Rear air inlet type heat-conducting smoking device

A smoking device and air intake technology, which is applied in the directions of smokers' products, tobacco, and applications, can solve the problems of restricting the use of combustion accelerants, difficult to ignite, and incomplete combustion of carbon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

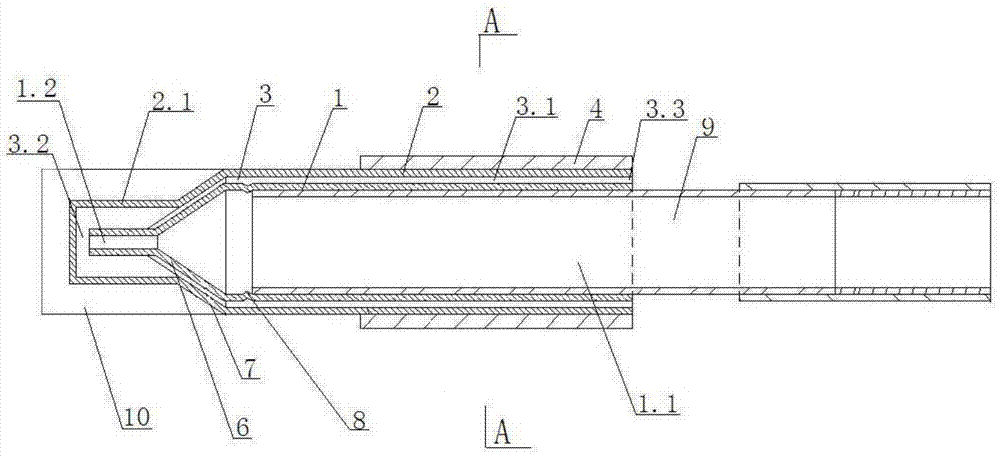

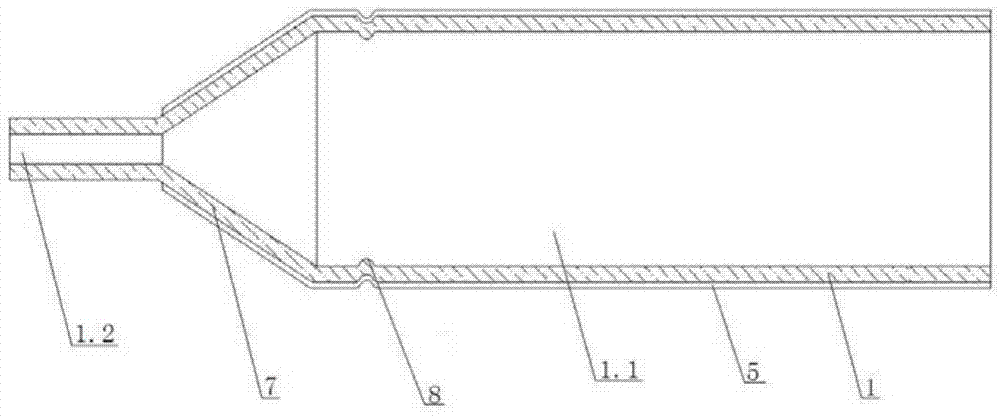

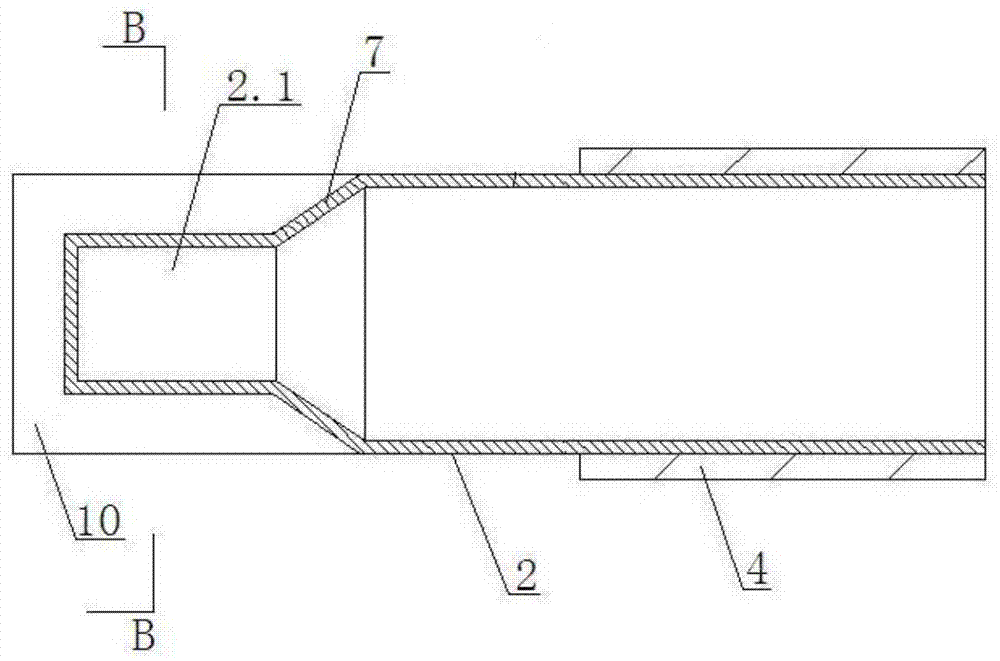

[0022] Such as Figure 1 to Figure 5 As shown in the illustrated embodiment, a rear air-intake heat-conducting smoking device includes an inner heat-conducting shell 1, an outer heat-conducting shell 2 sleeved outside the inner heat-conducting shell 1, and the inner surface of the outer heat-conducting shell 2 The air intake interlayer 3.1 is formed between the outer surface of the inner heat conduction shell 1; one end of the inner heat conduction shell 1 has a small opening as the inner air intake 1.2, and the other end is open as the smoke insertion part 1.1; the outer heat conduction shell 2 is close to the inside One end of the smoke insertion part 1.1 of the layer heat conduction shell 1 is also open, where an airflow inlet 3.3 is formed between the end of the inner heat conduction shell 1 and the end of the outer heat conduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com