Assembly type residential steel structure system

A steel structure, prefabricated technology, applied in the direction of structural elements, elongated structural components for load-bearing, building components, etc., can solve the problems of destroying the integrity and applicability of indoor space, furniture decoration and room layout restrictions, etc. To achieve product quality controllable, flexible division, to meet the effect of fire prevention and anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

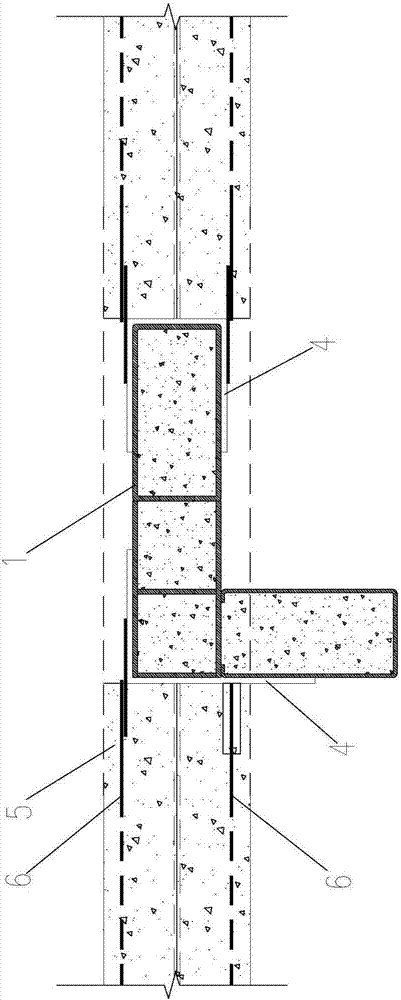

[0038] Please refer to the attached figure 1 to attach Figure 5-4 所示,本发明为一种装配式住宅钢结构体系,其由钢板剪力墙1、叠合型钢组合梁2以及叠合楼板3等几部分组成,且钢板剪力墙1、叠合型钢组合梁2以及叠合楼板3均能够够工厂生产完成,并在现场装配拼装。

[0039] 其中,所述钢板剪力墙1上焊接有加筋板4。所述叠合型钢组合梁2端部和钢板剪力墙1连接。所述叠合型钢组合梁2上外包一层外包混凝土层5,外包混凝土层5内铺设受力钢筋6。所述受力钢筋6连接至加筋板4上。所述叠合楼板3连接至叠合型钢组合梁2上。

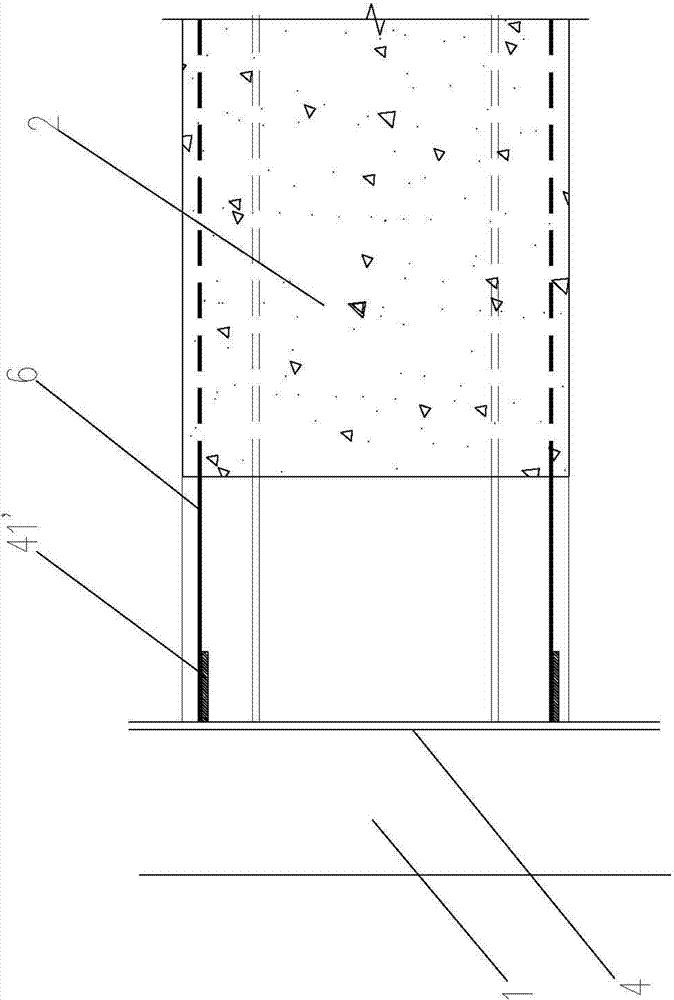

[0040] 进一步的,所述钢板剪力墙1由若干空腔钢板模块11组合焊接而成,形成多种形式的空腔,如十字型、T型、L型或一字型。请参见说明书附 Figure 4-1 to Figure 4-4 ,其给出了四种不同形式的基本单元,且均可由工厂生产完成。

