Chip testing system

A chip testing, chip technology, applied in the direction of electronic circuit testing, measuring electricity, measuring devices, etc., can solve the problems of poor airflow, incomplete heat dissipation of temperature-controlled heat dissipation equipment, slow heat dissipation, etc., to achieve smooth airflow, rapid and thorough heat dissipation , to facilitate the effect of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

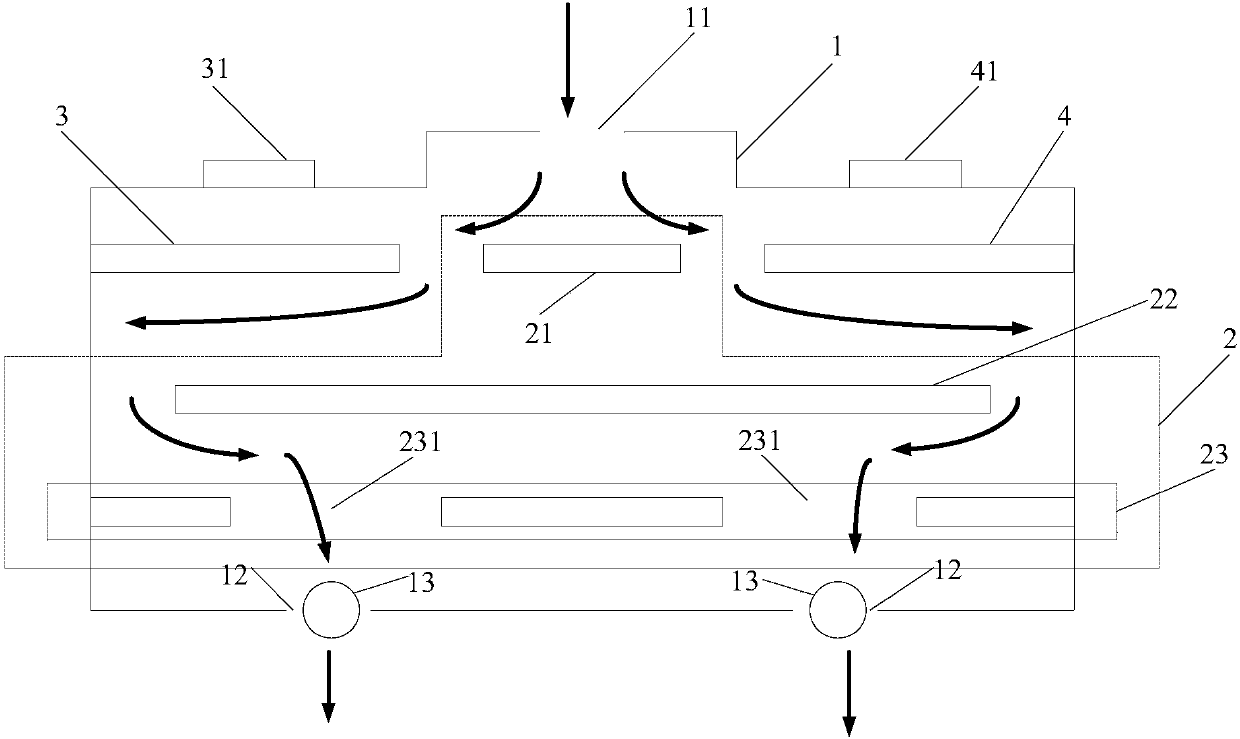

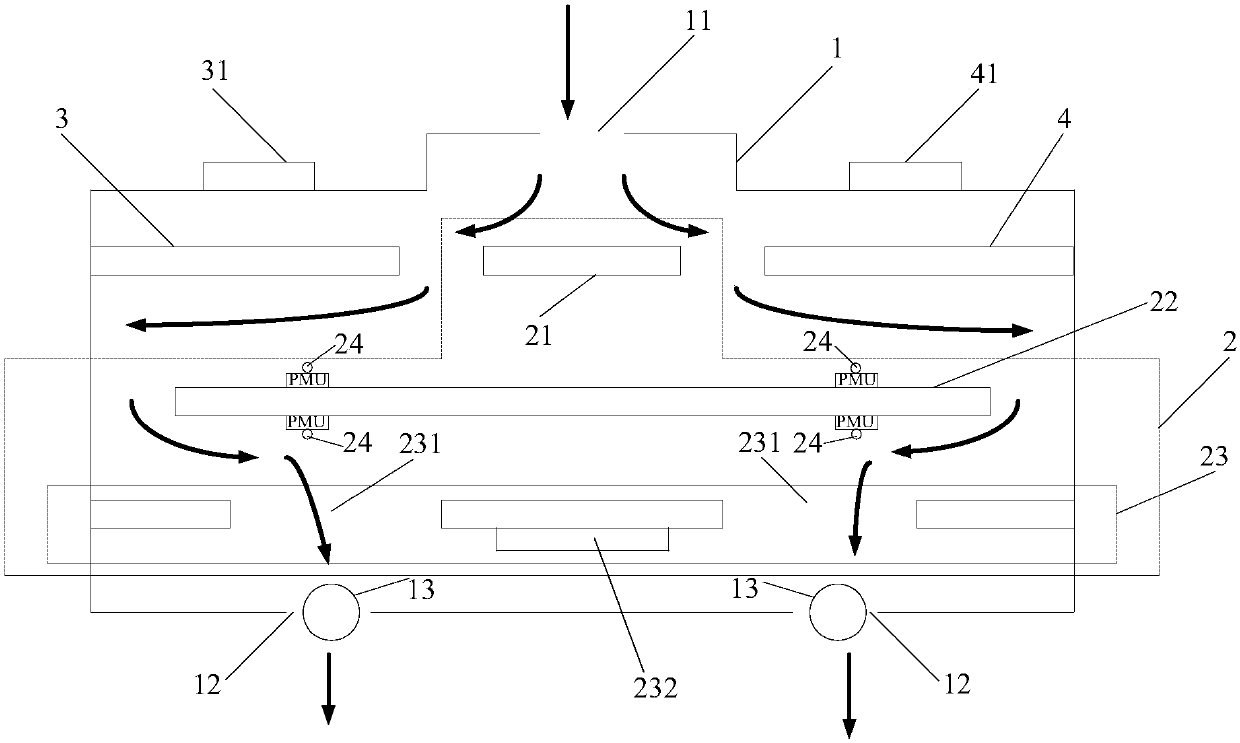

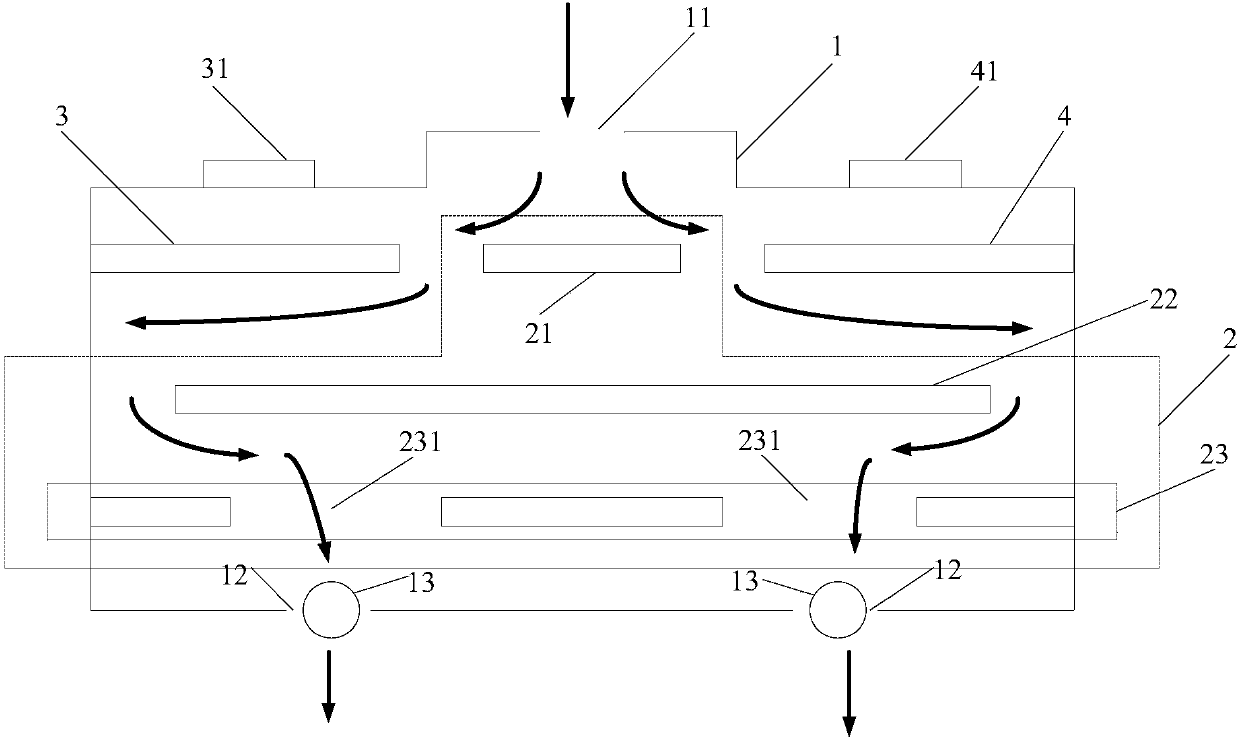

[0021] refer to figure 1 , which shows a structural block diagram of an embodiment of a chip testing system of the present invention, which may specifically include a heat dissipation chassis 1, a chip testing device 2 disposed in the heat dissipation chassis 1, a first chip interface board 3 and a second chip interface board 4. The chip testing device 2 includes a main control board 21, a measurement unit board 22 and a power supply board 23, an air inlet 11 is arranged on the top of the heat dissipation chassis 1, and at least one air outlet 12 is arranged on the bottom of the heat dissipation chassis 1 together with at least one air outlet 12. A corresponding at least one fan 13, the first chip interface board 3, the second chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com