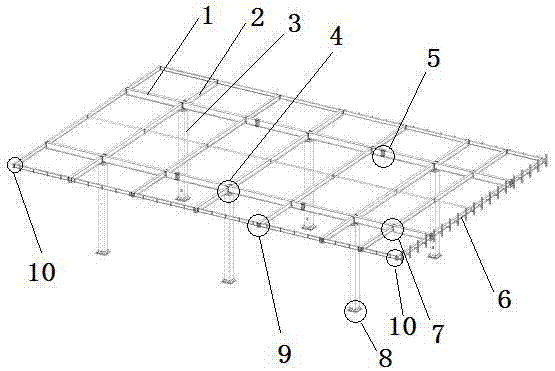

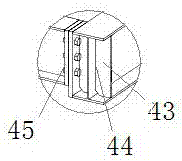

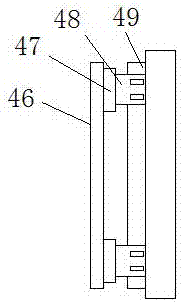

[0047] see figure 1 - image 3It can be known that a gas station light steel structure canopy of the present invention is composed of a column 3, a main beam 1 and a secondary beam 2 arranged at the top of the column 3; the top of the main beam 1 and the secondary beam 2 is provided with a roof 17; The column 3 is a steel square tube, and the column 3 is connected and fixed to the ground through the column foot 8; the interior of the column 3 integrates an electrostatic grounding node 11, an oil lamp box line tube 12, a monitoring line tube 13, a canopy lighting and cornice light box line tube 14; The top of the column 3 is provided with a main beam 1 and a secondary beam 2, and the top of the main beam 1 and the secondary beam 2 are connected with the top of the column 3 through a column-beam node 4; the main beam 1 and the secondary beam 2 are connected through a beam-beam node 7; the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com