[0041] 所述空腔钢板模块11内填充有混凝土12。所述空腔钢板模块11的一侧或两侧开设圆孔,使空腔内混凝土12连成整体。所述混凝土12为普通混凝土、轻骨料混凝土、自密实混凝土、高强度混凝土或轻质发泡混凝土。

[0042] 所述钢板剪力墙1由基本单组合成,并将钢结构与混凝土结构有效的结合起来,充分发挥混凝土剪力墙的建筑布局灵活、钢结构制作工业化程度高、施工速度快的优势,同时发挥钢材轻质高强、混凝土刚度大的材料性能优势,对目前建筑结构体系中的缺点,是一个很好的解决方案。

[0043] 所述加筋板4和受力钢筋6的连接方式可以采用以下两种:

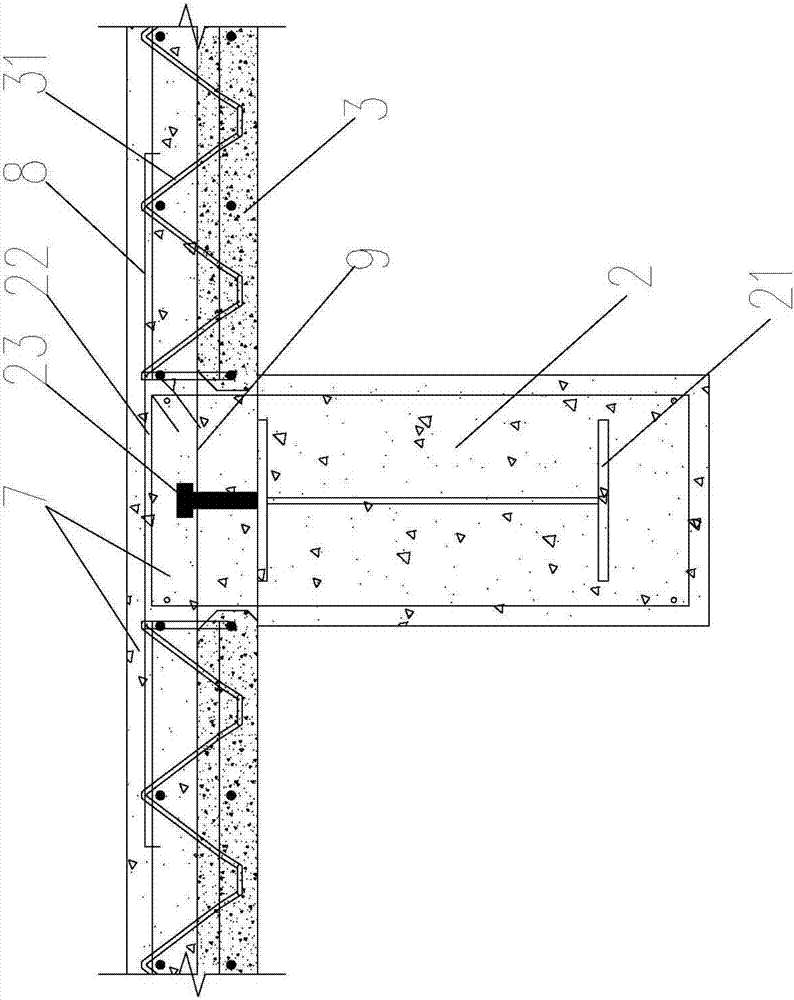

[0044] 1.所述加筋板4上竖直焊接有锚固套41,该锚固套41埋设于钢板剪力墙1内,所述受力钢筋6插入锚固套41内。

[0045] 2.所述加筋板4上竖直焊接有连接板41’;所述连接板41’和受力钢筋6焊接,并埋设于外包混凝土层5内。

[0046] 所述叠合型钢组合梁2内设有型钢21和箍筋22;所述型钢22的顶部焊接栓钉23;部分箍筋22和受力钢筋6外露出外包混凝土层5。

[0047] 所述叠合型钢组合梁2发挥了钢结构梁的轻质高强的优势,又发挥了混凝土梁的防火耐腐蚀的优势。外包混凝土层5使钢梁得到了天然的保护,型钢21被包覆其中又提高了结构梁的强度,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com