Optical cable and electric cable laying method applicable to intelligent substation

A smart substation and cable laying technology, which is applied in the direction of cable laying equipment, etc., can solve the problems of large floor area and one-time cost investment, inability to effectively avoid cable crossing, poor maintainability, etc., and achieve optimal fire prevention effects and construction procedures. Well-ventilated, easy-to-replace effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0043] Optical cables and cable laying methods applied to smart substations, the specific steps are as follows:

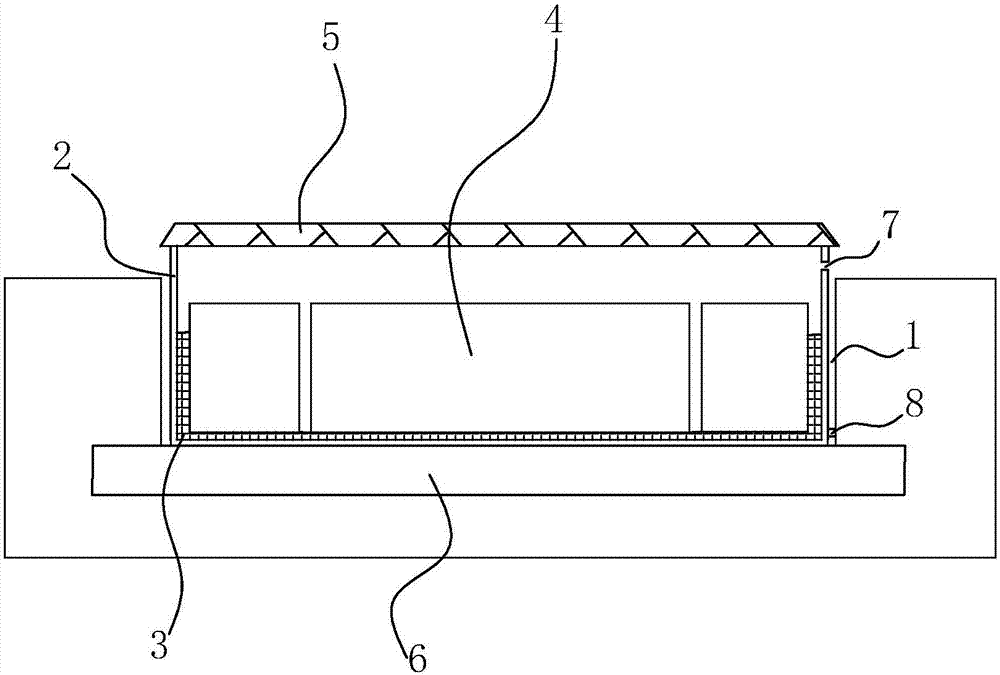

[0044] Step a. Ground trenching: According to the design drawing, measure the center line of the trench 1, set up the center pile, draw the line with a white line before excavation, set control piles on both sides of the foundation pit position and record the distance between the two piles and the center of the foundation pit. After the white line is positioned, the trencher is used to excavate the earthwork until the design elevation is reached, and the foundation pit can be obtained. The cable or optical cable is laid on the ground as required, and then the trench is excavated. Trough 1 is leveled; compared with the traditional cable laying method, this method requires shallower trenching, less earthwork excavation, no embedded parts, sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com