Mounting module and mounting method for lower wire pipe of railway vehicle

A rail vehicle and module installation technology, which is applied in the field of rail vehicles, can solve problems such as the difficulty of finding the ignition point, difficulty in dissipating heat, and large safety risks, so as to facilitate on-site modification and maintenance, reduce safety risks, and ensure construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

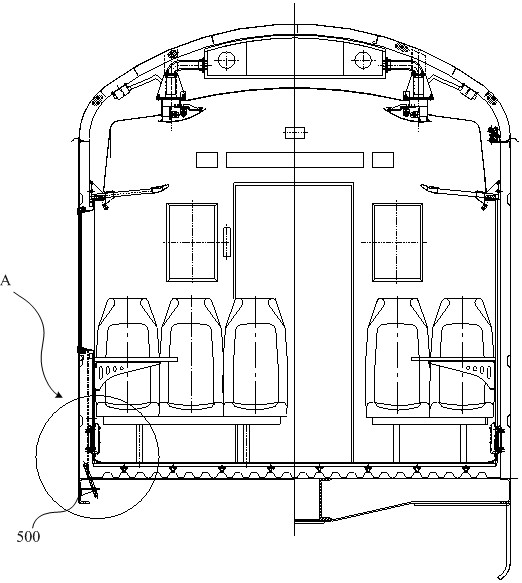

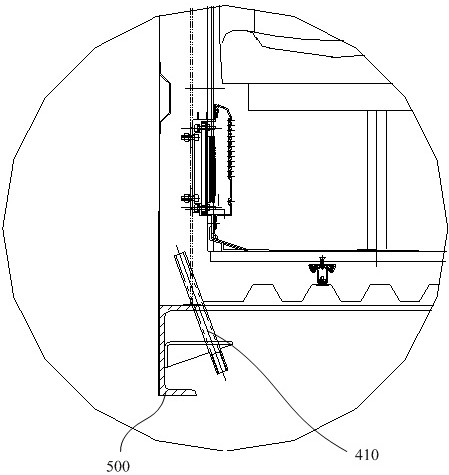

[0046]During the transformation and maintenance of rail vehicles, pipelines will be added, so it is necessary to add downline pipes to the rail vehicles. During the extension process of the downline pipe, operations such as drilling and welding are required.

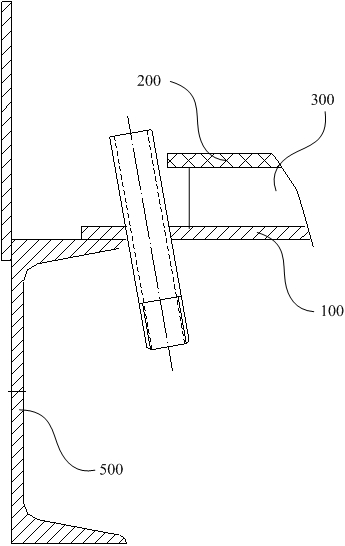

[0047] Such as image 3 As shown, the existing rail vehicle downline pipe is welded on the iron floor 100 , a wooden floor 200 is arranged above the iron floor 100 , and a cold-proof layer 300 is arranged between the iron floor 100 and the wooden floor 200 . The downpipe passes through the through hole of the iron floor 100 from below the iron floor 100 and stretches out onto the iron floor 100 . From below the iron floor 100, welding is carried out at the joint between the iron floor 100 and the downline pipe. The heat generated by welding is transferred upwards to the cold-proof layer 300 and the wooden floor 200, and the heat is not easy to dissipate, which may easily cause a fire. If a fire point occurs in the col...

Embodiment 2

[0060] The structure of the rail vehicle down pipe installation module is the same as that described in Embodiment 1.

[0061] The rail vehicle downline pipe installation module is installed and used at the vehicle site during the rail vehicle transformation. The following steps must be followed for installation and use:

[0062] S11: According to the wiring requirements, select a suitable size down-line tube.

[0063] S21: Apply an anti-rust primer to the surface of the seamless steel pipe of the downline pipe, so as to avoid corrosion of the downline pipe during use.

[0064] S31: Wrap masking tape on the thread of the seamless steel pipe of the downline pipe to prevent the thread of the seamless steel pipe from being damaged, affect the stability of the threaded connection with the connector, and avoid loosening due to thread damage;

[0065] S21: According to the cross-sectional size of the lower wire tube and the inclination angle of the lower wire tube, open a first ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com