Can be assembled with environmentally friendly exterior walls

A technology of environmental protection walls and exterior walls, applied in the field of composite walls, can solve problems such as inability to achieve industrialization, industrialization, assembly, green energy saving, labor and resource consumption, and complicated exterior wall methods, so as to reduce manufacturing costs, The effect of preventing rainwater corrosion and being easy to cooperate with steel structure construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

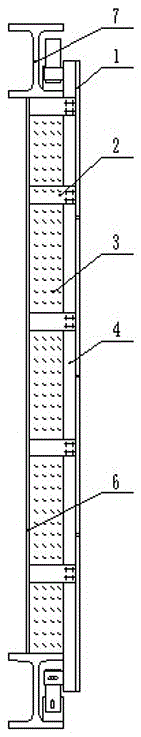

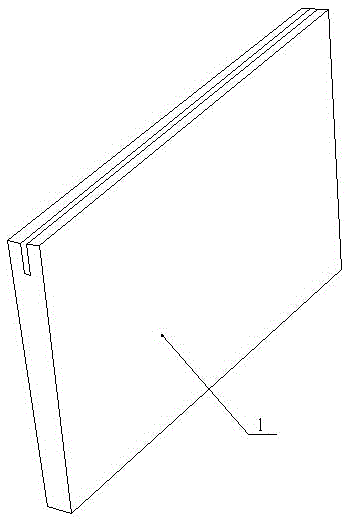

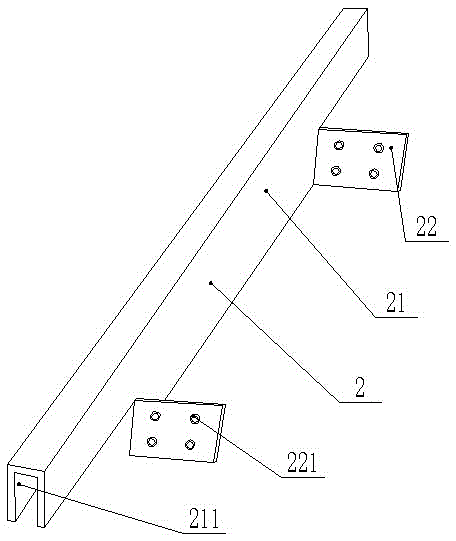

[0022] The environmental protection exterior wall 1 can be assembled, and the environmental protection wall is provided with the exterior wall 1, the pendant 2, the heat insulation wall 3, the first keel 4, the filling wall, the second keel 5 and the inner wall 6 from the outside to the inside, and the pendant 2 includes a horizontal The bar 21 and the two mounting plates 22 vertically arranged on the same side of the cross bar 21 have a transverse groove 211 on the cross bar 21. The two mounting plates 22 are of the same size. Holes 221, the upper and lower ends of the outer wall 1 are respectively inserted into the transverse grooves 211 of two pendants 2, and the pendants 2 are connected to the heat insulation wall 3 after passing through the mounting holes 221 with a plurality of screws;

[0023] Wherein, the first keel 4 includes two vertical rods 41, and the two vertical rods 41 are connected by a plurality of horizontal frames 42, and the upper part of one vertical rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com