A rear intake type heat conduction smoking device

A smoking device and air-intake technology, which is applied in smoker supplies, tobacco, applications, etc., can solve the problems of restricting the use of combustion accelerants, incomplete combustion of carbon, and difficult ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

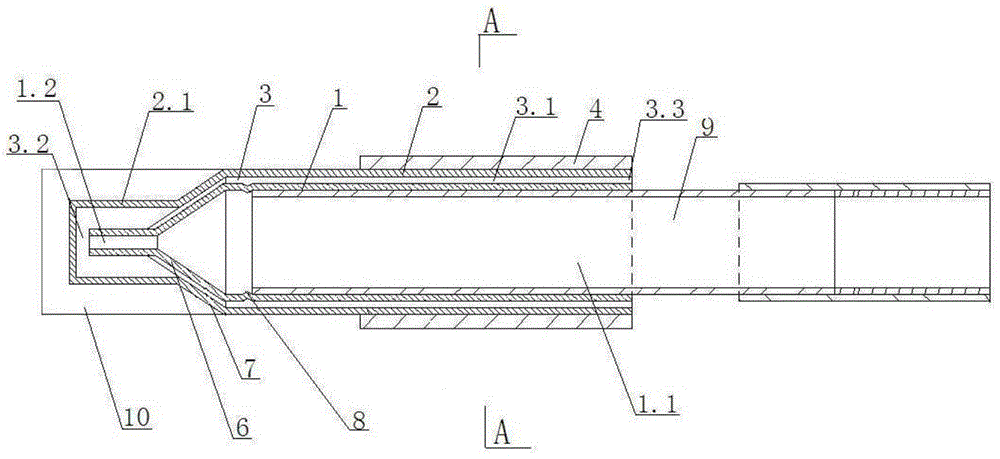

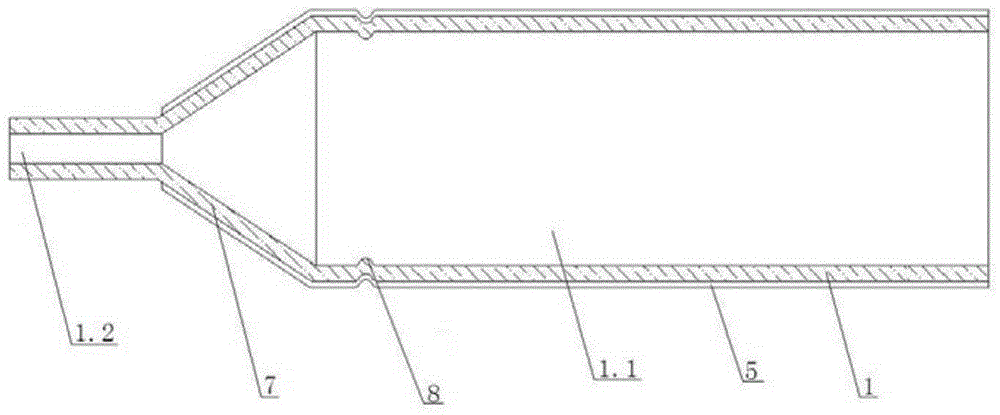

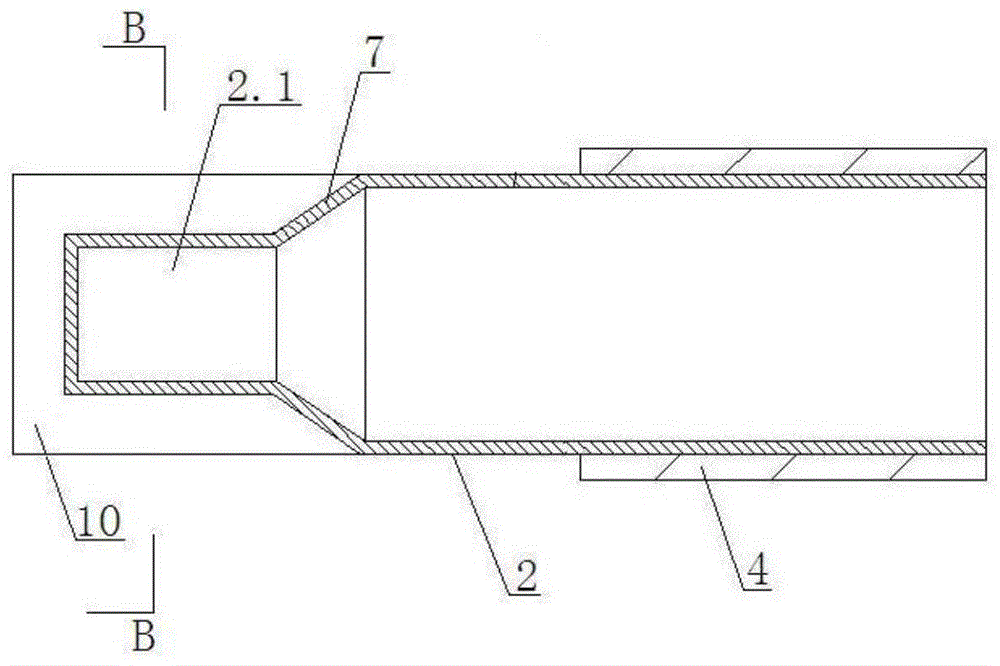

[0022] Such as Figure 1 to Figure 5 As shown in the illustrated embodiment, a rear air-intake heat-conducting smoking device includes an inner heat-conducting shell 1, an outer heat-conducting shell 2 sleeved outside the inner heat-conducting shell 1, and the inner surface of the outer heat-conducting shell 2 The air intake interlayer 3.1 is formed between the outer surface of the inner heat conduction shell 1; one end of the inner heat conduction shell 1 has a small opening as the inner air intake 1.2, and the other end is open as the smoke insertion part 1.1; the outer heat conduction shell 2 is close to the inside One end of the smoke insertion part 1.1 of the layer heat conduction shell 1 is also open, where an airflow inlet 3.3 is formed between the end of the inner heat conduction shell 1 and the end of the outer heat conduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com