Prefabricated light steel structure factory building and construction method thereof

A prefabricated assembly and construction method technology, applied in industrial buildings, building structures, buildings, etc., can solve the problems of small proportion of steel and lack of steel skeleton assemblers, and achieve low steel consumption, good economic benefits, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

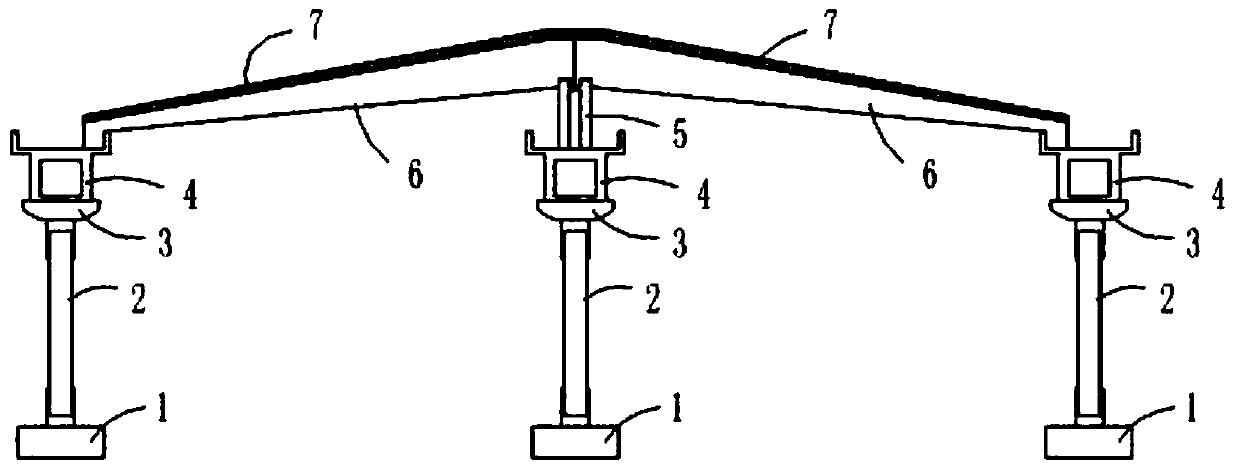

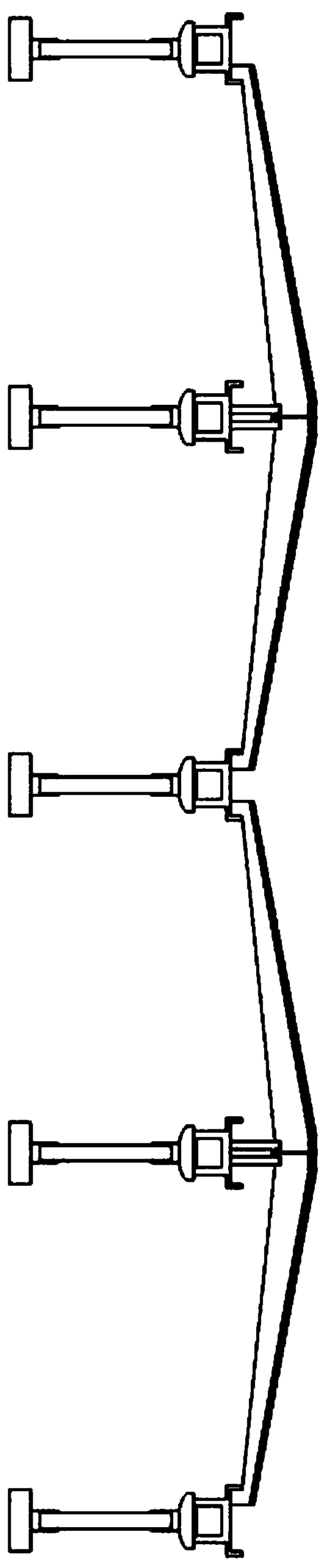

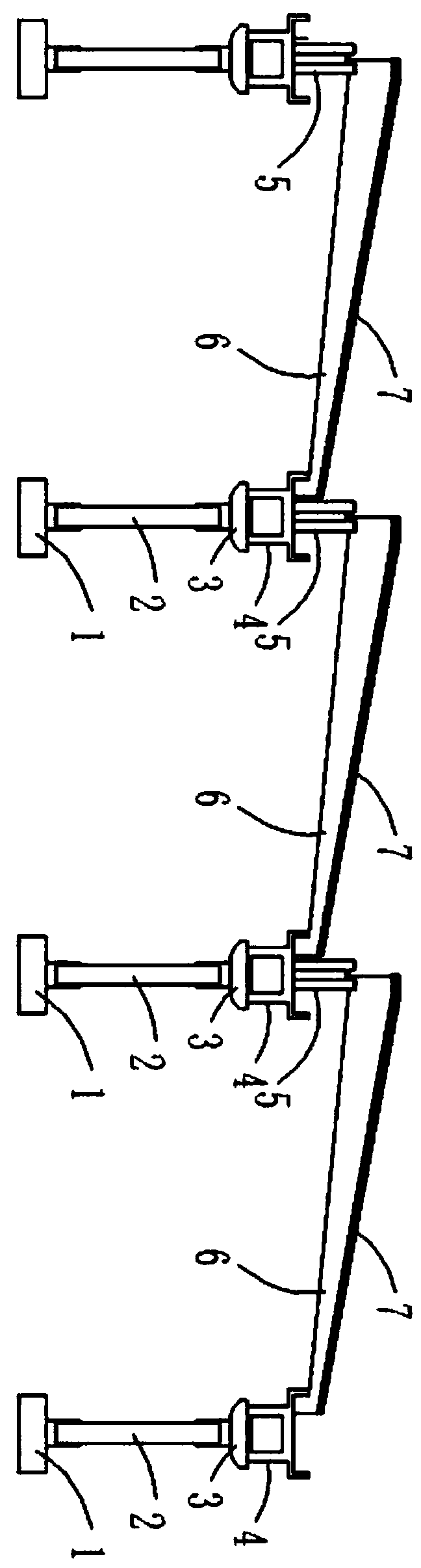

[0043] Embodiment 1: as figure 1 , 9 A prefabricated light-weight steel structure factory building is shown, including a foundation base 1, supporting row columns 2, supporting T-pillars 3, supporting girders 4, drop supports 5, room frames 6 and skin components 7;

[0044] The upper end of the base 1 is provided with a first connection square tube 10; the support row column 2 includes a support column 21 and a connection column 22; the support T column 3 includes a second connection square tube 31 and a support column 32; the skin assembly 7 includes sandalwood bars 71 and The skin panel 72; the second connecting square tube 31 is arranged at the lower end of the pillar 32;

[0045] like Figure 5 , 6 , 7, there are four support columns 21, and each support column 21 is uniformly provided with a plurality of connection notches 210 from top to bottom, and the connection notches 210 are "L" shaped; as Figure 8 As shown, the connecting column 22 is evenly provided with a pl...

Embodiment 2

[0050] Embodiment 2: Different from Embodiment 1, the height of the first connecting square pipe 10 and the second connecting square pipe 31 is 30 cm; the distance between the connecting notches 210 and the distance between the connecting plugs 220 is 60 cm.

Embodiment 3

[0051] Embodiment 3: Different from Embodiment 1, the height of the first connecting square pipe 10 and the second connecting square pipe 31 is 40 cm; the distance between the connecting notches 210 and the distance between the connecting plugs 220 is 80 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com